Professional Documents

Culture Documents

Tall Building Design and Construction Factors

Uploaded by

Mohd AlifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tall Building Design and Construction Factors

Uploaded by

Mohd AlifCopyright:

Available Formats

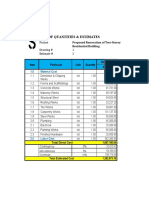

BLD 510 Construction Technology III

BSc (Hons) Construction Management

BLD 510

Construction Technology III

TALL BUILDINGS

Prepared and Presented By:

MUHAMMAD KAMAL AHMAD

Building Department Faculty of Architecture, Planning and Surveying University of Technology MARA

CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0 INTRODUCTION EVOLUTION OF TALL BUILDING WORLD TALLEST BUILDING PLANNING CONSIDERATION DESIGN FACTORS LOAD ACTION ON TALL BUILDING TALL BUILDING STRUCTURAL SYSTEM VERTICAL LOADING SYSTEMS HORIZONTAL LOADING SYSTEMS FLOOR SYSTEM FOR TALL BUILDING WALLS SYSTEM FOR TALL BUILDING FOUNDATION SYSTEM FOR TALL BUILDING CONSTRUCTION ASPECT OF TALL BUILDING SAFETY SYSTEM FOR TALL BUILDING

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

1.0 INTRODUCTION

The term tall buildings is not defined in specific term related to height or the number of storeys. A building is considered tall when its structural analysis and design are in some way affected by the lateral loads, particularly sway caused by such loads. According to Emporis Standards Committee (ESC) Tall Building is defined as a building 35 meters or greater in height, which is divided at regular intervals into occupiable levels. To be considered a high-rise building a structure must be based on solid ground, and fabricated along its full height through deliberate processes (as opposed to naturally-occurring formations). According to the regulations of Danish, German and some other European countries, the 72ft. (21.6m = 8 stories buildings), having fire-fighting equipment, are known as tall buildings. Definitions represented by the U.S. Council on tall buildings and urban settlement refers to tall buildings as these in which the height, influences the planning, construction and spaces application aspects of the building considerably without specifying the number of stories.

1.1 REASON FOR USING TALL BUILDING

SPACE LIMITATION

the process migration urban

PRESTIGE

free imposing advertisements for their owners and even the city it is sited. as a show of economic power political or

increase in the population density of cities increasing land prices make it necessary to maximise space utilisation by building upwards.

dominate the landscape and easily become landmarks human ego and competition

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

2.0 EVOLUTION OF TALL BUILDING

3 2 1

Reinforced concrete established. Architectural emphasis on reasons, functional and technological facts. Transition of structural systems from rigid frame to more efficient structural systems

Steel structures and sophisticated services such as mechanical lifts and ventilation, limitations on the height of buildings were removed.

Masonry wall bearing structures with thick and messy walls. The horizontal and lateral loads of these structures were mainly Resisted solely by the load bearing masonry walls.

The First Evolution of Tall Buildings

Reliance Building Chicago, 1894

Guaranty Building, Buffalo, 1895.

Carson Pirie Scott Department Store, Chicago, 1904

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

The Second Evolution of Tall Buildings

Woolworth Building, New York, 1930

Chrysler Building, New York, 1930

Empire State Building, New York, 1931 (highest structure in 19th century)

The Third Evolution of Tall Buildings

World Trade Centre, New York, 1972

Sears Tower, Chicago, 1974

Petronas Twin Tower, Kuala Lumpur, 1996.

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

3.0 WORLD TALLEST BUILDINGS

***

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

List of World Tallest Buildings

Refer to Appendix 1. Refer to Appendix 2

4.0 PLANNING CONSIDERATIONS

The selection of a tall building structure is not based merely on understanding the structure in its own context. The selection may be more function of factors related to cultural, social, economical and technological needs. Some of the factors: a. General Economic Considerations b. Soil Condition c. Height to width Ratio of a Building d. Fabrication and Erection Consideration e. Mechanical Systems Considerations f. Fire Rating Considerations g. Local Considerations h. Availability and Cost of Main Construction Materials

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. General Economic Considerations

How much the projects costs to build. How much the finished project costs to operate (e.g. expenses associated with utilities, maintenance, insurance, taxes, interest on borrowed money) As the height of the building increases, more and more space is needed for structure, mechanical systems and elevators, leaving less rental space. The costs of elevators and mechanical systems increase with height. Cost for sophisticated construction equipment as building get taller.

b. Soil Condition

The performance of a building is dependent on the strength of the soil which it is founded. The foundation or substructure binds the superstructure to the soil. If the bearing capacity of the soil is rather low, piles or caissons may be required to reach the proper foundation support.

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

toc. Height to- Width Ratio of Building

As the minimum height-towidth ratio increases, so should the buildings inherent stiffness The stiffness of the building structure is dependent on size and number of bays, structural systems and rigidity of members and connections. The general height-to-width for a plane frame structure in the range of 5 to 7.

d. Fabrication and Erection Considerations

The planning of fabrication and erection procedures may indicate important factors concerning structural systems selection. Should be a minimum number of structural pieces to shorten construction time, complicated closed form shapes should be avoided and field welding should be minimized.

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

e. Mechanical Systems Considerations

Average more than one-third of total tall building costs. Effects on the building overall appearance and economic selection of a structural systems.

f. Fire Rating Considerations

Almost all floors are beyond the reach of fire truck ladders, fire fighting and rescue action are from the inside of a building. Total emergency evacuation is impossible within a reasonably short period of time. Must be able to ensure the following: * structural integrity for a certain period of time. * confinement of the fire, to prevent it from spreading to certain building areas. * adequate exit systems. * effective smoke and fire detection systems. * sprinklers and necessary smoke and heat venting.

Mals MKays

Building Department, UiTM

BLD 510 Construction Technology III

BSc (Hons) Construction Management

g. Local Considerations

For example, height limitation, zoning regulations.

h. Availability and Cost of Main Construction Materials

If a desired material is hard to acquire, it may delay the building schedule and add significantly to building costs.

Mals MKays

Building Department, UiTM

10

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mobility

Evacuatian

Materials

DESIGN AND CONSTRUCTION CONSIDERATION

Earthquakes Heat

Wind

Speed

5.0 DESIGN

the structural elements of the building must responds to all this forces where members must be arranged and connected to one another in such manner as to absorb the forces and guide them safely with a minimum effort to the ground. building must cope with vertical forces of gravity and horizontal forces of wind above grund and the seismic forces below ground

building envelope has to accommodate the differences in temperature, air pressure and humidity between exterior and interior environments

requires a team approach between the various disciplines of design, material fabrication and building construction

TOTAL DESIGN APPROACH

Mals MKays

Building Department, UiTM

11

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Design Parameters

Design Process and Tools

Mals MKays

Building Department, UiTM

12

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Design Elements of Tall Building Form

6.0 LOAD ACTION ON TALL BUILDINGS

Dead Loads Live Loads Wind Loads Seismic Loading Construction Loads

Loads Due to Restrained Volume Changes of Materials Rain, Snow & Ice Loads Water and Earth Pressure Loads Impact and Dynamic Loads Blast Loads Combination of Loads

Mals MKays

Building Department, UiTM

13

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. Dead Load

Static forces caused by the weight of every element within the structure. The forces resulting in dead load consists of the weights of the load bearing elements of the building, floor and ceiling finishes, permanent partition walls, faade cladding, storage tanks, mechanical distribution systems etc.

b. Live Load

Occupancy Loads : Loads caused by the contents of objects within or on a building. Not part of the structure Include weights of people, furniture, movable partitions, mechanical equipments (e.g computers, business machines) etc. Variable and unpredictable. Change in live loads not only over time but also as a function of location.

