Professional Documents

Culture Documents

View Content

Uploaded by

3668770Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

View Content

Uploaded by

3668770Copyright:

Available Formats

2010 ECI Conference on The 13th International Conference on

Fluidization - New Paradigm in Fluidization Engineering

% FILE:

/main/production/doc/data/journals/services.bepress.com/uidization xiii/assets/location.incHotel

Hyundai, Gyeong-ju, Korea% FILE:

/main/production/doc/data/journals/services.bepress.com/eci/assets/proceedings/pdftitlepage.tex

(cont)

Editors: % FILE:

/main/production/doc/data/journals/services.bepress.com/uidization xiii/assets/editors.incSang

Done Kim,Korea Advanced Institute of Science and Technology, Korea

Yong Kang, Chungnam National University, Korea

Jea Keun Lee, Pukyong National University, Korea

Yong Chil Seo, Yonsei University, Korea % FILE:

/main/production/doc/data/journals/services.bepress.com/eci/assets/proceedings/denes.tmpl

(cont)

Year Paper

FLUIDIZATION TECHNOLOGY FOR

STABLE STARTUP OF COMMERCIAL

FCC UNIT

Sung Won Kim

Gyung Rok Kim, Jae Wook Shin

Ik Sang Yoo

Hun Sik Kang

Sang Hoon Park

FLUIDIZATION TECHNOLOGY FOR

STABLE STARTUP OF COMMERCIAL

FCC UNIT

Abstract

Conditions for maintaining good uidization in the start-up of FCC have

been determined. Catalyst deuidization and consequent catalyst losses from

reactor cyclone are mainly aected by catalyst properties and stripper oper-

ating condition based on previous commercial startup experiences. Eect of

ne catalyst contents on bed uidity was determined. Bed uidity in stripper

was analyzed with slip velocity. Finally new startup guide was proposed and

it was successfully applied to commercial FCC process of SK energy, Korea.

SK energy Institute of Technology

SK energy Institute of Technology

SK energy Ulsan Complex

SK energy Ulsan Complex

SK energy

http://services.bepress.com/eci/uidization xiii/103

Copyright c 2011 by the authors.

Fluidization Technology for Stable Startup of Commercial

FCC Unit

Sung Won Kim

1

*, Gyung Rok Kim

1

, Jae Wook Shin

1

, Ik Sang Yoo

2

,

Hun Sik Kang

2

and Sang Hoon Park

3

1

SK energy Institute of Technology 140-1 Wonchon-dong, Yuseong-gu, Daejeon 305-712,

Korea

2

SK energy Ulsan Complex, 110, Kosa-dong, Nam-gu, Ulsan, 680-130, Korea

3

SK energy, 99 Seorin-dong, Jongro-gu, Seoul 110-110, Korea

*T: 82-42-866-7314; F: 82-42-866-7804; E: kswcfb@skenergy.com

ABSTRACT

Conditions for maintaining good fluidization in the start-up of FCC have been

determined. Catalyst defluidization and consequent catalyst losses from reactor

cyclone are mainly affected by catalyst properties and stripper operating condition

based on previous commercial startup experiences. Effect of fine catalyst contents

on bed fluidity was determined. Bed fluidity in stripper was analyzed with slip

velocity. Finally new startup guide was proposed and it was successfully applied to

commercial FCC process of SK energy, Korea.

INTRODUCTION

Fluid catalytic cracking (FCC) is an industrial process that converts high molecular-

weight hydrocarbons to lower molecular-weight products of high value. A modern

FCC unit consists of three major parts: riser, stripper and regenerator. The FCC

utilizes a circulation system whereby heavy oil contacts hot circulating catalyst and

is lifted up a riser in which catalytic reaction occurs. The catalyst and reactor vapor

products exit the reactor vessel and are sent for further processing. The catalyst

passes through a steam stripping zone then enters a standpipe and is transported to

the regenerator which burns off the coke on the catalyst and thus reactivates the

catalyst. The heat from the combustion of the coke raised the catalyst temperature

and the catalyst is transported down the standpipe to meet again the fresh oil feed.

