Professional Documents

Culture Documents

A-60 - Marine March

Uploaded by

nafarroa77Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A-60 - Marine March

Uploaded by

nafarroa77Copyright:

Available Formats

March 2006

A-60 Marine Fire Dampers

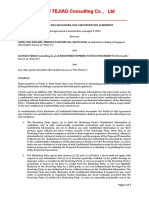

Tests and Approvals A60 Fire Rated. Lloyds Register of Shipping Approved. Marine Equipment Directive compliant. USCG Approved. Germanischer Lloyds Approved. American Bureau of Shipping Approved. Corrosion Tested. Vibration Tested. Features Lightweight, cost effective design. Rectangular and Circular Flanged casings. Galvanised and 316 Stainless steel casing options. 430 stainless steel and 316 stainless steel blade options. Electrical actuator option ~ 60 second reset time. Unique and patented Electrical Thermal Release for ultimate safety Healthy indication light when fully functional Multi-position mounting. Pneumatic actuator option ~ 3 second reset time Pneumatic Thermal release Solenoid options Status beacon/switchbox options.

Actionair A-60 Marine Fire Damper

Designed for inclusion in Marine and Offshore Projects

YY denotes last two digits of year that Wheelmark is affixed to damper.

Dampers Designed and Built in UK

www.actionair.co.uk

A-60 Marine Fire Dampers

Introduction

Actionair has, for many years, been associated in the design, development and manufacture of life safety equipment, including the supply of fire damper products to the offshore and marine industry. The Actionair A-60 Fire Damper has been specifically engineered to meet stringent legislation. The A-60 Marine Fire Damper compliments the comprehensive range of automatic fire and smoke dampers and associated controls, provides the complete solution for shipboard air conditioning and ventilation systems fire safety engineering strategies. The A-60 Marine Fire Damper has been designed for inclusion in air conditioning and ventilation systems and is tested and approved for fitting to class A-60 divisions (bulkheads and decks), when suitably insulated (refer to insulation details).

Specification

The Actionair A-60 Marine Fire Damper is constructed from galvanised steel 1.2mm thick, 40mm flanged rectangular or circular casing, (316 stainless steel option available). 75mm interlocking 430 grade stainless steel aerodynamic blades, steel blade end bearings and 300 grade stainless steel peripheral gasketting. (316 grade stainless steel blade and blade end bearing available). The totally enclosed precise movement opposed blade drive is positioned out of the airstream for protection against damage, and is hard wearing and free running. Electrical The Actionair direct-coupled spring return fail-safe electrical control modes are fitted with halogen free low smoke and fume electrical cable. They have a 60 second reset time and a 20 second release time. Each actuator has a 72C rated electrical thermal release (ETR). The ETR incorporates a safety electrical interlock that only permits actuator operation when correctly fitted. A green Healthy indication lamp is built into the ETR housing to give a simple and clear visual check that the actuator is receiving power, the ETR is correctly fitted, and the thermal fuse is intact. A manual test switch allowing periodic operation of the damper for testing purposes simulates actual fail-safe release under smoke/fire conditions. End switches are provided with each mode for reset and release monitoring. Pneumatic The Actionair direct coupled spring return fail-safe pneumatic control mode requires an air pressure of between 5 to 8 bar (72 to116 psi) to operate. They have 3 second reset and release time. Each actuator has a pneumatic thermal release (PTR). The PTR assembly is supplied with 500mm nylon tubing that connects to the quick fit couplings of the PTR and actuator. Incorporated is a failsafe 74C fusible link. When this operates, air exhausts from the actuator, permitting the spring return actuator to go to the failsafe position, thus closing the damper. Switch box and solenoid accessories are available for monitoring and control. Approval list Lloyds Register of Shipping Approval to IMO Fire Test Procedures Code, Annex 1, part 3, for Class A60 bulkheads and decks. Marine Equipment Directive 96 /98 /EC. USCG approved (product category 164.139). Germanischer Lloyds Approved to IMO Res. A.754. (18) and IMO Res. MSC61(67), Annex 1 Part 3. American Bureau of Shipping Approved to: 2005 Steel Vessel Rules 1-1-4/7.7. Please note maximum size restrictions - see page 3. All certificates are available via the Actionair website. www.actionair.co.uk

Range and Application

The A-60 dampers can be used where the maximum system pressure is up to 1500 Pa and duct velocities to 15m/s. A-60 Marine Fire Dampers are designed for applications in normal dry filtered air systems and should be subjected to a planned inspection programme, with cleaning and light oil lubrication in accordance with good industry practice. When exposed to fresh air intakes and/or inclement conditions please refer to Actionair Technical Sales Office. The A-60 Marine Fire Damper is suitable for both vertical and horizontal applications, with airflow in either direction. The dampers are normally open, and fail-safe to the closed position. Electrical ETR Pneumatic PTR

Fail-safe is by means of a unique and patented Electrical Thermal Release (ETR) which operates at 72 C, or if power supply is interrupted. The ETR incorporates a safety feature, that ensures the fail-safe status of the damper if the ETR is not fitted on to the ductwork. Additionally a green LED lamp is built into the ETR housing. This gives the user a simple and clear visual check that the Actuator is receiving power, the ETR is correctly fitted, and the thermal fuse is intact. A manual test switch allows periodic operation of the damper for testing purposes, simulating actual fail-safe release under fire conditions. The associated electrical control modes are available in 24 Volt, 120 Volt or 230 Volt versions.

