Professional Documents

Culture Documents

Fermentedtreasures Ginger Beer Brewing

Uploaded by

guennikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fermentedtreasures Ginger Beer Brewing

Uploaded by

guennikCopyright:

Available Formats

An Exposition on the Fermentation of Ginger- Beer Plant

Brewing with the Gelatinous Ginger Beer Plant: Converting Lactic-Acid Beverages to Alcoholic Ginger Beer Composition of the Ginger- Beer Plant: As Isolated by H. Marshall Ward, The Organisms Comprising the Ginger- Beer Plant: a.) Saccharomyces pyriformis The principal yeast in Ginger- Beer Plant (GBP). It consumes oxygen & sugar and produces alcohol and CO2. It is a weak alcohol producer (4.4% maximum abv [H. M. Ward, 1892]). b.) Cryptococcus qlutinis c.) Unknown aerobian top-yeast Produces alcohol and other by-products from oxygen & sugar (H. M. Ward, 1892) d.) Saccharomyces cerevisiae (beeryeast) Also known as Baker's Yeast or Brewer's Yeast, this organism has been used for centuries as leavening for bread and as a fermenter of alcoholic beverages. e.) 3-4 unknown yeasts of rare occurrence f.) Bacterium vermiforme (later named Lactobacillus hilgardii) The principal bacterium in GBP, responsible for generating lactic acid and, ultimately, acetic acid. g.) Mycoderma cerevisiae This aerobian yeast prefers cool temperatures --50 to 60 F. (10-15 C)-- and glucose for best growth. It cannot invert cane sugar or bring about its fermentation (H. M. Ward, 1892). h.) Bacterium Aceti (later re-classified Acetobacter aceti) In concert with aerobian top yeast (c.) produces ether when in oxygen environment (H. M. Ward, 1892). A. aceti is a common contaminant in all industrial fermentation facilities and is responsible for generating turbidity, ropiness, discoloration, and off-flavors in beer (Kough, 1991). i.) A spore-forming bacillus j.) Large spore-forming bacillus k.) 2-3 Other Schizomycetes not identified l.) Oidium lactis m.) Blue mould- Penicillium glaucum n.) A brown Torala-like form, Dematium pullulans o.) One or more species of unknown Torala

Instructions with observations on brewing with the Ginger- Beer Plant: Lemon Ginger Beer (8.7% alcohol by volume): A 2-quart (2 liter) Mason jar or equivalent vessel 1 Quart (1 liter) distilled water 1-1/2 Cups (375 ml) white sugar (27%) 2 Tablespoons (30 ml) powdered ginger 2 Tablespoons (30 ml) lemon juice 1-Teaspoon (5 ml) Cream of Tartar 6 black peppercorns 3 Tablespoons (45 ml) of Ginger Beer Plant 1 coffee filter and a rubber band, or an airlock 1 strainer, a funnel, and a 12 inch (30 cm) square sheet of muslin cloth Optional: 1 hydrometer to measure specific gravity Fermentation Procedure: Day zero: Add sugar, ginger, lemon juice, and Cream of Tartar to distilled water in mason jar, cap and shake well to mix. This also mixes oxygen into the solution to aid in feeding the yeast. For those interested, the specific gravity (SG) of the solution should be approx. 1.104 (13.7% potential alcohol). Uncap and add the peppercorns and Ginger Beer Plant. Cover the Mason jar with a coffee filter secured by a rubber band. This allows the free movement of replacement oxygen into the jar. Place jar in a sunny window, preferably, or anywhere that will maintain a temperature between 80-90 F. (27-32 C.). Day one: After 24 hours, strain out the Ginger Beer Plant and peppercorns, taking care to save the solution. Rinse out the jar and, using a funnel and muslin cloth, carefully pour the solution back into it. To speed up the straining, you may occasionally lift the cloth by its four corners in one hand and GENTLY squeeze the cloth with the other. Replace the peppercorns into the strained solution. Gently rinse the Ginger Beer plant in cool water and either use for another batch or rest in sugar water in the fridge. The solution should be 2-2.5% alcohol (SG ~1.085) at this point. This straining process is to maintain the high quantity (at this time) of yeasts in the solution while minimizing the quantity of lactic and acetic acid producing bacteria that would otherwise inhibit the alcohol producing qualities (which we want to maintain) of