This completes the catalyst circulation loop.

FCC process has turn-around time every 2 or 3 years and following start-up time of

about 5 days. The FCC unit experiences different situations in the start-up by

variations of temperature, pressure and feed before reaching steady state compared

to normal condition. Fluidization is of prime importance in the FCC unit since all

phases of the process are performed in fluidized beds at all times as it circulates

through the reactor/regenerator system. Therefore, lack of fluidization in the start-up

1 Kim et al.: FLUIDIZATION TECHNOLOGY FOR STABLE STARTUP OF COMMERCIAL FCC UNIT

Produced by The Berkeley Electronic Press, 2011

with various conditions can lead to catalyst defluidization, or worse, shut-down of

unit.

Many Companies that own FCC unit have experienced troubles with catalyst

carryover from reactor cyclone to main column during the catalyst circulation step of

startup. Recently, studies about poor fluidization in deep fluidized beds of group A

particles have been reported with large cold model tests (1-3). However, studies

about commercial FCC reactors are relatively sparse in open literature.

In this study, troubles with catalyst carryover in startup of FCC unit are analyzed in

viewpoint of fluidization with previous experiences. From the analysis, conditions for

maintaining good fluidization in the start-up have been determined. A new startup

procedure with successful application to FCC unit of SK energy is proposed.

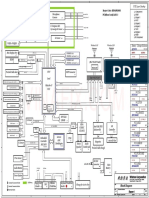

PLANT DESCRIPTION

The FCC (or RFCC) Unit was originally

designed by UOP in 1994 for a capacity

of 50,000 BPSD in Ulsan Complex of SK

energy, Korea. The unit has operated

with residue feed rates near 57,000

BPSD since first start-up in 1996. The

schematic diagram of the FCC is shown

in Fig. 1. The reactor riser is 60 m long.

The upper section is 35 m long with a

diameter of 1.6 m ID and, the lower

section is 25 m long with a diameter of

1.0 m ID. The riser utilizes a Suspended

Catalyst Separation System (SCSS): a

vented riser with two stages of cyclones

directly connected to the riser. These

direct connected cyclone systems are

widely used because of the yield benefits

by dipleg sealing of first cyclone for

minimizing the amount of hydrocarbon

which enters the stripper and is therefore

exposed to long residence time which

results in overcracking to coke and light

gases. The unit has six sets of two stage

cyclones inside the reactor.

The stripper has a diameter of 4.0 m ID

and a tangent length of 12 m. Steam is

introduced at bottom, middle and top

regions of the stripper through pipe grids.

It mostly rises up countercurrent to the

downwardly flowing stripper bed. The stripper has ring-donut type baffles in order to

achieve efficient use of steam.

The regenerator employs a two-stage regeneration system. The two-stage

regenerator consists of an upper regenerator (1st stage) and a lower regenerator

(2nd stage). The first stage regenerator has a diameter of 10.4 m ID and a tangent

length of 13.7 m. The second stage regenerator has a diameter of 5.5 m ID and a

tangent length of 10.5 m.

Air

Air

Feed

Flue Gas

To Fractionation

Regenerator

Riser

Stripper

Lift media

Fig. 1 Schematic diagram of FCC unit

2 The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering [2010], Vol. RP6, Article 103

http://services.bepress.com/eci/fluidization_xiii/103

Normal Startup Procedure

Normal startup of the FCC unit part in plant can be divided into the following steps:

1. Steam out the reactor and main column, and heat up the catalyst section.

2. Load catalyst to the regenerator and heat catalyst.

3. Circulate heated catalyst between the reactor and regenerator.

4. Start oil to the riser.

5. Establish normal operating conditions.

Trouble Experiences

SK energy experienced two troubles

with catalyst carry-over from reactor

cyclone during the catalyst circulation

step of startup attempts in 2005.

During the first startup attempt,

catalyst was probably carried over to

the Main Column due to issues with

the first stage reactor cyclones. The

reactor cyclones are not efficient at

inlet velocity between 4 and 11 m/s

and steps must be taken to minimize

the period that velocities are within this

critical range. It is conjectured that

catalyst carryover can occur because

the velocity is high enough to entrain

catalyst in the vapor (steam), but still

lower than required to collect efficiently particles.

