Professional Documents

Culture Documents

Liquid Nitrogen Improves Cold Rolling 33006030glb

Uploaded by

Nuno TeixeiraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquid Nitrogen Improves Cold Rolling 33006030glb

Uploaded by

Nuno TeixeiraCopyright:

Available Formats

Liquid Nitrogen Improves Cold Rolling Of Strip Stock

Using liquid nitrogen as a coolant in cold rolling can dramatically increase productivity as well as improve product quality. G. Plicht, H. Hfinghoff, H. Schillak, T. Demski and R. Edwards of Air Products and Chemicals, Inc. and C.D. Wlzholz describe the new Air Products cool rolling technology.

In an effort to help strip producers attain higher mill speeds and maintain a brighter strip surface quality while reducing downtime, C.D. Wlzholz, a metal strip manufacturer, and Air Products jointly developed a new cooling technique with liquid nitrogen. This technique, the Air Products cool rolling technology, uses liquid nitrogen as the cooling medium during the final or skin pass rolling step. Use of the Air Products cool rolling technology in rolling mills has shown that it can increase production rates dramatically compared to traditional dry rollingin fact, in some cases by up to 50 percent. This technology can also replace conventional lubricants in wet rolling and can reduce strip surface quality issues present with wet rolling. In addition, the Air Products cool rolling technology can reduce the number of work roll changes, can reduce or eliminate the need for any strip cleaning process and can minimize product losses caused by post rolling corrosion.

Conventional cold rolling and its problems

Cold rolling is a process that simultaneously deforms and strengthens metal. It is used as the final stage in the manufacture of metal strip, after hot rolling (Figure 1).

Hot strip Warmband

Four-high stand Quarto -Walzgerst

Annealing Glhe

Dressiergerst Cold strip Rerolling stand Kaltband

Coolants/lubricants Khl/Schmierstof Strip steel Bandstahl Work or Arbeits- bzw. backing rolls Sttzwalzen

Bandreinigu Strip cleaning

Rerolling stand Dressiergerst

Figure 1: In the manufacture of strip stock, hot rolling is typically followed by cold rolling.

Hot rolling can achieve large dimensional changes in a single step, but gives poor dimensional control and surface finish. Because it is carried out at temperatures above the re-crystallization temperature of the metal, hot rolling does not increase the strength of the metal. Cold rolling, on the other hand, takes place without re-crystallization, so the material undergoes work hardening. As a result, cold rolling can be used to fine-tune the mechanical properties of the strip, as well as yield a product with a high-quality surface finish. Cold-rolled steel strip is typically used for motor vehicle bodies and domestic appliances.

1

There are two types of cold rollingdry and wet. Dry rolling, as the name suggests, takes place without lubricants. The result is a high-quality bright surface finish, but at the cost of low line speed. The problem with dry cold rolling is the high heat generated in the roll gap by friction and the plastic deformation of the metal (Figure 2).

Fig. 6. Forces on the rolled strip and on th e rolls during cold rolling, with drags [2] a lever arm, k w deformation resistance, ld pressed length, n 1,n2 speeds, r 1,r2 roll radii, F force, FR backward force, F V forward force, Md roll torque

Figure 2:

In dry cold rolling, friction and plastic deformation in the roll gap produce heat that slows production and can damage both the product and the rolls.

Most of this heat is dissipated in the rolls and the product. However, if the resulting temperature rises too high, the metal surface of the strip or the working rolls can oxidise. Product that is damaged in this way has to be rejected, while damage to the rolls requires frequent reconditioning. In practice, strip producers run their rolling mills at the highest speeds possible until the product begins to tarnish. The heat of friction generated between the rolls and strip causes high temperatures and increased wear on the work rolls. As a result, strip producers need to change the rolls frequently, which in turn mean high costs for downtime and regrinding of the rolls. Frequently, the product also suffers heat damage; this can be a significant cost, particularly in the case of valuable materials such as copper or stainless steel. To reduce friction and remove heat, strip producers often perform wet rollingcooling the rolls by adding an oil or emulsion, which also acts as a lubricant. This allows them to significantly increase the line speed by reducing the heat of friction between the work rolls and strip. However, wet rolling has issues as well. For instance, the use of rolling fluids results in a matt surface compared to a brighter finish found in dry rolling. Plus there is the capital cost of the lubricant circuit and the ongoing costs of monitoring and adjusting the emulsion composition. With flammable fluids, safety is a critical issue. The biggest problem at C.D. Wlzholz was rust spots on the strip surface. The downstream cleaning equipment was unable to remove all traces of the emulsion; the resulting moisture caused rust to develop during storage or transport to the customer. The resulting rejections were very costly.

