Professional Documents

Culture Documents

Mumetal Permimphy Supermimphy Eng

Uploaded by

vsraju2Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mumetal Permimphy Supermimphy Eng

Uploaded by

vsraju2Copyright:

Available Formats

MUMETAL PERMIMPHY

SUPERMIMPHY

Fe-Ni SOFT MAGNETIC ALLOYS

I. INTRODUCTION

Mumetal, Permimphy and Supermimphy are the crystalline soft magnetic alloys with :

the highest permeabilities

the lowest coercive fields

the lowest magnetic losses.

The table below gives their nominal composition in weight % :

Ni Mo Si Mn C Fe

80-

81

4.5-

6

0.05-

0.4

0-

0.5

0.01 balance

II. APPLICATIONS

The principal applications for these alloys are :

High performance magnetic cores, produced as stacked profiled laminations or toroids

(wound tape or stacked rings). The uses of these magnetic cores include measuring

instruments, ground fault circuit breakers and line transformers for computer modems.

Magnetic shielding, to protect certain components and sub-assemblies from disturbance by

extraneous magnetic fields, or for the manufacture of screened chambers, in medical

apparatuses, for example.

In the field of electrical safety, high sensitivity relay components for ground fault circuit

breakers.

Magnetic sensors : reading and recording heads for magnetic tape systems.

Current sensors, with or without a Hall effect probe.

All applications requiring the use of a high permeability magnetic material, with a low coercive

field and low losses, in the range from low frequencies up to 1 MHz.

III. PRODUCT RANGE

Imphy Alloys offers a complete range of Fe-Ni grades centred on the 80% Ni composition. The

alloy chemistries and manufacturing processes have been specially designed to enhance certain

characteristics, depending on the intended application :

Optimum magnetic properties

Ease of fabrication (stampability, drawability, etc.)

Stability of the magnetic properties with temperature

Good stability of the magnetic properties under mechanical loading.

III. 1. MUMETAL

This grade covers the majority of common applications, both for shielding and for magnetic

cores, due to a maximum relative permeability in continuous fields of up to 350 000 and a coercive

field level of 0.6 A/m (typical values measured on 1.5 mm thick strip).

III. 2. PERMIMPHY

This grade, which is obtained using special refining conditions, offers magnetic properties as

high as those of Mumetal together with an excellent aptitude for the large series mechanical stamping

of profiles.

III. 3. SUPERMIMPHY

These grades represent the highest level of magnetic properties.

In the form of finished tape wound cores made from strip less than 0.10 mm (0.004) thick, the

maximum relative impedance permeability at 50 Hz

maxz

reaches 400 000.

There are two Supermimphy grades, a standard alloy Supermimphy L and a Low Stress

version Supermimphy LLS. The chemical composition of the latter alloy is specifically adjusted to limit

the deleterious effect of mechanical stresses occurring in service, after heat treatment. A typical case

is the application of a resin coating to protect components such as current sensors or computer

modem line transformers.

IV. PHYSICAL PROPERTIES

Typical

values

Units

Density

*

Specific heat

*

Thermal conductivity

*

Mean CTE between -50 C and +200 C

Electrical resistivity

*

Curie point

Coefficient of magnetostriction at saturation

*

"

"

Melting temperature

8.7

460

19

12.10

-6

60

420

1-3

1450

g.cm

-3

J.kg

-1

.C

-1

W.m

-1

.C

-1

C

-1

.cm

C

10

-6

C

*

measured at ambient temperature

.

V. FINAL HEAT TREATMENT

The optimum magnetic properties of the Mumetal, Permimphy and Supermimphy grades are

obtained only after high temperature heat treatment of the finished sheets or parts.

The principal aim of this treatment, which is essential, is to recrystallize the material.

The final heat treatment must imperatively be performed under appropriate conditions,

according to the recommendations given below.

V. 1. ATMOSPHERE

Hydrogen, which helps to reduce certain residual impurities, is the best protective atmosphere.

However, cracked ammonia and vacuum are alternative possibilities.

All necessary precautions must be taken to eliminate the risk of contamination, particularly by

oxygen and water vapour. The parts to be treated must be thoroughly cleaned and degreased. The

inert powder (alumina, magnesia) often used to isolate the parts must be perfectly anhydrous.

In all cases, the dew point inside the furnace must be less than 40 C.