Meanwhile, a temperature divergence (up to 43C) was observed within the Reactor

Stripper. An increasing temperature differential (AT) between stripper TIs 40057 and

40058 as shown in Fig. 2 is not usual and indicates fluidization problems in the

stripper. Temperatures in the stagnant region will lag behind the active side. It might

be possible that the catalyst level in the first stage cyclone increases if one side of

the stripper becomes stagnant and the first stage diplegs are sealed. If the cyclone

catalyst level gets too close to the cyclone outlet tube, catalyst will be entrained and

carried over to the second stage cyclones and to the main column. A rough estimate

of catalyst mass carried to the Main Column was 67ton. History of these phenomena

is shown in Fig. 3.

During the second attempted startup, Reactor cyclone velocity was more closely

controlled but, catalyst was carried over to the main column. Though the unit was

started up with the diplegs unsealed, radial AT in bottom region of stripper is drifted

apart. The second attempt at circulation and startup resulted in 3 apparent catalyst

loss events, one of which occurred when sealing the cyclone diplegs, one during

transition from low to high velocity, and a final apparent loss just prior to and

following introduction of feed to the riser. The possible cause of all three losses

during the second attempted startup can probably be attributed to a local

defluidization in the stripper and following catalysts accumulate in the cyclones.

Fig. 2 Location of two thermocouples in bottom

region of stripper

3 Kim et al.: FLUIDIZATION TECHNOLOGY FOR STABLE STARTUP OF COMMERCIAL FCC UNIT

Produced by The Berkeley Electronic Press, 2011

For a couple of weeks afterwards, it was attempted to seal the cyclone diplegs by

increasing the bed height of stripper. Finally, dipleg was sealed with minor catalyst

carryover and the unit worked under normal operation.

Fig. 3 History of catalysts carryover

RESULTS AND DISCUSSION

Root Cause Analysis

From root cause analysis, it is concluded that the main mechanism for carryover

was more related to fluidization problems in stripper because any area with no gas

flow or insufficient entrained gas can become defluidized and stagnant during the

steps in startup. When this occurs under a primary cyclone dipleg, it partially or fully

prevents flow of the catalyst separated in the cyclone from flowing to the stripper. In

this case, once the catalyst flow from the primary cyclone is restricted, the second

cyclone loading increases to the point where the second cyclone dipleg is

overloaded. Finally, any catalyst amount greater than this will be carried out of the

second cyclone to the main column.

However, it is noticed that the carryover occurred even though steam rate in stripper

was same with normal operation before catalyst circulation. Also, stripper exhibits

better fluidization characteristics at high catalyst flux rates in normal operation.

These mean that operating conditions within normal or design ranges did not

significantly affect fluidization in the stripper.

Approaches

There are two major factors on fluidization in stripper. First, the catalyst in the unit

must remain in a fluidized state at all times. Second, the flow of catalyst and gas

should have uniformity in entire stripper. From two view points, practical approaches

are proposed

4 The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering [2010], Vol. RP6, Article 103

http://services.bepress.com/eci/fluidization_xiii/103

1) Particle Size Distribution (PSD)

Catalyst properties have the greatest effect of fluidization characteristics, especially

the PSD. If the amount of fines contents (less than 45 m) gets low, FCC unit has

fluidization problems in a bubbling bed.

In this study, fluidity (U

mb

/U

mf

) which is one of fluidization index was measured to get

a base for good fluidization quality. Catalysts, namely equilibrium catalysts (E-cat),

were obtained from FCC unit in normal operation and fine content was controlled by

adding or removing the fine in E-cat. To get the fluidity, U

mb

and U

mf

were measured

in a cold model reactor (0.05 m id.) with air. Experimental results are summarized in

Table 1.

