Professional Documents

Culture Documents

Banki Blade Turbine Calculations 19153

Uploaded by

Juan FernándezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Banki Blade Turbine Calculations 19153

Uploaded by

Juan FernándezCopyright:

Available Formats

Blade calculations for

water turbines

of the Banki type

By

P. Verhaart

March 1983

Department of

Mechanical Engineering

-.-

=

Eindhoven University of Technology

Report WPS3-83.03.R351

BANKI TURBINE BLADE CALCULATIONS

THE BLADE STRENGTH PRODUCT

By P.Verhaart

Department of Mechanical Engineering

Eindhoven University of Technology

9 March 1982

SUMMARY

During the years 1978 and 1979 in Indonesia a number of previously

installed Banki type water turbines developed cracks at the blade

ends near the supports leading to breakage. In order to prevent

recurrence of blade failure a calculation procedure was developed

which can be programmed on a pocket calculator (HP-67). Blades

calculated according to this procedure have so far (early 1982)

behaved well. In this report the method is explained, hoping

thereby to swell the so-far meagre stock of practical design

information on this useful small water turbine.

Introduction

During the years 1977 and 1978 a number of small (8 to 30 kW) Banki

turbines was designed and built in Indonesia under the responsibility of

personel of the Eindhoven University of Technology at the time employed in

a cooperation project with the Bandung Institute of Technology. Not long

after installation cracks developed in the runner blades starting from the

periphery and near the supporting flanges. Further use of the turbine

resulted in breaking of the affected blades. A little later similar

troubles occurred in Nepal where a Swiss team had been developing the same

type of water turbine.

In response to this problem a calculating procedure was developed which is

quite amenable to further refinement but which has, so far as we know,

resulted in longer blade life of existing machines and a better design for

newly produced machines. In this paper, details about the calculation of

the fatigue strength of blades are given.

2 Geometry of the Banki Runner

The runner geometry is best explained with the aid of Fig. 1. From

Banki's article [1] we derive the following ratios:

o = 2r = 6,1236g

1

r

2

= 2,0177g

R = 2,2516g

830321 Banki Turbine Blade Calculations 2

-------

rM

-<

-<

L .J

I

I

I

i

...:I

i

!

!

...

,

L.J

~ - A

FIGURE 1. BANKI RUNNER DIMENSIONS.

The following symbols occur in the figure:

c

D

L

I

n

R

r

velocity of the water from the nozzle

runner outer diameter

total effective blade length

length of a blade section between supports

number of blades

pitch circle radius

outer runner radius

r

2

inner runner radius, locus of the ends of

the skeleton lines of the blades

t

u

w

a

width of channel between two succesive

blades normal to the flow direction

thickness of the blades

peripheral velocity of the runner

relative velocity of the water in a

channel between two succesive blades

angle between absolute water velocity

and peripheral velocity of runner

angle between relative velocity wand

peripheral velocity u

angle of pipe section forming a blade

curvature radius of blade inside surface

pitch of blades on pitch circle

2.1 Constructive Dimensions

mls

m

m

m

m

m

m

m

m

mls

mls

rad

rad

rad

m

m

8\

Some of the dimensions defined above need further clarification.

The total effective blade length L properly is the length of the runner

minus the total thickness of the supporting flanges. It is the length of

blade that actually deflects the water jet and as such it cannot be

represented properly in the drawing.

The blade length between supports 1 is self explanatory. It plays a major

role in this report. The number of supporting disks can be chosen such

2

830321 Banki Turbine Blade Calculations 3

that the bending stress due to hydraulic forces on the blade can be kept

at a safe value.

The number of blades n is also a compromise. From a fluid dynamics point

of view a large number of blades is desirable but in practice only a

limited number can be accomodated due to manufacturing constraints.

The pitch circle radius R is a purely manufacturing parameter. It needs

to be known in order to be able to scribe the slots for the blades on the

supporting disks.

The inner radius r

2

is another constructive dimension. It fixes the

position of the inner ends of the blades on the supporting disks. It is

good practise to drill holes of a diameter equal to the blade thickness t

to obtain well defined end positions for the blade slots in the supporting

disks.

The width of the channel s1 formed by two successive blades is a very

important dimension determining the distributed load on the blades.

The blade thickness t not only has its influence on the bending strength

of the blade, it also decreases the theoretical channel width between

blades. In order to admit a certain volume flow of water the real runner

has a slightly greater length than the theoretical one where no allowance

was made for blade thickness.

The radius of curvature of the inside of the blade Q is needed to scribe

the blade slot outlines on the supporting disks.

The pitch [ is used to set out the n blade slots on the pitch circle.

2.2 Fluid Dynamical Dimensions

The absolute water velocity of the jet c is usually taken to be the

velocity attained by the complete conversion of the head into kinetic

energy using a nozzle efficiency ~ of:

~ = 0,96 ... 0,98

The peripheral velocity of the runner u. With the values of the angles of

entry and relative velocity as set out in Banki's article [1] the ratio:

u/c = 0,484

The relative velocity w of the water in a blade channel at the entry of

the runner normally satisfies the condition that the ratio:

w/c = 0,5546

In the theoretical analysis the relative velocity is not constant

throughout the blade channel.

The angle between the absolute and peripheral velocity a is taken as:

a = 0,2792 rad

or 16 0

The angle between relative velocity and peripheral velocity ~ is taken as:

~ = 0,5236 rad or 30 0

The angle of pipe section forming the blade profile 6 is taken as:

6 = 1,2828 rad

o

or 73,5

3

830321 Banki Turbine Blade Calculations

3 Outline of the Procedure

After a brief description of the quantities that have been taken

into account the relations that are assumed to exist between them are

defined. In the succeeding section the final expression is derived in

detail. The calculator program is described in a separate section.

3.1 Factors of Influence

The components of the load on the blades that were taken into

account in the analysis are the following:

4

a) The hydraulic force, periodic in nature, resulting from the water jet

entering the runner.

b) The centrifugal force, constant at constant angular runner velocity.

The components of the load not taken into account are the following:

c) Torsion resulting from transmission of torque to the output shaft

end.

d) Shear stress resulting from transmission of torque to output shaft

end.

e) Bending moment from the entry of the water jet into the runner.

3.2 Discussion

Component b) in most cases turns out to be insignificant compared

to component a) but was easy to include into the calculator program.

Component c) is of the same magnitude as in the shaft of the runner.

