Professional Documents

Culture Documents

Artigo Concret

Uploaded by

Mayara RodriguesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Artigo Concret

Uploaded by

Mayara RodriguesCopyright:

Available Formats

Title: Author and coauthors Filiations: Abstract Keywords: chemical treatment, elephant grass ash, potassium, pozolanic activity,

waste agroindustry.

Introduction Energy cogeneration (Ernesto, cordeiro) Mineral addition Potassium extraction

The work presented here is part of an extensive study aimed to allow the use of elephant grass ash as pozolanic material. Material and Methods Materials The elephant grass (Pennisetum purpureum) was collected from a campus of the University of So Paulo. (fala que partes da planta foi usado, a forma que foi preparado para queima corte secagem, diminuio da partcula) The ashes were obtained by burned control in an electrical furnace with a 10 C/min heating rate, first at 400 C for 20 min, and then at 700 C for 60 min, as presented in Figure 1.

Figure 1. Burning conditions of sugar cane straw

Treatment It was make two cleaned to extraction of potassium: the clear it was making in the grass (EGC) (DELLA et al., 2006) then it was burning and gets the ash, the other clear it was make in the ash (LIMA et al., 2011). The both cleaning used the acid chloridric (HCl) solution and compared with the ash without the cleaning. The first clear, it was used 10% v/v of HCl in 1000 mL for 60g of grass, so that solution was heating and when boiled over stay it stirring during 2 h. The second one, used 3% v/v of HCl in 500 mL to 50,5 g of ash, then it was stay for 1h / 90C with agitation. Thus, we have three treatments (Table 1). Table 1. Treatment WC Without the clear CG Clear in the grass CA Clear in the ash

Elephant Grass ash characterization

The samples, in its natural condition, were analyzed by morphology characterization. For the mineralogical and physical characterization the samples were previously ground. Scanning electron microscopy (SEM) studies were carried out using a Hitachi Analytical instrument, model TM3000. The acquisition program was TM3000 and the program to quantify was SwifED. Granulometric distributions of ashes were measured using a Shimadzu Sald-201V apparatus which allows an analysis of particles by laser diffraction from 0.5 to 500 m, in liquid mode as dispersant. Mineralogical characterization of the ashes was carried out by the X-ray diffractions, with the purpose to know the structure of the analyzed material. X-ray difractograms were obtained using a Panalytical XPert Pro with X Celerator and data were compared in International Centre for Diffraction Data and Panalytical Inorganic Crystal Structure Database.

Measurements recorded in 2 = 5-70 intervals at a step angle of 0.02 and acquisition time of 2 s per step. Chemical composition was carried out by X-ray fluorescence with the PANalytical X Axios Advanced apparatus. The loss on ignition (LOI) of the ash was determined by heating the sample up to 950 C + 50 C according to ASTM C-114 [2003] recommendations, and was calculated as Equation 1:

W110 = weight of the sample oven-dried (110 C + 10 C) W950 = weight of the sample calcinated in a furnace (950 C + 50 C) CONDUTIVIDADE Calcium hydroxide (CH) and deionized water were used in electrical conductivity analysis.

PRXIMA REUNIO: 19/04/2012

LIMA, Samantha Pinheiro Bus de et al. Production of silica gel from residual rice husk ash. Qum. Nova [online]. 2011, vol.34, n.1, pp. 71-75. ISSN 0100-4042.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CovestroDocument2 pagesCovestroRonaldo CamargoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Justine J. Beroy: Career ObjectivesDocument5 pagesJustine J. Beroy: Career ObjectivesJustine BeroyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Acceleration GrpahDocument14 pagesAcceleration GrpahRAFAEL TORRESNo ratings yet

- 8th ICCIT - 2005 - 564Document5 pages8th ICCIT - 2005 - 564Amit BiswasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- ChemCAD and ConcepSys AIChE Spring 09Document28 pagesChemCAD and ConcepSys AIChE Spring 09ConcepSys Solutions LLCNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

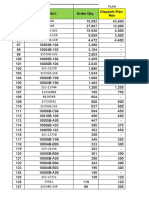

- Order Qty Vs Dispatch Plan - 04 11 20Document13 pagesOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Sample of Wet Soil Has A Volume of 0Document8 pagesA Sample of Wet Soil Has A Volume of 0eph0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Good Practices in Government Resource Planning, Developed Vs Developing CountriesDocument11 pagesGood Practices in Government Resource Planning, Developed Vs Developing CountriesFreeBalanceGRPNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- VLE Lactic Acid Ethyl Lactate Esterification PDFDocument7 pagesVLE Lactic Acid Ethyl Lactate Esterification PDFAseem Kashyap0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Right Stuff PDFDocument4 pagesThe Right Stuff PDFNeelank Tiwari100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliDocument29 pages1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliYogeesh B ENo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- How Is Electrical Energy MeasuredDocument4 pagesHow Is Electrical Energy MeasuredSonya ReddyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Stair Cases DesignDocument19 pagesStair Cases DesignWrishad Zia93% (14)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Autodesk Inventor - Sheet Metal Punch IfeaturesDocument6 pagesAutodesk Inventor - Sheet Metal Punch IfeaturesNdianabasi UdonkangNo ratings yet

- Eje Delantero BMW F10Document94 pagesEje Delantero BMW F10Daniel Muñoz SotomayorNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- V.K Jain-Advanced Machining Processes-Allied Publications PDFDocument370 pagesV.K Jain-Advanced Machining Processes-Allied Publications PDFMayank Vyas100% (1)

- Estimation Software For Presure VesselDocument36 pagesEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Piping Handbook - Hydrocarbon Processing - 1968Document140 pagesPiping Handbook - Hydrocarbon Processing - 1968VS271294% (16)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Simatic EKB Install 2012-03-08Document2 pagesSimatic EKB Install 2012-03-08Oton SilvaNo ratings yet

- FR-8x Editor Eng01 WDocument8 pagesFR-8x Editor Eng01 WRadulian Daniel100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Valve Body PDFDocument9 pagesValve Body PDFTimur TOT100% (2)

- SF6 Novec 4710Document4 pagesSF6 Novec 4710Fidya Eka PrahestiNo ratings yet

- Cbse PMT 2012Document33 pagesCbse PMT 2012Vishal RamakrishnanNo ratings yet

- Glass Inspection CriteriaDocument4 pagesGlass Inspection CriteriabatteekhNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- CoreJava Ratan CompleteMarerial PDFDocument398 pagesCoreJava Ratan CompleteMarerial PDFSivaShankar100% (7)

- Mimaki Install Guide (En)Document16 pagesMimaki Install Guide (En)หน่อง นพดลNo ratings yet

- ITP InstrumentationDocument9 pagesITP InstrumentationzhangyiliNo ratings yet

- Electro Magnetic Induction PDFDocument28 pagesElectro Magnetic Induction PDFPuran BistaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Design For Manufacturing Course - by DFRDocument257 pagesDesign For Manufacturing Course - by DFRhlgc63100% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)