Table 1 Experimental results of U

mf

, U

mb

and fluidity

Effect of fines contents in FCC catalysts on fluidity is shown in Fig. 4. The fluidity

increases with increasing the fines content. The increment of 1 wt.% of fines

increases 0.057 of fluidity. It indicates that a certain loss of fines could make poor

fluidization in some region like near the wall of the stripper because Group A

materials with high fines contents retain air longer than Group A materials with low

fines (2). From previous experiences, it is noticed that most of the catalyst fines

were carried over to the main column during the prior catalyst loss incident like

passage of critical range of cyclone inlet gas velocity. Also, fines loss usually occurs

from the regenerator during the catalyst heatup period at relative low pressure even

though regenerator was filled up with equilibrium catalyst of high fines contents

before solid circulation.

Case I

E-cat

Case II

No fine

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

2.1

2.2

0 2 4 6 8 10

U

m

b

/

U

m

f

[

-

]

Fine content (less than 45 m ) [wt.%]

Fig. 4 Effect of fine content on catalyst fluidity

In this study, a guiding equation for fines makeup to E-cat bed has been proposed.

Even Abrahamsen and Geldart(5)s equation for prediction of fluidity has been

Particles d

p

[mm] F

45

[wt.%] U

mf

[m/s] U

mb

[m/s] U

mb

/U

mf

[m/s]

No fines 61.2 0.20 0.0040 0.0065 1.63

Fines case I 60.35 5.00 0.0035 0.0067 1.91

E-cat 60.1 6.58 0.0033 0.0066 2.00

Fines case II 59.9 7.98 0.0032 0.0068 2.13

5 Kim et al.: FLUIDIZATION TECHNOLOGY FOR STABLE STARTUP OF COMMERCIAL FCC UNIT

Produced by The Berkeley Electronic Press, 2011

widely used, it covers wide range of Geldart A particles, so that it is not enough for

exact prediction in urgent decision. Measured fluidities for FCC catalysts with

various fines contents have been correlated with gas and particle properties based

on Abrahamsen and Geldart study (5).

| |

| |

934 . 0 934 . 0 80 . 0

45

52 . 0 13 . 0

00 . 1 exp 2466

g P P

g g

mf

mb

g d

F

U

U

=

(1)

Eq. (1) can provide PSD management guide for fluidized bed quality in the unit by

informing desired PSD of fresh catalyst for make-up. Also, a unit startup guideline of

fines contents more than 6 wt. % is added in new procedure based on fines contents

in normal operation with good fluidity.

2) Catalyst and gas flow

Even though catalysts have good

fluidity, identification of

hydrodynamics in the stripper is

important because many FCC have

different design and its limitation in

catalyst and gas flow. Flow

problems encountered in

commercial FCC stripper have

been reported as bridging (1) or

gas bypassing (2). These have

been found in operating with deep

beds of Group A particles (3). They

are results of localized

defluidization of the catalyst in

areas where fluidizing gas does not

properly reach the catalyst.

Measurement of pressure

fluctuation can give information

about these problems at normal

operation. However, it is not easy

in startup steps because bed

quality changes as time passes. To

eliminate gas bypassing and

bridging, FCC reactor licensor

adopted baffle design inside of stripper. This eliminates stagnant areas of catalyst

near the walls of the stripper resulting in a more uniform catalyst flux at normal

condition, but did not work well in no or low catalyst flow range with showing radial

temperature divergence like Fig. 3.

Hydrodynamics in stripper with baffles can be affected by not only gas flow rate but

also catalyst flux. In this study, fluidizing velocity in stripper was analyzed with slip

velocity(U

sl

) like eq. (2).

( ) | | ) 1 c c c

= =

p

s

g

s

g

sl

G

U

U

U

U

(2)

Effect of catalyst circulation rate on fluidizing velocity is shown in Fig. 5(a). Before

catalyst circulation, steam rate is set at about 4.4 ton/min. The steam velocity in

Fig. 5 (a) Effect of catalyst circulation rate on

fluidizing velocity

(b) Effect of solid circulation rate on Usl/Ug

1.0

1.5

2.0

2.5

3.0

3.5

0 10 20 30 40 50

U

s

l

/

U

g

[

-

]

Cat. Circulation rate [T/min]

Stripper top region

Stripper bottom region

(b)

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0 10 20 30 40 50

V

e

l

o

c

i

t

y

[

m

/

s

]

Cat. Circulation rate [T/min]

Ug at Top

Ug at bottom

Usl at top

Usl at bottom

(a)

6 The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering [2010], Vol. RP6, Article 103

http://services.bepress.com/eci/fluidization_xiii/103

stripper increases 1.6 times at normal condition with increasing temperature by

circulation of hot catalyst. However slip velocity increases 3-5 times with reaching

normal catalyst circulation rate of 40 ton/min.

