Professional Documents

Culture Documents

Walmart Case Solution

Uploaded by

Anubhav KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Walmart Case Solution

Uploaded by

Anubhav KumarCopyright:

Available Formats

Subject Title: Student Name: Enrolment No: Wal-Marts Supply Chain Management Practices Using IT/Internet to manage the

e supply chain (OPER028) Q-a) Wal-Mart used information technology (IT) comprehensively in managing all the functions of the supply chain. Explain how the company used IT in procurement, warehouse & logistics management, and inventory management. What benefits did the company reap by using IT? Wal-Mart employed the most advanced IT tools and applications in all supply chain functions, starting from demand forecasting, procurement, logistics, distribution and inventory management. The company focused on bringing efficiency to every function of the supply chain so as to offer its customers products at the lowest possible prices. Wal-Mart has been proactive in using the Internet as a ubiquitous communication infrastructure to drive mega-efficiencies. It had always been the first mover in the retailing industry to embrace new technologies for managing the supply chain processes. Technology helped them to buy the right merchandize at the right time, and have it in the right place at the right price. Beginning in the late 1970s, Wal-Mart employed an advanced logistics technique known as cross docking. It enabled the company to receive goods and dispatch them to the respective stores/customers in less than a day, thus minimizing inventory storage and handling costs. Use of IT in Procurement Wal-Mart used EDI (Electronic Data Interchange) to save time and made its procurement process more efficient. Wal-Mart placed orders for huge quantities of goods with its suppliers. By placing bulk orders, Wal-Mart could negotiate the best prices for goods and got significant discounts. The bar code scanners placed at the check-out counters in each store scanned and processed the bar-codes on each product moving out of the store. The information, including the type of the product, its manufacturer and its price was recorded on the computer systems at the store. The information was instantly passed on to the centralized data warehouse through satellite links. An analysis of the daily, weekly and monthly sales data helped the store manager determine what products were selling and in what quantities. Accordingly, the store manager could place the purchase order with the merchandizing division at the headquarters. The computer systems of Wal-Mart were connected to those of its suppliers. EDI enabled the suppliers to download purchase orders along with store-to-store sales information relating to their products sold. On receiving information about the sales of various products, the suppliers shipped the required goods to Wal-Mart's distribution centers. By planning its purchases well, Wal-Mart was able to stock goods in right quantities and avoided over stocking at the stores.

Use of IT in Warehouse & Logistics management Over the decades, Wal-Mart had gained significant expertise in warehouse and logistics management. Its fully automated distribution centers and its own dedicated fleet of trucks helped Wal-Mart ship inventories at much lower costs compared to its competitors. In the late 1980s, Wal-Mart started employing IT-enabled tools and techniques to further enhance its warehouse and logistics management capabilities. At the distribution centers, the bar-codes on the goods entering the centers were scanned, following which they were sorted out according to the orders received from the individual stores. This process ensured that the inventory stayed at the stores for very little time and also enabled quick replenishment of goods at the stores. In 1998, Wal-Mart installed a voice-based order filling (VOF) system in all it grocery distribution centers. The system consisted of portable voice recognition Talkman terminals (VRTT) and a built-in speed spectrum radio module that communicated over the company's wireless local area network (LAN). By installing the VOF system, Wal-Mart eliminated mispicks and product labelling costs since the system did not require paper lists and labels to be affixed on the goods for locating them. Wal-Mart made significant investments in IT to quickly locate and replenish goods at the stores. The company asked its suppliers to ship goods in store-ready displays called PDQ (pretty darn quick) displays. Goods were packed in attractive PDQ displays that arrived at the stores ready to be boarded on the racks. Wal-Mart's employees could directly replace the empty racks at the stores with fully packed racks, instead of refilling each and every item at the racks, thus saving valuable time. Though at the individual store level, the time saved per employee was not much, the aggregate time saved considering all the stores and its employees was quite substantial. Wal-Mart equipped all drivers of the company-owned trucks with the latest mobile systems to ensure round-the-clock real-time connectivity with them. In the mid-1990s, Wal-Mart installed advanced global positioning system (GPS)' technology-based communication/tracking systems in its trucks. Drivers could activate the system by voice, and interact with the staff at the distribution center/stores. The system enabled the company's satellite network to locate any truck anywhere in the US and neighbouring countries. It also delivered computer-generated instructions to the concerned order-picking staff in the center/stores through headsets.

Use of IT in inventory management In 1987, Wal-Mart installed a satellite communication system (SCS), believed to be the largest privately managed system in the US, at an estimated cost of $750 million. The system established virtual communication links between all Wal-Mart stores and distribution centers with the company headquarters, through a two-way voice and data and one-way video communication (from headquarters to stores).

