Professional Documents

Culture Documents

Dairy Farm

Uploaded by

TESFALEWATEHEOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dairy Farm

Uploaded by

TESFALEWATEHECopyright:

Available Formats

PROFILE ON DAIRY FARM

TABLE OF CONTENTS PAGE I. SUMMARY 22-3

II.

PRODUCT DESCRIPTION AND APPLICATION

22-3

III.

MARKET STUDY AND PLANT CAPACITY

22-3

A. MARKET STUDY B. PLANT CAPACITY AND PRODUCTION PROGRAMME

22-3 22-6

IV.

MATERIALS AND INPUTS

22-7

A. MATERIALS B. UTILITIES

22-7 22-7

V.

TECHNOLOGY AND ENGINEERING

22-8

A. TECHNOLOGY B. ENGINEERING

22-8 22-8

VI.

MANPOWER AND TRAINING REQUIREMENT

22-10

A.

MANPOWER REQUIREMENT

22-10 22-10

B. TRAINING REQUIREMENT

VII.

FINANCIAL ANALYSIS

22-11

A. TOTAL INITITAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEFITS

22-11 22-12 22-13 22-14

22-3 I. SUMMARY

This profile envisages the establishment of dairy farm with annual production capacity of 1,171,200 liters of milk.

The current demand for milk in Somali region is estimated at 36,944 tonnes. The demand is projected to reach 49,171 tonnes by the year 2015.

The project will create employment opportunities for about 52 persons.

The total investment cost of the project is estimated at Birr 8.04 million, out of which about Birr 2 million will be for plant machienry and equipment.

The project is financially viable with internal rate of return (IRR) of 15% and net present value (NPV) of Birr 2.25 million, discounted at 10.5%.

II.

PRODUCT DESCRIPTION AND APPLICATION

Milk is a traditional constituent of the Ethiopian diet, espsecially in lowland areas where the livelihood is based on cattle production. Liquid milk handled traditionally has a very limited shelf-life. In modern dairy production exotic cross breeds or pure breed cattles are used and the milk is processed to have longer shelf-life.

III.

MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past Supply and Present Demand

According to FAO, the country's total cow milk production in year 1995 was estimated at 738 thousand tonnes. The production almost remained constant over the past seven years which lie between 738 and 750 tonnes. Currently, fresh milk is not imported. Hence, the domestic demand is supplied through local production.

22-4

However, to estimate the current demand for milk, the " 1995/96 house hold income, consumption and expenditure survey" revised and published in 1998 by CSA is used as a base. The demand estimated based on the above survey is sown in Table 3.1 Table 3.1 HOUSE HOLD CONSUMPTION OF MILK Income Group No of persons in the Group < 600 600 -999 1000-1399 1400-1999 2000-2599 2600- 3399 3400-4199 4200 -5399 5400- 6599 6600- 8999 9000-12599 12600- 16199 16200 -19999 > 20,000 Total 39,733 215,708 548,063 2,048,185 3,285,193 5,746,321 7,014,673 9,606,476 7,770,271 8,746,435 5,061,294 1,331,572 612,842 662,299 52,689,066 Average consumption (cc) 303 1,244 1,579 2,131 4,175 8,129 9,829 11,326 13,577 14,565 15,670 17,792 20,998 Total consumption (Tonne) 65 682 3,234 7,001 23,991 57,022 94,422 88,006 118,750 73,718 20,866 9,678 13,907 512,567

As can be seen in the above Table, the total national consumption of milk at the time of the survey was 512,567 tonnes, considering total number of the population, which was 52,689,066 the per capita consumption will be 9.73 liters. Milk is highly perishable in nature that it is difficult to transport it and thereby exploit the maket at wider geographical coverage. Thus, considering the nature of the product it was found more appropriate to rely on the regional market rather than national. Hence, considering the per capita consumption i.e. 9.73 liters and the population of somali region which was 3,797 thousand in year 2000 ( statistical abstract 2000), the current demand of Somali region is assumed to be 36,944,810 liters per annum.