The latter has been designed to withstand the combined stress resulting

from torsion as well as from bending.

Component d) is constant at constant power output and angular velocity.

It is the result of the parallel displacement of the blade supports when

the latter undergo angular displacement as the result of torque

transmission to the shaft. This component was dismissed without thorough

examination. It would add a constant amount of tensional stress near some

of the supporting flanges.

--------- - - ----

-

compression

---------r-'

-

tension

FIGURE 2. FORCES ON A RUNNER.

Component e) results in a periodic tension and compression imposed on the

blades. This, however, is not superimposed upon the hydraulic induced

stress as it occurs a quarter revolution before and after the latter as

can be seen in Fig. 2.

4

830321 Banki Turbine Blade Calculations 5

4 Developing the Strength Product Concept.

The strength product concept enables one to do the fatigue strength

calculation for the blade beforehand as it were. Usually the blades for a

Banki type turbine are made from steel pipe which is sectioned lengthwise.

When the outer diameter and the wall thickness of the pipe with which one

intends to build a Banki runner is known, the strength product can be

calculated. This enables the turbine manufacturer to specify the maximum

head of water for which his turbine is suited. Conversely it gives him

the safe length of blades between supports if the head of water under

which the turbine is going to be used is specified. As steel pipes come

in standardised sizes it is also possible to give a turbine builder a list

of pipe sizes with the associated strength product for each pipe size.

4.1 Assumptions

a) The blades are treated as uniform beams of constant cross section,

fixed at both ends.

b) The hydraulic force of the water jet is treated as a uniformly

distributed centric load along the length of the blades.

4.2 Functional Relations

The well known relation between the uniformly distributed load and

the maximum bending moment states that it is directly proportional to the

magnitude of the distributed load and to the square of the length of the

beam.

M

Wl

2

=

12

( 1 )

where:

M is the bending moment Nm

W ~ s the distributed load N/m

1 is the length of the beam between supports m

A further relation exists between the bending momemt and the flexural

stress:

where:

a =

a

e

I

Me

I

is the flexural stress

is the maximum fibre distance from the

neutral plane in the blade cross section

is the area moment of inertia of the blade

cross section

(2)

m

The distributed load W from (1) with fixed runner geometry is equal to the

force on the concave side of a blade divided by its length. The force on

the concave side of the blade is a result of the change in moment of

momentum of the part of the water jet that enters a blade channel. As the

moment of momentum can be expressed in the square of the relative velocity

of the water on entering the blade channel the distributed load can be

'. ,

5

830321 Banki Turbine Blade Calculations

written in the following form:

where:

2

W = Aw

W

A

w

B

g

Z

2

A(B/(2gZ

is the distributed force along the blade

constant dependent on the geometry

and number of blades

relative velocity in blade channel

geometry dependent proportionality constant

between absolute and relative velocity

acceleration of gravity

head of water

(3 )

N/m

m/s

2

m/s

m

6

Combining (1) and (3) we get a relation between the bending moment and the

head where the bending moment M is directly proportional to the product of

the head Z and the section length 1 to the second power.

(4 )

where:

C is a constant of proportionality

Combining (4) with (2) we obtain an expression for the bending stress a in

terms of the blade geometry quantities (I, e and 1) and the head Z e.g.

a =

2

CZl e

I

The expression can be rearranged as follows:

(5 )

(6)

When from literature or experiment a safe value for the bending stress a

can be found and substituted in the expression (6), it will produce a

maximum value for the head times the square of the blade section length

when the blade quantities e and I are substituted. In this way the safe

section length for given blade dimensions and a given head can be

calculated. The term between brackets on the left of the = sign we call

"Strength product".

4.3 Derivation of the Expressions

4.3.1 Massflow Through a Blade Channel

From inspection of Fig. 1 the mass flow per blade channel ~ s seen

to be:

Qmc

=

Qw

lS

1

W

where:

Qmc

~ s

Q

w

is

the mass flow

the density of water

(7 )

kg/s

kg/m

3

6

830321 Banki Turbine Blade Calculations 7

In order to find an expression in known quantities for s1 we look again at

Fig. 1. We see that the channel width s1 is the projection of the chord

of the arc between two successive intersections of blade skeleton lines

with the runner perimeter.

The arc length 1 is equal to the circumference divided by the number of

a

blades.

where:

n is the number of blades

Now in practice the number of blades is always above 20. When the chord

length is substituted for the arc length a very small error is made. The

angle between the tangent to the concave blade surface at its intersection

with the runner periphery and the tangent to the runner periphery at that

same spot is p. From the figure we see that:

This is without taking into account the blade thickness t. When blade

thickness is taken into account the expression changes into:

lTDsinp

= ------ - t

n

(8)

The channel width s1 is only one of the two dimension of the cross section

of the blade channel. The other is the length of the blade section 1.

The cross sectional area is the product:

A = s 1

1

(9 )

The relative velocity can be found from the velocity triangle, see

Fig. 3.

FIGURE 3. VELOCITY TRIANGLE AT RUNNER ENTRANCE.

From the figure and using the cosine rule we obtain:

222

w = u t C - 2uccoscr

Under design conditions:

u = O,484c

7

830321 Banki Turbine Blade Calculations 8

a = 0,2792 rad

So that, substituting these values in the cosine expression and working it

out, we obtain:

2 2

w = O,3038c

or:

w = O,5511c

Expressing the relative velocity w in the head we obtain:

w = O,7794f(gZ) ( 10)

Combining equations (8), (9) and (10) we get an expression for the volume

flow Q through a blade channel of width s1 and length 1

vc

where:

= O,7794( ------ - t)lf(gZ)

n

is the volume flow per blade channel

3

m /s

To obtain the massflow Q per blade channel the volume flow is multiplied

mc

by the density of water Q . Expressing the massflow per channel section in

w

known quantities and ratios we obtain:

Q

2439 - t)lfZ

mc = , n

( 11)

4.3.2 Torque Transmitted by a Blade Channel

The torque transmitted by a blade channel is the change in moment

of momentum of the massflow passing through a blade channel. At the

entrance the circumferential component c of the absolute velocity is:

u

c = ccosa

u

While the distance from the centre of rotation is r

1

(= 0/2)

At the exit of the blade channel the relative velocity has a radial

direction and thus the circumferential component is equal to the local

runner velocity u

2

:

u =

2

And the radius is r

2

.