the yeasts. There will still be sufficient of these bacteria to prevent infection of the solution by alien bacteria. Days two through four: For this first batch, taste the solution daily to acquaint you with the progress by placing a small amount on your tongue. During this time period there will be a pronounced sweetness, with a considerable lemon-ginger bite and a gradual alcohol and pepper taste increase. The aroma will be distinctly lemon-ginger, and faintly alcoholic. During this time period also, there will be a steady increase of alcohol to 4.4% (SG ~1.070) and a solution PH of ~5.0. At this point, the primary yeast S. pyriformis (a) stops producing more alcohol (H. M. Ward), leaving further alcohol generation up to the lesser quantities of beer yeast (d) and top yeast (c). At this point also the Acetobacter aceti (h), an acid intolerant (PH 5.4-6.3) species, should form appreciably less acetic acid. Predictably, it will take a further eleven days (nearly three times as long) to double the alcohol content. Days five through nine: Taste during this time period, while still sweet, will show the beginnings of a movement towards a more balanced lemon-ginger-pepper alcohol. The aroma, still primarily lemonginger, begins to also manifest a whiskey aroma. Also, by the end of this time period the solution alcohol content will be 6.8% (SG ~1.052) and have a PH of ~4.6. That alcohol concentration should disable the primary bacteria Lactobacillus hilgardii (f) from forming appreciably more lactic acid and fully disable the Acetobacter aceti (h) from forming further acetic acid. Days ten through fourteen: Taste during this time period will show the final movement towards a nicely balanced lemon-ginger-pepper having a distinct alcohol taste. Taste wise; it ultimately resembles an equivalent to a good sipping whiskey. The aroma is now primarily that of a whiskey with a faint lemon component. By the end of this time period the alcohol content is 8.7% (SG ~1.038). Further fermentation evolves gas (~2ul/s) but no increase in alcohol or decrease in SG. The PH at this point is ~4.0, strongly acidic. Bottling the finished product and refrigerating for five days produced a mildly effervescent, excellent tasting sipping beverage (dont think youre going to drink a water glassful at a sitting!) without the otherwise expected trademark of the Ginger Beer Plant, that explosive effervescence on opening the bottle. Note: Ginger Beer Plant cannot be used to brew beer. Components of the Ginger- Beer Plant (most likely Mycoderma cerevisiae (g) and Acetobacter aceti (h)) will turn your concoction sour.

Copyright 2006 (c) Fermentedtreasures.com All rights reserved

You might also like

- Malting Barley StoryDocument8 pagesMalting Barley StoryeduenglerNo ratings yet

- Spicing Up Your BeerDocument7 pagesSpicing Up Your BeerJacintoChurriqueNo ratings yet

- How To Malt at HomeDocument32 pagesHow To Malt at HomeMaurício Maciel SoaresNo ratings yet

- Beer Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Beer Drinks at HomeFrom EverandBeer Cocktail Recipes: Ultimate Book for Making Refreshing & Delicious Beer Drinks at HomeNo ratings yet

- Beer Judge Certification Program: Guide To Beer StylesDocument30 pagesBeer Judge Certification Program: Guide To Beer StylesazbrewerNo ratings yet

- Rice BeerDocument8 pagesRice BeerPied7PiperNo ratings yet

- Cider Making Made EasyDocument6 pagesCider Making Made Easybartolomej7No ratings yet

- Yeast Propagation and Maintenance 128Document25 pagesYeast Propagation and Maintenance 128Rafael BarrosNo ratings yet

- Ginger Beer: (Using Double Fermentation Based Loosely On La MéthodeDocument2 pagesGinger Beer: (Using Double Fermentation Based Loosely On La MéthodevelivolantNo ratings yet

- Late Hop & Hop OilsDocument3 pagesLate Hop & Hop OilsBill LimaNo ratings yet

- Spicing Up Your BeerDocument7 pagesSpicing Up Your BeerPablo Jutglá MonederoNo ratings yet

- Eighty Years of Rapid Maturation Studies - Distiller MagazineDocument18 pagesEighty Years of Rapid Maturation Studies - Distiller Magazineamul ghimireNo ratings yet

- Juicy NeipaDocument3 pagesJuicy NeipaRoberto AthaydeNo ratings yet

- 300 Clones de CervejasDocument642 pages300 Clones de CervejasBruno MoraesNo ratings yet

- 2017 Raintree Nursery CatalogDocument96 pages2017 Raintree Nursery CatalogWirelessWomanNo ratings yet

- Zymurgy Bob's Making The CutsDocument2 pagesZymurgy Bob's Making The CutsTy FitwillyNo ratings yet

- Sam Calagione Extreme Brewing An Enthusiasts Guide To Brewing Craft Beer at Home 2006Document186 pagesSam Calagione Extreme Brewing An Enthusiasts Guide To Brewing Craft Beer at Home 2006Bruno Noriega100% (2)

- The Artisan's Guide To Crafting Distilled Spirits: Small-Scale Production of Brandies, Schnapps and Liquors - Food & Beverage TechnologyDocument4 pagesThe Artisan's Guide To Crafting Distilled Spirits: Small-Scale Production of Brandies, Schnapps and Liquors - Food & Beverage TechnologysohyxumaNo ratings yet