Liquid nitrogen: a better solution

Using liquid nitrogen, C.D. Wlzholz and Air Products jointly developed the Air Products cool rolling technologya new cooling technique that provides the same or greater productivity as conventional wet rolling, without aqueous emulsions.

Liquid nitrogen is often used in the industry as a special-purpose refrigerant. Its advantages include a large heat capacity, the ability to generate a very low temperature if required, and the fact that it evaporates without leaving any moisture or residues. Nitrogen, also non-flammable, reduces the risk of fires and explosions and can be discharged safely into the atmosphere after use. The Air Products cool rolling technology (Figure 3) uses spray bars to distribute nitrogen at a preferred temperature, between 170 C and 196 C, over the metal strip as it enters the rolls.

LIN

H2 O

ca .1 00

H2O H2O

. ca 10 0

LIN

Figure 3: The Air Products cool rolling technology uses liquid nitrogen to cool the rolls and the product. The rapid removal of heat allows the line speed to be increasedin some cases dramatically. Conventional emulsions also work as lubricants, reducing the generation of heat by minimising friction. In contrast, liquid nitrogen has little lubricating effect; instead it removes frictional heat due to its very high heat capacity. Once its work is done, the liquid nitrogen evaporates, leaving no residue.

Counting the benefits

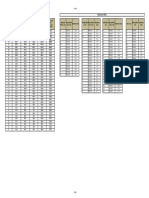

Using the Air Products cool rolling technology during the final pass, C.D. Wlzholz was able to eliminate rejects caused by rust spotting, which had been a serious problem with emulsions. The use of nitrogen also creates an oil-free strip surface. As a result, the company was able to eliminate the post-cleaning step, which for technical reasons had limited the rolling speed. The result was a line speed increase of up to 200 percent, greatly increasing overall productivity. Analysis shows that conversion to the Air Products cool rolling technology reduced the costs of final-pass rolling by around 25 percent. This savingd includes the operating costs of the Air Products cool rolling technology itself. Liquid nitrogen has also been used on a dry cold rolling line at C.D. Wlzholz. Again, it increased the line speed by up to 200 percent, the maximum speed that the current machinery is capable of operating at. Table 1 shows the typical benefits from an Air Products cool rolling technology installation. Air Products developed analysis software to predict the economics of the Air Products cool rolling technology in any given circumstance.

H2O

Safety

Capital expenditure

Maintenance Consumables

Quality

Minimises fire and explosion hazards Eliminates noxious oil vapour Minimises emulsion residues in the work area and the associated slipping hazard Higher line speed, hence higher productivity, with little investment and no need to expand the plant Eliminates emulsion circuits, downstream cleaning systems and CO2 extinguishing systems Increases work roll life Eliminates emulsion monitoring and cleaning system or emulsion circuit maintenance Decreases the number of roll changing and refurbishing Eliminates emulsions or additives and filter preparation Decreases electricity consumption Improves consistent surface quality Increases uniform roughness Decreases rejects due to rust Allows mirror-finish surfaces at higher line speeds Enables the possibility to expand product ranges due to the oil- and greasefree process Table 1:

Typical benefits to be expected from the Air Products cool rolling technology.

Experience has shown that liquid nitrogen is usually cheaper than emulsion per tonne of rolled material, even at the existing line speed. Any speed increase or other production benefit can then be counted on top of this basic savings.