Expressing u

2

in c we get:

8

830321 Banki Turbine Blade Calculations

The moment transmitted by a blade channel then becomes:

T = Q c(r

1

cosa-

c mc

2

0,484r

2

-------)

r

1

substituting (11) for Q and the current values for the proportions,

mc

expressing the radii in Q we get:

9,619Q

Tc = 24842,1(--n--- - t)QZI (12)

4.3.3 Point of Application of the Hydraulic Forces

In Fig. 4 we see that the tangential component of the hydraulic

force is assumed to have its point of application at the centre of the

blade arc.

F---_-.-...t.

FIGURE 4. POINT OF APPLICATION OF HYDRAULIC FORCES.

From the figure and with the cosine rule we get:

where:

y

equals 2Qsin(6/4)

m

substituting the current values in the expression gives the result:

r/Q = 2,6236

( 13)

The position of the blade in relation to the tangential force F can be

seen from Fig. 5.

In the triangle formed by r, Rand Q, the centric force Fc works along Q

while the hydraulic force F is perpendicular to r. Thus the angle ~ is

the complement of the included angle ~ between rand Q.

9

9

830321

Banki Turbine Blade Calculations

---------------

---------

FIGURE 5. FORCES ON A BLADE.

Using the cosine rule:

or:

222

r + Q - R

= arccos(---2rg--- )

Using the current values we obtain:

= 1,0049

The angle 1 is then:

1 = U/2 - 1,0049 = 0,5659

o

or 32,4

4.3.4 Distributed Load on a Blade

rad

rad

In Fig. 5 the relation between F and F is clearly seen. As the

c

10

blade can only transmit forces resulting from pressure (and thus normal to

the blade surface) the centric force must apply at the centre of the arc.

If the pressure is not constant along the arc a torsional moment is

superimposed. This latter is not here taken into account. The force F is

therefore the projection of the centric force F :

c

or:

F cos1 = F

c

F

= 1,1847F

( 14)

10

------

y

x

830321 Banki Turbine Blade Calculations

The force F can be found from (12) dividing the torque T by r:

c

F =

T

c

r

Using the current values we obtain:

9,619Q

F = 9468,7(------ - t)Zl

n

And for the centric force normal to the blade F :

c

9,619Q

Fc - 11217,4(--n--- - t)Zl N

Finally, dividing F by the section length 1 we obtain the distributed

c

load W:

( 15)

where:

W is the distributed load N/m

11

In (15) we have an expression for the distributed load on a blade

expressed in properties of the blade e.g. thickness and inside radius of

curvature, in a property of the runner e.g. the number of blades and in a

"condition of employment" e.g. the head.

4.3.5 Area Moment of Inertia of the Blade

In Fig. 6 the simplified shape of the blade cross-section is

shown.

y

------,- --- -----

\

\

FIGURE 6. BLADE CROSS SECTION.

--------

What we need to know is the area moment of inertia in respect to the

neutral plane X-X.

As a direct evaluation of the area moment of inertia with respect to the

X-axis appears to be a rather complicated operation, the indirect method

'1

830321 Banki Turbine Blade Calculations

is employed using Steiner's theorem.

I

x

where:

2

I - Ay

Y

I is the area moment of inertia with respect

x

I

Y

A

y

to the X-axis

is the area moment of inertia with respect

to the Y-axis

1S the cross sectional area of the

blade profile

is the distance of the centre of gravity

of the section from the Y-axis

From Fig. 6 the terms in (16) can be derived:

6t(2g + t)

A = ----------

2

y =

6t(2g + t)

I =

y 8

( 16)

4

m

4

m

2

m

m

The extreme fibre distance from the neutral plane e is found to be:

e = y - gcos(6/2)

Substituting the current values into the above equations we obtain the

following:

A = 0,6414(2g + t)t

y =

(2g + t)t

4 4

I = 0,2231{(g+t) - g }

y

The extreme fibre distance e is:

e =

The area moment of inertia can be written out as follows:

4.3.6 Bending Stress on Blade Section

In this analysis the blade is treated as a beam of constant cross

section, rigidly fixed at both ends (see Fig. 7).

12

12

830321 Banki Turbine Blade Calculations

FIGURE 7. BLADE SECTION AS A RIGIDLY FIXED BEAM.

Adapting the well known equation from applied mechanics for this case we

can write for the bending moment:

2

W{6X(1 - X) - 1 }

M = -----------------

12

where X varies from zero to 1.

The maximum values are found for X = 0 and for X = 1 when:

M =

Nm

( 17)

Which means that the highest values for the bending moment occur near the

ends of the blade sections. The negative sign means that the topside of

the beam near the supports (in Fig. 7) is subjected to tensional stress.

The tensional stress that occurs in the beam can be expressed in known

quantities:

13

substituting W from (15) and rearranging the following expression emerges:

(J = ( 18)

4.3.7 Strength Product

The tensional stress (J occurs in each runner blade once per

revolution. In order to make a safe runner construction the value for (J

has to be chosen according to fatigue strength criteria. As the

alternating load takes place in the presence of water a low fatigue

strength results. Consulting various sources (2], [3], (4], a value:

a =( 22

2

N/mm

for mild steel seems in the correct order of magnitude. When this value

is substituted for a in (18), the expression can be rewritten as follows:

Z12 = 23534,951 /{(9,619Q/n - t)e}

x

( 19)

13

830321 Banki Turbine Blade Calculations 14

This expression gives the safe value of the product of the net head Z

(in m) and the square of the length 1 (in m) of a runner blade section

between supporting discs (if the fatigue stress of 22 N/mm2 is considered

safe) .

In practice runner dimensions are given in mm and the head is given in m.

How does (19) change in that case?

Expressing 1 in mm requires the part to the right of the = sign to be

multiplied by 10

6

.

. . 4 -12

Expresslng I ln mm produces a factor 10

x

Expressing Q, t and e in mm gives a factor 10-

6

in the denominator and thus

10

6

in the numerator.

Adding these powers of 10 together we get exactly zero which means that

4

(19) is also valid for Z in mi 1, Q, t and e in mm and I in mm. This

x

gives manageable figures.

In (18), on the other hand, all powers of 10 cancel out when the above

mentioned quantities (except Z) are expressed in mm and thus 0 remains ln

2

N/m .

NOT E

The expression (19) is not dimensionallY homogenous. In the

numerical coefficients the numerical values of the acceleration of gravity

and the density of water have been used. In the unlikely case of anyone

wishing to rewrite (19) in other units conversion has to start from

equation (10) ..