The special purpose design Pneumatic Thermal Release (PTR) assembly is supplied with 500mm nylon tubing that connects to the quick fit couplings of the PTR and actuator. Incorporated is a failsafe 74C fusible link. When this activates, air exhausts from the actuator, enabling the PTR to spring return to the fail-safe position, thus closing the damper.

www.actionair.co.uk

A-60 Marine Fire Dampers

Insulation Details

Bulkhead (Vertical)

STRUCTURAL STEEL CORE 75

Deck (Horizontal)

COAMING

300 150 40

See Below

*

See Below

50

DAMPER

COAMING

See Below CONNECTION OF DAMPER TO COAMING

225

25

40

40 CONNECTION OF DAMPER TO COAMING MINERAL FIBRE INSULATION (110Kg PER CUBIC METRE) 50

25 DAMPER 40

* Table of Minimum Total Coaming Insulation Length (Applies to all approval bodies)

Application Vertical bulkhead up to 750 x 750 (0.5625msq) Vertical bulkhead above 0.5625 msq Horizontal deck up to 750 x 750 (0.5625msq) Insulation Thickness 75mm 40mm 75mm Minimum Total Insulation Length 725mm refer to graph below 725mm refer to graph below 725mm

Horizontal deck above 0.5625 msq Horizontal deck (all sizes)

The same area/insulation criteria applies for multiple arrangements

Graph Showing Minimum Insulation length for Damper above 750mm x 750mm Base Damper (Applies to all approval bodies with the exception of ABS)

1100 1050

Coaming Insulation Example For a damper size of 910mm x 925mm. Area = 0.85 msq Vertical Installation Insulation Thickness = 75mm (line 2 of table) Insulation Length = 975mm (refer to graph) Horizontal Installation Insulation Thickness = 40mm Insulation Length = 975mm Insulation Thickness = 75mm Insulation Length = 725mm

0.5 0.55 0.6 0.65 0.7 0.8 0.85 0.9 0.95

1

Total Insulation length (mm)

1000 950 900 850 800 750 700

(line 4 of table) (refer to graph) (line 5 of table) (line 5 of table)

Area (msq) Note: for circular, use square base damper area.

www.actionair.co.uk

150

A-60 Marine Fire Dampers

Testing

The Actionair A60 marine fire damper has undergone extensive fire testing in single and multiple arrangements. The dampers were incorporated in steel bulkheads and decks and tested to the Marine Fire Resistance Test in accordance with IMO resolution A754. (18) for a duration of 60 minutes. Changes to the originally supplied product may invalidate the certification and/or warranty. Certification EC Type Examination (Module B) Certificate. EC (Module D) Certificate of Conformity. Certificate of Fire Approval. Germanischer Lloyds Fire Certification. ABS Approved. ISO 9001; 2000 Certification. Corrosion Tested to BSEN 60068-2-52, severity 2 conditions. Vibration Tested to BS EN 60068-2-6 (5Hz to 350Hz @ 2g). All Certification and Test Reports are available by contacting the Actionair Sales Office. Changes / modifications to the original supplied product may invalidate certification and/or warranty.

Casing Features

The standard 1.2mm galvanised steel flanged type casing, having a single penetration for the drive control, complies to Class A & B of Eurovent 2/2 and Test Procedures for Classes A, B ,& C of the HVCA Ductwork Specification DW144. Pre-punched bolt holes are provided as standard (refer to page 7 and 8). In addition Stainless Steel peripheral gasketing is included, which allows for expansion under full fire conditions. The 1.2mm casing has obvious benefits, for example being lighter in weight, allowing easier installation. Casings manufactured in Type 1.4401 (316 grade) Austenitic Stainless Steel are available as an optional extra.

www.actionair.co.uk

A-60 Marine Fire Dampers

Blade Features

The damper blades are aerodynamic double skin, type 1.4016 (430 grade) Ferritic Stainless Steel, which are 75mm wide and when closed interlock to form a positive fire resisting shield. Incorporated in the blade are steel blade end bearings. Optional blades in Type 1.4401 (316 grade) Austenitic Stainless can be provided. Incorporated in the blade are 316 Stainless Steel blade end bearings.