For more information

Corporate Headquarters Air Products and Chemicals, Inc. 7201 Hamilton Boulevard Allentown, PA 18195-1501 USA Telephone: 800-654-4567 Fax: 800-272-4449 E-mail: gigmrktg@airproducts.com Europe Air Products PLC Hersham Place Molesey Road Hersham Walton-on-Thames Surrey KT12 4RZ UK Telephone: 0800 389 0202 (from within the UK) or +44 (0)1270 614114 Fax: +44 (0)1932 258502

tell me more

www.airproducts.com/metals

Air Products and Chemicals, Inc., 2006 330-06-030-GLB 4

You might also like

- The Iron Puddler My life in the rolling mills and what came of itFrom EverandThe Iron Puddler My life in the rolling mills and what came of itNo ratings yet

- Asme-Bpvc Sec II-A Int Vol 44Document8 pagesAsme-Bpvc Sec II-A Int Vol 44mostafa aliNo ratings yet

- Effects of Alloying Elements in SteelDocument12 pagesEffects of Alloying Elements in SteelyatheendravarmaNo ratings yet

- Stainless Steel Technical PresentationDocument23 pagesStainless Steel Technical PresentationRavi Teja100% (1)

- Shot Blasting Efect On Stainless Steel PDFDocument54 pagesShot Blasting Efect On Stainless Steel PDFlistiodjoeNo ratings yet

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFDocument11 pagesWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezNo ratings yet

- Accelerated CoolingDocument7 pagesAccelerated CoolingHarikrishnan N SivaprasadNo ratings yet

- Asme Section II A Sa-249 Sa-249mDocument10 pagesAsme Section II A Sa-249 Sa-249mAnonymous GhPzn1xNo ratings yet

- Steel Plates SpecsDocument37 pagesSteel Plates SpecsNugraha BintangNo ratings yet

- Duplex Stainless Steel 329 or 1.4460 PDFDocument2 pagesDuplex Stainless Steel 329 or 1.4460 PDFtien100% (1)

- AbrasivesDocument49 pagesAbrasivesfockewulNo ratings yet

- China Foundry SectorDocument9 pagesChina Foundry Sectoralex metalNo ratings yet

- Corrosion Challenges in Petroleum Refinery and Petrochemical IndustryDocument21 pagesCorrosion Challenges in Petroleum Refinery and Petrochemical IndustryjasminaNo ratings yet

- HSMM Overview Rel 2 0Document29 pagesHSMM Overview Rel 2 0Satpal SinghNo ratings yet

- NBS18 Heat TreatmentDocument46 pagesNBS18 Heat Treatmentshailesh_tiwari_mechNo ratings yet

- Outokumpu Supra Range DatasheetDocument12 pagesOutokumpu Supra Range DatasheetMichelNo ratings yet

- A Guide To The Language of Steel - ArcelorMittalDocument4 pagesA Guide To The Language of Steel - ArcelorMittalHoa Khanh NguyenNo ratings yet

- Reduction Ratio Chart in Steel Rolling MillDocument1 pageReduction Ratio Chart in Steel Rolling MillSoumyo Broto DasNo ratings yet

- An Overview On High Manganese Steel CastingDocument10 pagesAn Overview On High Manganese Steel CastingdrackensohnNo ratings yet

- Raw vs. Part Heat Treatments - What Is The Difference.Document4 pagesRaw vs. Part Heat Treatments - What Is The Difference.skluxNo ratings yet

- Yield (Engineering) PDFDocument9 pagesYield (Engineering) PDFariyosageNo ratings yet

- Bar Basics and TerminologyDocument24 pagesBar Basics and TerminologyEdwin MPNo ratings yet

- Production Engineering Lab VIII SemDocument24 pagesProduction Engineering Lab VIII Semsunil kumawatNo ratings yet

- Calculations For Hot Stretch Reducing ProcessDocument8 pagesCalculations For Hot Stretch Reducing ProcessKANo ratings yet

- Steel Pickling in Challenging Conditions: Mika MaanonenDocument40 pagesSteel Pickling in Challenging Conditions: Mika MaanonenRohit SharmaNo ratings yet

- MCM AllDocument7 pagesMCM AllPalanisamy RajaNo ratings yet

- Riview On Cold Drawing Process PDFDocument7 pagesRiview On Cold Drawing Process PDFAmandeep Singh GujralNo ratings yet

- Materials For Ultra Supercritical Fossil Power Plants by R. ViswanathanDocument66 pagesMaterials For Ultra Supercritical Fossil Power Plants by R. ViswanathanHASAN IZHAR KHANNo ratings yet

- AnyCasting Software Intro SAND PrintDocument45 pagesAnyCasting Software Intro SAND PrintChuah Chun KitNo ratings yet

- Gas Atmosphere Heat Treatment PDFDocument59 pagesGas Atmosphere Heat Treatment PDFsmani170No ratings yet