By employing IT extensively in its supply chain processes over the decades, Wal-Mart emerged as a leading player in the retailing industry. The company's efforts at strengthening its SCM systems by installing advanced IT tools proved to be highly beneficial. Wal-Mart was able to achieve just-in-time inventory replenishment in a majority of its stores across the US.

Q-b) Briefly describe the process followed by the company to implement collaborative planning, forecasting, and replenishment (CPFR). Why do you think the company was not able to widen the supplier base willing to implement CPFR? Advanced inventory management system called 'Retail Link' launched in 1990, was the first step towards implementing CPFR. Retail link connected Wal-Mart's EDI network with an extranet, accessible to Wal-Marts thousand suppliers. Retail Link connected Wal-Mart's EDT network with an extranet, was accessible to Wal-Mart's thousands of suppliers. It provided suppliers with historical sales data of their products for past 24 month period; allowed them to track the status of their invoice; conduct further analysis of the data, and make demand forecasts for their products for the next twelve-month period. The analytical software in the retail link system enabled the manufacturers to get data relating to their products, as and when they required. They could find out how their product was performing vis-a vis competitors' products in a particular product category. Wal-Mart initially launched CPFR as a pilot project with Warner-Lambert (Lambert), with its Listerine product line in 1996. The pilot project was conducted in a Lambert plant and three Wal-Mart distribution centres. Both Wal-Mart and Lambert separately developed their projected demand for Listerine for a six-month period and exchanged demand forecasts and actual sales information. Using the CPFR software they arrived at a common forecast. The results were quite encouraging. Lambert was able to increase the stock position of Listerine from 87% to 98%. The encouraging results of the pilot project prompted Wal-Mart to extend CPFR to other key suppliers, including Sara Lee Corporation and P&G. Wal-Mart's CPFR implementation with apparel maker Sara Lee also yielded good results. The pilot was conducted on 23 branded women underwear items, which were distributed to an estimated 2,400 Wal-Mart stores. On the basis of a jointly developed forecast, the inventories were replenished. Following the pilot, the sales of Sara Lee branded apparel at Wal-Mart increased by 35% in 41 weeks. In the same period, the inventory turnover increased by 30%. A 23% reduction in the inventories at the store level was also observed. The overall impact was an increase in the Gross Margin Return on Investment19 (GMROI) by 49%. Following the success of CPFR pilot projects, Wal-Mart decided to extend the benefits of CRER to its thousands of suppliers through its web-enabled Retail Link system. To further enhance the existing CPFR, in October 2002, Wal-Mart asked its 14,000 suppliers to switch over from the existing Value Added Networks EDI (VAN-EDI) to web-enabled EDI. However, while implementing it, the suppliers had to adhere to a set of new data transmission protocols, called EDI-INT and AS2, in order to ensure security of transactions. Following the meeting in November 2003 with its top suppliers, Wal-Mart outlined the plan for implementing RFID. The company planned to implement RFID in phases. The suppliers, initially, would not be required to put tags on each and every item shipped to Wal-Mart. Instead, they had to tag the pallets and crates in which the goods were packed. To begin with, Wal-Mart required its suppliers to ship the tagged pallets and crates to three distribution

centres in Texas, US, which catered to about 150 stores. By the year-end, they had to extend it to all the 102 distribution centres. While Wal-Mart was pretty confident of implementing RFID, not all the suppliers were clear about what they ought to do. They were left with no other option but to comply with WalMart's requirements as they could not afford to lose their business with Wal-Mart. The reason for the company not able to widen the supplier base willing to implement CPFR was the huge investments in time and money for implementing CPFR. In order to implement, a significant amount of time had to be spent on developing forecasts and analysing sales data. To add to that not many suppliers new about the implementation process of RFID and it was an unproven technology.