Mals MKays

Building Department, UiTM

14

BLD 510 Construction Technology III

BSc (Hons) Construction Management

c. Wind Loads

Lateral action caused by winds. Wind velocity in general increases with height. The taller the building is, the more exposed the building to strong winds. Can cause the parts of the external wall or roof to be blown off. If the building is slender, it will sway or vibrate in the wind. Major problem for the designer of tall buildings.

d. Seismic Loading

The earths crust is not static; its subject to constant motion. Seismic motion acts on the building by shaking the foundation back and forth. The mass of the building resists this motion, setting up inertia forces throughout the structure

Mals MKays

Building Department, UiTM

15

BLD 510 Construction Technology III

BSc (Hons) Construction Management

e. Construction Loads

Loads during construction of a building example contractors commonly stockpile heavy equipment and materials on a small area of the structure. Causes concentrated loads that are much larger than the assumed live loads which the structure was designed.

7.0 TALL BUILDING STRUCTURAL SYSTEMS

Linear Elements

- Column and Beam - Capable of resisting axial and rotational beam

Surface Elements

- Wall : either solid with peforation or trussed, capable of carrying axial and rotational forces

- Floor : solid or ribbed, supported on floor framing, capable of supporting forces in and perpendicular to the plane

Spatia Elements

- Faade envelope or core for example, tying the building together to act as a unit

Mals MKays

Building Department, UiTM

16

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- types of structural systems

Parallel Bearing Walls Cores and Faade Bearing Walls Self Supporting Boxes Cantilevered Slab Flat Slab Interspatial Suspension Staggered Truss Rigid Frame Rigid Frame and Core Trussed Frame Belt-Trussed and Core Tube in Tube Bundled Tube

a. Parallel Bearing Walls

Comprised of plannar vertical elements that are prestressed by their own weight, thus efficiently absorb lateral force action. Used mostly for apartment building ahere large free spaces are not needed and mechanical systems do not necessitate core structures.

Mals MKays

Building Department, UiTM

17

BLD 510 Construction Technology III

BSc (Hons) Construction Management

b. Cores and Facades Bearing Walls

Planar vertical elements form exterior walls around a core structure. This allows for open interior spaces, which depend on the spanning capacities of the floor structure. The core houses mechanical and vertical transportation systems and adds to the stiffenes of the building

c. Rigid Frame

Rigid joints are used between an assemblage of linear elements to form vertical and horizontal planes. The vertical planes consists of columns and girders mostly on a rectangular grid A similar organizational grid is used is used for the horizontal planes consisting of beams and girders. With the integrity of the spatial skeleton depending on the strength and rigidity of the individual columns and beams, story height and column spacing become controlling design considerations

Mals MKays

Building Department, UiTM

18

BLD 510 Construction Technology III

BSc (Hons) Construction Management

d. Rigid Frame and Core

As rigid frame but introducing a core structure to increase the lateral resistance of the building as a result of the core and frame interaction. The core systems house the mechanical and vertical transportation systems.

e. Self Supporting Boxes

Boxes are prefabricated three dimensional units that resemble the bearing wall when they are place and joined together. The boxes are stacked like bricks in the English pattern bond resulting in a criss crossed wall beam system.

Mals MKays

Building Department, UiTM

19

BLD 510 Construction Technology III

BSc (Hons) Construction Management

f. Cantilevered Slab

Supporting the floor systems from a central core allown for a column-free space with the strength of the slab as the limit of the building size. Large quantities of steel are required especially with large slab projections. Slab stiffenes can be increased by tacking advantage of prestressing techniques.

g. Flat Slab

Generally consists of uniformly thick concrete floor slabs supported on columns No deep beams allowing for a mimimum story height

Mals MKays

Building Department, UiTM

20

BLD 510 Construction Technology III

BSc (Hons) Construction Management

h. Interspatial

Cantilevered story high framed structures are employed on every other floor to create usable space within and above the frame. The space within the framed floor is used for fixed operations, and the totally free space above the frame can adapt to any type of activity.

i. Suspension

Employing hangers instead of columns to carry the floor loads. The cables carry the gravity loads to trusses cantilevering from a central core.

Mals MKays

Building Department, UiTM

21

BLD 510 Construction Technology III

BSc (Hons) Construction Management

j. Staggered Truss

Story-high trusses are arranged so that each building floor rests alternatively on the top chord of one truss and the bottom of the next. Besides carrying the vertical loads, this truss arrangement minimizes wind bracing requirements by transferring wind loads to the base through web members and floor slab.

k. Trussed Frame

Combining a rigid (or hinged) frame with vertical shear trusses provides an increase in strength and stiffenes of the structure. The design of the structure may be based on using the frame for the resistance of gravity loads and the vertical truss for wind loads similar to the riogid frame and core case.

Mals MKays

Building Department, UiTM

22

BLD 510 Construction Technology III

BSc (Hons) Construction Management

l. Belt Trussed Frame and Core

Belt trusses tie the faade columns to the core, thus eliminating the individual action of frame and core. The bracing is called cap trussing when it is on the top of the building and belt trussing when around lower sections.

m. Tube in Tube

The exterior columns and beams are spaced so closely that the faade has the appearance of a wall with perforated window openings. The entire building acts as a hollow tube cantilevering out of the ground. The interior core (tube) increases the stiffenes of the building by sharing the loads with the facade tube.

Mals MKays

Building Department, UiTM

23

BLD 510 Construction Technology III

BSc (Hons) Construction Management

n. Bundled Tube

An assemblage of individual tubes resulting in a multiple-cell tube. The increase in stiffnes is apparent and allows for the greates height and the most floor area.

STRUCTURAL SYSTEMS FOR TALL BUILDINGS OF DIFFERENT HEIGHTS

Mals MKays

Building Department, UiTM

24

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

25

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Efficiency of structural systems of tall buildings

Building Cases

Empire State Building, New York John Hancock Centre, Chicago World Trade Centre, New York Sears Tower, Chicago Chase Manhattan, New York US Steel Building, Pittsburgh IDS Centre, Minneapolis Boston Co. Building, Boston Alcoa Building, San Francisco

Year

1931 1968 1972 1974 1963 1971 1971 1970 1969

Stories

102 100 110 109 60 64 57 41 26

Slender

9.3 7.9 6.9 6.4 7.3 6.3 6.1 4.1 4.0

kN/m2

2.02 1.42 1.77 1.58 2.64 1.44 0.86 1.01 1.24

Structural

Braced rigid frame Trussed tube Frame tube Bundled tube Braced rigid frame Shearwalls+outrigger+belt trusses Shearwalls+outrigger+belt trusses K-braced tube Latticed tube

John Hancock Centre Empire State Building

U.S Steel Tower

Alcoa Building, San Francisco

Boston Co. Building, Boston

8.0 VERTICAL LOADING SYSTEMS OF TALL BUILDINGS

The main function of the vertical loading systems is to transfer the dead and live loads of the superstructure to the substructure. Systems of transferring the loads: - Structural Wall System - Skeleton frame System - Suspension System - Composite Wall Frame System - Cantilevered Floor System - Transfers System

Mals MKays

Building Department, UiTM

26

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. Structural Wall System

Loads are transmitted to the ground via floor and wall (designed as load bearing wall). Masonry and brick load bearing were common during the late 19th and late 20th century. Now load bearing walls are made from reinforced concrete ;high performance concrete (HPC) . Usually of precast concrete panels systems and cast in situ concrete buildings using tunnel forms. Usually residential type because the internal wall layout do not need to be changeable such as in office building.

b. Skeleton Frame System

Loads are transferred to the beam and column grid to the ground. Using RC or Steel frame. Faster to erect especially when structural steel is used

Mals MKays

Building Department, UiTM

27

BLD 510 Construction Technology III

BSc (Hons) Construction Management

c. Suspension System

The floors of the building are suspended over a long span. Ability to provide a column free floor. Three types: i. Hanger system ii. Bridge System iii. Catenary System

i. Hanger System

Loads are transmitted upwards through vertical tensile members to outrigger arms. The loads are then transferred from the outriggers to one or more piers that transmit the loads to the ground. The tensile members can be hangers or cables and the pier tower are either monolithic reinforced concrete load bearing walls or steel framed tower. e.g Sabah Foundation Building ; Hong Kong & Shanghai Bank Building, Hongkong.