- The Cider Makers' Hand Book - A Complete Guide for Making and Keeping Pure CiderFrom EverandThe Cider Makers' Hand Book - A Complete Guide for Making and Keeping Pure CiderNo ratings yet

- Craft Cider Making - Food & Beverage TechnologyDocument4 pagesCraft Cider Making - Food & Beverage TechnologymepacykuNo ratings yet

- 06-13HawaiiBeverage Guide MagazineDocument51 pages06-13HawaiiBeverage Guide MagazineHIBevGuideNo ratings yet

- HPP Drink MIX TEA & RECIPEDocument8 pagesHPP Drink MIX TEA & RECIPENur kholis MajidNo ratings yet

- Malt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupDocument33 pagesMalt & The Malting Process: Kelly J. Kuehl - National Sales Director The Country Malt GroupOleg Burlac100% (1)

- Yeast: The Practical Guide To Beer Fermentation (Brewing Elements) - Chris WhiteDocument4 pagesYeast: The Practical Guide To Beer Fermentation (Brewing Elements) - Chris WhitefufifujiNo ratings yet

- 101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsFrom Everand101 Old Time Receipts for Beer, Wine, Whiskey, other Spirits and AccoutrementsNo ratings yet

- Tracing Dissolved Oxygen Pickup in Beer PackagingDocument37 pagesTracing Dissolved Oxygen Pickup in Beer Packagingfrank_91No ratings yet

- Ginger BeerDocument85 pagesGinger BeerAron Farkas100% (1)

- Home Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsFrom EverandHome Brewing Beer And Other Juicing Recipes: How to Brew Beer Explained in Simple Steps: How to Brew Beer Explained in Simple StepsNo ratings yet

- White ClawDocument2 pagesWhite ClawsoundaryaNo ratings yet

- 1-2 J Palmer Real Examples of Water AdjustmentDocument26 pages1-2 J Palmer Real Examples of Water AdjustmentrarasriwindhuNo ratings yet

- Operations Assignment Costa CoffeeDocument14 pagesOperations Assignment Costa Coffeesachishindes0% (2)

- The Perfect Keg: Sowing, Scything, Malting and Brewing My Way to the Best-Ever Pint of BeerFrom EverandThe Perfect Keg: Sowing, Scything, Malting and Brewing My Way to the Best-Ever Pint of BeerNo ratings yet

- Farmhouse Ale Quest: Down the Rabbit-hole: Blog posts 2010-2015From EverandFarmhouse Ale Quest: Down the Rabbit-hole: Blog posts 2010-2015No ratings yet

- 2014 MBAA Chris White Yeast ManagementDocument30 pages2014 MBAA Chris White Yeast ManagementAdrián LampazziNo ratings yet

- Robo Brew 35 L InstructionsDocument5 pagesRobo Brew 35 L Instructionssteve_milenNo ratings yet

- CRM Report of Coca Cola.Document8 pagesCRM Report of Coca Cola.akushdwNo ratings yet

- Enological Studies - I. Experiments in Cider Making Applicable to Farm Conditions II. Notes on the Use of Pure Yeasts in Wine MakingFrom EverandEnological Studies - I. Experiments in Cider Making Applicable to Farm Conditions II. Notes on the Use of Pure Yeasts in Wine MakingNo ratings yet

- Ginger Ale Verses BeerDocument9 pagesGinger Ale Verses BeerSwami AbhayanandNo ratings yet

- Recipes for Brewing Different Types of Beers and AlesFrom EverandRecipes for Brewing Different Types of Beers and AlesNo ratings yet

- Make Yeast StarterDocument2 pagesMake Yeast StarterAlexandraNo ratings yet

- What Are The Functions of Sodium Metabisulfite?: Chemical PropertiesDocument4 pagesWhat Are The Functions of Sodium Metabisulfite?: Chemical PropertiesSuria Cahaya100% (1)

- BeerDocument21 pagesBeermichol20140% (1)

- Beyond Malt HopsDocument46 pagesBeyond Malt Hopsbartolomej7No ratings yet

- Homebrew - Small Barrel StrategiesDocument37 pagesHomebrew - Small Barrel StrategiesMarco RibaltaNo ratings yet

- Cask CleaningDocument4 pagesCask Cleaningde_klusNo ratings yet

- The New Cider Maker's Handbook Press ReleaseDocument1 pageThe New Cider Maker's Handbook Press ReleaseChelsea Green PublishingNo ratings yet

- Pitch Temperatures in Traditional Farmhouse BrewingDocument20 pagesPitch Temperatures in Traditional Farmhouse BrewingJuan Antonio DiazNo ratings yet