5 Working with the Strength Product

5.1 Summary of Formulae

1) Strength Product:

Z12 = 23534,95Ix/{(9,619Q/n - t)e} ( 19)

2) Area Moment of Inertia:

3) Maximum Fibre Distance:

e =

With the aid of the above collection of formulae it should not be too

difficult to calculate the strength product, especially if a modern

programmable pocket calculator is used.

5.2 Using the Strength Product

The expression (19) gives the highest value of the product of the

head Z and the square of the section blade length 1 which will keep the

alternating tensional stress in the blade below the value of 22 N/mm2

(which is considered safe for mild steel).

14

830321 Banki Turbine Blade Calculations 15

If the head under which the turbine has to work is known, the safe section

length is easily calculated.

If the head is not known, as in the case of a series production, it is

easy to indicate the maximum permissible head.

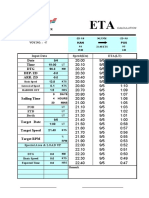

6 HP-67 Calculator Program

As well as the strength product, a number of other useful

calculations was programmed in order to make the fullest use of the

programming memory space available in the HP-67 pocket calculator. In

order to be able to instruct small metal workshops in urban and rural

areas in developing countries, it seemed useful to include the

calculations for all the main dimensions of a Banki runner.

Under the assumption that mild steel pipe is the raw material for the

blades, the program starts after the pipe's wall thickness t (mm) and its

outer diameter d (mm) are entered. From these data all the runner

dimensions as well as the strength product are generated. For the number

of blades a simple rule of thumb has been evolved.

A second part of the program calculates dimensions and the strength

product for other numbers of blades.

A third part of the program calculates the centrifugally induced tensional

stress S in the blades.

c

For a given head Z and blade section length 1 the tensional bending stress

is calculated.

6.1 Number of Blades

The number of blades must be such that the runner can be

fabricated. If the runner has more than two supporting discs, welding will

also have to be done between the blades. It was felt there should be some

direct relation to the diameter of the runner which resulted in the

following relation:

or, expressed in g:

Thus the program can run after the dimensions of the pipe, the blades are

going to be made from, are entered.

6.2 Program Details

The program is available from:

HP User's Program Library Europe

under number:

60954 D, Banki Crossflow Turbine Runner Design.

The addres is:

HEWLET-PACKARD SA.

User's Program Library Europe

7 Rue du Bois-du-Lan

P.O.Box CH-1217 Meyrin 2 GENEVA-SWITSERLAND

15

830321 Banki Turbine Blade Calculations 16

When ordered the program description comes complete with two magnetic

cards, one containing the 220 program steps, the other containing a number

of constants to be entered into the memories.

As the program, at the time it was composed, used a different method to

calculate the distributed load W, the resulting strength product is some

58 % higher than with the calculation method just described. To remedy

this it is sufficient to change the value of the constant that goes into

memory A to:

23534,95 (was 37037,8)

The values that have to be entered into memory registers if no data

card is available are the following:

REG.NR VALUE COMMENT

0 0,6414085 standard value of 6/2

4 0,1633 = Q/D

5 0,3295

A 23534,95 constant for calculating Zl2

I 6,541666667*10-

10

6.2.1 Description

The program consists of 4 parts under the labels A through D.

Part A:

Calculates runner dimensions and Strength Product after entering wall

thickness t and outer diameter d (in that order) of the pipe that will be

used to make the blades.

Part B:

Calculates the new pitch [ and Strength Product when a new value for the

number of blades n is entered.

Part C:

Calculates the bending stress a at the edge of the blades near the

supports resulting from the hydraulic load when the head Z and the blade

section length I are entered.

Part D:

Calculates the bending stress S in the blades resulting from centrifugal

c

forces acting on the blades.

16

830321 Banki Turbine Blade Calculations

6.2.2 User Instructions

STEP INSTRUCTION

Load program card, both sides

Load data card, 1 side only

VARIABLE KEY

1

2

3

4

Enter wall thickness t t (mm) ENTER

Input outer diameter of pipe

d in mm d (mm)

5

6

7

8

Initialize A A

Display runner diameter D R/S

Display number of blades n R/S

Display radius of inner circle

r

2

9 Display radius of pitch circle

R

10 Display pitch r

11 Display strength Product

Z12

For other wall thickness and/or

R/S

R/S

R/S

R/S

other pipe diameter repeat steps 3 ... 11

12 Key in desired number of

blades n

1

13 Initialize B

14 Display Strength Product

Zl2

B

R/S

For other numbers of blades repeat steps 12 ... 14.

Steps 12 ... 14, can be run immediately after step 5.

15

16

17

Enter head Z

Input blade section length 1

Initialize C

Steps 15 ... 17 can be run

immediately after step 5.

18 Initialize D

19 Enter rotational frequency

f (Hz)

20 Input blade section length

1 (mm)

21 Restart program

Z (m) ENTER

1 (mm)

C

D

f (Hz) ENTER

1 (mm)

R/S

Steps 18 ... 21 can be run immediately after step 5.

RESULT

t (mm)

d (mm)

Q (mm)

D (mm)

n (-)

R (mm)

r (mm)

2 2

Zl (m*mm)

n

1

(-)

r (mm)

Z (m)

1 (mm)

r (N/mm2)

54435

f (Hz)

1 (mm)

S (N/mm)

c

17

17

830321 Banki Turbine Blade Calculations

6.2.3 Example

In this example all the possible calculations will be done. This

enables the user to check the program.

The following data are from one of the turbines that broke down.

Head: 5,3 m ; Blades made from pipe of 174,8 mm outside diameter and

4,4 rom wall thickness. The section length was 640 mm.

STEP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

INSTRUCTION VARIABLE KEY

Load program card, both sides

Load data card, 1 side only

Enter wall thickness t in rom 4.4

Input outer diameter of pipe

d in mm 174.8

Initialize A to display Q (mm)

Display runner diameter D (mm)

Display number of blades n

Display radius of inner circle

r

2

(mm)

Display radius of pitch circle

R in mm

Display pitch [ (mm)

Display strength Product

2 2

Zl (m*mm)

Key in desired number of

blades n

1

22

Initialize B for pitch [ (mm)

Display Strength Product

2 2

Zl (m*mm)

Enter head Z (m) 5.3

Input blade section length

I (mm) 640

Initialize C to calculate a (N/mm2)

Initialize D

Enter rotational frequency

f (Hz)

Input blade section length

I (mm)

Restart program to calculate

S (N/mm2)

c

2.97

640

ENTER

A

RIS

RIS

RIS

RIS

RIS

RIS

B

RIS

ENTER

C

D

ENTER

RIS

RESULT

4.4

174.8

83.