Optional Silicon blade seals can be provided for low leakage requirement at ambient temperature.

41.5 12.7 75

Control Modes

The IP54 rated Control Modes, are located outside of the ductwork for ease of access and installation. Control Modes fitted to dampers up to 400mm high, can be fitted in any one of three orientations i.e. vertically down, horizontally or vertically up. Positions 1, 2, or 3). Two sizes (Compact and Universal) of Control Mode are utilised. This flexibility ensures that the smaller damper sizes and Control Mode require the minimal amount of room. For damper sizes above 400mm high the control mode is fitted vertically. Correctly sized Control Modes are designed to fit only to the relevant sized damper. The control modes are direct coupled to the damper utilising a unique user friendly positive connection system. This allows the dampers and actuators to be supplied separately, offering shipping and storage benefits. Control Mode Standard Parameters

1000

DAMPER DRIVE SHAFT

MOUNTING PLATE

ADAPTOR PLATE

150

85 Position 3

Position 2

LABEL SIDE

Position 1 30 100

Fig.1 Three Position Compact

150

123

Position 3

Position 2 248 Position 1 100

LABEL SIDE

Fig.2 Three Position Universal

150

DAMPER HEIGHT 400

Single Position Universal Fig. 3

LABEL SIDE

Three Position Compact Fig. 1

Three Position Universal Fig. 2

100

100

100

400 DAMPER WIDTH

1000

Fig. 3 Single Position Universal

1 Position Actuator

www.actionair.co.uk

248

155

A-60 Marine Fire Dampers

Application and Wiring

Control Mode 5 24V A.C. or D.C. Control Mode 6 230V A.C. 50/60Hz Control Mode 120 120V A.C. 50/60Hz Power On Damper motors open. Power Off Damper springs closed. ETR Operates Damper springs closed. Release Time 20 seconds. Reset Time less than 60 seconds. 8W (Maximum Motoring) 3W (Maximum Reset). End Switches Rated at 250V 1.5 Amp (Maximum). Mode 5 24V System

SUPPLY 24V A.C. or D.C. TYPICALLY 7W (MOTORING) 2W (RESET)

BLACK

1 2

M

WHITE

1 2 3 A.C. 250V 6(3)A 4 5 6 ELECTRICAL THERMAL RELEASE (MUST BE FITTED FOR DAMPER OPERATION). (SPRING BIASED TEST SWITCH) DIAGRAM SHOWS ACTUATOR IN FULLY RELEASED STATE CONTACT MADE BETWEEN 4 AND 6 WHEN DAMPER FULLY RESET CONTACT MADE BETWEEN 1 AND 2 WHEN DAMPER FULLY RELEASED

To isolate from main power supply, the system must incorporate a device, which disconnects the phase conductors, with at least 3mm contact gap. 2 x 1 metre of halogen free, low smoke and fume electric cables are included with each control mode. The ETR is also prewired with 0.5 metre halogen free low smoke and fume cable.

TF 72 C

Mode 6 230V System

N L1 SUPPLY 230V A.C.50/60 Hz TYPICALLY 8W (MOTORING) 3W (RESET

BLUE

M

BROWN

1 2 3 4 A.C. 250V 6(3)A 5 6 ELECTRICAL THERMAL RELEASE (MUST BE FITTED FOR DAMPER OPERATION). (SPRING BIASED TEST SWITCH) DIAGRAM SHOWS ACTUATOR IN FULLY RELEASED STATE CONTACT MADE BETWEEN 4 AND 6 WHEN DAMPER FULLY RESET CONTACT MADE BETWEEN 1 AND 2 WHEN DAMPER FULLY RELEASED

TF 72 C

Pneumatic Operation Air On Damper opens. Air Off Spring closure. Release time 2 4 secs. Reset time 2 4 secs. Air inlet 6mm dia. quick fit coupling. 74 C Pneumatic Thermal Release (PTR). Air consumption to reset @ 5.5 bar 535 cc. External mechanical position indicator. Test operation by removing fusible link element.

www.actionair.co.uk

A-60 Marine Fire Dampers

All dimension are in millimetres

Dimensional Data

Pneumatic Spring Return Actuator

55 59 CABLE ENTRY POINTS

*SWITCHBOX / STATUS BEACON

222

Pneumatic Thermal Release (PTR)

4mm Dia. 500mm long connection to actuator.

