Professional Documents

Culture Documents

Kiln Shell Corrosion

Uploaded by

NaelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kiln Shell Corrosion

Uploaded by

NaelCopyright:

Available Formats

Kiln Shell Corrosion

Cement

ICTM R. Krischanitz May 2008

29 Kiln Shell Corrosion

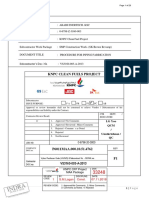

PC kiln, 4.15 x 58 m, 2450 tpd, <20% alternative fuels:

Fracture of kiln shell at rm 38.5 - despite phosphating it during

previous kiln stops

Kiln shell thickness:

Original thickness 20mm

Thickness within fracture area (groove) 8mm

Average thickness in brick joints 14mm

Thickness below bricks 17mm

Ref: DAVILA, J.C. et al., 1995, Influencia del Refractario en la Corrosion de la Coraza del Horno Rotatorio para

Cemento, ALAFAR XXIV Congreso, Cartagena, pp 157-183

Fracture of kiln shell due to corrosion

3 29 Kiln Shell Corrosion

Preferred

corrosion below

joints,

condensation of

moisture during

kiln stops

Corrosion of kiln shell (rm. 65, calcining zone)

4 29 Kiln Shell Corrosion

wet cardboards

Corroded kiln shell within the calcining zone

5 29 Kiln Shell Corrosion

Loss of shell

thickness 6 mm/a

Fuels: Coal + pet

coke, tyres,

palletised sewage

sludge

Kiln shell corrosion (rm. 29, second tyre)

6 29 Kiln Shell Corrosion

Thickness

15 mm

Scales from the kiln shell

7 29 Kiln Shell Corrosion

RHI Technical Centre Leoben, Austria

Dense layer of magnetite and hematite

mag

hem

Porous layer of hematite and KCl

hem

KCl

Microscopical appearances of scales

8 29 Kiln Shell Corrosion

Composition of scales

<@W A B C D E F G

Fe

2

O

3

44 90 88 17 56 n.a. 81

SO

3

11 7 5 1 1 -

K

2

O 24 - 2 43 16 6

Na

2

O 4 - - - 2 1

Cl

-

6 1 4 36 11 6

F

-

7 - - - - -

PbO - - 1 - - -

Fe

3

O

4

777 777 7 77 777 77

Fe

2

O

3

777 7 77 777

FeS 77 77 7 7 77

FeS

2

77

Fe(OH)

2

7

FeSO

4

.H

2

O 7

K

2

SO

4

77

KCl 77 7 777 77 77 77

Na

2

SO

4

7 7

NaCl 7

NaF 7

Pb

2

(SO

4

)O 7

W (wt.%)

WW W g7

9 29 Kiln Shell Corrosion

Kiln Feed / Coating

Kiln gas

KCl, K

2

SO

4

KCl, K

2

SO

4

KCl, K

2

SO

4

KCl, K

2

SO

4

Preheater

Evaporation of volatiles in preheating zone

10 29 Kiln Shell Corrosion

Lower melting points of

chlorides in comparison to

sulphates. Eutectic melts

have even lower melting

points. The lower the

melting point the higher

the infiltration depth.

Phase diagram:

acc. to O.S.Dombrovskaya 1933

Phase diagram KCl K

2

SO

4

11 29 Kiln Shell Corrosion

Spalling of basic bricks

caused by KCl after 3 months

operation

Infiltrated refractory bricks

12 29 Kiln Shell Corrosion

Reduce chlorine input to the kiln (selection of appropriate raw materials /

substitute fuels, install a by-pass)

Keep evaporation rate of volatile components as low as possible (avoid

reducing operation conditions, use of mineralizers, other process measures)

Reduce permeability of lining (e.g. reduction of joints by use of ISO shapes in

the basic zone, use of mortar lining)

Extension of the basic lining area

Install refractories with low (zero) permeability

Apply gas-tight coatings on the kiln shell (paints, flame / plasma sprayed

metallic or ceramic layers etc.)