508.3

24.

167.5

186.9

48.8

819815.

22.

53.2

742071.

5.

640.

64.

54435.

3.

640.

5.

18

18

0321

STEP

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

028

029

030

031

032

033

034

035

036

037

038

039

040

041

042

043

044

045

046

047

048

049

050

051

052

053

054

055

Banki Turbine Blade Calculations

19

6.2.4 Program Listing

- - . ~ - - - .

KEY KEY COMMENT

ENTRY CODE

f LBL A 31 25 .11

h RAD 35 42

2 02

81

5TO 2 33 02

h x<=>Y 35 52

STO 1 33 01

-

51

STO 3 33 03

RCL 4 34 04

81

STO 6 33 06

RCL 5 34 05

*

71

STO C 33 13

9 x"2 32 54

RCL 3 34 03

-- .. ---.-

9 x"2 32 .54

+ 61

c-.:J

f Vx 31 54

STO D 33 14

"l:)

c:

RCL 6 34 06

cu

h PI 35 73

ar:

*

71

,

N

RCL 6 34 06 ~ L

83

,

c:

1 01

...

,

2 02

c

en

*

71

0. ._,

LLlQ.

RCL 1 34 01

I-

en

+ 61

....

81

0

83

c:

0

5 05

. ~

....

+ 61

cu

~

h CF 1 35 61 01

:::J

u

f LBL 0 31 25 00

~

cu

f INT 31 83

u

STO 7 33 07

h 1/x 35 62

h PI 35 73

*

71

f sin 31 62

RCL D 34 14

*

71

2 02

*

71

STO E 33 15

h F? 1 35 71 01

GTO 2 22 02

RCL 2 34 02

4 04

h y"x

35 63

RCL 3 34 03

4 04

,

- ------

,-..--....... ---..... ---..... ---_ ..... _. ~ . . --_ ..... _-_ .. _-.

STEP KEY

ENTRY

056 h y"x

057 -

058 RCL 0

059 2

060 *

061 ENT

062 f sin

063 +

064 *

065 8

066 :

067 STO 8

068 RCL 2

069 3

070 h y"x

071 RCL 3

072 3

073 h y"x

074 -

075 ENT

076 9 x"2

077 RCL 2

078 9 x"2

079 RCL 3

080 9 x"2

081 -

082 ENT

083 h R"

084 h x<=>y

085 :

086 2

087 *

088 3

089 :

090 RCL 0

091 :

092 RCL 0

093 f sin

094 *

095 h Rv

096 :

097 RCL 0

098 f sin

099 9 x"2

100 *

101 4

102 *

103 9

104 :

105 RCL 0

106 :

107 STO - 8

108 h R"

109 RCL 0

110 f cos

KEY

CODE

35 63

51

34 00

02

71

41

31 62

61

71

08

81

33 08

34 02

03

35 63

34 03

03

35 63

51

41

32 54

34 02

32 54

34 03

32 54

51

41

35 54

35 52

81

02

71

03

81

34 00

81

34 00

31 62

71

35 53

81

34 00

31 62

32 54

71

04

71

09

81

34 00

81

33 51 08

35 54

34 00

31 63

COMMENT

---.--

.,

....

o

(II

....

L

/'-CU

00.

...

"l:)

c:

cu

0-

-4")(

.....

en

0. ....

LLlO

I-

enc:

o

. ~

....

cu

~

:J

u

~

cu

u

~ . - -----

.

i -4" .,

: ...

!.-'+-,

0

, .

, c:

'00 0

! ~ ~

I en ~

i 0. :::J

LLI u

I- ~ .

en cu

u

19

830321

Banki Turbine Blade Calculations 20

. - ~ .-_' .. _._--- ---<--

----- . "- --".

-,

-- ---' ... -- - _.---._-

STEP KEY KEY COIIIfIIIENT STEP KEY KEY CO .... ENT

ENTRY CODE ENTRY CODe

111 RCL 3 34 03

'" -- --- - _ .

166

*

71

112 71

*

N 167 h RTN 35 22

113 51

c

- N -' 168 f LBL D 31 25 14

114 STO 9 33 09

fO"I -II,

.- N 169 RCL 0 34 00

115 f LBL 2 31 25 02

....

170 f cos 31 63

116 RCL 9 34 09

0

11\ 171 RCL 3 34 03

117 h 1/x 35 62

.- c

.- 0 172

*

71

118 RCL 8 34 08

. ~

(I) ..

173 RCL 9 34 09

119

*

71

CL. 1'0

W -' 174 + 61

120 RCL A 34 11

.... ::J

! (I) U 175 ENT 41

121 71

-'

*

; 1'0 176 ENT 41

122 RCL 6 34 06

u

177 RCL 0 34 00

123 h PI 35 73 178 f sin 31 62

._.- -

124

*

71 179

*

71

125 2 02

1oo,J'

180 RCL C 34 13

126

81 I

181 + 61

-_ .. ~ - - -

127 RCL 7 34 07

1J

128 81

c

1'0

182 h x<=>y 35 52

183 RCL 0 34 00

129 RCL 1 34 01 fO"Ia::

130 51

11\

-

.-

,

131 81

N

L

184 f cos 31 63

185

*

71

186 CHS 42

132 STO B 33 12

fO"I

,

133 h F? 1 35 71 01

fO"I c

.-

134 GTO 3 22 03

,

(l)Q

135 RCL 3 34 03

CL.

w

,

136 DSP 1 23 01

.... Ci

(I)

137 RIS 84

138 RCL 6 34 06

>-

1'0

139 RIS

-'

84

Q.

140 DSP 0 23 00

(I)

. ~

141 RCL 7 34 07

Q

......

187 RCL 3 34 03

188 + 61

U

189 9 ->P 32 72

0(1)

N

190 h x<=>y 35 52

N ....

0

191 CHS 42

192 h PI 35 73

a O ~

-0 . ~

193 + 61

.- ..

1'0

194 RCL 0 34 00

(I) -'

CL. ::J

195

-

51

wu

.... -'

196 f cos 31 63

(I) 1'0

u

142 RIS 84

c

143 DSP 1 23 01

..

