Professional Documents

Culture Documents

Shell and Tube Heat Exchanger

Uploaded by

PRATIK P. BHOIRCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell and Tube Heat Exchanger

Uploaded by

PRATIK P. BHOIRCopyright:

Available Formats

Company Name

Address

Project Name Project Number

REV DATE BY APVD

Sheet

REV

1

DATE

of

BY

1

APVD

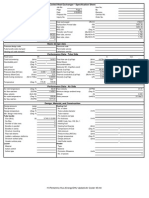

SHELL & TUBE HEAT EXCHANGER

Form XXXXX-YY-ZZ

Owner's Name Plant Location Case Description Equipment label Plant section Process service Design code Shells per unit Surface per unit DATA PER UNIT

Units Equipment name

English

Metric

TEMA ft2

Exchanger type Series Surface per shell

Parallel ft2

SHELL SIDE IN Stream No. Fluid Total fluid flow Total vapor flow Total liquid flow Total steam flow Fluid vaporized / condensed Density Dynamic viscosity Specific heat capacity Thermal conductivity Latent heat Normal temperature Max temperature Min temperature Pressure Pressure drop allowed Pressure drop calculated Flow velocity Number of passes Film transfer coefficient Fouling coefficient Heat duty FT factor Effective mean temperature difference Minimum surface required CONSTRUCTION & MATERIALS PER SHELL Tubes Material Count Length Design pressure at max temp Number of tubes blanked Shell Material Length Design pressure at max temp Baffle material Tubesheet material Bonnet material Branches Shell side inlet Tube side inlet NOTES 1. 2. 3. 4. 5. OUT IN

TUBE SIDE OUT

lb/h lb/h lb/h lb/h lb/h lb/cu ft lbm/ft.s Btu/lb.F Btu.ft/h.ft2.F Btu/lb F F F psia psi psi ft/s

Btu/h.ft2.F Btu/h.ft2.F Btu/h F ft2

ft psia

Pitch O.D. Test pressure

in in psia

Square Triangular Wall thickness Max external pressure

Welded in psia

ft psia

I.D. Test pressure Baffle type

in psia

Wall thickness Min internal pressure Baffle pitch Tubesheet thickness Bonnet type

in psia in in

in N.B. in N.B.

Shell side outlet Tube side outlet

in N.B. in N.B.

You might also like

- Furnace Heater Process Data SheetDocument1 pageFurnace Heater Process Data SheetmunatsiNo ratings yet

- Specification Sheet Shell and Tube ExchangerDocument1 pageSpecification Sheet Shell and Tube ExchangerDanang PrakosaNo ratings yet

- Steam Surface Condenser SpecificationsDocument2 pagesSteam Surface Condenser SpecificationsAndinata SitepuNo ratings yet

- Orifice Plate Data SheetDocument2 pagesOrifice Plate Data SheethasnacuNo ratings yet

- Static Mixer DataDocument6 pagesStatic Mixer DataArun GuptaNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatorDan Toader100% (1)

- 34510193Document4 pages34510193gutmontNo ratings yet

- Water Cooled Chiller Package Data SheetDocument9 pagesWater Cooled Chiller Package Data SheetMohan VarkeyNo ratings yet

- Data Sheet Fixed Bed ReactorDocument1 pageData Sheet Fixed Bed ReactorPolanqNo ratings yet

- English Unit Spec SheetDocument3 pagesEnglish Unit Spec SheetDanang PrakosaNo ratings yet

- Heat Exchanger Spec SheetDocument1 pageHeat Exchanger Spec SheetAnnabellee ChuaNo ratings yet

- Heat Exchanger Design OptimizationDocument26 pagesHeat Exchanger Design OptimizationEhsan MoemeniNo ratings yet

- Spek UAL MalaysiaDocument1 pageSpek UAL MalaysiaRiski SuhardinataNo ratings yet

- Air-Cooled Heat Exchanger: EngineeringDocument1 pageAir-Cooled Heat Exchanger: EngineeringaminNo ratings yet

- Thermex customer project specsDocument1 pageThermex customer project specshuangjlNo ratings yet