Effect of solid circulation rate on U

sl

/U

g

is shown in Fig. 5(b). U

sl

/U

g

is largely

increased with solid circulation rate, especially in bottom region with relative low

steam rate. It means that turbulence in bottom region of stripper is increased by

catalyst flow and stagnant region could be depleted by the turbulence. Also, high

catalyst flux is helpful for increase of gas velocity by increment of bed temperature.

Another reason for the effectiveness of high catalyst flux in eliminating stagnant

zone is that the downward solids flow pushes and separates the upward gas flow

with preferential flow direction. This makes the gas flow redistributed. Also, the

redistribution of gas flow exposes more catalyst surface area which allows the gas

to permeate the solids and makes it easier to aerate the solids and prevent

defluidization.

Startup with New procedure

New procedure for startup is based on a principle of keeping fluidization state all the

time as discussed above. In management of particle properties, PSD and fine

content are checked before shutdown for turn-around of unit because withdrawn

catalysts are used for startup. In startup time, the PSD and fine content are carefully

managed by eq. (1) which provides information of type (fine content) and makeup

rate of fresh catalyst for makeup.

Some procedures are modified to get high catalyst circulation rate especially at

cyclone dipleg sealing time. In previous procedure, regenerator temperature was

kept at about 700, which means low catalyst circulation rate because the rate in

FCC unit is controlled by temperature difference(AT) between regenerator and

stripper. Use of a lower regenerator catalyst bed temperature is preferred for high

circulation rate, as this requires more catalyst circulation flow to maintain the heat-

up rate, thus more catalyst enters the cyclones and discharging from the reactor

cyclone diplegs.

Based on previous operation data, it is found that about 30 ton/min of circulation rate

shows better fluidization state with uniform radial AT, especially around catalyst

discharge region from cyclone dipleg for stable stripper operation and the rate

corresponds to slip velocity of 94 U

mf

at the discharge region which is near terminal

velocity of catalyst. To get the circulation rate, a control plan of the AT between

regenerator and stripper is reflected in new procedure as shown in Fig. 6.

Time

Stripper

Regenerator

(Less than200)

(525)

(650~700)

(Above 250)

(525)

(350)

(550)

(700)

T

e

m

p

e

r

a

t

u

r

e

T

e

m

p

e

r

a

t

u

r

e

Time

(a) (b)

Start of Cat. Circulation

Dipleg sealing of cyclone

Fig. 6 Comparison of previous and new startup procedures

7 Kim et al.: FLUIDIZATION TECHNOLOGY FOR STABLE STARTUP OF COMMERCIAL FCC UNIT

Produced by The Berkeley Electronic Press, 2011

Finally, the new procedure was successfully applied to startup in 2008. It is proved

to work well as keeping fluidity in stripper with showing uniform radial AT in stripper

bottom (less than 2) and minimization of catalyst loss from unavoidable change

with quick passage through critical region of reactor cyclone inlet velocity.

CONCLUSION

Conditions for maintaining good fluidization in the start-up of FCC have been

determined. To prevent catalysts defluidization in stripper as main cause, catalyst

properties and hydrodynamics for good fluidization state are identified based on

normal condition. Effect of fine catalyst contents on bed fluidity was determined and,

bed fluidity in stripper was analyzed with slip velocity. Finally new startup guide to

keep good fluidity in start-up was proposed and the guide was successfully applied

to startup of commercial FCC unit in 2008.