In practice, a hydrogen flow rate of the order of 5 volumes/hour is employed, and if necessary,

a holding shelf at around 400C is incorporated in the heating cycle to guarantee that the dew point in

the furnace is correct.

V. 2. TEMPERATURES

Imphy Alloys recommends holding for 2 to 6 hours at 1 100 1 175C. The heating rate has

little influence on the magnetic properties. In contrast, a lower heat treatment temperature will

adversely affect the permeability level.

V. 3. COOLING RATE

The cooling rate determines the degree of short range ordering of the atoms and therefore has

a marked influence on the permeability of the Fe-80% Ni alloys.

In the majority of ordinary cases, simple furnace cooling is sufficient, provided that the cooling

rate is of the order of 100 to 300C/h between 600 and 300C.

However, to optimize certain magnetic properties, such as the initial permeability or the

rectangularity of the hysteresis cycle, or to reduce variations in permeability around ambient

temperature, it may be necessary to accurately adjust the cooling conditions between 600C and

300C.

A good practical solution is to allow the parts to cool slowly in the furnace down to a holding

temperature situated between 400 and 520C, followe d by holding for about 1 hour, then to rapidly

remove them from the furnace in order to finish the treatment with a high cooling rate (of the order of

1000C/h). The value of the holding temperature dep ends on the desired magnetic properties.

Another possibility is to perform a second treatment, typically of 1 hour at about 500C, followed by

rapid quenching (1000C/h), after the initial high temperature treatment (2 to 6 hours at 1 100 1

175C ).

V. 4. OXIDATION TREATMENT

For certain applications, the parts must be covered with a thin layer of oxide (e.g. electrical

insulation of Mumetal profiles).

In this case, during the final stage of the heat treatment, the protective atmosphere is replaced

by an atmosphere with a controlled oxidizing potential (for example, holding in air for 1 hour at about

500C).

V. 5. CUSTOM HEAT TREATMENT

When the magnetic property requirements are particularly demanding, Imphy Alloys can place

its extensive experience in the heat treatment of magnetic alloys at the users disposal. Moreover,

IUPs subsidiary MECAGIS possesses a range of high performance heat treatment equipment

devoted to magnetic alloys, and can perform heat treatments for customers on any parts whose

magnetic properties must be optimized.

VI. MAGNETIC PROPERTIES

The tables below give typical values of the magnetic properties measured after heat treatment, in

compliance with the standards:

- ASTM AS96

- DIN 50560

- IEC 60404

VI. 1. DIRECT CURRENT

Measurements made on 35*26*0.34 mm ring specimens after heat treatment for 4h at 1170C,

followed by cooling at 200C/h.

Grade

Bs (1)

(Tesla)

Br (2)

(Tesla)

Hc (2)

(A/m)

4

(3)

max

Mumetal 0.76 0.5 0.6 120000 350000

Permimphy 0.75 0.45 0.65 150000 320000

Supermimphy L 0.75 0.4 0.35 550000 570000

Supermimphy LLS 0.7 0.23 0.4 285000 300000

(1) practical saturation measured for H = 800 A/m.

(2) remanent induction B

r

and coercive field H

c

measured from H = 80 A/m.

(3) measured for H = 4 mA/cm (peak value)

On massive products : DC measurements made on 24*20*10 mm cores

Grade

Heat treatment Bs (1)

(Tesla)

Hc (2)

(A/m)

zmax

1050C under vacuum 0.73 19 150000

Permimphy

4h 1170C in H2 0.73 10 300000

(1) practical saturation measured for H = 80 A/m.

(2) coercive field H

c

measured from H = 80 A/m.

VI. 2. 50-60 Hz ALTERNATING CURRENT

Measurements made on 36*25*0.34 mm ring specimens after heat treatment for 4h at 1170C,

followed by cooling at 200C/h.

Grade

4z

(1)

zmax

Mumetal 50000 95000

Permimphy 50000 80000

Supermimphy L 70000 95000

Supermimphy LLS 70000 85000

(1) sinusoidal excitation field H = 4 mA/cm (peak value)

Measurements made on 30*20*0.07 mm toroidal cores after heat treatment for 4h at 1170C and

optimum arrest temperature

(1) sinusoidal excitation field H = 4 mA/cm (peak value)

Grade

4z

(1)

zmax

Supermimphy L/LLS 340000 400000

VII. TYPICAL MAGNETIZATION CURVES

applied field (A/m)

DC magnetization curves for Mumetal, Permimphy, Supermimphy L and Supermimphy LLS.