Select corrosion resistant steel type for kiln shell

Sacrifice layer

cf also: Jns, E.S. & stergrd, 1999, Investigation into kiln shell corrosion of rotary cement kilns, ZKG International,

vol. 52, No. 2, pp. 68-79

Measures to prevent kiln shell corrosion

13 29 Kiln Shell Corrosion

Heat resistant up to 400C

Chemical resistance against alkaline salts

Chemical resistance against corrosive gases (H

2

S, HCl, SO

2

, CO

2

and O

2

)

Resistance against acids

Abrasion resistant (movement of the lining)

Coating must be applicable on sight

Requirements for coatings

14 29 Kiln Shell Corrosion

Materials tested by University of Leoben / RHI

D. Jellen: Verringerung der Ofenmantelkorrosion von Drehrohrfen in der

Zementindustrie durch Beschichtungen

: - polyamide resin with graphite pigments

- silicon resin with FeO pigments and inhibitors

- silicon-modified alkyd resin

- zinc ethyl silicate

- phosphoric acid

WW , flame sprayed: - Al

- NiCr 50/50

- Ni based Cr-B

- Zn, Zn/Al 85/15

W , plasma sprayed: - Al

2

O

3

Studied types of coating

15 29 Kiln Shell Corrosion

Ignition test at 400C:

kiln atmosphere: CO

2

20%

H

2

O 10%

SO

2

2%

HCl 2%

O

2

13%

N

2

53%

additionally the specimens were

coated with alkaline-salts

Low temperature corrosion:

at 40C in an exsiccator which

base has been covered with HCl (21%)

Weight differences were measured over a longer period of time (up to1000 h)

Performed tests

16 29 Kiln Shell Corrosion

Paintings: embrittlement occurs at moderate temperatures (e.g. 200C),

loss of adhesion on substrate

Phosphate treatment guarantees no protection against corrosion at high

temperatures. After the ignition tests no phosphate detectable anymore.

Metallic coating: protective effect is good / very good (e.g. Al) but

adhesion on substrate is difficult to maintain

Ceramic coating: high porosity of the ceramic layer leads to corrosion of

the substrate and finally spalling of coating

Spray procedure expensive and time consuming (14 days one layer 5rm,

3,8m ), rough surface difficult to clean from mortar

Results of investigation

17 29 Kiln Shell Corrosion

Fused cast refractories

Zero permeability

Very expensive

Very brittle / low thermal shock resistance

Silica-impregnated alumina bricks (RESISTAL IS)

Reduced open porosity (15-20% less porosity)

Greatly reduced permeability (80-90% less permeability)

Formation of protective reaction layer of alkali silicates at hot face

(reaction sealing)

Refractories with low (zero) permeability

18 29 Kiln Shell Corrosion

What is a sacrifice layer?

Method developed in Mexican cement plants (lamina de

sacrificio)

A sheet of stainless steel between refractory lining and kiln shell

Steel type: 1.4301 (AISI 304), 1.4571 (AISI 316)

Dimension:

(A) 900 mm wide endless coil, 0.38 mm thickness, or

(B) 1.220 x 2.440 mm, 0.79 mm thickness, point welded

Sacrifice layer against kiln shell corrosion

19 29 Kiln Shell Corrosion

900 mm wide

endless coil,

0.38 mm

thickness

Sacrifice layer (A)

20 29 Kiln Shell Corrosion

Type of

steel

used for

sacrifice

layer

Sacrifice layer (A)

21 29 Kiln Shell Corrosion

Cutting pieces

of 2-3 m length

Sacrifice layer (A)

22 29 Kiln Shell Corrosion

Four sheets

ready for

installation

Sacrifice layer (A)

23 29 Kiln Shell Corrosion

SL installed

between

ANKRAL

bricks and the

cleaned kiln

shell

Sacrifice layer (A)

24 29 Kiln Shell Corrosion

Sacrifice layer (A)

25 29 Kiln Shell Corrosion

Plates of

0.79 mm

thickness

are point

welded to

the kiln

shell

Sacrifice layer (B)

26 29 Kiln Shell Corrosion

Sacrifice layer (C)

vertical overlap: 2 5cm

horizontal overlap: 5 20cm

magnets

wooden bar

refractory

bricks

stainless steel sheets

1.4301 / AISI 304

0,40 x 1000mm

lining rig

Stage 1

Stage 2

27 29 Kiln Shell Corrosion

Steel shell with sacrifice layer

(rm 30-35): very light corrosion

Steel shell without sacrifice

layer (rm 52): strong corrosion

Fuel: Combustleo + alternative fuels (PET, tyres, industrial waste)