NOTATION

U

mf

: Minimum Fluidization Velocity (m/s)

U

mb

: Minimum Bubbling Velocity (m/s)

F

45

: Fraction of Catalyst Below 45 m

d

p

: Mean Average Particle Diameter (m)

g : Gravity Acceleration (m/s

2

)

p

: Particle Density (Kg/ m

3

)

g

: Gas Density (Kg/m

3

)

g

: Gas Viscosity (Kg/m Sec)

REFERENCES

(1) Senior, R.C., Smalley, C.G., Gbordzoe, E., Hardware Modifications to

Overcome Common Operating Problems in FCC Catalyst Strippers, Fluidization IX,

L.S. Fan, T.M. Knowlton Eds., Engineering Foundation, New York (1998), 725-732.

(2) Knowlton, T.M., Karri, S.B.R. and Issangya, A., Scale-up of Fluidized-bed

Hydrodynamics, Powder Technol., 150 (2005), 72-77

(3) Issangya, A.S., Knowlton, T.M. and Reddy Karri, S.B., Detection of Gas

Bypassing Due to Jet Streaming in Deep Fluidized Beds of Group A Particles,

Fluidization XII, X. Bi, F. Berruti and T. Pugsley Eds., Engineering Conferences

International, New York (2007), 775-782.

(4) Bruni, G.., Lettieri, P., Newton, D. and Barletta, D., An Investigation of the Effect

of the Interparticle Forces on the Fluidization Behavior of Fine Powders linked with

rheological studies, Chem. Eng. Sci., 62 (2007), 387-396.

(5) Abrahamsen, A.R. and Geldart, D., Behaviour of Gas-Fluidized Beds of Fine

Powders PartI. Homogeneous Expansion, Powder Technol., 26 (1980), 35-46.

(6) King, D., Fluidized Catalytic Crackers. An Engineering Review, Fluidization VII,

O.E. Potter and D.J. Nicklin Eds., Engineering Foundation, New York (1992), 15-26.

8 The 13th International Conference on Fluidization - New Paradigm in Fluidization Engineering [2010], Vol. RP6, Article 103

http://services.bepress.com/eci/fluidization_xiii/103

You might also like

- Improve FCCU Operations Using ChemicalDocument7 pagesImprove FCCU Operations Using Chemical3668770No ratings yet

- Hydrogen and Utility Supply Optimization - 2Document21 pagesHydrogen and Utility Supply Optimization - 23668770No ratings yet

- Increasing FCC Output by Oxygen Enrichment - 2 PDFDocument7 pagesIncreasing FCC Output by Oxygen Enrichment - 2 PDF3668770No ratings yet

- Distillation Column Pressure ControlDocument11 pagesDistillation Column Pressure Control3668770100% (1)

- Hydroprocessing - Corrosion - Wash - Water PDFDocument9 pagesHydroprocessing - Corrosion - Wash - Water PDF3668770No ratings yet

- Catalyst Circulation in Pressure BalanceDocument2 pagesCatalyst Circulation in Pressure Balance3668770No ratings yet

- Hydrogen ManegmentDocument8 pagesHydrogen Manegment3668770No ratings yet

- 7 CompressorsDocument49 pages7 Compressorsparvin.f100% (1)

- Calculating heat and material balances for a municipal incineratorDocument9 pagesCalculating heat and material balances for a municipal incinerator3668770No ratings yet

- Types and Functions - Design Considerations - Sizing Criteria - Calculation Method - Specification Data SheetDocument21 pagesTypes and Functions - Design Considerations - Sizing Criteria - Calculation Method - Specification Data Sheet3668770No ratings yet

- PumpsDocument36 pagesPumps3668770No ratings yet

- FCC Unit Optimization Using The Magna Cat ProcessDocument17 pagesFCC Unit Optimization Using The Magna Cat Process3668770No ratings yet

- HP BITUMEN HANDBOOKDocument53 pagesHP BITUMEN HANDBOOKAnuj Mathur100% (1)

- NPRA 2000 Cat Cracker TranscriptDocument70 pagesNPRA 2000 Cat Cracker Transcript3668770100% (3)

- NPRA 2000 Cat Cracker TranscriptDocument70 pagesNPRA 2000 Cat Cracker Transcript3668770100% (3)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fu Look Closer To CVPR 2017 PaperDocument9 pagesFu Look Closer To CVPR 2017 PaperMahmoudNo ratings yet