- Shell & Tube Heat ExchangersDocument16 pagesShell & Tube Heat ExchangersShawala AzharNo ratings yet

- Flow Device Operating ParametersDocument110 pagesFlow Device Operating Parameterspankajskec33% (3)

- Air Cooler 45 Case1 PDFDocument2 pagesAir Cooler 45 Case1 PDFHeny MarthaNo ratings yet

- Full Containment Refrigerated Liquefied Gas (RLG) TanksDocument2 pagesFull Containment Refrigerated Liquefied Gas (RLG) TanksaminNo ratings yet

- Adsorption Gas Treatment Plant - Design Information: Spec. NumberDocument5 pagesAdsorption Gas Treatment Plant - Design Information: Spec. NumberabhmarsNo ratings yet

- General Information: Air PreheaterDocument2 pagesGeneral Information: Air PreheateraminNo ratings yet

- Orifice Plate Specification DetailsDocument1 pageOrifice Plate Specification Detailsrufino.perea.1000No ratings yet

- Pressure Gauge Specification SheetDocument1 pagePressure Gauge Specification Sheetsairam2234No ratings yet

- Equipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetDocument1 pageEquipos para Procesos Intercambiadores de Calor 1: Heat Exchanger Specification SheetAlejandro EchevarriaNo ratings yet

- Waste Heat Recovery UnitDocument15 pagesWaste Heat Recovery UnitEDUARDONo ratings yet

- Air-Cooled Heat Exchanger Specification SheetDocument4 pagesAir-Cooled Heat Exchanger Specification SheetPanca KurniawanNo ratings yet

- PT VICO Indonesia heat exchanger designDocument4 pagesPT VICO Indonesia heat exchanger designSoraya ZahraNo ratings yet

- GEA Air Cooler Data-SheetDocument1 pageGEA Air Cooler Data-SheetMohamed RadwanNo ratings yet

- Film Temp Calculation For Thermic Fluid ApplicationDocument2 pagesFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuNo ratings yet

- SampleDocument1 pageSampleDara NorrisNo ratings yet

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658No ratings yet

- List of ContentslisfDocument6 pagesList of ContentslisfSenah DaunNo ratings yet

- Control ValveDocument1 pageControl ValveAjay TiwariNo ratings yet

- Protego Flame Arrestor, Breather Valve Data SheetDocument1 pageProtego Flame Arrestor, Breather Valve Data Sheetbhalchandrak1867100% (1)

- Thermoacoustic Refrigeration PresentationDocument20 pagesThermoacoustic Refrigeration PresentationNishad NoorudeenNo ratings yet

- Heat Exchanger Specification Sheet: in FT FT Performance of One UnitDocument10 pagesHeat Exchanger Specification Sheet: in FT FT Performance of One UnitAnonymous Wd2KONNo ratings yet

- DS Press GaugeDocument1 pageDS Press GaugeqdzungNo ratings yet

- Tema Style HX DatasheetDocument1 pageTema Style HX Datasheet404FileNotFoundNo ratings yet

- Standard Instrument Data Sheet Rotameters (Variable Area Flowmeters)Document1 pageStandard Instrument Data Sheet Rotameters (Variable Area Flowmeters)Faizal YaacobNo ratings yet

- Training On Equipment Sizng of Process EquipmentDocument15 pagesTraining On Equipment Sizng of Process EquipmentAgam Duma Kalista WibowoNo ratings yet

- Heat Exchanger Design OptimizationDocument38 pagesHeat Exchanger Design OptimizationJose AndradeNo ratings yet

- Basic Data SheetDocument15 pagesBasic Data Sheeterkamlakar2234No ratings yet

- Heat Exchanger Study GuideDocument3 pagesHeat Exchanger Study GuideLarryNguyenNo ratings yet

- Pressures: Boiler Data Summary UnitDocument12 pagesPressures: Boiler Data Summary UnitKNOW_WELLNo ratings yet

- Airfinfancooler1 Dummy DocxDocument2 pagesAirfinfancooler1 Dummy DocxUmar Faizal SNo ratings yet

- Technical Dairy: 1-Boiler and Auxillaries Main BoilerDocument59 pagesTechnical Dairy: 1-Boiler and Auxillaries Main Boilersuleman247No ratings yet