144 RCL C 34 13

c

41

145 RIS 84

L

41

146 RCL D 34 14

....

....

147 RIS 84

. ~

C01J

148 f LBL 3 31 25 03

11\

.- L

149 RCL E 34 15

0

....

150 RIS 84

04'N

151 RCL B 34 12

11\ C

.- -'

152 DSP 0 23 00

-II

(l)N

153 h RTN 35 22

CL.

w ....

154 f LBL B 31 25 12

.... 0

(I)

155 DSP 1 23 01

c

156 h SF 1 35 51 01

0 ---

. ~

..

,.... t)

157 GTO 0 22 00

1'0

-' -0

158 h RTN 35 22

::J ....

U

....

159 f LBL C 31 25 13

-'

0

1'0

160

9 xA2

32 54

u coc

11\0

161

*

71

.- . ~

..

162 RCL B 34 12

(I) 1'0

CL.-'

163

81

W::J

.... U

164 2 02

(I) -'

1'0

165 2 02

u

197

*

71

198 RCL 2 34 02

199 9 )("2 32 54

200 RCL 3 34 03

201

9 xA2

32 54

202

-

51

203 RCL 0 34 00

204

*

71

205

*

71

206 RIS 84

207

*

71

208 2 02

209

*

71

210 h PI 35 73

211

*

71

212 9 x"2 32 54

213

*

71

214 RCL 9 34 09

215

*

71

216 RCL 8 34 08

217

.

81 .

218 h RC 1 35 34

219

*

71

220 h RTN 35 22

830321 Banki Turbine Blade Calculations

6.3 Bibliography

1. Banki, D. (1918 )

Neue Wasserturbine.

Zeitschrift fuer das Gesamte Turbinenwesen.

Vol. 15 Nr 21 (30 July 1918)

R.Oldenbourg Verlag. Berlin, Munich.

2. Rolfe, S.T., Barson, J.M. (1977)

Fracture and fatigue control in structures

Prentice Hall.

3.Dubbel's Taschenbuch fuer die Maschinenbau (1974)

Springer.

4. Overbeeke, J.L. (1982)

Eindhoven University of Technology

Personal communication.

21

21

830321 Banki Turbine Blade Calculations

6.4 List of Symbols and Units

Symbol

A

A

B

C

D

I

I

x

I

Y

L

M

Qmc

Qvc

R

W

W

Z

c

e

t

u

w

y

[

a

Meaning

constant dependent on the geometry and

number of blades

cross sectional area

geometry dependent proportionality constant

between absolute and relative velocity

constant of proportionality

runner outer diameter

area moment of inertia of the blade

cross section

area moment of inertia with respect

to the X-axis

area moment of inertia with respect

to the Y-axis

total effective blade length

bending moment

mass flow

volume flow per blade channel

pitch circle radius

distributed force along the blade

distributed load

head of water

velocity of water from the nozzle

maximum fibre distance from neutral

plane in blade cross section

acceleration of gravity

length of a blade section between supports

length of the beam between supports

number of blades

inner runner radius, locus of the ends of

the skeleton lines of the blades

width of channel between two succesive

blades normal to the flow direction

thickness of the blades

peripheral velocity of the runner

relative velocity of the water in the

channel between two succesive blades

distance of the centre of gravity

of the section from the Y-axis

pitch of the blades on the pitch circle

angle between absolute water velocity

and peripheral velocity of runner

angle between relative velocity wand

peripheral velocity u

angle of pipe section forming a blade

curvature radius of blade inside surface

density of water

flexural stress

Unit

2

m

m

4

m

4

m

4

m

m

Nm

kgls

3

m Is

m

N/m

N/m

m

m/s

m

2

m/s

m

m

m

m

m

m/s

mls

m

m

rad

rad

rad

m

kg/m

3

N/m2

22

22

You might also like

- Cavitation Tests of Hydraulic Machines - Procedure and InstrumentationDocument12 pagesCavitation Tests of Hydraulic Machines - Procedure and InstrumentationanacatarinabarradasNo ratings yet

- Structural Health MonitoringFrom EverandStructural Health MonitoringDaniel BalageasNo ratings yet

- 1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgDocument13 pages1 Sheet of Calculation (Explanatory Note) See File 625167RR - 01.dwgbanhrangNo ratings yet

- 15-Hydraulic Turbines-New031211 (Compatibility Mode) PDFDocument86 pages15-Hydraulic Turbines-New031211 (Compatibility Mode) PDFMuhammad Noman50% (2)

- Trifurcation Penstock ModellingDocument6 pagesTrifurcation Penstock Modellingmr_yusufsyaroni6332No ratings yet

- Vertical Kaplan Turbines and Governing Equipment SpecificationsDocument24 pagesVertical Kaplan Turbines and Governing Equipment Specificationshangmann169No ratings yet

- Dynamic Analysis - WIPDocument6 pagesDynamic Analysis - WIPSridhar TholasingamNo ratings yet

- Sabarigiri HEP 11 - Chapter 7 PDFDocument81 pagesSabarigiri HEP 11 - Chapter 7 PDFPremkumar Vasudevan100% (1)

- Analyzing Stator Core Vibration and Temperature in a Hydropower GeneratorDocument6 pagesAnalyzing Stator Core Vibration and Temperature in a Hydropower GeneratorSridhar TholasingamNo ratings yet

- Penstock Quality ManagementDocument7 pagesPenstock Quality ManagementaudiihussainNo ratings yet

- Cavitation in Francis PDFDocument373 pagesCavitation in Francis PDFAlberto AliagaNo ratings yet

- Sickle PlateDocument24 pagesSickle PlateStalyn SimbañaNo ratings yet

- Sonapani Mini Hydel Project Generation Data 2009-2013Document4 pagesSonapani Mini Hydel Project Generation Data 2009-2013sienlangphiooNo ratings yet

- Characteristics Curves of Francis TurbineDocument2 pagesCharacteristics Curves of Francis Turbinebhucools0% (1)

- Pelton Turbine1Document8 pagesPelton Turbine1rjrahul25No ratings yet

- Erection of Pelton Turbine Components Step-by-Step GuideDocument91 pagesErection of Pelton Turbine Components Step-by-Step Guidebhanu prasad100% (1)

- L4 Pelton TurbinesDocument26 pagesL4 Pelton TurbinesPera KojotNo ratings yet

- Part 7 Bill of Quantities - Final PDFDocument6 pagesPart 7 Bill of Quantities - Final PDFSujeet JhaNo ratings yet

