Professional Documents

Culture Documents

Extruded Heat Sink Design

Uploaded by

Siveshwar BongulaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extruded Heat Sink Design

Uploaded by

Siveshwar BongulaCopyright:

Available Formats

Heat Sink Design Aluminum Extrusions

1.) Overview

The purpose of this technical brief is to give the new designer or engineer the basics in the limitations of designing an aluminum extrusion. Extrusions are 2 dimension shapes that can be fabricated after manufacture to produce net shape parts. To help minimize cost and maximize efficiency extruded aluminum heat sink need to be low in weight, high in exposed surface area and simple in design. Violation of these basic design criteria will result in less than optimized heat sinks for the specific application.

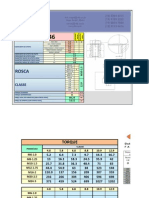

2.) Tolerances

In general an extruded shape has a wider tolerance than a machined part. In many machined aluminum parts holding feature tolerances can be done at +/- 0.005 inches or better. In extrusion, due to the nature of the process, these feature tolerances can be up to +/- 0.100 inches or more depending on the overall size of the profile and its technical complexity. Most extruders, including Thermshield, LLC, comply with The Aluminum Association standard tolerance listings which vary allowable tolerances based on the overall circle size of the extrusion. In most cases the following tolerances apply to given dimensions:

+/- tolerance in inches

Up to 10 circle Less than 0.125 0.006 0.125 to 0.249 0.007 0.250 to 0.499 0.008 0.500 to 0.749 0.009 0.750 to 0.999 0.010 1.000 to 1.499 0.012 1.500 to 1.999 0.014 2.000 to 3.999 0.024 Greater than 10 circle 0.014 0.015 0.016 0.017 0.018 0.019 0.024 0.034

4.000 to 5.999 6.000 to 7.999 8.000 to 9.999 10.00 to 11.99 12.00 to 13.99 14.00 to 15.99 16.00 to 17.99

0.034 0.044 0.054 ---------------------

0.044 0.054 0.064 0.074 0.084 0.094 0.104

3.) Circle Sizes

Most extrusions are made in large hydraulic presses that use a specifically shaped tool to form parts. The size of the press is designated by the number of tons of force it can apply and the maximum circle size of the tooling. The circle size of the tool limits the overall size of the maximum extrusion profile that can be made by a given press. This largest allowable size is the combination of width and height that will fit within the given circumscribed diameter. Press circle sizes range from 2.0 inches to as large as 30.0 inches. In general the larger the tool size the fewer presses are available in the world.

4.) Extrusion Ratios

One of the limiting factors in the extrusion process is the ratio of fin height to minimum air gap between fins. This air gap between fins represents the amount to tool steel material used in the production die that helps to hold back the flow of heated aluminum during the extrusion process. If the distance between fins is too narrow and tall the result will be die failure. Die failure can be either fin thickness that shift changing the width of the air gap setting fin thickness out of tolerance. The other failure mode is breaking of the steel resulting in redesign and remanufacture of the die. The limitation on extrusion ratios varies with the overall size of the extrusion profile. Extrusion ratios of 14 to 1 are common place for dies that are less than 4 inches in diameter. Ratios of only 10:1 or less are more typical for dies that are 10.0 inches and above. Some manufacturers can produce ratios of up to 22:1 depending on many factors. There is no set limitation on ratios that can be calculated. The limit of the ratio depends on many factors including the type of

extrusion press, the skill of the operator, the alloy being pressed and many other details.

5.) Physical Properties

The most common aluminum alloy used for extrusion is 6063, 98.9 % aluminum.. The most common temper is T5. This alloy has excellent physical characteristics, can be made in various tempers and is relatively low in cost. Following are typical properties: Coef. Thermal Expansion 13X10-6 inch/inch Thermal conductivity 209 W/MK Electrical Resistivity 3.1 X 10-6 ohm CM Melting temp 616 C Density 2.7 g/cc Tensile strength, yield 145 Mpa

For further information please contact: Christopher A. Soule Engineering Director Thermshield, LLC (603) 524-3714 csoule@thermshield