255

160 INPUT: 6mm Dia. Quick release connector, pressure range 5 8 Bar.

115

95

102

*SOLENOID *Optional Extras

Square and Rectangular (A-60 RECT)

150 50 MIN 75 MAX 150 150 150 MIN 75 MAX 150 230 40

Circular (A-60 CIRC)

DAMPER DIA 100 -1000 40

20

DAMPER WIDTH* 100 - 1000

40

DAMPER DIA 100 -1000

40

40

20

DAMPER HEIGHT 100 -1000

Circular Damper Fixing Hole Details

Electrical Actuator

25 56 8

Pneumatic Actuator

25

8

Damper Dia. No. of Holes 100 - 250 251 - 500 501 - 750 751 - 1000 4 off 8 off 12 off 16 off

Hole Dia. 7.0 10.0 12.0 12.0

150

100

150

78

40

MINIMUM REMOVAL DIMENSION 90mm

78

14

40

MINIMUM REMOVAL DIMENSION 300mm

PLAN VIEW CROSS SECTION SHOWING CONTROL MODE DIMENSIONS

www.actionair.co.uk

A-60 Marine Fire Dampers

Multiple Assemblies

DAMPER WIDTH 1580 Maximum

Multiple width assemblies (2 x 1) have been tested and approved to a size of 1580mm wide x 750mm high.

50 TOP

DAMPER HEIGHT 750 Maximum

MOTOR

MOTOR

12mm DIA. HOLES IN EACH CORNER AND EQUALLY SPACED AT 150mm MAX. CENTRES BOTH SIDES OF FLANGES ON EACH INDIVIDUAL DAMPER 20 40 FLANGE ALL AROUND 1.2 STEEL x 75mm WIDE JOINING STRIP. (BOTH SIDES) RIVETTED WITH 3.2mm STEEL RIVETS AT 100mm CENTRES, ON SITE BY OTHERS

150

Weights

Calculated Weights (Kg) of A-60 Rectangular (Excluding Actuator) 100 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 3.8 4.1 4.4 5.0 5.7 6.0 6.6 7.3 7.6 8.2 8.9 9.2 9.9 150 4.2 4.5 4.8 5.4 6.1 6.4 7.0 7.7 8.0 8.6 9.3 9.6 10.3 200 4.6 4.9 5.2 5.8 6.5 6.7 7.4 8.1 8.4 9.0 9.7 250 5.1 5.3 5.6 6.3 7.0 7.3 8.0 8.7 9.0 9.7 10.4 300 350 400 5.5 5.8 6.1 6.8 7.5 7.8 8.6 9.3 9.6 6.0 6.3 6.5 7.3 8.1 8.3 9.1 9.9 6.4 6.7 7.0 7.8 8.6 8.9 9.7 10.5 450 500 6.9 7.2 7.4 8.3 9.1 9.4 7.4 7.6 7.9 8.7 9.6 9.9 550 600 7.8 8.1 8.4 9.2 8.3 8.5 8.8 9.7 650 8.7 9.0 9.3 10.2 11.2 11.5 12.5 13.5 13.8 14.8 15.8 16.1 17.1 18.1 18.4 19.4 20.4 20.6 21.6 700 9.2 9.4 9.7 10.7 11.8 12.0 13.1 14.1 14.4 15.4 16.5 16.7 17.8 18.8 19.1 20.1 21.2 21.5 22.5 750 9.6 9.9 10.2 11.2 12.3 12.6 13.6 14.7 15.0 16.1 17.2 17.4 18.5 19.6 19.9 20.9 22.0 22.3 23.4 3.00kg 800 10.1 10.4 1.6 11.7 12.8 13.1 14.2 15.3 15.6 16.7 17.8 18.1 19.2 20.3 20.6 21.7 22.8 23.1 24.2 850 900 950 1000 10.5 11.0 11.5 10.8 11.3 11.7 11.1 11.5 12.0 12.2 12.7 13.2 13.3 13.9 14.4 13.6 14.1 14.7 14.8 15.3 15.9 15.9 16.5 17.1 16.2 16.8 17.4 17.4 18.0 18.6 18.5 19.2 19.9 18.8 19.4 20.1 19.9 20.6 21.4 21.1 21.8 22.6 21.4 22.1 22.8 22.5 23.3 24.1 23.7 24.5 25.3 23.9 24.7 25.6 25.1 25.9 26.8 11.9 12.2 12.5 13.7 14.9 15.2 16.5 17.7 18.0 19.3 20.5 20.8 22.1 23.3 23.6 24.9 26.1 26.4 27.7 Calculated Weights (Kg) of A-60 Circular (Excluding Actuator) 100 Dia. 150 Dia. 200 Dia. 250 Dia. 300 Dia. 350 Dia. 400 Dia. 450 Dia. 500 Dia. 550 Dia. 600 Dia. 650 Dia. 700 Dia. 750 Dia. 800 Dia. 850 Dia. 900 Dia. 950 Dia. 1000 Dia. 5.2 6.4 7.6 9.4 11.2 12.7 14.7 16.9 18.5 20.8 23.2 24.9 27.5 30.2 32.1 34.9 37.8 39.9 43.0