On request, Imphy Alloys can provide customers with the data points corresponding to these curves in

computer format.

VIII. MECHANICAL PROPERTIES

VIII. 1. COLD ROLLED STRIP

The figures given below are typical values, for measurements made in compliance with the standards :

- NF EN 10002 for tensile tests

- EN ISO 6507 for hardness measurements

- NFA 04102 for grain size measurements.

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0 1 2 3 4 5 6 7 8 9 10

champ appliqu (A/m)

Mumetal

Permimphy

Supermimphy L

Supermimphy LLS

Property

Cold worked

condition

Annealed

condition

Finished

parts treated

at 1 170C

Hardness

(HV)

325 160 110

UTS (MPa) 1050 650 530

0.2% PS

(MPa)

1030 280 160

Elongation

(%)

3 35 45

Grain size _ 8 0-3

On request, Imphy Alloys can supply non-standard conditions when required by the customer.

VIII. 2. MASSIVE PRODUCTS

Property

As-hot processed condition

(bars, sheets, forgings)

Hardness (HV) 150 +/- 50

Grain size 4 - 10

On request, Imphy Alloys can supply non-standard conditions when required by the customer.

IX. IMPLEMENTATION

IX. 1. CUTTING AND SHEARING

Cutting operations are generally performed in the cold worked condition.

IX. 2. BENDING, DEEP DRAWING, STRETCHING, LATHE SPINNING, STAMPING

For these forming processes, the metal is used in the softened condition, i.e. after having

received an annealing treatment.

Depending on customer requirements, Imphy Alloys can adapt the softening treatment for

bending or deep drawing operations.

When the annealed metal is subjected to significant plastic strain, work hardening occurs,

whose extent can be estimated from the following table:

Plastic strain

(% reduction in thickness)

10 25 50 75

Hardness (HV) 220 270 300 330

UTS (MPa) 686 834 981 1079

Elongation (%) 25 10 4 2

An intermediate softening treatment may sometimes prove necessary during the forming

sequence.

Imphy Alloys recommends the following procedure : holding for a minimum of 1 hour at 850

900C. It is essential to take all necessary precau tions to prevent contamination of the metal, including

a clean furnace and clean parts and a protective atmosphere with a dew point less than 40C.

IX. 3. MACHINING

The behaviour of Mumetal, Permimphy and Supermimphy differs from that of stainless steels :

they are sticky alloys whose chips tend to adhere to the tool. Relatively slow cutting speeds must

therefore be employed :

Turning

Milling Drilling

Tool

High speed steel High speed steel High speed steel

Lubricant Soluble or whole oil Soluble or whole oil Soluble or whole oil

Cutting angle () 10 10 -

Rake angle () 6 6 6

Cutting speed

(m/minute)

25 25 15

Advance rate (mm/rev) 0.25 - 0.10

The use of a carbide tool enables these cutting speeds to be doubled.

The parts must be thoroughly cleaned after machining to avoid all risk of contamination.

IX. 4. WELDING

The rules for welding Mumetal and Permimphy are similar to those for austenitic stainless

steels.

Imphy Alloys recommends welding without filler metal. Resistance spot welding is by far the

most common technique employed, but electron beam and argon arc welding are also possible.

Welding should normally be carried out before final heat treatment of the parts, even in the

case of spot welding.

IX. 5. BRAZING

It is imperative to perform brazing after the final high temperature heat treatment.

The magnetic properties in the braze zones are usually impaired.

IX. 6. CORROSION RESISTANCE

The corrosion resistance of Mumetal, Permimphy and Supermimphy is better than that of

carbon steels, due to their high nickel content. However, they are not stainless and their oxidation

resistance must be verified in each particular case.

X. AVAILABLE FORMATS

Grade Treated

cores (1)

Treated parts

(1)

Cold rolled strip Long and massive

products (2)

Mumetal

Permimphy

Supermimphy L

Supermimphy LLS

(1): profiles, stacked laminations, rotor and stator sheets, shielding, plates for chemical machining

sold by MECAGIS, a subsidiary of Imphy Ugine Prcision.