Central Pier Tower Tension Ring

Hanger Elements

Curtain Wall Facade

Sabah Foundation Building Structural System

Mals MKays

Building Department, UiTM

28

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Hongkong & Shanghai Bank Building, Hong Kong

ii. Bridge System

The floor slabs are suspended between two or more towers or mega columns. No intermediate columns used to support the floor slabs. e.g ; Tabung Haji Building, Petronas Twin Towers, OCBC Singapore.

Corner core RC tower ; contains either stairs or risers and toilets

Central core RC tower; contains lifts shafts

Floor slab structural girder and beams

Tabung Haji Building

OCBC Singapore

Knights of Columbus Building

Mals MKays

Building Department, UiTM

29

BLD 510 Construction Technology III

BSc (Hons) Construction Management

iii. Cantenary System

Example: Federal Reserve bank of Minneapolis Consisted of a pair of catenary members that span between two towers. Both catenary members lie on the long facades of the building

Mals MKays

Building Department, UiTM

30

BLD 510 Construction Technology III

BSc (Hons) Construction Management

d. Composite Wall-Frame System

The skeleton frame and structural load bearing walls are used together. Several arrangements: i. - the wall are arranged to form a core. - the frame surrounds the core walls. - tubes configuration. ii.- the walls are located at opposite ends of square shaped plan; generally Cshaped. - the frame is located between the end walls. iii.- the walls are located at the corners of square shaped or rectangular shaped plan. - the corner walls are L-shaped. - the frame is located within the plan and four corner walls.

Mals MKays

Building Department, UiTM

31

BLD 510 Construction Technology III

BSc (Hons) Construction Management

e. Cantilevered Floor System

Floor slabs rest on beams cantilevering from a central tower. The loads of the building is transferred to the foundation through the central tower. E.g: Nagakin Capsule Tower, Marina Building, Miami & Turnig Torso Malmo

Mals MKays

Building Department, UiTM

32

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

33

BLD 510 Construction Technology III

BSc (Hons) Construction Management

f. Transfer System

For building where lower floors have lesser columns than the rest of the building. The transfer is in the form of a horizontal elements. Consists of mega column and mega beams at lower floor Skeleton frame is positioned above the transfer mega structures. The loads are transferred from the transfer mega beams to the mega columns and then to the foundation.

8.1 Minimizing Vertical Loads

Foundations costs may be lower if the total vertical loads can be reduced Some of the ways are: reducing the floor plan area as the building increases using lighter materials in the upper floors using steel instead of R.C for the structural system reducing the cross-section area of the structural members in the upper floors placing the heavier M&E plant in an adjunct building e.g using district cooling system.

Mals MKays

Building Department, UiTM

34

BLD 510 Construction Technology III

BSc (Hons) Construction Management

9.0 HORIZONTAL LOADING SYSTEM

Horizontal (lateral) forces act on the superstructure and substructure of buildings. Two types of horizontal forces: i. Wind Forces ii. Earthquake Forces

WIND FORCES

Wind is variable both in direction and strength. Wind exerts loads on the tall structure causing it to oscillate or sway like a pendulum. Oscillations must be kept to a minimum: to ensure occupants psychological and physical comfort. to prevent deterioration of joints in the curtain walling and building services.

EARTHQUAKES

Earthquakes create lateral forces on a tall building causing it to sway. Cause the ground to move horizontally and vertically Earthquake-resistant building has to absorb or counteract the forces.

Mals MKays

Building Department, UiTM

35

BLD 510 Construction Technology III

BSc (Hons) Construction Management

9.1 Preventing Oscillation of Tall Building

Three main ways: 1. Structural methods by either stiffening or having heavier mass. - Shear Walls - Moment Resistant Frame Systems : eg tube systems - Bracing - Diagrid systems Counteracting the oscillation by either damping devices or top-to-bottom structural tie members. - Guying methods - Damping Devices : Passive dampers or Active dampers Aerodynamic methods.

2.

3.

a. Structural Methods

i. Shear Walls Structural elements to induce stiffenes in the building. Monolithic walls of reinforced concrete, brick or masonry can be used to provide stiffenes ; walls with a moment resistant frame. Location of the shear walls are: - Central core of building - Ends or corners of building - At certain wall position inside the building

Mals MKays

Building Department, UiTM

36

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. Structural Methods

ii. Moment Resistant Frame Systems (also known as Skeleton Frame) Three dimensional grid of linear column and beams connected each other using rigid or semi rigid connections. Usually used tubes systems load bearing columns of the exterior perimeter are placed together to form a tube. - single tube ; tube within tube; bundling of tubes; braced tubes e.g : Xerox Building USA, Sears Towers USA

Mals MKays

Building Department, UiTM

37

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

38

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. Structural Methods

iii. Bracing Adding braces to the frame. The bracing can be in different locations in the structure. The bracing configurations includes: - some vertical and/or horizontal bays of the frame are braced. - solid beam bracing- used to brace shear walls together. - vertical truss consists of mega column, mega beam and mega brace single plane truss arrangement that is located along the height of the moment resistant frame. - a mega space truss that housed floor slabs, minor columns and beams. E.g: Bank of China, Hong Kong, John Hancock Building, USA, Hong Kong Shanghai bank, Hong Kong

Mals MKays

Building Department, UiTM

39

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

40

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

41

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. Structural Methods

iv. Diagrid Systems Consists of a grid of diagonal members that cross each other. The distrubution of the load is similar to that experienced in a single layer grid dome. The diagrid is tied to the core by the floor elements along the height of the building. At the top of the building the diagrid terminates to either a ring beam or the core itself. Hearst Tower ; Swiss Re Building, London; Hubbell Lighting Headquarters Greenville, S.C

Mals MKays

Building Department, UiTM

42

BLD 510 Construction Technology III

BSc (Hons) Construction Management

b. Counteracting The Oscillation

i. Guying Method Top-to-bottom structural tie members are installed to the main vertical structure to prevent swaying of the structure. The structural tie members are either steel cables that are stretched or monolithic R.C Fins that are extended between the ground and the top of the tall buildings. Usually used for towers.

b. Counteracting The Oscillation

ii. Damping Services

The devices are used in the structure of lighter tall buildings (normally of steel frame construction) and tall pencil thin towers and spires of super tall buildings. Several types of dampers * Passive Dampers : is tuned to react to the movement of the building - viscoelastic dampers - passive tuned mass dampers - pendulum tuned mass dampers - liquid tuned mass dampers - viscous liquid dampers * Active Dampers : require sensors to detect the movement and initiate the mechanical hydraulic piston actuators that push against the damper mass and structure.

Mals MKays

Building Department, UiTM

43

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Passive Dampers

i. Viscoelastic Dampers Viscoelastic material is placed at various points in the structure ; often a rubber or neoprene pad sandwiched between the faces of two steel members. The pad provide shear resistance to the oscillations forces. Eg. Former World Trade Centre New York.

Passive Dampers

ii. Passive Tuned Mass Dampers These are sliding or horizontal moving mass of steel or concrete tuned to move in reaction to the horizontal movement of the building. The slab lies on a bed of oil and held in position by heavy springs (or hydraulic pistons) attached to the structural frame of the building. The movement of the building causes the mass to compress some spring and extend the others. The extended springs pulls on the building frame while the compressed springs pushes on the time. This counteracts the movement of the building Usually located at top of building where the swing of the oscillation is most.