22 -5

2.

Demand Projection

The demand for milk is assumed to grow parallel with the growth of population, hence 2.9% growth rate is used to project the future demand. Table 3.2 shows demand projection of milk in Somali region.

Table 3.2 PROJECTION DEMAND Year 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 Demand for Milk ('000 liters) 36,945 38,016 39,119 40,253 41,420 42,623 43,858 45,129 46,438 47,785 49,171

3.

Pricing and Distribution

Milk proudced by traditional farmers is sold directly to consumers in the nearby towns or it is processed to butter and cheese by traditional processing means. Some small holder farmers around Addis Ababa deliver their milk to the milk collection centers that supply to the processing plant at Addis Ababa. Farmers who sale their product directly to consumers usually negotiate on the price in most cases following the local price in the market. The price of milk at national level (average price for some sellected towns) in the 1990s is

summairzed in Table 3.3.

22 -6 Table 3.3 ANNUAL AVERAGE NATIONAL MILK PRICE Year 1990 1991 1992 1993 1994 1995 1999 Av. Annual Price (Birr ltr) 1.05 1.20 1.55 1.77 2.04 2.19 2.74

Source: CSA Retailprices of selected towns

The envisaged project is recommended to set its price at Birr 2 per liter tonne.

The product can be distributed by estblishing own distributing stores in major towns or by using commissioned agents.

B.

PLANT CAPACITY AND PRODUCTION PROGRMME

1.

Plant Capacity

The dairy farm would have 160 milking cows at 80 % calving rate. The cows should be exotic breeds. Average yield per cow is estimated at 20 liters per day. Overall daily total production is about 3200 liters /day. The dairy farm will have milk processing and packing facilities. Moreover, there is also fodder (alfalfa), silage (maize) and hay (pasture) production unit for own consumption.

2.

Production Programme

The dairy farm output is expected to be about 50 per cent of its full capacity at the initial year and grow to 80, and 100 per cent in the second and third year, respectively.

22 -7

IV.

MATERIALS AND INPUTS

A.

MATERIALS

Intial stock of dairy imported breeds of 160 incalf hifers are considered. A total of about Birr 1.05 million investiment is required, out of which Birr 1.02 million is in foreign currency. The internal stock would be replaced after five years of production and then the subsiquent replacement will take place within the same time interval.

Annual inputs and feed requirement with the corrosponding estimated cost is indicated in Table 4.1. Table 4.1 ANNUAL RAW MATERIALS AND COSTS OF DAIRY FARM AT FULL CAPACITY No 1 2 3 Description Feed (tonnes) Concentrate (tonnes) Veterenary & A.I service Total UTILITIES Qty 990 140 Sum Cost, Birr in 000 Local Foriegn 148 112 0.2 2.8 260.2 2.8

Total 148 112 3.0 263

B.

Annual requirements of water and electricity of the dairy farm is estimated to be 10512 m3 and 60225 Kwh, respectively. Total cost of utilities at full capacity of the farm is about Birr 22,200.

22-8

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

1.

Production Process

After construction and establishment of the farm including buildings, farm structures, fodder production, etc incalf heifers will be purchased from a reliable supplier. These hifers would give birth in six to nine months time and production of milk will be started nearly at the end of the the first year. Daily milk production is estimated to be 3000 to 3400 liters per day. The milk will be taken directly from the milking parlor with pipe line to a cooling tank for temporaty storage and processed immediately. One per cent of the fat content is separated and chilled in a cold store. Then, the cream is either churned to butter or sold as it is depending on the availability of local market. After cream separation process, the milk is filtered and sealed with plastic bags or bottled and distributed to the market.

2.

Source of Technology

The machinery and equipment required can be supplied by Hagbes Ethiopia PLC

B.

ENGINEERING

1.