- Commercial Cold Test ProColdDocument8 pagesCommercial Cold Test ProColdpolNo ratings yet

- Canon 70 200 F4 Is Repair en PDFDocument10 pagesCanon 70 200 F4 Is Repair en PDFfastbuuuuNo ratings yet

- New Text DocumentDocument3 pagesNew Text Documentlokendra singhNo ratings yet

- Solution To Unattended Upgrades Shutdown Prompt of Deepin 20 ShutdownDocument4 pagesSolution To Unattended Upgrades Shutdown Prompt of Deepin 20 ShutdownGudang Berita & HiburanNo ratings yet

- Basic RoutingDocument18 pagesBasic RoutingAnno MelloNo ratings yet

- NASA: 70842main FS-1998-09-34-LaRCDocument2 pagesNASA: 70842main FS-1998-09-34-LaRCNASAdocumentsNo ratings yet

- ThinkPad Carbon X1 LRV-1 14282-2M 14282-3Document100 pagesThinkPad Carbon X1 LRV-1 14282-2M 14282-3zomikula100% (3)

- Softcam Llaves PowervuDocument28 pagesSoftcam Llaves Powervualfredonogueraocando100% (1)

- 1.identity With Windows Server 2016Document86 pages1.identity With Windows Server 2016selvaraj krishnaNo ratings yet

- Rock Drill & SluDocument36 pagesRock Drill & SluElizabeth Octagon100% (2)

- Research Methodology - Unit - 3 - NotesDocument10 pagesResearch Methodology - Unit - 3 - Notessatya prakashNo ratings yet

- ZF NMV221 1315 - 751 - 102 - A Technical ManualDocument6 pagesZF NMV221 1315 - 751 - 102 - A Technical ManualYoseph GetahunNo ratings yet

- RSA Death Claim FormDocument4 pagesRSA Death Claim FormMartha MtikaNo ratings yet

- How Technology Has Changed VolunteeringDocument9 pagesHow Technology Has Changed VolunteeringSusana Maria Cunha TeixeiraNo ratings yet

- Machine Learning Lab ManualDocument30 pagesMachine Learning Lab ManualPriyanka VermaNo ratings yet

- Electronic Cash Register Programming-ManualDocument27 pagesElectronic Cash Register Programming-ManualRendy Adam FarhanNo ratings yet

- General and Particular Differential Equations Solutions - Videos, Examples PDFDocument1 pageGeneral and Particular Differential Equations Solutions - Videos, Examples PDFTakudzwa ZengeraniNo ratings yet

- Free PMP Practice QuestionsDocument1 pageFree PMP Practice QuestionsTman LetswaloNo ratings yet

- Preparing and Interpreting Technical DrawingDocument20 pagesPreparing and Interpreting Technical DrawingAriel Santor EstradaNo ratings yet

- MEC85 - Matlab S2023Document3 pagesMEC85 - Matlab S2023Aidan McNabbNo ratings yet

- Sheet 4Document5 pagesSheet 4vector mosesNo ratings yet

- Coins Pro APIDocument74 pagesCoins Pro APIwarren madayagNo ratings yet

- Automated Traffic Control System ProjectDocument15 pagesAutomated Traffic Control System ProjectisukuruNo ratings yet

- Quiz 1Document2 pagesQuiz 1محمد الشافعيNo ratings yet

- Daniefer M - Best BuyDocument6 pagesDaniefer M - Best BuyArchana mittalNo ratings yet

- Bug Life CycleDocument3 pagesBug Life CycleLakshmiNo ratings yet

- Climate Solutions HandbookDocument44 pagesClimate Solutions HandbookMARIVEL BASANo ratings yet

- Data Analysis and Time Series for Environmental ApplicationsDocument60 pagesData Analysis and Time Series for Environmental Applicationskk chanNo ratings yet

- ABM Module C - Unit 25 HRM & ITDocument6 pagesABM Module C - Unit 25 HRM & ITprjiviNo ratings yet