- Reaction Tank Design For WWTPDocument9 pagesReaction Tank Design For WWTPDavid LambertNo ratings yet

- DAT Exchanger PlateDocument2 pagesDAT Exchanger PlateEDUARDONo ratings yet

- Single Phase 20150209171147194Document2 pagesSingle Phase 20150209171147194zlajaviNo ratings yet

- Flare Stack Data SheetDocument4 pagesFlare Stack Data SheetAnonymous QSfDsVxjZ100% (1)

- Heat Exchanger Specification SheetDocument5 pagesHeat Exchanger Specification SheetNur Izzati KamrulnizamNo ratings yet

- Screw ConveyorDocument6 pagesScrew ConveyorJobsonReisNo ratings yet

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFDocument15 pagesRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngNo ratings yet

- General Fabrication and Performance Information Section 3: FIGURE G-5.2 Heat Exchanger Specification SheetDocument1 pageGeneral Fabrication and Performance Information Section 3: FIGURE G-5.2 Heat Exchanger Specification SheetMoises Rodriguez SanchezNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetMohamed AshrafNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Introduction To Finite Element ModelingDocument5 pagesIntroduction To Finite Element Modelingmastura_rahim_3No ratings yet

- Ex 1001Document1 pageEx 1001kannanjbrNo ratings yet

- Introduction To Finite Element ModelingDocument5 pagesIntroduction To Finite Element Modelingmastura_rahim_3No ratings yet

- ILMENITE AND RUTILE RESOURCESDocument14 pagesILMENITE AND RUTILE RESOURCESRakesh MishraNo ratings yet

- Sthe SecondDocument33 pagesSthe SecondkannanjbrNo ratings yet

- Emoticons at ChatropolisDocument35 pagesEmoticons at ChatropoliskannanjbrNo ratings yet

- Sy Hs 230Document2 pagesSy Hs 230Vishnu RajaranganNo ratings yet

- Engineering Thermodynamics Lecture Notes (A Very Rough Draft)Document34 pagesEngineering Thermodynamics Lecture Notes (A Very Rough Draft)kannanjbr100% (1)

- SG3526Document12 pagesSG3526pionalabzNo ratings yet

- Pulp and Paper Industry Water TreatmentDocument3 pagesPulp and Paper Industry Water TreatmentkannanjbrNo ratings yet

- Main SeminarDocument17 pagesMain SeminarkannanjbrNo ratings yet

- The Research of Inverter Welding Power Source Based On DSP For Self-Shielded Flux-Cored WireDocument6 pagesThe Research of Inverter Welding Power Source Based On DSP For Self-Shielded Flux-Cored WirekannanjbrNo ratings yet

- 41 - 1 - New Orleans - 03-96 - 0466Document6 pages41 - 1 - New Orleans - 03-96 - 0466kannanjbrNo ratings yet

- 41 - 1 - New Orleans - 03-96 - 0466Document6 pages41 - 1 - New Orleans - 03-96 - 0466kannanjbrNo ratings yet

- Waste PlantDocument7 pagesWaste Plantawhk2006No ratings yet

- Tuning GuideDocument12 pagesTuning GuidekannanjbrNo ratings yet

- 06 Thermal Rs PDFDocument39 pages06 Thermal Rs PDFsssuganthiNo ratings yet

- 06 Thermal Rs PDFDocument39 pages06 Thermal Rs PDFsssuganthiNo ratings yet

- Experimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionDocument10 pagesExperimental Investigation of Combustion, Performance and Emission Characteristics of Di Diesel Engine Under Hcci Mode With Porous Medium CombustionkannanjbrNo ratings yet

- M.tech. Energy Tech-06Document19 pagesM.tech. Energy Tech-06kannanjbrNo ratings yet

- Task38 CouplingDocument8 pagesTask38 CouplingkannanjbrNo ratings yet

- IES 2007 General Ability Test SummaryDocument27 pagesIES 2007 General Ability Test SummaryJuned Azlaan ShaikhNo ratings yet

- CommentsDocument1 pageCommentskannanjbrNo ratings yet