Machinery and Equipment

Machinery and equipment required for dairy farm are listed in Table 5.1. Total costs are estimated to be Birr 2 million, out of which Birr 1.7 million ( 87.7%) is in foreign currancy. 2. Land, Building and Civil Works

The dairy farm will have farm buldings and shades for cows and calves. In addition, the farm will have pasture and natural open areas. Areas of building , shades, pasture and open areas are 288 m2, 576 m2, 80 ha, and 1440 ha, respectively. The total cost of land, at the rate of Birr 36 per ha, and for 60 years of land holding is estimated at Birr 3.28 million. The total cost of building and civil works at the unit cost of Birr 1500 per m2 for building and Birr 1000 for shade is estimated at Birr 1,008,000.

22 -9

Free access is necessary in and round the dairy farm. Therefore, about 45 km on-farm access road will be constructed out of which 5 km would be access to the farm gate. Total rural road cnstruction cost is estimated at about Birr 600,000

3.

Proposed Location

The proposed location of dairy farm will be near the outskirts of big cities like Jigjiga and Gode towns.

Table 5.1 LIST OF MACHINERY AND EQUIPMENT Tota; cost ( in '000 Birr) No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 Description Tractor (70 hp) Trailers (6 ton) Disc harrow Dipping vat Water pump Cruch Tools (miscellanous) Water tank (7000 lts) Vet. Clinic equipment (set) Milk processing equipment Tank insulated External reserviour Parallel filters (set) Regulator Compact plate pasturizer Butter mold Butter churm for curning Spiral air copmresser Water refregrator Centrifugal pump Connecting pipes, valves, etc Laboratort equipment Balance instrument Authomatic filter sealer for plastic bags Total Qty 2 2 1 1 3 1 1 2 1 1 1 1 1 1 4 1 1 1 1 1 1 1 1 1,700 300 2,000 Unit price (Birr) 173,500 50,000 50,000 50,000 64,000 5,000 25,000 13,000 50,000 Lump sum F.C 312.3 90.0 45.0 45.0 172.8 4.5 22.5 23.4 45.0 939.5 L.C 34.7 10.0 5.0 5.0 19.2 0.5 2.5 2.6 5.0 215.5 Total 347.0 100.0 50.0 50.0 192.0 5.0 25.0 20.0 50.0 1,155.0

22 -10

VI.

MANPOWER AND TRAINING REQUIREMENT

A.

MANPOWER REQUIREMENT

Manpower requirement of the farm and the corresponding labour cost are shown in Table 6.1 below.

Table 6.1 MAN POWER REQUIRED AND LABOUR COST No 1 2 3 4 5 6 7 8 Description Dairy farm Manager Time keeper Milk processing plant workers Barn workers Tractor operators Veterenarian Pasture area worker Driver Sub -Total Employees benefit (25%) Grand total 52 Req. No. 1 2 4 30 2 1 10 2 52 Monthly salary, Birr 1500 600 500 300 400 850 300 400 Annual salary, Birr 18000 14400 24000 108000 9600 10200 72000 9,600 265,800 66,450 332,250

B.

TRAINING REQUIREMENT

A two weeks training will be provided for the manager and other four workers of the dairy farm at the site of the project by the machinery supplier. Total cost of training will be Birr 28,250.

22 - 11

VII.

FINANCIAL ANALYSIS

The financial analysis of the dairy project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

2 years 30 % equity 70 % loan

Tax holidays Bank interest Discounted cashflow Land value

4 years 10.5% 10.5% Based on estimated lease rate of the region

Repair and maintenance

5 % of the total plant and machinery

Accounts receivable Raw material local Raw materials import Work in progress Finished products Cash in hand Accounts payable

30 days 30 days 90 days 1 day 1 day 5 days 30 days

A.

TOTAL INITIAL INVESTMENT COST

The total initial investment cost of the project including working capital is estimated at Birr 8.04 million, out of which about 21% will be required in foreign currency. For details see Table 7.1.