- A Case Study of The Effectiveness of Rolling Process To Manufacture The Strip of Leaf Spring P. S. ChauhanDocument5 pagesA Case Study of The Effectiveness of Rolling Process To Manufacture The Strip of Leaf Spring P. S. ChauhanSamir BoseNo ratings yet

- 1 A Polishing Machine BookDocument35 pages1 A Polishing Machine BookPradeep AdsareNo ratings yet

- CarburisingDocument4 pagesCarburisingSelva KumarNo ratings yet

- Heat TreatmentDocument21 pagesHeat TreatmentChernet MerknehNo ratings yet

- Aco HadfieldDocument22 pagesAco HadfieldFelipe ZanellaNo ratings yet

- The Influence of Lamellar Graphite Cast Iron Annealing On Hardness and StructureDocument11 pagesThe Influence of Lamellar Graphite Cast Iron Annealing On Hardness and StructureJaromír Roučka100% (1)

- Thin Slab Casting - New PossibilitiesDocument16 pagesThin Slab Casting - New PossibilitiesAnkit KumarNo ratings yet

- Sheet Metal WorkDocument29 pagesSheet Metal WorkSolcastic SoulNo ratings yet

- State of The Art in The Control of Inclusions During Steel Ingot CastingDocument29 pagesState of The Art in The Control of Inclusions During Steel Ingot Castinggaurav vermaNo ratings yet

- Yield Improvement Steel Castings PDFDocument321 pagesYield Improvement Steel Castings PDFMy Dad My WorldNo ratings yet

- CRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Document16 pagesCRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Samir BoseNo ratings yet

- MS - 003400 - 01 Rev 29Document22 pagesMS - 003400 - 01 Rev 29Arjun PrajapatiNo ratings yet

- SA253MA DetailDocument16 pagesSA253MA Detailksquare2001100% (1)

- Proses Manufaktur - Fundamental of Metal FormingDocument35 pagesProses Manufaktur - Fundamental of Metal FormingAnatolium IrgrandeNo ratings yet

- SKD61-Forged Hot Work Tool SteelDocument1 pageSKD61-Forged Hot Work Tool SteelAgustine SetiawanNo ratings yet

- The Precipitation Hardening SSsDocument3 pagesThe Precipitation Hardening SSsClaudia MmsNo ratings yet

- Liquid NitridingDocument7 pagesLiquid NitridingSenthil_kumar_palaniNo ratings yet

- 15ME103-Materials Tech - Unit IIIDocument79 pages15ME103-Materials Tech - Unit IIIVedanth ArulvelNo ratings yet

- Austenitizing Heat Treatment PDFDocument20 pagesAustenitizing Heat Treatment PDFsivajirao70100% (1)

- G. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityDocument7 pagesG. Krauss and D.K. Matlock Colorado School of Mines: C. v. White Kettering UniversityMadhusudhan ModemNo ratings yet

- Meehanite Worldwide Specification Handbook Ver09.07.2013 PDFDocument203 pagesMeehanite Worldwide Specification Handbook Ver09.07.2013 PDFUlises Quintana Carhuancho100% (1)

- World Oil CorrosionDocument4 pagesWorld Oil CorrosionmutemuNo ratings yet

- Material SelectionDocument5 pagesMaterial SelectionIwan SurachwantoNo ratings yet

- Uddeholm Pocket Book PDFDocument80 pagesUddeholm Pocket Book PDFPeter NomikosNo ratings yet

- Steckel Mill 1 PDFDocument178 pagesSteckel Mill 1 PDFSomnathNaskarNo ratings yet

- Uddeholm Heat Treatment Eng 1710 E9Document20 pagesUddeholm Heat Treatment Eng 1710 E9Sinan YıldızNo ratings yet

- Course Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDocument21 pagesCourse Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDinesh Killada50% (2)

- Overheat Induced Failure of A Steel Tube in An Electric Arc Furnace (EAF) Cooling SystemDocument7 pagesOverheat Induced Failure of A Steel Tube in An Electric Arc Furnace (EAF) Cooling SystemArif Ockta100% (1)

- Transient StabilityDocument16 pagesTransient StabilityRavi Kumar BanalaNo ratings yet

- Case Study: Meera P NairDocument9 pagesCase Study: Meera P Nairnanditha menonNo ratings yet