100

78

20

10.2 10.7 10.4 11.0 11.4 11.9 12.3 12.9 12.6 13.2 13.5 14.2 14.5 15.1 14.7 15.4 15.7 16.4 16.6 17.3 16.9 17.6 17.8 18.6 18.7 19.6 19.0 19.8 19.9 20.8

10.2 10.8 11.1 11.7 11.4 12.0 12.2 12.9 13.1 13.8 13.4 14.0 14.2 14.9 15.1 15.8 15.4 16.1 16.2 17.0 17.1 17.9 17.4 18.2 18.2 19.1

10.2 10.8

10.3 11.0 11.6 11.1 11.8 12.4 11.3 12.0 12.7 12.1 12.8 13.5 12.8 13.6 14.3 13.1 13.9 14.6 13.9 14.7 15.4 14.6 15.4 16.3 14.9 15.7 16.5 15.6 16.5 17.4 1.85kg 3.00kg

10.0 10.7 10.7 11.4 11.4 12.1 11.6 12.4 12.3 13.1 13.0 13.8 13.2 14.1 13.9 14.8

10.5 10.9 10.8 11.2 11.5 11.9 12.2 12.6 12.4 12.8

1000 13.1 13.5

Compact Including Adaptor Plate Universal Including Adaptor Plate

Pneumatic Including Adaptor Plate

www.actionair.co.uk

A-60 Marine Fire Dampers

Acoustic Data

The data presented is from the Laboratory Determination of Acoustic and Aerodynamic Performance of A-60 Marine Fire Dampers. A programme of extensive tests was carried out by an independent test facility, approved under the NAMAS Scheme, in accordance with BRITISH STANDARDS Nos. 4196, 4773, 4856, 4857 and 4954. From the selection of a duct velocity within the operational parameters of the damper a resultant pressure drop from Table 1 can be determined and the sum of these two components applied to the Velocity x Pressure Drop Vs Sound Power Level Graph. (Table 2). The graph is the result of a full range of acoustic tests with the blades set in the fully open position. The Spectrum Correction Data is applied to the number obtained from the graph and a complete Sound Spectrum of Flow Generated Noise for both Outlet (in duct) and Breakout (casing radiated) is obtained. Example: Duct with a design velocity of 8 m/sec and the A-60 Marine Fire Damper RECT damper blades in the fully open position. Pressure Drop = 22 Pa (Table 1). Multiply Velocity x Pressure Drop 8 x 22 = 176. From Sound Power Graph (Table 2) plot 176 on horizontal Velocity/Pressure axis against the A-60 Marine Fire Damper RECT outlet (induct) graph to obtain 47 dBW on Vertical Sound Power Level Axis. Add or subtract corrections to the 47dBW to provide full spectrum analysis. Damper Leakage Table 3

A-60 Marine Fire Damper damper closed blade leakage. Standard (without blade seals) Optional (with blade seals)

1500 1000

500

DIFFERENTIAL PRESSURE (Pa)

100

10 1 10 50 100 200

LEAKAGE (I/s per m2)

Pressure Drop Vs Velocity Table 1

100 90 80 70 60 50 40

Velocity (m/s) X Pressure Drop (Pa) Vs Sound Power Level (dBW) Table 2

90

80

) CT DU (IN ET TL ) OU CT C IR DU (IN 0C ET -6 A TL OU CT RE 0 A-6

EXAMPLE LINE

70 30 SOUND POWER LEVEL (dBW)

EXAMPLE LINE

PRESSURE DROP (Pa)

20

A-6 0R EC T A-6 0C IRC

60

50

10 9 8 7 6 5 4 3 2

40

EC R TB EA KO

UT

30

A-6

0R

20

A-6

0C

IR

R CB

EA

KO

UT

10

1 1 2 3 4 5 6 7 8 9 10 15

0 4000 5000 6000 7000 8000 9000 10000 400 500 600 700 800 900 1000 40 50 60 70 80 90 100 2000 3000 200 300 10 20 30

VELOCITY (m/s)

VELOCITY X PRESSURE DROP (m/s Pa)

Outlet (Induct) Spectrum Corrections Octave Band63 125 250 500 1k 2k 4k 8k A-60 RECT 5 4 5 5 3 1 -3 -5 A-60 CIRC 9 4 4 5 3 1 -3 -6

Breakout Spectrum Corrections 63 125 250 500 1k 2k 4k 8k Hz 8 11 9 6 -3 -6 -14 -17 dB 6 10 8 4 -3 -3 -11 -14 dB

www.actionair.co.uk

A-60 Marine Fire Dampers

Certification

USCG-EU EC Type Examination (Module B)

USCG - EU (Module D) Certificate of Conformity

Germanischer Lloyd Approval Certificate For a live update http://www.gl-group.com/newbuilding/approvals/cert/4331602.pdf