Effect of sacrifice layer in a PREPOL kiln

4.8 x 75m, 4.800 tpd

28 29 Kiln Shell Corrosion

Davila, J.C. et al., 1995, Influencia del Refractario en la Corrosion de la Coraza del

Horno Rotatorio para Cemento, ALAFAR XXIV Congreso, Cartagena, pp 157-183

Jns, E.S. & stergrd, 1999, Investigation into kiln shell corrosion of rotary cement

kilns, ZKG International, vol. 52, No. 2, pp. 68-79

Jellen, D., 1999, Verringerung der Ofenmantelkorrosion von Drehrohrfen in der

Zementindustrie durch Beschichtungen. Thesis, Montanuniversitt Leoben.

References

29 29 Kiln Shell Corrosion

NNN.*.

Thank you for your attention!

You might also like

- Clinker Cooler SystemDocument69 pagesClinker Cooler SystemzementheadNo ratings yet

- Thermal & Chemical - Kilb 2015Document37 pagesThermal & Chemical - Kilb 2015Moud SaklyNo ratings yet

- Ikn Brochure 2014 HighresDocument28 pagesIkn Brochure 2014 HighresJarrod ClarkNo ratings yet

- 7holcim PDFDocument41 pages7holcim PDFbulentbulut100% (2)

- Rotary Kilns For Cement PlantsDocument6 pagesRotary Kilns For Cement PlantsAngshuman Dutta100% (3)

- Kiln Inlet Lamella Seal FLSDocument2 pagesKiln Inlet Lamella Seal FLSamir100% (3)

- Kiln LiningDocument39 pagesKiln LiningMUNNALURU UMAKANTHA RAO100% (1)

- Cement Kiln ReportDocument22 pagesCement Kiln Reportamir100% (1)

- Cement Kiln DustDocument36 pagesCement Kiln DustjagrutNo ratings yet

- A Better Kiln CoatingDocument2 pagesA Better Kiln Coatingamir100% (4)

- Kiln Inlet Section Casting Procedure (LAFARGE)Document8 pagesKiln Inlet Section Casting Procedure (LAFARGE)Nael100% (3)

- Snowman FormationDocument1 pageSnowman FormationKEERTHI INDUSTRIES100% (1)

- Opening PPE Course 2008Document7 pagesOpening PPE Course 2008vikubhardwaj9224No ratings yet

- Combined PDF Courses Outlines A&E 2011Document47 pagesCombined PDF Courses Outlines A&E 2011emad sabriNo ratings yet

- Kiln Mechanics - (1.1) - ''Basic Notions''Document55 pagesKiln Mechanics - (1.1) - ''Basic Notions''Diego AlejandroNo ratings yet

- K Precalciners1 PDFDocument30 pagesK Precalciners1 PDFKEERTHI INDUSTRIES100% (1)

- Clinker CoolersDocument76 pagesClinker CoolersShariq Khan100% (6)

- New Products - Wirsing 2015Document70 pagesNew Products - Wirsing 2015Moud Sakly100% (1)

- Kiln Emergency Conditions OkDocument30 pagesKiln Emergency Conditions OkmustafNo ratings yet

- The KilnDocument43 pagesThe Kilnraja ghoshNo ratings yet

- Heat correction of kiln cranks is cost effectiveDocument4 pagesHeat correction of kiln cranks is cost effectiveMohamed Shehata100% (2)

- Thermal Expansion Effects and Mechanical Issues for Kiln PatrollersDocument30 pagesThermal Expansion Effects and Mechanical Issues for Kiln Patrollersbulentbulut100% (3)

- Precalciners: Cement Manufacturing Course 2003Document29 pagesPrecalciners: Cement Manufacturing Course 2003Salud Y Sucesos100% (1)

- Cement Manufacturing Performance Report of GC 2007Document12 pagesCement Manufacturing Performance Report of GC 2007stoneblind100% (1)

- Hot Kiln SurveyDocument2 pagesHot Kiln SurveyHenok Moges KassahunNo ratings yet