22 -12

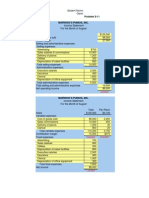

Table 7.1 INITIAL INVESTMENT COST ('000 Birr) Sr. No. 1 2. 3. 4. 5. 6. land Building and Civil Work Plant Machinery and Equipment Office Furniture and Equipment Vehicle Pre-production Expenditure * Total Investment cost 7 Working Capital Total Cost Items Foreign Currency 1,700.00 1,700.00 0.95 1,700.95 Local Currency 3,283.20 1,008.00 300.00 100.00 500.00 1,124.00 6,315.20 31.38 6,346.55 3,283.20 1,008.00 2,000.00 100.00 500.00 1,124.00 8,015.20 32.33 8,047.5 Total

B.

PRODUCTION COST

The annual production cost at full operation capacity is estimated at Birr 1.62 million (see Table 7.2). The material and utility cost accounts for 17 per cent while repair and

maintenance take 6 per cent of the production cost.

* Pre- production expenditure include interest during construction ( Birr 924,000), training (Birr 28,250) and the balance accounts for cost of registration, licensing and formation of the company including legal fees, commissioning expenses etc.

22 - 13

Table 7.2 ANNUAL PRODUCTION COST ('000 BIRR)

Year Items Raw Material and Inputs Labour direct Utilities Energy and Power Spare parts Maintenance and repair Factory overheads Administration Overheads Total Operating Costs Depreciation Cost of Finance Total Production Cost 3 131.5 79.70 11.10 50.00 33.20 106.30 411.90 405.10 580.30 1,397.30 5 210.40 127.60 17.80 80.00 53.20 106.30 595.20 405.10 567.60 1,567.90 7 263 159.50 22.20 100.00 66.40 106.30 717.40 405.10 505.70 1,628.30 10 263 159.50 22.40 100.00 66.40 106.30 717.40 365.10 421.60 1,504.20

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the second year of operation. Important ratios such as profit to total sales, net profit to equity (Return on equity) and net profit plus interest on total investment (return on total investment) will show an increasing trend during the life-time of the project.

The income statement and the other indicators of profitability show that the project is viable.

22 -14

2.

Break-even Analysis

The break-even point of the project is estimated by using income statement projection.

BE =

Fixed Cost Sales Variable Cost

30 %

3.

Pay-Back Period

The investment cost and income statement projection are used to project the pay-back period. The project's initial investment will be fully recovered within 8 years.

4.

Internal Rate of Return and Net Present Value

Based on the cashflow statement, the calculated IRR of the project is 15 % and the net present value at 10.5% discount rate is Birr 2.25 million.

D.

ECONOMIC BENEFITS

The project can create employment for 52 persons.

In addition to supply of the domestic

needs, the project will generate Birr 4.03 million interms of tax revenue. Moreover, the Regional Government can collect employment, income tax and sales tax revenue. The establishment of such factory will have a foreign exchange saving effect to the country by substituting the current imports.

You might also like

- Profile On Production of GlucoseDocument15 pagesProfile On Production of Glucosebig johnNo ratings yet

- Sesame FarmDocument16 pagesSesame Farmvusi_zwe28100% (1)

- Moringa Oil Business Plan and BudgetDocument15 pagesMoringa Oil Business Plan and BudgetMoringaidNo ratings yet

- Maize StarchDocument15 pagesMaize StarchpadhaiNo ratings yet

- Inner FabricsDocument19 pagesInner Fabricsabel_kayelNo ratings yet

- The Impact of Invasive Alien Species On The Forage and Pasture Genetic Resource Diversity in The Pastoral Area of Afar National Regional State, Northeastern of Ethiopia.Document6 pagesThe Impact of Invasive Alien Species On The Forage and Pasture Genetic Resource Diversity in The Pastoral Area of Afar National Regional State, Northeastern of Ethiopia.IJEAB JournalNo ratings yet