Mals MKays

Building Department, UiTM

44

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Passive Dampers

iii.Pendulum Tuned Mass Dampers A suspended mass acting as pendulum is used. The pendulum mass is held by pistons. Act similar to the passive tuned mass damper. Need high head room E.g : Taipei 101 building.

Passive Dampers

iv.Liquid Tuned Mass Dampers Consists of two large tanks or more whose water contents flow from tank to tank in response to lateral forces that sway the building. The sloshing forces of the water on the sides of the tanks as it moves from one tank to another counteract the swaying forces. Water tank for firefighting or air conditioning system of the building can be used for this purpose.

Mals MKays

Building Department, UiTM

45

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Passive Dampers

v. Viscous Liquid Dampers.

Similar to the use of hydraulic pistons in cars to absorb vibrations from the road. Special hydraulic pistons contains viscous liquid are placed at suitable locations throughout the buildings. E.g: Torre Mayor Building, Mexico City

Active Dampers

Require sensors to detect the movement and initiate the mechanical hydraulic piston actuators that push against the damper mass and structure. Require external mechanisms and electricity to move them in response to the horizontal movement of the building. Computers are used to fine tune the responses to the swaying of the building.

Mals MKays

Building Department, UiTM

46

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Hybrid Damper

Passive active damper that have both the passive damper and active damper The passive damper is used to for the initial movement up to a dynamic movement point where it turns off and the active damper activates to respond to the movement. Now used as an earthquake measure rather than resist wind induced oscillation. E.g: Fukuoka Building, Japan.

12345

c. Aerodynamics Methods

The building cross sectional plan is designed to have minimum air turbulence that could cause oscillation. The reduction or air turbulence can be obtained by: i. have circular plan rather than rectangular or square plan of the building. ii cutting or rounding off the corners of the building. iii. Providing for perforation at the corners of the building or in the building. iv. Having channels in the buildings silhouette that allow the wind to be channeled away from the face of the building e.g: Shanghai World Financial Centre

Mals MKays

Building Department, UiTM

47

BLD 510 Construction Technology III

BSc (Hons) Construction Management

10.0 FLOOR SYSTEM FOR TALL BUILDING

Tall buildings has many floors. Have to fulfill several functions bearing of loads, fire resistance, sound insulation, heat insulation and aesthetics. Divided to three parts: floor structural floor finish ceiling (soffit of floor) finish

Mals MKays

Building Department, UiTM

48

BLD 510 Construction Technology III

BSc (Hons) Construction Management

10.1 Floor Structural System

Parts of the building that contribute to the structural stability of the building. Two structural functions: Vertical Loading Function

To carry the live loads and dead loads . Has to transfer loads to either support beams of the structural frame or supporting structural walls. Must stiff enough as to neither noticeably deflect due to the load nor felt to oscillate when repetitive impact loads are applied.

Horizontal Loading Function

To act as internal struts of the buildings horizontal loading structural systems. Depth of the slab and its supporting joists/girders influences the degree of stiffness of the overall building; but more materials and increases the loads exerted on the foundation foundation costs will increased

Dilemma to the designer ; use of lighter materials (steel or lightweight reinforced concrete, using trusses and creating cavities in the structure ) to reduce loads and costs but building tend to sway in the wind.

Types of Floor Structures:

LIGHT WEIGHT OR NORMAL CONCRETE FLOOR STRUCTURES

-the main and structural material is reinforced concrete -the floor plate is supported by r.c joists that span between the perimeter beams of the floor bay. -generally use cast-in-situ concrete floors but sometimes precast concrete is used for the floors. -if have long spans without intermediate supporting columns, prestressed concrete slabs or either prestressed concrete joints are used.

Mals MKays

Building Department, UiTM

49

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Types of Floor Structures:

COMPOSITE FLOOR STRUCTURES

- combination of steel and concrete - may be one of the following: * cast in situ concrete slab on corrugated metal deck. * precast concrete planks on beams * steel joists embedded in concrete

Mals MKays

Building Department, UiTM

50

BLD 510 Construction Technology III

BSc (Hons) Construction Management

10.2 Floor Finishes

Screed Floor usually cement screed which is laid on the concrete slab. tiling or membrane type covers are laid on the screed. access boxes for the m &E ducts laid in the floor slab are positioned relevant to the layout of the floor. Raised Floor proprietary raised floor are installed onto the floor creating a false floor. space within the raised floor accommodate M & E ducts, cables etc and allows the use of under floor air conditioning plenums.

10.3 Ceiling Finishes

Wet Construction either plastered or spray finished or cemented acoustic tiling that are clad directly to the floor soffit. usually for residential building. Dry Construction dry boards or tiles fastened on a frame either suspended from the floor soffit or fixed directly to the floor soffit. dry boards are made from gypsum, wood cement etc ceiling are either attached directly to the floor or suspended with hanging wires or rods from the floors.

Mals MKays

Building Department, UiTM

51

BLD 510 Construction Technology III

BSc (Hons) Construction Management

11.0 WALL SYSTEM FOR TALL BUILDING

Walls enclose space and serves the functions of weather exclusion, thermal and sound insulation. It also provides adequate strength, stability, durability, fire resistance aesthetic appeal, etc.

11.1 Factors of External Walls System

Visual panel, shape and size joint locations, joint sizes daylighting, nightlighting blinds, shades materials, colours, finishes integration with interior design, e.g cabling behind partitions. Integrity air and water tightness ; sealing, drainage, indoor air quality loading; static, dynamic, fatigue movements ; loads, thermal, moisture exceptional loads; blast, intrusion, impact fire ; resistance, reaction, spread verticality and horizontally

Mals MKays

Building Department, UiTM

52

BLD 510 Construction Technology III

BSc (Hons) Construction Management

11.1 Factors of External Walls System

Physics/Environment/Comfort heat transfer lighting sound transmission ; noise from street, next room ventilation moisture ; rainwater, humidity, condensation, degradation, mould growth. Buildability tolerance pre-assembly stick, unitised, panelised quality ; QA, factory work, site work Maintenance access ; cleaning, inspection, repair, replacement life cycle ; component life, inspection cycle, repair, replacement serviceability ; cleaning, repairability, replaceability

11.2 Type of Walls

Load Bearing walls function as shear walls; generally of reinforced concrete. Non Load Bearing Walls most walls used in tall buildings are non load bearing. can be reinforced concrete, brick, composite materials, glass, metal sheets etc. used to enclose the building structure and provide a face or faade.

Mals MKays

Building Department, UiTM

53

BLD 510 Construction Technology III

BSc (Hons) Construction Management

11.3 Type of External Walls

a. Curtain Walling b. Infill Panels c. Cladding

a. Curtain Walling

A form of external lightweight cladding attached to a frame structure forming a complete envelope or sheath around the structural frame. Non load bearing claddings which have to support only their own deadweight and imposed wind loadings which are transferred to the structural frame through connectors which are usually positioned at floor levels. A series of vertical mullions spanning from floor to floor interconnected by horizontal transoms forming openeings into which can be fixed panels of glass or infill panels of apaque materials. Constructed by using a patent or proprietary systems produced by profile metal fabricators.

Mals MKays

Building Department, UiTM

54

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- curtain walling details

Mals MKays

Building Department, UiTM

55

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- type of curtain walling

Stick curtain walling Stick and unit curtain wall Unitised or panel curtain wall

i. Stick System

Uses site assembled framing members, mullions (verticals) and transoms (horizontal) Glazing and infill panels are fixed into the carrier framing grid by clamping them into a glazing rebate The infill panels consists of mineral wool insulation. The carrier framework remains visible. E.g. Sears Tower.

Mals MKays

Building Department, UiTM

56

BLD 510 Construction Technology III

BSc (Hons) Construction Management

ii. Stick and unit system

The panels are attached to a stick type or grid type or truss type carrier framework fixed to the building structure.