10

www.actionair.co.uk

A-60 Marine Fire Dampers

Certification

SAS F040322 Lloyds Registered Certificate of Fire Approval

ABS Approval Certificate

www.actionair.co.uk

11

A-60 Marine Fire Dampers

w w w. a c t i o n a i r. c o . u k

Standard Ordering Procedure

Please Specify

Series

A-60 RECT(Galv) A-60 Marine Fire Damper 430 Ferritic Stainless Steel Blades. Square or Rectangular Flanges. Galvanised Casing. A-60 CIRC (Galv) A-60 Marine Fire Damper 430 Ferritic Stainless Steel Blades. Circular Flanged . Galvanised Casing. A-60 RECT (316) A-60 Marine Fire Damper 316 Austenitic Stainless Steel Blades. Square or Rectangular Flanges. Stainless Steel Casing. A-60 CIRC (316) A-60 Marine Fire Damper 316 Austenitic Stainless Steel Blades. Circular Flanged. Stainless Steel Casing.

Control Modes Control Mode 5 Control Mode 6 Control Mode 120 Pneumatic

24V A.C. or D.C. 230V A.C. 50/60Hz 120V A.C. 50/60Hz 5 - 8 Bar Air Supply

Seals Standard Optional

(without blade seals) (with blade seals)

Flange Holes Drilled (Standard) Undrilled (Optional)

Accessories (Electrical) A range of indicator panels, push button switches and damper test units are also available. The housing for these units are manufactured in rigid ABS plastic. The Damper Connection Box is in galvanised steel. Damper Test Unit Reset and release indication. Spring bias (power OFF) test switch. Power normally ON. Damper Status Indicator Reset and release indication. DTU24 DTU120 DTU230 DSI24 DSI120 DSI230 Damper Control Unit Switch ON/OFF function. Reset and release indication. DCU24 DCU120 DCU230 Damper Connection Box DCB24 DCB230 24V AC/DC 120V AC 230V AC 24V AC/DC 120V AC 230V AC 24V AC/DC 120V AC 230V AC 24V AC/DC 230V AC XNNN00010 XNNN00305 DNNN00029 DPNN00412 XNNN00308 DPNN00413 XNNN00309 XNNN00310 XNNN00311 XNNN00312 XNNN00325

PRODUCED BY GRAPHIC PARTNERSHIP 01227 457292 : Actionair Brochure Part Number LNNN00197.

Accessories (Pneumatic) Solenoid, (24, 120, or 230 volt). Switchbox (Status Beacon).

Example 3 / I Quantity

A-60 RECT (Galv) I Series

400 (W) x 250 (H) I Duct size

M5

I Control Modes

Standard Undrilled I Options

DCU

I Accessories

no compromise...

Actionair, South Street, Whitstable, Kent CT5 3DU England. T: (01227) 276100 F: (01227) 264262 Int: Code: +441227 E: sales@actionair.co.uk W: www.actionair.co.uk

Part of Ruskin Air Management Limited

Quality System Assessed to ISO 9001: 2000

Ruskin Air Management Limited

You might also like

- Types of DampersDocument22 pagesTypes of DamperstsrajaNo ratings yet

- General Damper BrochureDocument8 pagesGeneral Damper BrochureATM Serviços HidráulicosNo ratings yet

- Maxon A Ha NiseriesDocument4 pagesMaxon A Ha Niseriescrown1973No ratings yet

- TB 00700001 eDocument9 pagesTB 00700001 eRicardo LopezNo ratings yet

- Comprehensive Circuit Protection For Control Panel ApplicationsDocument16 pagesComprehensive Circuit Protection For Control Panel Applicationsasimnaqvi2003No ratings yet

- CAT L-200 20 Switches Pages 613-654Document42 pagesCAT L-200 20 Switches Pages 613-654Miguel Angel Beltran VelazquezNo ratings yet

- En PyrotenaxSystem2000 DS H57049 Tcm432 26219Document5 pagesEn PyrotenaxSystem2000 DS H57049 Tcm432 26219thanna9783No ratings yet

- Idealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingDocument4 pagesIdealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingmoorthysanmukamNo ratings yet

- IP Protection Ratings and Upgrades for Cummins Generator AlternatorsDocument7 pagesIP Protection Ratings and Upgrades for Cummins Generator AlternatorsariwibowoNo ratings yet

- MS 02 316Document12 pagesMS 02 316gazwang478No ratings yet

- Mah Sahu 021 2015Document26 pagesMah Sahu 021 2015Karthikeyan SankarrajanNo ratings yet

- SevereEnviroment CatalogDocument8 pagesSevereEnviroment CatalogSteven HungNo ratings yet