You might also like

- Maule David Pass PetDocument215 pagesMaule David Pass PetNgoc NguyenNo ratings yet

- Magang Iron & SteelDocument125 pagesMagang Iron & SteelAntonio AntonioNo ratings yet

- Longman New Real TOEIC Actual Tests For Listening ComprehensionDocument192 pagesLongman New Real TOEIC Actual Tests For Listening ComprehensionVũ NguyễnNo ratings yet

- Unit 1: I'll Take It!Document4 pagesUnit 1: I'll Take It!peanutmilk0% (1)

- Level e Student Edition William H SadlierDocument32 pagesLevel e Student Edition William H SadlierThảo Vũ ThuNo ratings yet

- Chapter 1: Management FundamentalsDocument47 pagesChapter 1: Management Fundamentalsapi-296300471No ratings yet

- 이은수쌤 11setDocument74 pages이은수쌤 11setAnonymous 43May4KBNo ratings yet

- (PDF) Ielts Speaking Vocabulary Helen Nguyen - Academia - EduDocument1 page(PDF) Ielts Speaking Vocabulary Helen Nguyen - Academia - EduLeila AlmasNo ratings yet

- Try Ed Online Learning for FreeDocument1 pageTry Ed Online Learning for FreeZafer ÜnalNo ratings yet

- Oxford Grammar For Schools 4 Class Audio CD TracklistDocument2 pagesOxford Grammar For Schools 4 Class Audio CD TracklistAnonymous n4yCqIt100% (1)

- Masan Group CorporationDocument31 pagesMasan Group Corporationhồ nam longNo ratings yet

- Istep Ms PDFDocument81 pagesIstep Ms PDFJorge SantanaNo ratings yet

- Deriving Conclusions from PassagesDocument18 pagesDeriving Conclusions from PassagesBhagavathi Sankar KNo ratings yet

- De Cuong Hk2 Anh 4 Thi DiemDocument5 pagesDe Cuong Hk2 Anh 4 Thi DiemNguyen Xuan MenNo ratings yet

- Words Ending in - OusDocument4 pagesWords Ending in - OusMacz8t Yam-Yam100% (1)

- Weekly Lesson Plan - Uceda InstituteDocument2 pagesWeekly Lesson Plan - Uceda InstituteLayla Immigration Advisor100% (1)

- Pet Reading and WritingDocument27 pagesPet Reading and Writingasadmahmood1No ratings yet

- Unit 4 Interview - ReadingDocument2 pagesUnit 4 Interview - ReadingNguyễn Quốc VươngNo ratings yet

- 08 Ec4t3r PDFDocument25 pages08 Ec4t3r PDFณัฐกรานต์ ไชยหาวงศ์No ratings yet

- ĐỀ THI, KIỂM TRA MÔN TIẾNG ANHDocument16 pagesĐỀ THI, KIỂM TRA MÔN TIẾNG ANHDuong NguyenNo ratings yet

- Reading ExamDocument8 pagesReading ExamNur HidayaNo ratings yet

- Four variables of sentence meaningDocument2 pagesFour variables of sentence meaningNgọc ThảoNo ratings yet

- Testbank Chap 04Document354 pagesTestbank Chap 04Anh Tran HoangNo ratings yet

- Youth Center (Business Model Canvas)Document13 pagesYouth Center (Business Model Canvas)Hein Tay ZaNo ratings yet

- Answers To Key Questions: 8 PPC PPCDocument32 pagesAnswers To Key Questions: 8 PPC PPCrslpaperboyNo ratings yet

- GramUnit 1 PDFDocument12 pagesGramUnit 1 PDFJanineP.DelaCruzNo ratings yet

- Summary Chapter 4Document3 pagesSummary Chapter 4Hoàng VyNo ratings yet

- Complete DocumentDocument70 pagesComplete DocumentQasim RaoNo ratings yet

- Environment Natural Disasters PDFDocument6 pagesEnvironment Natural Disasters PDFTeo Khim SiangNo ratings yet

- Mock IGCSE 1 - 2020 - English - Reading & WritingDocument13 pagesMock IGCSE 1 - 2020 - English - Reading & WritingRiyaz MohamedNo ratings yet

- To The Teacher: Concept Cards and Other Materials That Can Be Used For Intervention If Test Results IndicateDocument90 pagesTo The Teacher: Concept Cards and Other Materials That Can Be Used For Intervention If Test Results IndicateAnna ZhangNo ratings yet

- InStep's Relocation from Paris to BeauchampDocument23 pagesInStep's Relocation from Paris to BeauchampDung Dương DươngNo ratings yet

- Business Vocabulary Builder Unit 15Document2 pagesBusiness Vocabulary Builder Unit 15Fco Javier Romero CondeNo ratings yet

- English Module 3 For Teen LearnersDocument49 pagesEnglish Module 3 For Teen LearnersmatejakuzmaNo ratings yet

- EL 202 English for Work Course OutlineDocument3 pagesEL 202 English for Work Course OutlineCee PhanthiraNo ratings yet

- BMI - Business Model CanvasDocument1 pageBMI - Business Model CanvasDario Bernardo Montufar BlancoNo ratings yet