- Whole Wheat FlourDocument4 pagesWhole Wheat FlourSHRUTI AGRAWALNo ratings yet

- Profile On Sheep and Goat FarmDocument14 pagesProfile On Sheep and Goat FarmFikirie MogesNo ratings yet

- Niger Seed OilDocument16 pagesNiger Seed Oilbig johnNo ratings yet

- Prosopis juliflora: A drought-tolerant tree with many usesDocument5 pagesProsopis juliflora: A drought-tolerant tree with many usesZewdu LegesseNo ratings yet

- Tin Containers Making-PlantDocument26 pagesTin Containers Making-PlantEsayas Mekonnen100% (1)

- Baking PowderDocument29 pagesBaking PowderTed Habtu Mamo AsratNo ratings yet

- Avocado - Processing PlantDocument48 pagesAvocado - Processing PlantTesfaye Kibret TesfayeNo ratings yet

- Hats and Head GearsDocument20 pagesHats and Head Gearsabel_kayel100% (1)

- Plastic Cont.Document25 pagesPlastic Cont.John100% (1)

- Profile On The Production of VinegarDocument28 pagesProfile On The Production of VinegarTed Habtu Mamo Asrat100% (1)

- Profile On The Production of Weighing ScaleDocument26 pagesProfile On The Production of Weighing ScaleDagim GBZNo ratings yet

- Small Scale-Paper MakingDocument17 pagesSmall Scale-Paper MakingGnana SS100% (1)

- Everything You Need to Know About Bleaching Powder ProductionDocument19 pagesEverything You Need to Know About Bleaching Powder ProductionKroya Hun100% (1)

- Guyiti Tengi FULL PROJECT FinalDocument51 pagesGuyiti Tengi FULL PROJECT FinalJemalNo ratings yet

- Techno - Economic Feasibility Study To Establish Gelatin & Glue Production PlantDocument53 pagesTechno - Economic Feasibility Study To Establish Gelatin & Glue Production PlantMohammed Abbas100% (1)

- Pre-Feasibility Study: Dairy Farm (10 Cows) EnvironmentallyDocument28 pagesPre-Feasibility Study: Dairy Farm (10 Cows) EnvironmentallyShani Ch100% (1)

- Avocado Farm and Processing PlantDocument14 pagesAvocado Farm and Processing Plantsamuel teferi100% (1)

- Tesfaye CorectttDocument4 pagesTesfaye CorectttTesfaye DegefaNo ratings yet

- KECHEMA POULTRY PRODUCTION PROJECT PROPOSALDocument22 pagesKECHEMA POULTRY PRODUCTION PROJECT PROPOSALmulubrhan mebratuNo ratings yet

- ColorCity Flour-MillDocument52 pagesColorCity Flour-MillANM Azam MehrabNo ratings yet

- Ambo University: Sebeta Milk Supply Section 7Document13 pagesAmbo University: Sebeta Milk Supply Section 7Falmeta EliyasNo ratings yet

- Business Proposal PaperDocument22 pagesBusiness Proposal Paperhayder nuredinNo ratings yet

- EPHIIIDocument35 pagesEPHIIITesfaye DegefaNo ratings yet

- Ethiopia's Growing Feed Industry and Training NeedsDocument60 pagesEthiopia's Growing Feed Industry and Training NeedsAndnet Assefa100% (2)

- Profile On Production of Socks & StockingDocument17 pagesProfile On Production of Socks & Stockinggetachew liger100% (1)

- Investment Office ANRS: Project Profile On SMALL SCALE Pineapple PlantationDocument24 pagesInvestment Office ANRS: Project Profile On SMALL SCALE Pineapple PlantationJohn100% (1)

- Sinidu WWWDocument55 pagesSinidu WWWTesfaye Degefa100% (1)