- LS 45 To 90Document2 pagesLS 45 To 90Nuno PaivaNo ratings yet

- Desiccant Dehumidifier: ML SeriesDocument2 pagesDesiccant Dehumidifier: ML SeriesbinhjukiNo ratings yet

- Aerofoil Climafan Brochure 50Hz (ENG) For RefDocument58 pagesAerofoil Climafan Brochure 50Hz (ENG) For RefAnonymous BbZceWkVnNo ratings yet

- Duct Liner (AFICO)Document4 pagesDuct Liner (AFICO)hshoooma65No ratings yet

- Miller Spectrum 875 XtremeDocument4 pagesMiller Spectrum 875 XtremeomaralihasNo ratings yet

- Carrier38CKC 50HzDocument20 pagesCarrier38CKC 50HzAaron LeveyNo ratings yet

- Bettis Cba 300 Series Pneumatic Actuators Us DataDocument6 pagesBettis Cba 300 Series Pneumatic Actuators Us DatasusantoNo ratings yet

- AXIAL FANS Complete Range of Axial FansDocument40 pagesAXIAL FANS Complete Range of Axial FansDanilo Magallanes SampagaNo ratings yet

- Aeroenfriador PDFDocument26 pagesAeroenfriador PDFfrankz89No ratings yet

- Up to 24 kV Ring Main Unit and Switchgear SystemDocument9 pagesUp to 24 kV Ring Main Unit and Switchgear SystemcatalinccNo ratings yet

- RMS 30 To 55Document2 pagesRMS 30 To 55nuno paivaNo ratings yet

- SV97Document2 pagesSV97nclogesh_1981No ratings yet

- Low Voltage Switchgear Specification SummaryDocument6 pagesLow Voltage Switchgear Specification SummaryDardakNo ratings yet

- Ultra Safe EXPDocument7 pagesUltra Safe EXPAnonymous dqbb02DUhNo ratings yet

- Technical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsDocument25 pagesTechnical Description Td-95/3 400 KV, 30 Mvar or 50 Mvar or 60 Mvar Shunt ReactorsK Vijay Bhaskar ReddyNo ratings yet

- MILLER - PlasmarezaciDocument28 pagesMILLER - PlasmarezaciIvan DulicNo ratings yet

- Brochure SILENT FLOW EN (All_version)Document8 pagesBrochure SILENT FLOW EN (All_version)MiguelOliveira1No ratings yet

- FD TCR Industrial 1Document8 pagesFD TCR Industrial 1HemonNo ratings yet

- Carrier Condensador 38ckcDocument36 pagesCarrier Condensador 38ckcMel MontenegroNo ratings yet

- Abb VariadorDocument52 pagesAbb VariadorPa TricioNo ratings yet

- Specialty HeatersDocument40 pagesSpecialty Heaterskvanps_kumarNo ratings yet

- 24abs3 4pdDocument66 pages24abs3 4pdleonardo_suarez_82No ratings yet

- Catalogo Termometro BimetalicoDocument8 pagesCatalogo Termometro BimetalicoNahbi Emilio PerezNo ratings yet

- ActairDocument16 pagesActairvj100% (1)

- Or YorkDocument32 pagesOr YorkJavier BarbeytoNo ratings yet

- PEE 1560-ACMV SpecDocument97 pagesPEE 1560-ACMV SpecjimiNo ratings yet

- 22 Ohm ResistorDocument11 pages22 Ohm ResistorDwp BhaskaranNo ratings yet

- Silicone Rubber Cold Shrink Connector Insulators 8440 SeriesDocument4 pagesSilicone Rubber Cold Shrink Connector Insulators 8440 SerieshendrabudimanNo ratings yet

- List of The Equipments (R)Document12 pagesList of The Equipments (R)Rubel RanaNo ratings yet

- CarlingSW V4 5Document12 pagesCarlingSW V4 5Yakov VillaverdeNo ratings yet

- Current Transformers (72.5 kV to 420 kV) SpecificationsDocument4 pagesCurrent Transformers (72.5 kV to 420 kV) SpecificationsPaulo CardosoNo ratings yet

- Monolithic Insulated Joint BrochureDocument8 pagesMonolithic Insulated Joint Brochuremarita_msNo ratings yet

- Manual de Celda UXDocument2 pagesManual de Celda UXvhcamiloNo ratings yet

- Topworx Position SwitchDocument60 pagesTopworx Position SwitchsarkaftNo ratings yet

- Watlow Cartridge HeatersDocument49 pagesWatlow Cartridge HeatersEliasNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 08329-1 Vertical Coiling Fire Rated ShuttersDocument5 pagesITCC in Riyadh Residential Complex J10-13300 08329-1 Vertical Coiling Fire Rated ShuttersuddinnadeemNo ratings yet

- Namur Solenoid Valves BFD27-2Document12 pagesNamur Solenoid Valves BFD27-2tungbk9No ratings yet