- 10 Golden Rules For Clinker Burning - INFINITY FOR CEMENT EQUIPMENT PDFDocument15 pages10 Golden Rules For Clinker Burning - INFINITY FOR CEMENT EQUIPMENT PDFNahro AdnanNo ratings yet

- Rueddenklau Snowman PreventionDocument102 pagesRueddenklau Snowman PreventionIonela Dorobantu100% (2)

- V2 Materials Technology 2Document2 pagesV2 Materials Technology 2RRHHNo ratings yet

- CKHC GLOSSARY 2008Document95 pagesCKHC GLOSSARY 2008Tamer Fathy100% (3)

- Classification Wirsing 2015Document49 pagesClassification Wirsing 2015Moud Sakly100% (1)

- Anh hưởng độ mịn xmDocument112 pagesAnh hưởng độ mịn xmBùi Hắc Hải100% (1)

- Clinker Burning Ordonez 2006Document63 pagesClinker Burning Ordonez 2006mustafNo ratings yet

- Cement KilnDocument2 pagesCement Kilnamir100% (2)

- Scenario - Hot Spot On Kiln - Questions - Jan12 FINAL-TABLESSEDocument11 pagesScenario - Hot Spot On Kiln - Questions - Jan12 FINAL-TABLESSEAnonymous 3ESYcrKPNo ratings yet

- Some Questions and Answers of CEMENT Rotary KilnDocument4 pagesSome Questions and Answers of CEMENT Rotary KilnSalud Y SucesosNo ratings yet

- Kiln Mechanics - (2.3) - ''Quizz Photos''Document7 pagesKiln Mechanics - (2.3) - ''Quizz Photos''Diego AlejandroNo ratings yet

- A To ZDocument126 pagesA To ZMohamed Osama RagaaNo ratings yet

- Cement Manufacturing Process Explained in 40 CharactersDocument28 pagesCement Manufacturing Process Explained in 40 CharactersRish-ab KanwarNo ratings yet

- Installation With Mortar - Umlauf 2015Document18 pagesInstallation With Mortar - Umlauf 2015Moud SaklyNo ratings yet

- Kiln Doctor FAQDocument3 pagesKiln Doctor FAQgvrr1954No ratings yet

- VDZDocument28 pagesVDZAnonymous iI88Lt100% (2)

- Plant Process Audits2 PDFDocument38 pagesPlant Process Audits2 PDFvilas bollabathiniNo ratings yet

- Kiln Mechanics 222222Document59 pagesKiln Mechanics 222222Said EL FakkoussiNo ratings yet

- Cement Ball Mill Inspection ProcedureDocument9 pagesCement Ball Mill Inspection ProceduremahantmtechNo ratings yet

- How to quickly handle a kiln hotspotDocument6 pagesHow to quickly handle a kiln hotspotMustafa Ramadan100% (4)

- 031 Introduction Cement Grinding With Ball Mill SystemsDocument4 pages031 Introduction Cement Grinding With Ball Mill SystemsCesar Orlando Guarniz JustinianoNo ratings yet

- Manufacturing Workforce Training - Optimized Kiln Control GuideDocument26 pagesManufacturing Workforce Training - Optimized Kiln Control GuideOUSSAMA LAKHILI100% (1)

- Sulfur Release During Alternative Fuels Combustion in Cement Rotary KilnDocument272 pagesSulfur Release During Alternative Fuels Combustion in Cement Rotary Kilnyinglv100% (1)

- Kiln Axial BalanceDocument10 pagesKiln Axial Balancejoe_frangieh0% (1)

- Raw Meal Susp PDFDocument48 pagesRaw Meal Susp PDFemadsabriNo ratings yet

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Kiln Shell CorrosionDocument29 pagesKiln Shell CorrosionfatamorgganaNo ratings yet

- KünneDocument28 pagesKünneMohd AliNo ratings yet

- CA Silicate & Other Insulation - Surface Dew PointDocument5 pagesCA Silicate & Other Insulation - Surface Dew PointjagrutNo ratings yet

- Non-Ferrous Metals: From Last LectureDocument18 pagesNon-Ferrous Metals: From Last LectureNooruddin SheikNo ratings yet

- Lecture 10Document6 pagesLecture 10Abhijeet BhagavatulaNo ratings yet

- Cement Kiln Refractory Writeup PDFDocument10 pagesCement Kiln Refractory Writeup PDFVijay BhanNo ratings yet