- Yeast Farming - Yeast - Aussie Home BrewerDocument5 pagesYeast Farming - Yeast - Aussie Home Brewerietram12No ratings yet

- Brew Like A MonkDocument3 pagesBrew Like A MonkSonia Cireaşă0% (1)

- 2010 SOQ 3 Belgian StrongDocument5 pages2010 SOQ 3 Belgian StrongJoao Carlos MaximianoNo ratings yet

- CBC Online Seminar Presentation Draught Beer Quality Workshop Addressing Draught Beer Dispense IssuesDocument40 pagesCBC Online Seminar Presentation Draught Beer Quality Workshop Addressing Draught Beer Dispense IssuesAnh TuanNo ratings yet

- StillDragon The Gin Basket Operation Manual v1 1 20140116Document46 pagesStillDragon The Gin Basket Operation Manual v1 1 20140116draganNo ratings yet

- Emerging: Brewing Is The Production ofDocument16 pagesEmerging: Brewing Is The Production ofSheerin SulthanaNo ratings yet

- Craft: The Brewers Association Guide To AmericanDocument16 pagesCraft: The Brewers Association Guide To AmericanMar KamonNo ratings yet

- Sustainable Brewing Concept LRDocument5 pagesSustainable Brewing Concept LRAndalusia Martha Novaline SiboroNo ratings yet

- Cocktails en ShootersDocument10 pagesCocktails en ShootersDawie AucampNo ratings yet

- ABOUT Cognac and BrandyDocument3 pagesABOUT Cognac and BrandyrajNo ratings yet

- Daftar Menu BazarDocument2 pagesDaftar Menu BazarnelisaNo ratings yet

- Haryana Liquor Price ListDocument3 pagesHaryana Liquor Price ListkavitamoarNo ratings yet

- Brew Guide 4Document9 pagesBrew Guide 4marketgraphicsnzNo ratings yet

- Summative Exam About BaristaDocument4 pagesSummative Exam About BaristaFrance Nicole Joy MoracaNo ratings yet

- Book 2Document20 pagesBook 2k.shaikhNo ratings yet

- Drinking Games ListDocument2 pagesDrinking Games ListGustavoNo ratings yet

- Coffee Industry AnalysisDocument6 pagesCoffee Industry AnalysisMichelle MoraNo ratings yet

- Sprite vs. Mountain Dew: Advertisement AnalysisDocument8 pagesSprite vs. Mountain Dew: Advertisement Analysisnehamishr26No ratings yet

- Fermentation - Calicdan, Rochelle GDocument5 pagesFermentation - Calicdan, Rochelle GCiel GevenNo ratings yet

- Korea Herald 20100504Document1 pageKorea Herald 20100504raiseyNo ratings yet

- Crystal Pepsi 2Document16 pagesCrystal Pepsi 2Prabhdeep SinghNo ratings yet

- Cointreau Cocktail NotebookDocument19 pagesCointreau Cocktail NotebookDiego Ignacio Venegas RiosNo ratings yet

- Starbucks Case StudyDocument1 pageStarbucks Case Studykaizer0% (1)

- (I) Indian Liquor (Whisky, Rum, Gin, Vodka, Brandy)Document7 pages(I) Indian Liquor (Whisky, Rum, Gin, Vodka, Brandy)Rahul KumarNo ratings yet

- The Beer Market in IndiaDocument57 pagesThe Beer Market in Indianachi1984100% (1)

- Bajigur Is A Hot and Sweet Beverage Native To TheDocument3 pagesBajigur Is A Hot and Sweet Beverage Native To TheVerlinda FortunaNo ratings yet

- JUICY MalaysiaDocument1 pageJUICY MalaysiaaidaNo ratings yet

- Marketing Management - 1 (MFT4CCMM01) : TOPIC: - Comparative Response StrategiesDocument15 pagesMarketing Management - 1 (MFT4CCMM01) : TOPIC: - Comparative Response StrategiesComplete AramNo ratings yet

- The Koffee Menu PutrajayaDocument2 pagesThe Koffee Menu PutrajayaKu AimanNo ratings yet

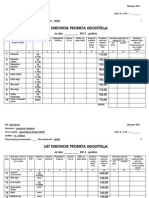

- List Dnevnog Prometa Ugostitelja: Za Dan - 2013 - GodineDocument6 pagesList Dnevnog Prometa Ugostitelja: Za Dan - 2013 - GodineЂорђе РосићNo ratings yet

- Eabl-1 16559Document26 pagesEabl-1 16559blitzalex180No ratings yet

- Menu Bukber Bulan Ramadhan Teras by AkininiDocument15 pagesMenu Bukber Bulan Ramadhan Teras by AkininiAulia MidiaNo ratings yet

- Agua 270420Document8 pagesAgua 270420Juan Renzo Hilario MuñozNo ratings yet