(2) : bars, profiled sections, forgings, hot rolled sheets

X. 1. FLAT PRODUCTS

Format

Thickness

(mm)

Maximum width

(mm)

Condition

0.025 to

0.07

300

Cold worked or

annealed

Cold rolled strip delivered in coils

0.07 to 3 640

Cold worked or

annealed

Cold rolled strip delivered as cut-to-length

sheets (maximum length 3500 mm)

0.1 to 3 10 to 640

Cold worked or

annealed

Hot rolled sheets 5 to 50 500 to 2 000

As-rolled and

pickled

Please consult Imphy Alloys for specific requirements.

X. 2. BARS

Diameter (mm) Standard lengths (mm)

13 2000 to 3000

14 80 3000 to 4000

> 80

Dependent on the diameter and the

quantity ordered

Please consult Imphy Alloys for specific requirements.

X. 3. FORGINGS AND CASTINGS

Study on request.

Rf : MAG/Mumtal/UK1 october 07

You might also like

- Modern Magnetic Materials - The ReviewDocument15 pagesModern Magnetic Materials - The ReviewMihaela LostunNo ratings yet

- Magnetic Flux ControllersDocument13 pagesMagnetic Flux ControllersAnonymous hQ0bP5Fg8INo ratings yet

- Nordic Tractor, The: The History and Heritage of Volvo, Valmet and ValtraFrom EverandNordic Tractor, The: The History and Heritage of Volvo, Valmet and ValtraNo ratings yet

- Current Topics in Amorphous Materials: Physics & TechnologyFrom EverandCurrent Topics in Amorphous Materials: Physics & TechnologyY. SakuraiRating: 5 out of 5 stars5/5 (1)

- Structure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsFrom EverandStructure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsNo ratings yet

- Siemens Absolute EncoderDocument4 pagesSiemens Absolute EncoderAditya Pavan VinjamuriNo ratings yet

- RefractoryDocument38 pagesRefractoryDucNo ratings yet

- Designing Transformer Slup265Document30 pagesDesigning Transformer Slup265Sheran ShahidNo ratings yet

- Trask TLT TutorialDocument7 pagesTrask TLT TutorialAnonymous Lf5zuYsNo ratings yet

- Precipitation Hardening in 350 Grade Maraging SteelDocument14 pagesPrecipitation Hardening in 350 Grade Maraging SteelAriel NemcoNo ratings yet

- ENGR 3050 Capacitive Displacement Sensor Lab IntroductionDocument3 pagesENGR 3050 Capacitive Displacement Sensor Lab IntroductionJamesNo ratings yet

- Design Solutions For DC Bias of Multilayer Ceramic Capactiors (MLCCS)Document3 pagesDesign Solutions For DC Bias of Multilayer Ceramic Capactiors (MLCCS)Nikola DulgiarovNo ratings yet

- Soft Magnetic Powder Composites and Potential Applications in Modern Electric Machines and DevicesDocument4 pagesSoft Magnetic Powder Composites and Potential Applications in Modern Electric Machines and DevicesnazaninNo ratings yet

- Transformer Distributed Capacitance PaperDocument9 pagesTransformer Distributed Capacitance PaperdaolmedoNo ratings yet

- Properties of Ferromagnetic Materials PDFDocument9 pagesProperties of Ferromagnetic Materials PDFSäjidëë KisÅnNo ratings yet

- Danes HM A Nesh 2003Document6 pagesDanes HM A Nesh 2003Rina OktapianiNo ratings yet

- Laws Governing Magnetic Circuits PDFDocument2 pagesLaws Governing Magnetic Circuits PDFVenkata SubramanianNo ratings yet

- David K. Ferry - 50 Years in The Semiconductor Underground (2015, Pan Stanford) PDFDocument173 pagesDavid K. Ferry - 50 Years in The Semiconductor Underground (2015, Pan Stanford) PDFpuceiroaleNo ratings yet

- Loop AntennaDocument12 pagesLoop Antennaalkesh.eng100% (1)

- Seminar Report On Magnetic Materials and Application in AutomotiveDocument41 pagesSeminar Report On Magnetic Materials and Application in AutomotiveSarath Nair0% (1)

- Magnets and Their Specifications: MEDER Electronic About MagnetsDocument6 pagesMagnets and Their Specifications: MEDER Electronic About MagnetsKant NautiyalNo ratings yet

- Ee6401 Electrical Machines - IDocument19 pagesEe6401 Electrical Machines - ISindhujaSindhuNo ratings yet