Mals MKays

Building Department, UiTM

57

BLD 510 Construction Technology III

BSc (Hons) Construction Management

iii. Unitised system

Large, integral factory assembled units, sometimes one storey high incoporating mineral wool insulations, windows, ventilators, doors and opaque facing. The panels are only anchored either to the building structure or to both the structure and adjacent panels.

Mals MKays

Building Department, UiTM

58

BLD 510 Construction Technology III

BSc (Hons) Construction Management

iv. Structural Glazing

Structural glass panels that are supported by a framework of moveable spider connectors steel trusses and outriggers. Popular for the faade of the podium annexes for many tall buildings The system allow for high head room as the glass can be span up to four stories high by an appropriately design framework

Mals MKays

Building Department, UiTM

59

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

60

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

61

BLD 510 Construction Technology III

BSc (Hons) Construction Management

b.Infill Panel

The wall is installed between the exterior floor slab and columns of the structural frame. The panel layout can be so arranged to expose some or all of the structural members creating various optical impressions. Wide variety of materials or combinations of materials can be employed such as glass, pre cast concrete, aluminium etc.

Mals MKays

Building Department, UiTM

62

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

63

BLD 510 Construction Technology III

BSc (Hons) Construction Management

c. Cladding

The wall (in the form of large panel) is attached directly to the structural frame of the buildings or a backing wall. The panels are one to two storey high and span one or more horizontal bays of structural frame. Require large fixings and anchors to hold them on the building.

Mals MKays

Building Department, UiTM

64

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

65

BLD 510 Construction Technology III

BSc (Hons) Construction Management

12.0 FOUNDATION SYSTEM FOR TALL BUILDING

Refer to foundation notes BLD 310 (Diploma in Building) and basement notes BLD 410 (Degree) Types of foundation used for Tall Building Piling : Displacement Piles Steel H Pile, Spun Pile : Replacement Piles Bored Pile, Barretts Pile Drilled Caisson Buoyancy Raft Foundation

a. Bored Pile

Mals MKays

Building Department, UiTM

66

BLD 510 Construction Technology III

BSc (Hons) Construction Management

b. Drilled Caisson

Mals MKays

Building Department, UiTM

67

BLD 510 Construction Technology III

BSc (Hons) Construction Management

c. Spun Pile

Mals MKays

Building Department, UiTM

68

BLD 510 Construction Technology III

BSc (Hons) Construction Management

d. Barretts Pile

e. Buoyancy Raft Foundation

Mals MKays

Building Department, UiTM

69

BLD 510 Construction Technology III

BSc (Hons) Construction Management

13.0 CONSTRUCTION OF TALL BUILDINGS

Nature of Tall Building Construction - Working at Heights : increases the risks of injury or deaths from falling or being hit by falling objects. : personnel and materials have to lifted to their working areas located at elevated heights. - Operating in Restricted Working Area : usually in built up areas on small sites : not much working space at ground level. - Repetitive Work Activities : usually repeating a cycle of activities associated with each floor.

13.1 Method of Construction

Conventional In Situ Reinforced Concrete Industrialised Building System (IBS) Prefab System Industrialised Formwork System Steel Structures

Mals MKays

Building Department, UiTM

70

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. Conventional reinforced concrete

Refer to Diploma Notes and Encik Kamran Notes in BLD 460 (Bach of Construction Management)

b. IBS Prefab System

Refer to PM Mafozah Murad Notes in BLD 460 (Bach Construction Management)

Mals MKays

Building Department, UiTM

71

BLD 510 Construction Technology III

BSc (Hons) Construction Management

b. IBS Steel Structures

Refer to PM Mafozah Murad Notes in BLD 460 (Bach of Construction Management)

b. IBS - formwork

Types of Formwork

Prefabricated Job Built Forms that can be reused, usually referred to as gang or gang forms. Manufactured Forms, generally purchased or leased, sometimes as a total system.

Mals MKays

Building Department, UiTM

72

BLD 510 Construction Technology III

BSc (Hons) Construction Management

i. prefabricated job-built forms

prefabricated forms are usually constructed substantially for the purpose of frequent reuse, commonly used for wall forming, and also for deck forming where multiple floors are being erected. these forms can either be ready made or custom made. Gang or Ganged Forms Flying forms

- gang or ganged forms

are built by assembling a number of small prefabricated panel forms into one large form. can be used on all types of work, their size being limited only by job conditions and the means for moving them. These large sections are erected, stripped and moved to the next location by cranes. provides good reuse of equipment, larger concrete placements and decreased erection and stripping time because the sections stay intact. no dismantling and reassembly of each individual panel for each concrete placement.

Mals MKays

Building Department, UiTM

73

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

74

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- flying / table forms

are large prefabricated forms for multi-storey building slabs. contain their own supporting system and levelling jacks, and are easily dropped away from the floor slab when the concrete reaches the specified strength. the form is then moved to the edge of the building, picked up by a crane, and moved to the next floor for setting and levelling. the name flying formwork is used because forms are flown from story to story by a crane

Mals MKays

Building Department, UiTM

75

BLD 510 Construction Technology III

BSc (Hons) Construction Management

ii. manufactured forms

speciality manufactured forms that reduce the time and labour formerly required at job sites these systems and panels are durable enough for many reuses. each proprietary panel systems has its own special ties and other accessories.

Mals MKays

Building Department, UiTM

76

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- pan forms

made of metal, fibreglass or plastic are used for floor slabs in multi-storey building . waffle slab floors have waffle-like indentations on the bottom surface formed by rectangular pans in the same manner as in the pan joist floor system. these forms are reusable and can be either rented or bought. they come in a wide range of sizes and depths.

Mals MKays

Building Department, UiTM

77

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

78

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- internal forms

are round or rectangular laminated fibre and cardboard forms placed in deep (or thick) floors or beams and left in place to lighten the dead weight of member these produce a floor slab similar to the pan joist floor except both top and bottom surfaces are flat. the duct like void create a space between the joists, inside of the element. the ends of the tubes and boxes are closed off so that concrete will not flow into them expanded polystyrene can also be used to create internal voids

- tunnel forms

combined the walls on either side of a room and the slab overhead soffit from into a single unit. typically, the wall forms hinge to allow the slab soffit form to be stripped, and the entire assembly is hoisted to the subsequent area to be formed

Mals MKays

Building Department, UiTM

79

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- column forms

square or rectangular columns can be built using the same system of form panels as used for walls. forms for round columns are available in laminated fiber, metal and glass fiber reinforced plastic as complete units

Mals MKays

Building Department, UiTM

80

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- slipforms

Slipforms place concrete by extrusion. The concrete is placed in the forms, which are then pulled or jacked vertically or horizontally, extruding the concrete, in the shape of the forms. The most spectaculars use of slipforms is for tall towers, silos, elevator shafts in tall buildings and building walls. The movement of the forms is slow enough for concrete to gain the strength to keep its shape and support its weight.

Mals MKays

Building Department, UiTM

81

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- jump forms / climbing forms

similar to slipforms except that rather than extruding the concrete, the form is filled with concrete, stripped and then jumped to the next level after the concrete has set. these gang forms may be lifted by crane or self raised (electrically or hydraulically). properly designed, they minimize the number of pieces to be handled and simplify the task of resetting the forms while meeting the tolerances specified

Mals MKays

Building Department, UiTM

82

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Jump form operation

Mals MKays

Building Department, UiTM

83

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Jump form operation

- stay-in-place forms

these forms are often steel or thin precast, prestressed concrete units that are placed on supporting formwork (when used for floors) and bonded to become the bottom of the concrete element. become part of the completed structure. they are often used for concrete floor and roof slabs cast over steel joists or beams, for bridge decks, for a top slab over a pipe trench or for other inaccessible locations where it is impractical and expensive to remove forms.