You might also like

- Hot-rolled steel product catalogueDocument30 pagesHot-rolled steel product catalogueShankar PranavNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Lecture Slides On Metrology and Inspection - PPTDocument30 pagesLecture Slides On Metrology and Inspection - PPTDeb PradhanNo ratings yet

- Limits & Fits _ Types of Fits Explained & Tolerance Charts _ FractoryDocument10 pagesLimits & Fits _ Types of Fits Explained & Tolerance Charts _ FractoryMangesh KetkarNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Ortlinghaus PlatesDocument19 pagesOrtlinghaus PlatesErsin KamburoğluNo ratings yet

- Sheet MetalDocument60 pagesSheet MetalAnonymous tQhtrPbNo ratings yet

- Alumec PDFDocument7 pagesAlumec PDFetamil87No ratings yet

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Stamping Design GuidelineDocument13 pagesStamping Design GuidelineVikram Borkhediya100% (1)

- Types of Fits: Engineering TolerancingDocument2 pagesTypes of Fits: Engineering TolerancingRandima GajanayakaNo ratings yet

- Ineos Polypropylene Processing GuideDocument18 pagesIneos Polypropylene Processing GuideLe Toan100% (1)

- PB Alumec EnglishDocument12 pagesPB Alumec EnglishByron RodriguezNo ratings yet

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocument5 pagesDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanypuneethudupiNo ratings yet

- W01 358 9603Document29 pagesW01 358 9603MROstop.comNo ratings yet

- Appendix A - Tolerances For Impression DieDocument21 pagesAppendix A - Tolerances For Impression Diekkozak99No ratings yet

- W01 358 7304Document29 pagesW01 358 7304MROstop.comNo ratings yet

- W01 358 7442Document29 pagesW01 358 7442MROstop.comNo ratings yet

- Everything You Need to Know About Limits, Fits and TolerancesDocument22 pagesEverything You Need to Know About Limits, Fits and TolerancesAbhay Sharma100% (1)

- W01 358 7047Document29 pagesW01 358 7047MROstop.comNo ratings yet

- W01 358 2132Document29 pagesW01 358 2132MROstop.comNo ratings yet

- Dr. A. Vinoth Jebaraj on tolerances and interchangeable partsDocument22 pagesDr. A. Vinoth Jebaraj on tolerances and interchangeable partsNikhil VermaNo ratings yet

- W01 358 7830Document29 pagesW01 358 7830MROstop.comNo ratings yet

- Multi Point Cutting Tool Design PDFDocument73 pagesMulti Point Cutting Tool Design PDFsrutiiNo ratings yet

- W01 358 7039Document29 pagesW01 358 7039MROstop.comNo ratings yet

- W01 358 7092Document29 pagesW01 358 7092MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 7091Document29 pagesW01 358 7091MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- W01 358 6910Document29 pagesW01 358 6910MROstop.comNo ratings yet

- W01 358 6900 Firestone Double Convoluted Air SpringDocument29 pagesW01 358 6900 Firestone Double Convoluted Air SpringMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- En 10029Document3 pagesEn 10029hamoody_007100% (1)

- Seminar Report HydroformingDocument11 pagesSeminar Report HydroformingAnuj Mandloi100% (2)

- W01 358 7742Document29 pagesW01 358 7742MROstop.comNo ratings yet

- W01 358 8118Document29 pagesW01 358 8118MROstop.comNo ratings yet

- Impression Die Forging Cold Forging Open Die Forging Seamless Rolled Ring ForgingDocument6 pagesImpression Die Forging Cold Forging Open Die Forging Seamless Rolled Ring Forgingakashdruva892No ratings yet

- Design Considerations of CastingsDocument8 pagesDesign Considerations of Castingshaqjmi100% (2)

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Boring OperationDocument9 pagesBoring Operation3pherNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Limits and FitsDocument6 pagesLimits and FitsPhyl CreatorNo ratings yet

- Static Data Description Assembly Order No.: Recommended Airmount Design Height 4.5 InchesDocument29 pagesStatic Data Description Assembly Order No.: Recommended Airmount Design Height 4.5 InchesMROstop.comNo ratings yet