- Chapter.3 Design of Commutator and BrushesDocument10 pagesChapter.3 Design of Commutator and BrushesFernando Rmz100% (1)

- Water Cooled Axial Flux Motor High TorqueDocument7 pagesWater Cooled Axial Flux Motor High TorqueSteven SullivanNo ratings yet

- Muon RutgersDocument19 pagesMuon RutgersAneider Sahedy AnguloNo ratings yet

- Magneto Hydro Dynamic Systems PPT Presentation Way2project inDocument17 pagesMagneto Hydro Dynamic Systems PPT Presentation Way2project in123ramnar100% (1)

- D.V.S. MurthyDocument14 pagesD.V.S. Murthypusd_9040% (5)

- A Fête of Topology: Papers Dedicated to Itiro TamuraFrom EverandA Fête of Topology: Papers Dedicated to Itiro TamuraY. MatsumotoNo ratings yet

- Breakdown in GasesDocument49 pagesBreakdown in GasesQais AlsafasfehNo ratings yet

- Types of MagnetismDocument5 pagesTypes of MagnetismNithish KumarNo ratings yet

- Fluxtrol Resource GuideDocument59 pagesFluxtrol Resource Guidexeron7126No ratings yet

- Philips Mosfet Class AbDocument9 pagesPhilips Mosfet Class AbAnthony Fernandez MendezNo ratings yet

- Induction Heating Process Design Using Comsol Multiphysics Software Version 42aDocument4 pagesInduction Heating Process Design Using Comsol Multiphysics Software Version 42areaktorenergiNo ratings yet

- Design and Simulation of Single Phase Inverter AirconditionerDocument60 pagesDesign and Simulation of Single Phase Inverter AirconditionerAmmar AL IdaneeNo ratings yet

- Lessons in Electronic Circuits VIDocument374 pagesLessons in Electronic Circuits VITugas100% (11)

- S. M. Ryvkin - Physics of P-N Junctions and Semiconductor Devices (1971, Springer US)Document375 pagesS. M. Ryvkin - Physics of P-N Junctions and Semiconductor Devices (1971, Springer US)FreddyNo ratings yet

- SW Radio PDFDocument5 pagesSW Radio PDFAhmed BoubakerNo ratings yet

- Electrical Nad Thermal ConditionDocument20 pagesElectrical Nad Thermal ConditionVexa BatolNo ratings yet

- RadioDesigners Handbook - Ch.5 - TransformersDocument28 pagesRadioDesigners Handbook - Ch.5 - Transformersbatum67No ratings yet

- Numerical Analysis of AC Losses in SuperconductorsDocument6 pagesNumerical Analysis of AC Losses in SuperconductorsRaghbendra TiwariNo ratings yet

- Dynamic Modeling of PMSMDocument10 pagesDynamic Modeling of PMSMHisham Magdi El DeebNo ratings yet

- Row Schott Technical Glasses View 2020-04-14Document80 pagesRow Schott Technical Glasses View 2020-04-14Oleg ChernovNo ratings yet

- 3b Lattice Vibrations PDFDocument25 pages3b Lattice Vibrations PDFAnonymous 7VebQhIM0% (1)

- Capacitive SensorDocument17 pagesCapacitive SensorPaul Jazz Lopez100% (1)

- Mumetal Permimphy Supermimphy EngDocument10 pagesMumetal Permimphy Supermimphy Englemco7777No ratings yet

- Magnetism and Stainless SteelDocument8 pagesMagnetism and Stainless SteelcanakyuzNo ratings yet

- DR Paper 1Document15 pagesDR Paper 1Malik Al TurkiNo ratings yet

- Themenbroschuere Heat TreatmentDocument4 pagesThemenbroschuere Heat TreatmentKaustubh JoshiNo ratings yet

- Data Sheet of Cobalt ChromiumDocument6 pagesData Sheet of Cobalt ChromiumDeva RajNo ratings yet

- Thermal Stability and Performance Data For Sm-Co 2 17 High-TemperatureDocument4 pagesThermal Stability and Performance Data For Sm-Co 2 17 High-TemperatureelectronenergyNo ratings yet

- IntroductiontosmaDocument2 pagesIntroductiontosmaJulian JayNo ratings yet

- Perminent MegnatDocument3 pagesPerminent MegnatsasimtechNo ratings yet

- Induction FurnaceDocument0 pagesInduction Furnaceshaishav upadhyayNo ratings yet