Mals MKays

Building Department, UiTM

84

BLD 510 Construction Technology III

BSc (Hons) Construction Management

13.2 Vertical Transportation & Handling / Elevated Access

Access to the interior and exterior of the building is needed for workers, materials and even plant or machinery. Workers have to be lifted to their work areas within the building being built so that they do not tire themselves climbing stairs. Materials have to be lifted to their installation positions within the building being built. The common equipment or machineries used are: Scaffolding Cranes Derricks Gondolas/Swinging Stage Hoists Elevator (lifts) Helicopters Rubbish Chute

a. Scaffolding

A temporary working platform erected around the perimeter of a building structure usually constructed from steel or aluminium alloy tubes clipped or coupled together to provide a means of access to high level working areas as well providing a safe platform from which to work. Supported from the ground or on a floor slab or platform Remain static and difficult to move. Types of Scaffolding:

Putlog scaffolds Independent scaffolds Cantilevered Scaffolds Truss-out scaffold Gantries

Mals MKays

Building Department, UiTM

85

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- component parts of tubular scaffold:

i. putlog scaffolds

These are scaffolds which have an outer row of standards joined together by ledgers which in turn support the transverse putlogs which are built into the beds joints or perpends as the work proceeds, they are only suitable for new work in bricks or blocks.

Mals MKays

Building Department, UiTM

86

BLD 510 Construction Technology III

BSc (Hons) Construction Management

ii. independent scaffolds

These are scaffolds which have two rows of standards each row joined together with ledgers which in turn support the transverse transoms. The scaffold is erected clear of the existing or proposed building but is tied to the building or structure at suitable intervals.

Tying-in

All putlog and independent scaffolds should be tied securely to the building structure at alternate lift heights vertically and not more than 6m centres horizontally. Suitable tying-in methods include connecting to tubes fitted between sides of window openings or to internal tubes fitted across window openings.

Mals MKays

Building Department, UiTM

87

BLD 510 Construction Technology III

BSc (Hons) Construction Management

iii. cantilever scaffolds

These are a form of independent tied scaffold erected on cantilever beams and used where it is impracticable, undesirable or uneconomic to use a traditional scaffold raised from ground level. Requires special skills and should therefore always be carried out by trained and experienced personnel.

iv. truss-out scaffold

A form of independent tied scaffold used where it is impracticable, undesirable or uneconomic to build a scaffold from ground level. The supporting scaffold structures is known as the truss out. Requires special skills and should therefore always be carried out by trained and experienced personnel.

Mals MKays

Building Department, UiTM

88

BLD 510 Construction Technology III

BSc (Hons) Construction Management

v. gantries

These are elevated platforms used when the building being maintained or under construction is adjacent to a public footpath. A gantry over a footpath can be used for storage of materials, housing units of accommodation and supporting an independent scaffold.

b. Cranes

These are lifting devices designed to raise materials by means of rope operation and move the load horizontally within their limitations of any particular machine. The range of cranes available is very wide and therefore choice must be based on the loads to be lifted, height and horizontal distance to be covered, time periods og lifting operations, utilisation factors and degree of mobility required Types of crane:

Mobile Crane Static Crane Tower Crane

Mals MKays

Building Department, UiTM

89

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- types of crane

i. Mobile Crane Self Propelled Cranes

Mobile cranes mounted on a wheeled chassis and have only one operator position from which the crane is controlled and the vehicle driven

Mals MKays

Building Department, UiTM

90

BLD 510 Construction Technology III

BSc (Hons) Construction Management

i. Mobile Crane Lorry Mounted Cranes

Mobile cranes consists of a lattice or telescopic boom mounted on a specially adapted truck or lorry. Have two operating positions: the lorry being driven from a conventional front cab and the crane being controlled from a different location. The lifting capacities can be increased by using outrigger stabilizing jacks.

Mals MKays

Building Department, UiTM

91

BLD 510 Construction Technology III

BSc (Hons) Construction Management

i. Mobile Crane Lorry Mounted Lattice Jib Cranes

These cranes follow the same basic principles as the lorry mounted telescopic cranes but they have a lattice boom and are designed as heavy duty cranes with lifting capacities in excess of 100 tones.

Mals MKays

Building Department, UiTM

92

BLD 510 Construction Technology III

BSc (Hons) Construction Management

i. Mobile Crane Track Mounted Cranes

These machines can be a universal power unit rigged as a crane or a purpose designed track mounted crane with or without a fly jib attachment. The latter type are usually more powerful with lifting capacities up to 45 tonnes. Can travel and carry out lifting operations on most site without the need for special road and hardstands provisions but they have to be rigged on arrival after being transported to site on a low loader lorry.

ii. Static Crane - Mast Cranes

Similar in appearance to the familiar tower cranes but they have one major difference in that the mast or tower is mounted on the slewing ring and thus rotates whereas a tower crane has the slewing ring at the top of tower and therefore only the jib portion rotates. Self erecting, of relatively low lifting capacity and are usually fitted with luffing jib.

Mals MKays

Building Department, UiTM

93

BLD 510 Construction Technology III

BSc (Hons) Construction Management

iii. Tower Cranes

Most tower cranes have to be assembled and erected on site prior to use and can be equipped with a horizontal of luffing jib. Wide range of models available often makes it difficult to choose a crane suitable for any particular site but most tower cranes can be classified into one of four basic groups:

Self Supporting Static Tower Cranes Supported Static Tower Cranes Travelling Tower Cranes Climbing Cranes

Example of Tower Cranes Details:

Mals MKays

Building Department, UiTM

94

BLD 510 Construction Technology III

BSc (Hons) Construction Management

iii. Tower Cranes Self Supporting Static Tower Crane

High lifting capacity with the mast or tower fixed to a foundation base. Suitable for confined and open sites.

iii. Tower Cranes Supported Static Tower Cranes

Similar in concept to self supporting cranes and are used where high lifts are required, the mast or tower being tied at suitable intervals to the structure to give extra stability.

Mals MKays

Building Department, UiTM

95

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Mals MKays

Building Department, UiTM

96

BLD 510 Construction Technology III

BSc (Hons) Construction Management

iii. Tower Crane Travelling (Rail Mounted) Tower Crane

Mounted on power bogies running on a wide gauge railway track to give greater site coverage. Only slight gradients can be accommodated therefore a reasonably level site or specially constructed railway support trestle is required.

iii. Tower Crane Climbing Cranes

Used in conjunction with tall buildings and structures. The climbing mast or tower is housed within the structure and raised as the height of the structure is increased. Upon completion the crane is dismantled into small sections and lowered down the face of the building

Mals MKays

Building Department, UiTM

97

BLD 510 Construction Technology III

BSc (Hons) Construction Management

- parts of a Tower Crane

All tower cranes consist of the same basic parts: The base is bolted to a large concrete pad that supports the crane. The base connects to the mast (or tower), which gives the tower crane its height. Attached to the top of the mast is the slewing unit -- the gear and motor -that allows the crane to rotate:

Mals MKays

Building Department, UiTM

98

BLD 510 Construction Technology III

BSc (Hons) Construction Management

On top of the slewing unit are three parts: The long horizontal jib (or working arm), which is the portion of the crane that carries the load. A trolley runs along the jib to move the load in and out from the crane's center: The shorter horizontal machinery arm, which contains the crane's motors and electronics as well as the large concrete counter weights: The operator's cab: The machinery arm contains the motor that lifts the load, along with the control electronics that drive it and the cable drum, as shown here: The motors that drive the slewing unit are located above the unit's large gear:

- how do they grow?

Tower cranes arrive at the construction site on 10 to 12 tractortrailer rigs. The crew uses a mobile crane to assemble the jib and the machinery section, and places these horizontal members on a 40foot (12-m) mast that consists of two mast sections. The mobile crane then adds the counterweights. The mast rises from this firm foundation. The mast is a large, triangulated lattice structure, typically 10 feet (3.2 meters) square. The triangulated structure gives the mast the strength to remain upright.