- 4.13.9 Typical Refractories in Industrial UseDocument8 pages4.13.9 Typical Refractories in Industrial UsePalash SwarnakarNo ratings yet

- Blast Furnace BF Refractory Lining PatternDocument5 pagesBlast Furnace BF Refractory Lining PatternSarthakShangariNo ratings yet

- Fire Clay, Alumina, Zirconum, Dina'S Bricks (Raw Material, Manufactoring, Properties Applications)Document11 pagesFire Clay, Alumina, Zirconum, Dina'S Bricks (Raw Material, Manufactoring, Properties Applications)Tokki TokkiNo ratings yet

- Ball Mill OptimizationDocument82 pagesBall Mill OptimizationRashek_119588% (16)

- Safeguards Against Hazards Section 2Document11 pagesSafeguards Against Hazards Section 2NaelNo ratings yet

- Handbook of Crushing PennsylvaniaDocument43 pagesHandbook of Crushing PennsylvaniaAngel Chavez100% (1)

- Brick Lining Installation-Golden RulesDocument34 pagesBrick Lining Installation-Golden RulesNael100% (10)

- Red RiverDocument16 pagesRed RiverNael100% (1)

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Chain KilnsDocument287 pagesChain KilnsNael100% (1)

- Bricks Calculator v.2Document1 pageBricks Calculator v.2Nael100% (4)

- Refractories in Cement ManufacturingDocument24 pagesRefractories in Cement ManufacturingNael91% (23)

- You Must Know This ManDocument4 pagesYou Must Know This ManNaelNo ratings yet

- LubricationDocument123 pagesLubricationNael75% (4)

- Women in The Quran & BibleDocument3 pagesWomen in The Quran & BibleNaelNo ratings yet

- Summary of Raw Grinding System PDFDocument1 pageSummary of Raw Grinding System PDFNaelNo ratings yet

- Cement Rotary Kiln Questions & AnswersDocument37 pagesCement Rotary Kiln Questions & AnswersNael95% (19)

- Mechanism of Clinker Coating Formation & FlameDocument39 pagesMechanism of Clinker Coating Formation & FlameNael93% (14)

- Superior Performance Through Innovative Technology - VEGA IndustriesDocument72 pagesSuperior Performance Through Innovative Technology - VEGA IndustriesNael50% (2)

- Simulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesDocument8 pagesSimulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesNael100% (1)

- Combinations To Form A RingDocument1 pageCombinations To Form A RingNael100% (4)

- Cement Chemistry Handbook - FullerDocument62 pagesCement Chemistry Handbook - FullerNael91% (34)

- Phillips Kiln Tires ServicesDocument53 pagesPhillips Kiln Tires ServicesNael100% (14)

- Combustion Process With Def.Document11 pagesCombustion Process With Def.Suresh VaddeNo ratings yet

- Raw Material Challenges in Cement ProductionDocument12 pagesRaw Material Challenges in Cement Productionm_verma21No ratings yet

- Refractory Lining Installation Guide-RHIDocument40 pagesRefractory Lining Installation Guide-RHINael100% (10)

- Grinding Aids-A Study On Their Mechanism of ActionDocument10 pagesGrinding Aids-A Study On Their Mechanism of ActionNael100% (1)

- CAPL Cement GlossaryDocument15 pagesCAPL Cement GlossaryrefeiiNo ratings yet

- Numerical Prediction of Cyclone Pressure DropDocument5 pagesNumerical Prediction of Cyclone Pressure DropNael100% (1)

- Refractory BricksDocument19 pagesRefractory BricksNael100% (3)

- Material and Energy Balance in Industrial PlantDocument26 pagesMaterial and Energy Balance in Industrial Plantconan45No ratings yet

- How To Control Kiln Shell CorrosionDocument72 pagesHow To Control Kiln Shell CorrosionNael100% (5)

- Rotary Kiln - Refractory Lining InstallationDocument41 pagesRotary Kiln - Refractory Lining InstallationNael94% (16)