- Sickle PlateDocument8 pagesSickle PlatepitamberNo ratings yet

- Hydropower Equipment and Generation StatiDocument54 pagesHydropower Equipment and Generation StatiAytac GuvenNo ratings yet

- Lateral Vibration of Hydro Turbine-Generator Rotor With Varying Stiffness of Guide BearingsDocument15 pagesLateral Vibration of Hydro Turbine-Generator Rotor With Varying Stiffness of Guide BearingsstevebensonNo ratings yet

- Strength Calculation of Lifting EyeDocument2 pagesStrength Calculation of Lifting EyeJacky TamNo ratings yet

- Is 7326 1 1992Document15 pagesIs 7326 1 1992Chayan BiswasNo ratings yet

- Impulse and Reaction TurbinesDocument11 pagesImpulse and Reaction TurbinesjoshivishwanathNo ratings yet

- Hydrodynamic Calculation Howell-Bunger ValveDocument31 pagesHydrodynamic Calculation Howell-Bunger ValveEng-CalculationsNo ratings yet

- Improving Concrete Containment Structures Associated With Fixed-Cone ValvesDocument49 pagesImproving Concrete Containment Structures Associated With Fixed-Cone Valvesnb_norooziNo ratings yet

- PS10 Karadzic-Bergant-Vukoslavcevic RevisedDocument15 pagesPS10 Karadzic-Bergant-Vukoslavcevic ReviseduroskNo ratings yet

- Upper Sanjen HEP Penstock OptimizationDocument9 pagesUpper Sanjen HEP Penstock OptimizationJuben BhaukajeeNo ratings yet

- Hydraulicturbines DrtinaDocument19 pagesHydraulicturbines DrtinanazarasimNo ratings yet

- Run Away SpeedDocument15 pagesRun Away SpeedSouravSawNo ratings yet

- Trufin Tubes in Condensing Heat TransferDocument2 pagesTrufin Tubes in Condensing Heat Transfercontactamit_shahNo ratings yet

- Final Report Upper Raghughat - RevisedDocument260 pagesFinal Report Upper Raghughat - RevisedEamNo ratings yet

- Chapter No .4 Steam Nozzle and Turbines. Marks-16Document70 pagesChapter No .4 Steam Nozzle and Turbines. Marks-16AMITH LAWRENCENo ratings yet

- Bifurcation Simulation ANSYSDocument8 pagesBifurcation Simulation ANSYSManjil PuriNo ratings yet

- Advanced Power Generation Course OutlineDocument52 pagesAdvanced Power Generation Course Outlineluter alexNo ratings yet

- General Technical-Parker/fittingsDocument34 pagesGeneral Technical-Parker/fittingsGerri Arceo ManjaresNo ratings yet

- Chapter 7 Hydro-MechanicalDocument14 pagesChapter 7 Hydro-MechanicalSujan Singh100% (1)

- Automizing The Design of Francis Turbine Spiral CaseDocument10 pagesAutomizing The Design of Francis Turbine Spiral CaseGökhan ÇiçekNo ratings yet

- WEG CatalogueDocument8 pagesWEG CatalogueSridhar TholasingamNo ratings yet

- Pelton Wheel Prac1Document15 pagesPelton Wheel Prac1siphyNo ratings yet

- Virtual Model Test For A Francis Turbine: Home Search Collections Journals About Contact Us My IopscienceDocument11 pagesVirtual Model Test For A Francis Turbine: Home Search Collections Journals About Contact Us My Iopsciencecojo_drNo ratings yet

- Kaplan Design TueDocument45 pagesKaplan Design Tuelucas.barravaiteNo ratings yet

- Gasketed Plate Heat Exchangers Equipment DesignDocument8 pagesGasketed Plate Heat Exchangers Equipment DesignAldren Delina RiveraNo ratings yet

- National Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryDocument11 pagesNational Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryBaishnaba KumbharNo ratings yet

- Stability Analysis of Two-Strut Gate Arm Shows Risk of Failure Under LoadsDocument2 pagesStability Analysis of Two-Strut Gate Arm Shows Risk of Failure Under LoadsPaolo AfidchaoNo ratings yet

- Plate Heat Exchanger Design & Application GuideDocument56 pagesPlate Heat Exchanger Design & Application GuidefelitosegundoNo ratings yet

- Major Hydroelectric Plants in IndonesiaDocument7 pagesMajor Hydroelectric Plants in IndonesiaAhmad FikriNo ratings yet

- PumpDocument33 pagesPumppramodtryNo ratings yet

- A Surge TankDocument23 pagesA Surge TankihllhmNo ratings yet

- Narrows II Final Design ReportDocument106 pagesNarrows II Final Design ReportnourooziNo ratings yet

- Gear Design 2Document15 pagesGear Design 2cracking khalifNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Internship Report Khan Khwar BeshamDocument21 pagesInternship Report Khan Khwar BeshamGeologist Fazal ElahiNo ratings yet

- Chapter 4 Heat Exchangers With High-Finned Trufin TubesDocument0 pagesChapter 4 Heat Exchangers With High-Finned Trufin TubesManuel ArroyoNo ratings yet

- Designing High-Strength Steel Hydropower ConduitsDocument4 pagesDesigning High-Strength Steel Hydropower ConduitsPremnath YadavNo ratings yet

- J Heat Transfer 1978 Vol 100 N3Document185 pagesJ Heat Transfer 1978 Vol 100 N3getsweetNo ratings yet

- Is 2825 1969Document286 pagesIs 2825 1969DEEPAK KUMAR MALLICKNo ratings yet

- Blade Calculations For Water Turbines of The Banki Type: Citation For Published Version (APA)Document24 pagesBlade Calculations For Water Turbines of The Banki Type: Citation For Published Version (APA)Anonymous Hy5Ir9QXNo ratings yet

- Design of High Efficiency Cross-Flow Turbine For Hydro-Power PlantDocument4 pagesDesign of High Efficiency Cross-Flow Turbine For Hydro-Power PlantChristopher VergaraNo ratings yet

- Chapter 1Document19 pagesChapter 1Hatem SalahNo ratings yet

- Turbina BankiDocument8 pagesTurbina BankiarielbankiNo ratings yet

- WHAMO Thesis Compiled 12-5Document147 pagesWHAMO Thesis Compiled 12-5Juan Fernández100% (1)

- Screen Capacity PaperDocument44 pagesScreen Capacity PaperJuan FernándezNo ratings yet