- MEPF BOQ - AZURE TargetDocument33 pagesMEPF BOQ - AZURE TargetUpendra ChariNo ratings yet

- 3.0 Hvac Boq - EstimateDocument6 pages3.0 Hvac Boq - EstimatefebousNo ratings yet

- Littelfuse SMD Osiguraci ObiljezavanjeDocument3 pagesLittelfuse SMD Osiguraci Obiljezavanjedra6anNo ratings yet

- Acum +cadxDocument22 pagesAcum +cadxArumugam MurugesanNo ratings yet

- Silentflow Blower Package Pressure and VacuumDocument8 pagesSilentflow Blower Package Pressure and VacuumahmedNo ratings yet

- EsabwDocument114 pagesEsabwadyro12No ratings yet

- Foxboro RTDDocument12 pagesFoxboro RTDJonathanGonzalezDiazNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Report Emerging TechnologiesDocument97 pagesReport Emerging Technologiesa10b11No ratings yet

- Kami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Document3 pagesKami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Anna HattenNo ratings yet

- DC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlDocument5 pagesDC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlAlisson Magalhães Silva MagalhãesNo ratings yet

- Leaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeDocument6 pagesLeaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeAnonymous iTNFz0a0No ratings yet

- Web Api PDFDocument164 pagesWeb Api PDFnazishNo ratings yet

- Bank NIFTY Components and WeightageDocument2 pagesBank NIFTY Components and WeightageUptrend0% (2)

- Journal Entries & Ledgers ExplainedDocument14 pagesJournal Entries & Ledgers ExplainedColleen GuimbalNo ratings yet

- AFNOR IPTDS BrochureDocument1 pageAFNOR IPTDS Brochurebdiaconu20048672No ratings yet

- Chapter 3 of David CrystalDocument3 pagesChapter 3 of David CrystalKritika RamchurnNo ratings yet

- Personalised MedicineDocument25 pagesPersonalised MedicineRevanti MukherjeeNo ratings yet

- Controle de Abastecimento e ManutençãoDocument409 pagesControle de Abastecimento e ManutençãoHAROLDO LAGE VIEIRANo ratings yet

- Bluetooth TutorialDocument349 pagesBluetooth Tutorialjohn bougsNo ratings yet

- "Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecDocument5 pages"Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecpspuzzlesNo ratings yet

- Multiple Choice: CH142 Sample Exam 2 QuestionsDocument12 pagesMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanNo ratings yet

- SQL Guide AdvancedDocument26 pagesSQL Guide AdvancedRustik2020No ratings yet

- Book Networks An Introduction by Mark NewmanDocument394 pagesBook Networks An Introduction by Mark NewmanKhondokar Al MominNo ratings yet

- Quantification of Dell S Competitive AdvantageDocument3 pagesQuantification of Dell S Competitive AdvantageSandeep Yadav50% (2)

- Iso 9001 CRMDocument6 pagesIso 9001 CRMleovenceNo ratings yet

- NLL - Elementary - Coursebook 2019 PDFDocument24 pagesNLL - Elementary - Coursebook 2019 PDFgilmolto100% (1)

- SD8B 3 Part3Document159 pagesSD8B 3 Part3dan1_sbNo ratings yet

- Polytechnic University Management Services ExamDocument16 pagesPolytechnic University Management Services ExamBeverlene BatiNo ratings yet

- 4 Wheel ThunderDocument9 pages4 Wheel ThunderOlga Lucia Zapata SavaresseNo ratings yet

- The Berkeley Review: MCAT Chemistry Atomic Theory PracticeDocument37 pagesThe Berkeley Review: MCAT Chemistry Atomic Theory Practicerenjade1516No ratings yet

- 3 - Performance Measurement of Mining Equipments by Utilizing OEEDocument8 pages3 - Performance Measurement of Mining Equipments by Utilizing OEEGonzalo GarciaNo ratings yet

- 50 Years of Teaching PianoDocument122 pages50 Years of Teaching PianoMyklan100% (35)

- Quality Management in Digital ImagingDocument71 pagesQuality Management in Digital ImagingKampus Atro Bali0% (1)

- Non Circumvention Non Disclosure Agreement (TERENCE) SGDocument7 pagesNon Circumvention Non Disclosure Agreement (TERENCE) SGLin ChrisNo ratings yet

- Evolution of Bluetooth PDFDocument2 pagesEvolution of Bluetooth PDFJuzerNo ratings yet

- Log File Records Startup Sequence and Rendering CallsDocument334 pagesLog File Records Startup Sequence and Rendering CallsKossay BelkhammarNo ratings yet

- Algorithms For Image Processing and Computer Vision: J.R. ParkerDocument8 pagesAlgorithms For Image Processing and Computer Vision: J.R. ParkerJiaqian NingNo ratings yet