- How To Write A Scientific Review Article - Enago AcademyDocument2 pagesHow To Write A Scientific Review Article - Enago Academyvsraju2No ratings yet

- Writing A Scientific Research Article: Format For The Paper Edit Your Paper! Useful BooksDocument33 pagesWriting A Scientific Research Article: Format For The Paper Edit Your Paper! Useful Booksvsraju2No ratings yet

- Magnetic Electric Properties and Hardness of 17-4Document8 pagesMagnetic Electric Properties and Hardness of 17-4vsraju2No ratings yet

- How To Write A Superb Literature ReviewDocument3 pagesHow To Write A Superb Literature Reviewvsraju2100% (1)

- Choosing A Journal - Publishing in The Sciences - Research Guides at University of Michigan LibraryDocument6 pagesChoosing A Journal - Publishing in The Sciences - Research Guides at University of Michigan Libraryvsraju2No ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material Specificationvsraju2No ratings yet

- Writing A Scientific Research ArticleDocument6 pagesWriting A Scientific Research ArticleUmi KalsumNo ratings yet

- What's The Difference Between Metal 3D Printing Processes - Machine DesignDocument15 pagesWhat's The Difference Between Metal 3D Printing Processes - Machine Designvsraju2No ratings yet

- EMR ReviewDocument43 pagesEMR Reviewvsraju2No ratings yet

- Aerospace Material Specification: Copper-Beryllium Alloy, Bars and Rods 98cu - 1.9be (CDA 172) Hard Temper (TD04)Document7 pagesAerospace Material Specification: Copper-Beryllium Alloy, Bars and Rods 98cu - 1.9be (CDA 172) Hard Temper (TD04)vsraju2No ratings yet

- Unit 1 Introduction To Research in General: 1.0 ObjectivesDocument44 pagesUnit 1 Introduction To Research in General: 1.0 Objectivesvsraju2No ratings yet

- Aerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress RelievedDocument9 pagesAerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress Relievedvsraju2No ratings yet

- Aerospace Material Specification: AMS5410 Rev. BDocument11 pagesAerospace Material Specification: AMS5410 Rev. Bvsraju2No ratings yet

- 3D Metal Printing Technology - Main2Document1 page3D Metal Printing Technology - Main2vsraju2No ratings yet

- Nasa STD 5020a - W CHG - 1Document114 pagesNasa STD 5020a - W CHG - 1Péricles Ferreira LeiteNo ratings yet

- 3D Printing PDFDocument6 pages3D Printing PDFRINTU STEPHENNo ratings yet

- Irjet V7i2660Document3 pagesIrjet V7i2660vsraju2No ratings yet

- The Best Metal 3D Printers in 2020Document22 pagesThe Best Metal 3D Printers in 2020vsraju2No ratings yet

- Dell WorkstationDocument8 pagesDell Workstationvsraju2No ratings yet

- 3.5 - Problems With The Square of Opposition - Humanities LibertextsDocument3 pages3.5 - Problems With The Square of Opposition - Humanities Libertextsvsraju2No ratings yet

- Online Shopping Study: 2019 REPORTDocument28 pagesOnline Shopping Study: 2019 REPORTvsraju2No ratings yet

- 1 s2.0 S2351978919308169 MainDocument11 pages1 s2.0 S2351978919308169 Maindhanalakshmi k sNo ratings yet

- Papers: Online Market Research: Methods, Benefi Ts and Issues - Part 1Document13 pagesPapers: Online Market Research: Methods, Benefi Ts and Issues - Part 1vsraju2No ratings yet

- Fulltext01 PDFDocument11 pagesFulltext01 PDFvsraju2No ratings yet

- Wear2 PDFDocument11 pagesWear2 PDFvsraju2No ratings yet

- 3D Printing PDFDocument6 pages3D Printing PDFRINTU STEPHENNo ratings yet

- Electrical Properties of Carbon Nanotube Based Fibers and Their Future Use in Electrical WiringDocument22 pagesElectrical Properties of Carbon Nanotube Based Fibers and Their Future Use in Electrical Wiringvsraju2No ratings yet

- Home About Us Administration Programmes Admission Photo Gallery Contact UsDocument6 pagesHome About Us Administration Programmes Admission Photo Gallery Contact Usvsraju2No ratings yet