- The Mechanism of Notifying and Record Keeping Three Forms Are Used For Notifying and Record KeepingDocument6 pagesThe Mechanism of Notifying and Record Keeping Three Forms Are Used For Notifying and Record KeepingRoger FernandezNo ratings yet

- Funny AcronymsDocument6 pagesFunny AcronymsSachinvirNo ratings yet

- IT Quiz QuestionsDocument10 pagesIT Quiz QuestionsbrittosabuNo ratings yet

- ExSchutzkatalog Englisch 1Document61 pagesExSchutzkatalog Englisch 1marius_brkt6284No ratings yet

- Marine Products: SL-3 Engine ControlsDocument16 pagesMarine Products: SL-3 Engine ControlsPedro GuerraNo ratings yet

- HP Mini 210-2120br PC Broadcom Wireless LAN Driver v.5.60.350.23 Pour Windows 7 Download GrátisDocument5 pagesHP Mini 210-2120br PC Broadcom Wireless LAN Driver v.5.60.350.23 Pour Windows 7 Download GrátisFernandoDiasNo ratings yet

- PosdmDocument29 pagesPosdmChandraBhushan67% (3)

- Compatibility Matrix For Cisco Unified Communications Manager and The IM and Presence Service, Release 12.5 (X)Document31 pagesCompatibility Matrix For Cisco Unified Communications Manager and The IM and Presence Service, Release 12.5 (X)Flavio AlonsoNo ratings yet

- Workbook, Exercises-Unit 8Document6 pagesWorkbook, Exercises-Unit 8Melanie ValdezNo ratings yet

- Data Sheet Speaker StrobeDocument4 pagesData Sheet Speaker StrobeAneesh ConstantineNo ratings yet

- Pat Lintas Minat Bahasa Inggris Kelas XDocument16 pagesPat Lintas Minat Bahasa Inggris Kelas XEka MurniatiNo ratings yet

- Book LoRa LoRaWAN and Internet of ThingsDocument140 pagesBook LoRa LoRaWAN and Internet of ThingsNguyễn Hữu HạnhNo ratings yet

- 1.SITXWHS003 Student Assessment Tasks 1Document58 pages1.SITXWHS003 Student Assessment Tasks 1Yashaswi GhimireNo ratings yet

- Translation and Distribution Agreement PDFDocument7 pagesTranslation and Distribution Agreement PDFClaudio Valerio Gaetani80% (5)

- MCQ (Chapter 6)Document4 pagesMCQ (Chapter 6)trail meNo ratings yet

- Among Us Hack Mod Menu Mod AlwaysDocument4 pagesAmong Us Hack Mod Menu Mod AlwaysC JNo ratings yet

- Leyson vs. OmbudsmanDocument12 pagesLeyson vs. OmbudsmanDNAANo ratings yet

- Amt in A Nutshell - ExplainedDocument2 pagesAmt in A Nutshell - ExplainedMis El100% (2)

- Azar Mukhtiar Abbasi: Arkad Engineering & ConstructionDocument4 pagesAzar Mukhtiar Abbasi: Arkad Engineering & ConstructionAnonymous T4xDd4No ratings yet

- Application For New Ration Card - Telangana & AP StatesDocument1 pageApplication For New Ration Card - Telangana & AP Statesping2gopiNo ratings yet

- Tales of Mystery Imagination and Humour Edgar Allan Poe PDFDocument289 pagesTales of Mystery Imagination and Humour Edgar Allan Poe PDFmatildameisterNo ratings yet

- BIR Form 2307Document20 pagesBIR Form 2307Lean Isidro0% (1)

- I. Characteristics of WastewaterDocument59 pagesI. Characteristics of WastewaterEljay VinsonNo ratings yet

- Accredited Architecture QualificationsDocument3 pagesAccredited Architecture QualificationsAnamika BhandariNo ratings yet

- Geometric Driver Components Serial Copy: Topsolid'WoodDocument22 pagesGeometric Driver Components Serial Copy: Topsolid'Wooddrine100% (1)

- Good Quality Practices at NTPC KudgiDocument8 pagesGood Quality Practices at NTPC KudgisheelNo ratings yet

- 5GMF WP101 11 5G Rat PDFDocument26 pages5GMF WP101 11 5G Rat PDFAvik ModakNo ratings yet

- Rosmary PollockDocument4 pagesRosmary PollockhbNo ratings yet