- The Technical Truth About Belt TensionersDocument2 pagesThe Technical Truth About Belt Tensionersricks_4No ratings yet

- 776 Dayton's Engineered Clearance-WebDocument6 pages776 Dayton's Engineered Clearance-WebNaukowyDrpNo ratings yet

- W01 358 7737Document29 pagesW01 358 7737MROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Static Data Description Assembly Order NoDocument29 pagesStatic Data Description Assembly Order NoMROstop.comNo ratings yet

- Surface Treatment and Painting ProcedureDocument7 pagesSurface Treatment and Painting ProcedureMohamedNo ratings yet

- Torque and clamp load calculation for M10 boltsDocument4 pagesTorque and clamp load calculation for M10 boltsmajonas77No ratings yet

- ASTM A1011 NovaDocument9 pagesASTM A1011 NovaAlonso BrocheroNo ratings yet

- Metal Cutting Processes 1 - TurningDocument14 pagesMetal Cutting Processes 1 - TurningmostafaNo ratings yet

- Buehler Technotes - Indentation Testing MappingDocument3 pagesBuehler Technotes - Indentation Testing Mappingdev-nullNo ratings yet

- Micro-hydro Power for Rural VillagesDocument2 pagesMicro-hydro Power for Rural Villagesxomi2530No ratings yet

- Design and Analysis of Single Point Cutting ToolDocument46 pagesDesign and Analysis of Single Point Cutting ToolkarthikeyanNo ratings yet

- List of Manufacturing Processes: CastingDocument10 pagesList of Manufacturing Processes: Castingjohndesign123No ratings yet

- SPC - CR - UR - 510 - 3, Urea GradeDocument35 pagesSPC - CR - UR - 510 - 3, Urea Gradesaadpervaiz14No ratings yet

- Saej 524 V 002Document5 pagesSaej 524 V 002Marcos Verissimo Juca de PaulaNo ratings yet

- Radiography Interpretation PDFDocument220 pagesRadiography Interpretation PDFVijay Kumar100% (1)

- Exploded assembly drawing caster parts listDocument1 pageExploded assembly drawing caster parts listlianaNo ratings yet

- A 02 1064Document4 pagesA 02 1064Marliton SalinasNo ratings yet

- Introduction To Ductile IronDocument8 pagesIntroduction To Ductile IronNatalino FonsecaNo ratings yet

- AL - CU - Integration - Preso - v7 24 Jul 08 ZipDocument80 pagesAL - CU - Integration - Preso - v7 24 Jul 08 ZipFreddy CadenaNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Technology Development For Hardfacing ofDocument2 pagesTechnology Development For Hardfacing ofabraham silva hernandezNo ratings yet

- D5-2 Prepainted Galvanized Galvalume Steel Coils With Protective Plastic FilmDocument2 pagesD5-2 Prepainted Galvanized Galvalume Steel Coils With Protective Plastic FilmFernandoCrespoMonNo ratings yet

- Iso 4948 1 1982Document4 pagesIso 4948 1 1982surya zenNo ratings yet

- Fibula Plate SynthesDocument32 pagesFibula Plate SynthesGeorgios MandelasNo ratings yet

- I Beam Channel Wheel SectionDocument2 pagesI Beam Channel Wheel SectionCorrine D. ThompsonNo ratings yet

- As 7703 Iso Fe Serie enDocument8 pagesAs 7703 Iso Fe Serie enprihartono_diasNo ratings yet

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDocument12 pages1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- Colour ChartDocument1 pageColour ChartgawaNo ratings yet

- Hilti Corrosion-Handbook EN PDFDocument48 pagesHilti Corrosion-Handbook EN PDFElenildo BarrosNo ratings yet

- Mould DesignDocument8 pagesMould DesignpakivermaNo ratings yet

- Thermophysical PropertiesDocument14 pagesThermophysical PropertiesKalinga BalNo ratings yet

- Grade 9 MetalworkDocument13 pagesGrade 9 MetalworkAidan O'HaraNo ratings yet

- Metallurgy and Steel Properties: Electron (-)Document10 pagesMetallurgy and Steel Properties: Electron (-)Ashish ManeNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)