- Mit PDFDocument70 pagesMit PDFvsraju2No ratings yet

- Wear3 PDFDocument8 pagesWear3 PDFvsraju2No ratings yet

- DHA - Jebel Ali Emergency Centre + RevisedDocument5 pagesDHA - Jebel Ali Emergency Centre + RevisedJam EsNo ratings yet

- FINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Document45 pagesFINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Edmar Cielo SarmientoNo ratings yet

- 1Document2 pages1TrầnLanNo ratings yet

- Microsoft Powerpoint BasicsDocument20 pagesMicrosoft Powerpoint BasicsJonathan LocsinNo ratings yet

- Army Aviation Digest - Apr 1971Document68 pagesArmy Aviation Digest - Apr 1971Aviation/Space History LibraryNo ratings yet

- APJ Abdul Kalam Success StoryDocument1 pageAPJ Abdul Kalam Success StorySanjaiNo ratings yet

- MEMORANDUM OF AGREEMENT DraftsDocument3 pagesMEMORANDUM OF AGREEMENT DraftsRichard Colunga80% (5)

- Porter's 5-Force Analysis of ToyotaDocument9 pagesPorter's 5-Force Analysis of ToyotaBiju MathewsNo ratings yet

- Operating Instructions: Rotary Lobe PumpDocument77 pagesOperating Instructions: Rotary Lobe PumpRuslan SlusarNo ratings yet

- Lecture 19 Code Standards and ReviewDocument27 pagesLecture 19 Code Standards and ReviewAdhil Ashik vNo ratings yet

- Rapp 2011 TEREOS GBDocument58 pagesRapp 2011 TEREOS GBNeda PazaninNo ratings yet

- PathologyDocument31 pagesPathologyStudy Usmle100% (1)

- Celula de CargaDocument2 pagesCelula de CargaDavid PaezNo ratings yet

- The One With The ThumbDocument4 pagesThe One With The Thumbnoelia20_09No ratings yet

- Overlay Control PlansDocument1 pageOverlay Control PlansSTS-SPARK GAMINGNo ratings yet

- Acute Suppurative Otitis MediaDocument41 pagesAcute Suppurative Otitis Mediarani suwadjiNo ratings yet

- PDF BrochureDocument50 pagesPDF BrochureAnees RanaNo ratings yet

- TechBridge TCP ServiceNow Business Case - Group 6Document9 pagesTechBridge TCP ServiceNow Business Case - Group 6Takiyah Shealy100% (1)

- API RP 7C-11F Installation, Maintenance and Operation of Internal Combustion Engines.Document3 pagesAPI RP 7C-11F Installation, Maintenance and Operation of Internal Combustion Engines.Rashid Ghani100% (1)

- FIREBASE Edited PresentationDocument12 pagesFIREBASE Edited PresentationNiraj MirgalNo ratings yet

- Asus x453Document5 pagesAsus x453Rhiry Ntuh AthryNo ratings yet

- VRARAIDocument12 pagesVRARAIraquel mallannnaoNo ratings yet

- LU 5.1 ElectrochemistryDocument32 pagesLU 5.1 ElectrochemistryNurAkila Mohd YasirNo ratings yet

- Dynamic Study of Parabolic Cylindrical Shell A Parametric StudyDocument4 pagesDynamic Study of Parabolic Cylindrical Shell A Parametric StudyEditor IJTSRDNo ratings yet

- The DIRKS Methodology: A User GuideDocument285 pagesThe DIRKS Methodology: A User GuideJesus Frontera100% (2)

- Power System Protection (Vol 3 - Application) PDFDocument479 pagesPower System Protection (Vol 3 - Application) PDFAdetunji TaiwoNo ratings yet

- TransistorsDocument21 pagesTransistorsAhmad AzriNo ratings yet

- Norman, K. R., Pali Philology & The Study of BuddhismDocument13 pagesNorman, K. R., Pali Philology & The Study of BuddhismkhrinizNo ratings yet

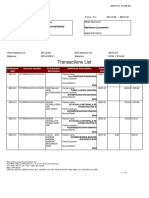

- Transactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinDocument12 pagesTransactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinConstantin MarilenaNo ratings yet

- Assignment November11 KylaAccountingDocument2 pagesAssignment November11 KylaAccountingADRIANO, Glecy C.No ratings yet