- Design Optimization of Crossflow TurbineDocument5 pagesDesign Optimization of Crossflow TurbineIfnu SetyadiNo ratings yet

- 01 Physical Quantities Units 3Document6 pages01 Physical Quantities Units 3hans1395No ratings yet

- Lectures On Theoretical Mechanics - 7 (Rotating Coordinate System: Coriolis Force Etc.)Document6 pagesLectures On Theoretical Mechanics - 7 (Rotating Coordinate System: Coriolis Force Etc.)Abhijit Kar Gupta100% (1)

- Duaso QuizDocument20 pagesDuaso QuizCharchar HernandezNo ratings yet

- M/V HYUNDAI VOYAGER ETA CalculationDocument20 pagesM/V HYUNDAI VOYAGER ETA CalculationPaing Myint Zaw OoNo ratings yet

- Physics 322 AumDocument57 pagesPhysics 322 AumManu ThomasNo ratings yet

- Physics111 Lecture03Document22 pagesPhysics111 Lecture03Juliana MosqueraNo ratings yet

- Fluid Mechanics II: Key Concepts of Fluid KinematicsDocument18 pagesFluid Mechanics II: Key Concepts of Fluid KinematicsYousef FarajNo ratings yet

- Math Prioritize Part 1Document202 pagesMath Prioritize Part 1Vincent Andrew SibalaNo ratings yet

- 19EE5803 UNIT-4 Path Planning: Prepared by S.ChithraDocument49 pages19EE5803 UNIT-4 Path Planning: Prepared by S.ChithraTizon Star100% (1)

- Physical Science Quarter 2 Module 7Document26 pagesPhysical Science Quarter 2 Module 7SHEENA MAE DALGUNTAS100% (3)

- Dimensional Analysis Iseet and Neet Entrance BasedDocument17 pagesDimensional Analysis Iseet and Neet Entrance BasedAnonymous vRpzQ2BLNo ratings yet

- 3 Curvilinear Motion v4Document82 pages3 Curvilinear Motion v4JonathanNo ratings yet

- Grade 7, Quarter 3Document44 pagesGrade 7, Quarter 3James Lacuesta TabioloNo ratings yet

- Graphical analysis of velocity and acceleration over timeDocument2 pagesGraphical analysis of velocity and acceleration over timeChaitanya GaurNo ratings yet

- DP Physics Questions from Chapter 2Document5 pagesDP Physics Questions from Chapter 2Enock KamugishaNo ratings yet

- CH-3 Magnetism (Phy +2)Document97 pagesCH-3 Magnetism (Phy +2)Dinesh KotnalaNo ratings yet

- PSV Closed System Force - Intergraph CADWorx & AnalysisDocument12 pagesPSV Closed System Force - Intergraph CADWorx & Analysist_rajith1179No ratings yet

- Physics 11 ProblemsDocument39 pagesPhysics 11 Problemssmohonto200516No ratings yet

- Module 3 4 Speed and VelocityDocument7 pagesModule 3 4 Speed and VelocityBaby-AnnieAquino-Ventura100% (1)

- Static Force Analysis Mechanisms ToolDocument30 pagesStatic Force Analysis Mechanisms ToolRyan AntonioNo ratings yet

- KS4 Physics IG 2022Document127 pagesKS4 Physics IG 2022Lungten PhuentshoNo ratings yet

- Motion: T (Physics and Earth Science)Document6 pagesMotion: T (Physics and Earth Science)ja ninNo ratings yet

- New Lesson Plan Demo JSDocument10 pagesNew Lesson Plan Demo JSrenantecruz.bascNo ratings yet

- Resisted Motion HSC Questions: Question 4sDocument10 pagesResisted Motion HSC Questions: Question 4sjNo ratings yet

- Class 11 - Physics WorksheetDocument1 pageClass 11 - Physics WorksheetSenthil RajNo ratings yet

- Kinematics Projectile Problems SolvedDocument9 pagesKinematics Projectile Problems SolvedMohammad JubranNo ratings yet

- 2.4-Rotational Mechanical System Transfer Functions: Table 3Document5 pages2.4-Rotational Mechanical System Transfer Functions: Table 3طه حسن شاكر محمودNo ratings yet

- KS4 / Edexcel GCSE Additional Science / Topics P2.9 and P2.10 / Past Exam Questions Nov07Mar08Document11 pagesKS4 / Edexcel GCSE Additional Science / Topics P2.9 and P2.10 / Past Exam Questions Nov07Mar08Paul BurgessNo ratings yet

- DVM 11 Physics FinalDocument3 pagesDVM 11 Physics Finalkirti dubeyNo ratings yet

- Circular Motion - Wikipedia, The Free EncyclopediaDocument9 pagesCircular Motion - Wikipedia, The Free EncyclopediaAkshat TyagiNo ratings yet

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Matrix Methods for Advanced Structural AnalysisFrom EverandMatrix Methods for Advanced Structural AnalysisRating: 5 out of 5 stars5/5 (1)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Offshore Pipelines: Design, Installation, and MaintenanceFrom EverandOffshore Pipelines: Design, Installation, and MaintenanceRating: 4.5 out of 5 stars4.5/5 (2)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareFrom EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareRating: 4.5 out of 5 stars4.5/5 (15)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- Built: The Hidden Stories Behind Our StructuresFrom EverandBuilt: The Hidden Stories Behind Our StructuresRating: 4 out of 5 stars4/5 (27)

- Design and Construction of Soil Anchor PlatesFrom EverandDesign and Construction of Soil Anchor PlatesRating: 5 out of 5 stars5/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesFrom EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraRating: 4.5 out of 5 stars4.5/5 (4)

- Structural Analysis: In Theory and PracticeFrom EverandStructural Analysis: In Theory and PracticeRating: 4.5 out of 5 stars4.5/5 (24)

- Concrete Structures: Repair, Rehabilitation and StrengtheningFrom EverandConcrete Structures: Repair, Rehabilitation and StrengtheningNo ratings yet

- Topology Design Methods for Structural OptimizationFrom EverandTopology Design Methods for Structural OptimizationRating: 2 out of 5 stars2/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Computational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignFrom EverandComputational Rheology for Pipeline and Annular Flow: Non-Newtonian Flow Modeling for Drilling and Production, and Flow Assurance Methods in Subsea Pipeline DesignRating: 3.5 out of 5 stars3.5/5 (2)