Mals MKays

Building Department, UiTM

99

BLD 510 Construction Technology III

BSc (Hons) Construction Management

To rise to its maximum height, the crane grows itself one mast section at a time! The crew uses a top climber or climbing frame that fits between the slewing unit and the top of the mast. Here's the process:

The crew hangs a weight on the jib to balance the counterweight. The crew detaches the slewing unit from the top of the mast. Large hydraulic rams in the top climber push the slewing unit up 20 feet (6 m). The crane operator uses the crane to lift another 20-foot mast section into the gap opened by the climbing frame. Once bolted in place, the crane is 20 feet taller!

- how much weight can they lift?

A typical tower specifications: crane has the following

Maximum unsupported height - 265 feet (80 meters) The crane can have a total height much greater than 265 feet if it is tied into the building as the building rises around the crane. Maximum reach - 230 feet (70 meters) Maximum lifting power - 19.8 tons (18 metric tons), 300 tonne-meters (metric ton = tonne) Counterweights - 20 tons (16.3 metric tons)

The maximum load that the crane can lift is 18 metric tons (39,690 pounds), but the crane cannot lift that much weight if the load is positioned at the end of the jib. The closer the load is positioned to the mast, the more weight the crane can lift safely. The 300 tonnemeter rating tells you the relationship. For example, if the operator positions the load 30 meters (100 feet) from the mast, the crane can lift a maximum of 10.1 tonnes.

Mals MKays

Building Department, UiTM

100

BLD 510 Construction Technology III

BSc (Hons) Construction Management

The crane uses two limit switches to make sure that the operator does not overload the crane:

The maximum load switch monitors the pull on the cable and makes sure that the load does not exceed 18 tonnes. The load moment switch makes sure that the operator does not exceed the tonnemeter rating of the crane as the load moves out on the jib. A cat head assembly in the slewing unit can measure the amount of collapse in the jib and sense when an overload condition occurs.

- why don't they fall over?

The first element of the tower crane's stability is a large concrete pad that the construction company pours several weeks before the crane arrives. This pad typically measures 30 feet by 30 feet by 4 feet (10 x 10 x 1.3 meters) and weighs 400,000 pounds (182,000 kg) -these are the pad measurements for the crane shown here. Large anchor bolts embedded deep into this pad support the base of the crane:

Mals MKays

Building Department, UiTM

101

BLD 510 Construction Technology III

BSc (Hons) Construction Management

c. Derricks

The Derricks crane is a simple and inexpensive solution for lifting heavy weights (10 tonnes or more) at long radius (up to 30m) Two types:

Guy Derrick Scotch Derrick

i. Guy Derrick

Guy Derrick has several guys (cable ties) that holding up the mast and to help slewing of the cranes boom. The other ends of the guys are anchored to the building structure. The boom is hinged to the base of the mast. Winches located at the mast base.: use to derrick the boom and hoisting the load

Mals MKays

Building Department, UiTM

102

BLD 510 Construction Technology III

BSc (Hons) Construction Management

ii. Scotch Derrick

Similar in design to the guy derrick except that it has no guys (cable ties), has a shorter mast and a longer boom. It is stabilized by having its two backstays to be loaded with ballast.

Mals MKays

Building Department, UiTM

103

BLD 510 Construction Technology III

BSc (Hons) Construction Management

d. Gondolas or Swinging Stage

These consists of a working platform in the form of a cradle which is suspended from cantilever beams or outriggers from the roof of a tall building to give access to the faade for carrying out light maintenance work and cleaning activities. The cradles can have manual or power control and be in single unit or grouped together to form a continuous working platform. If grouped together they are connected to one another at their abutment ends with hinges to form a gap of not more than 25mm wide. Many high rise building have a permanent cradle system installed at roof level and this is recommended for all buildings over 30m high.

Mals MKays

Building Department, UiTM

104

BLD 510 Construction Technology III

BSc (Hons) Construction Management

e. Hoists

These are designed for the vertical transportation of materials, passengers or materials and passengers. Materials hoists are designed for one specific use (i.e. the vertical transportation of materials) and under no circumstances should they be used to transport passengers. Most material host are of a mobile format which can be dismantled, folded onto the chassis and moved to another position or site under their own power or towed buy a haulage vehicle.

Passenger hoists are designed to carry passengers although most are capable of transporting a combined load of materials and passengers within the lifting capacity of the hoist. A wide selection of hoists are available ranging from a single cage with rope suspension to twin cages with rack and pinion operation mounted on two sides of a static tower.

Mals MKays

Building Department, UiTM

105

BLD 510 Construction Technology III

BSc (Hons) Construction Management

f. Elevators (lifts)

These move on tracks. They are more stable and have higher capacities as compared with a gondola.

Mals MKays

Building Department, UiTM

106

BLD 510 Construction Technology III

BSc (Hons) Construction Management

g. Helicopters

When it is not possible to use crane to lift the topmost part of the building (such as telecommunication tower mast) helicopter becomes a viable solution despite its very high cost.

g. Rubbish Chutes

Used to direct disposals of debris from various floor to the bin on the ground floor The simple concept of connecting several perforated dustbins. The tapered layered cylinders are produced from reinforced rubber with chain linkage for continuity. Overall length are generally 1100mm, providing an effective length of 1m. Hoppers and side entry unit are mede for special applications.

Mals MKays

Building Department, UiTM

107

BLD 510 Construction Technology III

BSc (Hons) Construction Management

13.3 Working Space

Space is limited. Among approaches to provide sufficient work space so that work can be done safely and efficiently:

multistory site accommodation. elevated site accommodation and platforms. use part of uncompleted structure. use nearby properties and public spaces. maximising prefabrication and standardisation

Mals MKays

Building Department, UiTM

108

BLD 510 Construction Technology III

BSc (Hons) Construction Management

a. Multi story site accommodation

Usually portable container cabins stacked up.

b. Elevated site accommodation and platform

site accommodation build upon scaffolding / gantry such that the site accommodation opens up to the street level.

Gantry to support cabin

Mals MKays

Building Department, UiTM

109

BLD 510 Construction Technology III

BSc (Hons) Construction Management

c. Use part of uncompleted structure

When the building is partially complete, it may be feasible to use some of the completed floor as site accomadati on.

d. Use nearby properties and public spaces

Rent space in an adjacent building for site accommodation.

Mals MKays

Building Department, UiTM

110

BLD 510 Construction Technology III

BSc (Hons) Construction Management

e. Maximising prefabrication and standardisation

If the contractor uses prefabricated components for the building, there is no need for space at site to store the raw materials. The components are built off site and transported to the site to be assembled into their final positions

14.0 Safety System For Tall Building Construction

The great heights, strong winds at heights and constricted working space make fatal falls and collisions very possible. Most accidents in a worksite are categorized under :

falls of person workers struck by falling objects

Accidents may result in high direct and indirect costs:

Direct Costs : medical costs, workers compensation and other insurance benefits. Indirect Costs : reduced productivity, job schedule delays, damage to equipment and facilities, low morale among workers and possible additional liability claims.

Mals MKays

Building Department, UiTM

111

BLD 510 Construction Technology III

BSc (Hons) Construction Management

14.1Falls of Person

Measures against fall of persons:

A working platform should be provided to workers whenever practicable : should be of adequate width, carrying capacity and with sufficient guardrails to afford a safe and steady foothold and handhold. The width should not be less than 635mm and toe-boards must be provided. Safety belts and lifelines; in the case where platform cannot be provided for reasons of space constraint.

Safety Belt

Mals MKays

Building Department, UiTM

112

BLD 510 Construction Technology III

BSc (Hons) Construction Management

14.2 Falling Objects

Measures against person struck by falling objects include:

Good housekeeping and minimizing debris being generated, hence less falling materials. Systematic and regular disposal of accumulated debris, provisions of perimeter overhead shelter. Access and egress shelters to building: provision of safety nets and provision of pedestrian walkway or hoarding The compulsory wearing of safety helmets.