- Industrial PharmacyDocument9 pagesIndustrial PharmacyMr nobodyNo ratings yet

- Glass-Fused-To-Steel UAN Liquid Fertilizer Storage SystemsDocument2 pagesGlass-Fused-To-Steel UAN Liquid Fertilizer Storage SystemsYogesh PatilNo ratings yet

- 75 File 1Document2 pages75 File 1Thị Nga VũNo ratings yet

- Doosan PUMA GT3100 CatalogDocument36 pagesDoosan PUMA GT3100 CatalogDmitryNo ratings yet

- MCP101Document9 pagesMCP101Sushant Cr7No ratings yet

- " Ice Jet Machining Process": Bhujbal Knowledge CityDocument9 pages" Ice Jet Machining Process": Bhujbal Knowledge Cityaniket wadheNo ratings yet

- Chapter 7 - Casting ProcessDocument34 pagesChapter 7 - Casting ProcessIjal HaizalNo ratings yet

- Division 6 Woods and Plastic ArchitectureDocument18 pagesDivision 6 Woods and Plastic ArchitectureIssah Jana A. BrevaNo ratings yet

- ESTOP TDS - Estofoam PU300 R01Document2 pagesESTOP TDS - Estofoam PU300 R01Fawwaz IlmiNo ratings yet

- 03 Enzyme KineticsDocument48 pages03 Enzyme KineticsCester Gale DucusinNo ratings yet

- CON1010 AssignmentDocument2 pagesCON1010 AssignmentEd PawliwNo ratings yet

- Photograph Booklet OF European Scale of Rusting FOR Anti-Corrosive PaintsDocument12 pagesPhotograph Booklet OF European Scale of Rusting FOR Anti-Corrosive PaintsElmey Bin JulkeplyNo ratings yet

- TAPPI Doc Material Floor TubesDocument18 pagesTAPPI Doc Material Floor Tubesa_parratNo ratings yet

- Internship Training at HMT Ltd - An IntroductionDocument31 pagesInternship Training at HMT Ltd - An Introductionprajwal bdvtNo ratings yet

- ISO 9692 1 2013 Welding and Allied ProcessesDocument20 pagesISO 9692 1 2013 Welding and Allied Processesluisgonzalezf95No ratings yet

- Mech 90 Final ExamDocument2 pagesMech 90 Final ExamJhay Cee ArabaNo ratings yet

- Gasket Contact Surface FlatnessDocument2 pagesGasket Contact Surface FlatnessSarfaraz KhanNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document5 pagesStructural Steel Plate and Strip To EN 10025Mbalekelwa MpembeNo ratings yet

- IG Cryogenic Gas Relief Valves ASME PRV19430 PRV29430 SeriesDocument5 pagesIG Cryogenic Gas Relief Valves ASME PRV19430 PRV29430 SeriesCimmangNo ratings yet

- Design Standards: SAE J534Document2 pagesDesign Standards: SAE J534alucard3750% (1)

- ECCA Presentation For Architecture Schools (New Template)Document34 pagesECCA Presentation For Architecture Schools (New Template)ridermateNo ratings yet

- Technical Specifications - Coating and Painting Works: 11.1. GENERALDocument6 pagesTechnical Specifications - Coating and Painting Works: 11.1. GENERALVictorVilceanuNo ratings yet

- Corrosion Prevention Pt2Document33 pagesCorrosion Prevention Pt2allanNo ratings yet

- Specification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsDocument7 pagesSpecification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsAnilNo ratings yet

- Fleet Welding Intermediate SMAW Stick Welding V1 05092014Document70 pagesFleet Welding Intermediate SMAW Stick Welding V1 05092014Maxcy LeoNo ratings yet

- Aluminium - Handling, Storage, Maintenance and CleaningDocument7 pagesAluminium - Handling, Storage, Maintenance and CleaningKiran KarthikNo ratings yet

- Arabi Fab Proc F1 Code 1Document23 pagesArabi Fab Proc F1 Code 1DarwishMohamedNo ratings yet

- HW#1Document7 pagesHW#1Kristianne Mae EchavezNo ratings yet

- Flux-Cored Arc WeldingDocument4 pagesFlux-Cored Arc WeldingCarlos BustamanteNo ratings yet

- Tolerances and Resultant Fits - SKF PDFDocument4 pagesTolerances and Resultant Fits - SKF PDFSamNo ratings yet