- Alphabet (Repaired)Document31 pagesAlphabet (Repaired)oktavianaNo ratings yet

- Strategic MGMT Ch01Document250 pagesStrategic MGMT Ch01Phuong NguyenNo ratings yet

- 4EB0 01 Summer 2016 Exemplar MaterialsDocument10 pages4EB0 01 Summer 2016 Exemplar MaterialsSaira Binte SalekNo ratings yet

- Taylor Anne Toeic AnalystDocument232 pagesTaylor Anne Toeic Analysteigo nochikaraNo ratings yet

- (Nicholas Falletta) McGraw-Hill's SSAT ISEE, 2nd e (B-Ok - Xyz) JamieDocument70 pages(Nicholas Falletta) McGraw-Hill's SSAT ISEE, 2nd e (B-Ok - Xyz) JamieJamie KimNo ratings yet

- The Hound of Baskervilles by Sir Arthur Conan DoyleDocument223 pagesThe Hound of Baskervilles by Sir Arthur Conan DoyleCristinaNo ratings yet

- FPT Organizational StructureDocument7 pagesFPT Organizational StructureTấn TrầnNo ratings yet

- Pathways LS Foundations Independent Student HandbookDocument6 pagesPathways LS Foundations Independent Student HandbookKhet NweNo ratings yet

- CH 16Document9 pagesCH 16NMBGolfer100% (1)

- 930 - Unit 3, Building RelationshipsDocument11 pages930 - Unit 3, Building RelationshipszaizaiannieNo ratings yet

- Industrial Training Details: Internship ReportDocument46 pagesIndustrial Training Details: Internship ReportAkshay MurudiNo ratings yet

- Ket Prep - Test 1 Pages 4-13Document10 pagesKet Prep - Test 1 Pages 4-13Fernanda SalesNo ratings yet

- Osg3 Class Audio TracklistDocument3 pagesOsg3 Class Audio TracklisttesslimaNo ratings yet

- 【写作解析】TPO1 35Document210 pages【写作解析】TPO1 35AkbarNo ratings yet

- Ways of Learning: Are You A Multi-Tasker?Document8 pagesWays of Learning: Are You A Multi-Tasker?AMPARITONo ratings yet

- Freeadditionandsubtractionwithin 1000 Logicpuzzle 2 NBT 73 NBT 2Document11 pagesFreeadditionandsubtractionwithin 1000 Logicpuzzle 2 NBT 73 NBT 2api-507836868No ratings yet

- Business Workshop 5 + Additional ExercisesDocument6 pagesBusiness Workshop 5 + Additional Exerciseslakoh41611No ratings yet

- Driverless Cars May Change DrivingDocument2 pagesDriverless Cars May Change DrivingNoemi Campillo MartinezNo ratings yet

- Self - Study Ebook (IM08)Document95 pagesSelf - Study Ebook (IM08)Bảo HàNo ratings yet

- Wal-Marts Supply Chain Management Practices (B) - Using IT Internet To Manage The Supply ChainDocument8 pagesWal-Marts Supply Chain Management Practices (B) - Using IT Internet To Manage The Supply Chainrakeshb11No ratings yet

- Role of Infarmation Technology in WalDocument12 pagesRole of Infarmation Technology in WalMukesh KumarNo ratings yet

- Wal Mart EssayDocument4 pagesWal Mart Essayshanaka100No ratings yet

- WalmartDocument19 pagesWalmartShweta RawatNo ratings yet

- SCM WalmartDocument5 pagesSCM Walmartmuditmathur24100% (1)

- ANF PROFILEDocument10 pagesANF PROFILEtasneem89No ratings yet

- Fly Ash News DigestDocument1 pageFly Ash News DigestAnubhav KumarNo ratings yet

- Parliamentary Questions NTPCDocument1 pageParliamentary Questions NTPCAnubhav KumarNo ratings yet

- Glossary of Shipment TermsDocument8 pagesGlossary of Shipment TermsAnubhav KumarNo ratings yet

- 2nd Annual International Fly Ash Utilization Summit - ReportDocument2 pages2nd Annual International Fly Ash Utilization Summit - ReportAnubhav KumarNo ratings yet

- A CostBenefit Analysis of UIDDocument3 pagesA CostBenefit Analysis of UIDAnubhav KumarNo ratings yet

- Fly Ash MissionDocument8 pagesFly Ash MissionAnubhav KumarNo ratings yet

- IHS McCloskey Coal Report Summary - Mar 22, 2013Document2 pagesIHS McCloskey Coal Report Summary - Mar 22, 2013Anubhav KumarNo ratings yet