Safety Helmet

Sidewalk Shed Protection

Safety Netting

Mals MKays

Building Department, UiTM

113

BLD 510 Construction Technology III

BSc (Hons) Construction Management

Safety Net Catch Platform

CASE STUDY:

PETRONAS TWIN TOWERS. TURNING TORSO, SWEDEN. BURJ HOTEL, DUBAI

Mals MKays

Building Department, UiTM

114

BLD 510 Construction Technology III

BSc (Hons) Construction Management

THANK YOU

Mals MKays

Building Department, UiTM

115

You might also like

- Design and Advancements in Tall Building StructuresDocument6 pagesDesign and Advancements in Tall Building StructuresSonny AndalisNo ratings yet

- Etabs Mate Quick Start - enDocument27 pagesEtabs Mate Quick Start - ensipilNo ratings yet

- Wind Engineering Challenges of The New Generation of Super-Tall BuildingDocument7 pagesWind Engineering Challenges of The New Generation of Super-Tall BuildingRodolfo JaegerNo ratings yet

- Structural Design of RC Buildings in the PhilippinesDocument12 pagesStructural Design of RC Buildings in the PhilippinesJohnson SambranoNo ratings yet

- Introduction - UBC - NEHRP - Comparison of Seismic Provision Fo 1997 UBC To 1997 NEHRPDocument25 pagesIntroduction - UBC - NEHRP - Comparison of Seismic Provision Fo 1997 UBC To 1997 NEHRPeplim60No ratings yet

- Structural Engineer seeks new opportunitiesDocument6 pagesStructural Engineer seeks new opportunitieschristian reyesNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Analysis and Design of Building Using EtabsDocument1 pageAnalysis and Design of Building Using Etabsinnovative technologiesNo ratings yet

- PEER/CSSC Tall Building Design Case Study Building #1Document27 pagesPEER/CSSC Tall Building Design Case Study Building #1bansaldhruvNo ratings yet

- Zamil Steel Vietnam (ZSV) : Total Steel Building SolutionsDocument80 pagesZamil Steel Vietnam (ZSV) : Total Steel Building SolutionsTuan Hung TrinhNo ratings yet

- RAM Concrete Shear Wall Design Verification ExampleDocument21 pagesRAM Concrete Shear Wall Design Verification ExamplePushpakaran Pillai100% (1)

- Super StructureDocument38 pagesSuper Structureapi-547204941No ratings yet

- Seismic Design Guidelines For Tall BuildingsDocument20 pagesSeismic Design Guidelines For Tall BuildingsIlanildo DiasNo ratings yet

- 1.0 Behaviour of Tall BuildingDocument22 pages1.0 Behaviour of Tall BuildingOne The100% (1)

- Mactan Belmont Luxury Hotel – Cast in Channel Loading AnalysisDocument9 pagesMactan Belmont Luxury Hotel – Cast in Channel Loading AnalysisJonathanNo ratings yet

- 1997 UBC Earthquake Design - Base ShearDocument7 pages1997 UBC Earthquake Design - Base ShearRamil Decena LaforteNo ratings yet

- Along Wind Load On Tall Buildings - Indian Codal ProvisionsDocument8 pagesAlong Wind Load On Tall Buildings - Indian Codal ProvisionsKeshav VaityNo ratings yet

- Seismic Analysis and Design of R.C.C Tall Building With Shear WallDocument9 pagesSeismic Analysis and Design of R.C.C Tall Building With Shear WallNaveen JatavNo ratings yet

- PP02B - Asep - NSCP 2015 Update On Appendix 1-BDocument10 pagesPP02B - Asep - NSCP 2015 Update On Appendix 1-BjimNo ratings yet

- Effects of Elevated Temperatures on CFRP-Strengthened RC BeamsDocument11 pagesEffects of Elevated Temperatures on CFRP-Strengthened RC BeamsJefreyMatuanMondranoNo ratings yet

- Seismic Info KnaufDocument20 pagesSeismic Info KnaufVarga Zoran100% (1)

- Final PaperDocument4 pagesFinal PaperEzekiel Eljay Macatangay0% (1)

- Lateral Deflection of Tall BuildingsDocument4 pagesLateral Deflection of Tall BuildingsAshnaBeeslallNo ratings yet

- Earthquake Resisting System Class NotesDocument17 pagesEarthquake Resisting System Class NotesatulNo ratings yet

- ASCE 41-17 Tier 1 ChecklistsDocument4 pagesASCE 41-17 Tier 1 ChecklistsAdita Rian Pradana100% (1)

- National Earthquake Hazards Reduction Program: A Research and Implementation PartnershipDocument2 pagesNational Earthquake Hazards Reduction Program: A Research and Implementation Partnershipnewbie_101No ratings yet

- Final ReportDocument41 pagesFinal ReportShohel RanaNo ratings yet

- 04 - Building Design Considerations, Design Output Verifications, and Report GenerationDocument145 pages04 - Building Design Considerations, Design Output Verifications, and Report GenerationJohn Paul UmaliNo ratings yet

- Modern Tall Building Cities – West vs East DifferencesDocument13 pagesModern Tall Building Cities – West vs East DifferencesAravind BhashyamNo ratings yet

- Precast concrete structures in 4 stepsDocument315 pagesPrecast concrete structures in 4 stepsJiana R. Al-sharifNo ratings yet

- ECE Dept Syllabus GUISTDocument78 pagesECE Dept Syllabus GUISTparisangelNo ratings yet

- Static Analysis and Design of G+20 RCC Framed Structure by Using ETABS SoftwareDocument15 pagesStatic Analysis and Design of G+20 RCC Framed Structure by Using ETABS SoftwareIJRASETPublicationsNo ratings yet

- L3 Lateral ForceDocument75 pagesL3 Lateral Forceapirakq100% (1)

- Analysis of Damage To The Existing Structure Under DistressDocument5 pagesAnalysis of Damage To The Existing Structure Under DistressInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- High Rise BuildingsDocument7 pagesHigh Rise BuildingsjenitaNo ratings yet

- Presentation On Disaster Management PU 1Document48 pagesPresentation On Disaster Management PU 1Sanjit Kumar KalwarNo ratings yet

- SEISMIC DESIGN TO EC8Document13 pagesSEISMIC DESIGN TO EC8Matumbi NaitoNo ratings yet

- Analysis of G+30 Highrise Buildings by Using Etabs For Various Frame Sections in ZoneIV and ZoneV PDFDocument15 pagesAnalysis of G+30 Highrise Buildings by Using Etabs For Various Frame Sections in ZoneIV and ZoneV PDFK.ANISHNo ratings yet

- PEB Product enDocument22 pagesPEB Product enFahad KhanNo ratings yet

- 2.2. Structural Analysis and DesignDocument3 pages2.2. Structural Analysis and DesignGian SanchezNo ratings yet

- Structures 1Document186 pagesStructures 1Muwaffaq m.100% (1)

- Precast Concrete: Instructional Slides Developed by Ned Cleland. P.E., PHDDocument175 pagesPrecast Concrete: Instructional Slides Developed by Ned Cleland. P.E., PHDMohamed SaaDNo ratings yet

- Earthquake Collapse PatternDocument16 pagesEarthquake Collapse Patterngaurav jagtap0% (1)

- Engineering Utilities 2: Building Plumbing SystemDocument97 pagesEngineering Utilities 2: Building Plumbing SystemJhon Russel Cruz AntonioNo ratings yet

- RCC BASE SHEAR CALCULATION FOR DIFFERENT ZONESDocument7 pagesRCC BASE SHEAR CALCULATION FOR DIFFERENT ZONESsurendra bhattaNo ratings yet