- Whirlpool Case Sudy SolnDocument5 pagesWhirlpool Case Sudy SolnAnubhav Kumar0% (1)

- Theory of Constraints in 40 CharactersDocument12 pagesTheory of Constraints in 40 CharactersAnubhav KumarNo ratings yet

- Global Marketing AssignmentDocument6 pagesGlobal Marketing AssignmentAnubhav KumarNo ratings yet

- MCD 10 5Document2 pagesMCD 10 5Dib KerdiehNo ratings yet

- Company Profile (NTT Data) PDFDocument16 pagesCompany Profile (NTT Data) PDFEka Dewi HendrawatiNo ratings yet

- History of StarbucksDocument10 pagesHistory of StarbucksSundus ButtNo ratings yet

- Secure Scheduling PresentationDocument15 pagesSecure Scheduling PresentationheidigrooverNo ratings yet

- Joseph Carlson - Netflix ValuationDocument4 pagesJoseph Carlson - Netflix ValuationNicoletta MarianiNo ratings yet

- Required Exercises Solutions Chapter 13Document4 pagesRequired Exercises Solutions Chapter 13Le TanNo ratings yet

- Revised Public Sector Audit NotesDocument15 pagesRevised Public Sector Audit NotesJoyce Anne GarduqueNo ratings yet

- M1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityDocument24 pagesM1439-GHD-MCL-MSS-056 Lockout and Tag Out For Islolation ActivityAnandu AshokanNo ratings yet

- Chapter - 10Document17 pagesChapter - 10Sudipa RouthNo ratings yet

- Business ModelDocument1 pageBusiness ModelMaddy AkuNo ratings yet

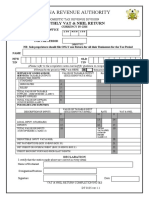

- Ghana Revenue Authority: Monthly Vat & Nhil ReturnDocument2 pagesGhana Revenue Authority: Monthly Vat & Nhil Returnokatakyie1990No ratings yet

- Public-Private Partnerships (PPPS) in Egovernment: Definition, Rationale, and Regulatory FrameworksDocument34 pagesPublic-Private Partnerships (PPPS) in Egovernment: Definition, Rationale, and Regulatory FrameworksSoenarto SoendjajaNo ratings yet

- HFM Implementation Centralizes ReportingDocument3 pagesHFM Implementation Centralizes ReportingSam SamamNo ratings yet

- Assign Purchase Organisation To A Company CodeDocument10 pagesAssign Purchase Organisation To A Company CodeRahul ShindeNo ratings yet

- A1 Pet ClinicDocument3 pagesA1 Pet ClinicAnn MaNo ratings yet

- Segmentacija, Targetiranje, PozicioniranjeDocument14 pagesSegmentacija, Targetiranje, Pozicioniranjecarina1983No ratings yet

- LNTDocument202 pagesLNTKumar AbhishekNo ratings yet

- Eclerx Research ReportDocument13 pagesEclerx Research ReportPragati ChaudharyNo ratings yet

- VIII. Consideration of Internal ControlDocument15 pagesVIII. Consideration of Internal ControlKrizza MaeNo ratings yet

- Systems IntegrationDocument76 pagesSystems IntegrationChaim Taylor100% (1)

- Algorithmic Trading Directory 2010Document100 pagesAlgorithmic Trading Directory 201017524100% (4)

- Starting a Business FactorsDocument12 pagesStarting a Business FactorsAngelo DumaopNo ratings yet

- The False Expectations of Michael Porter's Strategic Management Framework / Omar AktoufDocument33 pagesThe False Expectations of Michael Porter's Strategic Management Framework / Omar AktoufBiblioteca CHGMLNo ratings yet

- Tan General Merchandise financial analysisDocument2 pagesTan General Merchandise financial analysisCatty Kiara RamirezNo ratings yet

- Introducing PLAXIS CONNECT Edition: Frequently Asked QuestionsDocument4 pagesIntroducing PLAXIS CONNECT Edition: Frequently Asked QuestionsFidel Ruiz TorresNo ratings yet

- Performance Management Questionnaire for EmployeesDocument2 pagesPerformance Management Questionnaire for EmployeesAbhisek SarkarNo ratings yet

- Operation and StrategyDocument58 pagesOperation and StrategyAliya RaheelNo ratings yet

- ENTREP - Chap4Document5 pagesENTREP - Chap4Myla MoriNo ratings yet

- Research Proposal IFmDocument5 pagesResearch Proposal IFmYogeshPanchal100% (1)

- Quiz 405Document3 pagesQuiz 405Shaika HaceenaNo ratings yet