- Semeli Business PlanDocument17 pagesSemeli Business PlanSintayhuNo ratings yet

- Filter AidDocument18 pagesFilter Aidabel_kayelNo ratings yet

- Packaging FactoryDocument39 pagesPackaging FactoryYonasBirhanuNo ratings yet

- Omer 1Document54 pagesOmer 1Dereje MekonnenNo ratings yet

- Honey ProcessingDocument29 pagesHoney Processingyenealem Abebe100% (1)

- Investment Office ANRS: Project Profile On The Establishment of Milk Production and Processing PlantDocument27 pagesInvestment Office ANRS: Project Profile On The Establishment of Milk Production and Processing PlantYolanda Riddle100% (1)

- Shyam JVL Submitted ProjectDocument66 pagesShyam JVL Submitted ProjectRaj Kishore Goswami100% (1)

- KUNAP'S Final Feasibility StudyDocument51 pagesKUNAP'S Final Feasibility StudyMelat MakonnenNo ratings yet

- Cocks and Valves ProductionDocument28 pagesCocks and Valves ProductionYohannes Woldekidan100% (1)

- Profile On Mushroom FarmDocument20 pagesProfile On Mushroom FarmMartha Getaneh100% (1)

- Hawassa University Project Proposal on Bee Keeping & Honey Processing IndustryDocument25 pagesHawassa University Project Proposal on Bee Keeping & Honey Processing IndustryMohammednur Rahemmato100% (1)

- 2 Feasibility Study On DairyDocument40 pages2 Feasibility Study On DairyAdefrisNo ratings yet

- Abdulahi Hassen 2 PDFDocument14 pagesAbdulahi Hassen 2 PDFMelat MakonnenNo ratings yet

- Milk Pasteurizing Unit Pre-Feasibility StudyDocument15 pagesMilk Pasteurizing Unit Pre-Feasibility StudykhalidshNo ratings yet

- Cotton and Synthetic HoseDocument20 pagesCotton and Synthetic Hoseabel_kayelNo ratings yet

- Business Plan For Machinery Rental and Material SupplyDocument8 pagesBusiness Plan For Machinery Rental and Material SupplyAbenetNo ratings yet

- Group - 1 Entrepreneurship AssignmentDocument21 pagesGroup - 1 Entrepreneurship Assignmentbiniyam mulukenNo ratings yet

- Corrugated Paper BoxDocument13 pagesCorrugated Paper BoxhibadaNo ratings yet

- Model Project ProfilesDocument13 pagesModel Project Profilesabhisek guptaNo ratings yet

- Candy PDFDocument16 pagesCandy PDFGourav Tailor100% (1)

- Profile On Processing of MilkDocument18 pagesProfile On Processing of MilkAmber ChavezNo ratings yet

- Cattle Slaughtering HouseDocument17 pagesCattle Slaughtering HouseSentot NindyantonoNo ratings yet

- Wheat FlourDocument16 pagesWheat FlourRajesh Chowhan100% (4)

- Alcohol From Yam CassavaDocument15 pagesAlcohol From Yam Cassavadinba123No ratings yet

- Vinegar Business PlanDocument16 pagesVinegar Business Plantucahara100% (4)

- Tej ProcessingDocument13 pagesTej ProcessingTSEDEKENo ratings yet

- BiscuitDocument16 pagesBiscuitVishal JainNo ratings yet

- A Study On GST and Its Probable Impact On The Sales Tax Revenue of KeralaDocument62 pagesA Study On GST and Its Probable Impact On The Sales Tax Revenue of KeralaBENIX KANJIRAVILA83% (6)

- Marcellus Little-Champs Presentation DIRECTDocument19 pagesMarcellus Little-Champs Presentation DIRECTBijoy RaghavanNo ratings yet

- TerraPower Case PDFDocument7 pagesTerraPower Case PDFKaustav DeyNo ratings yet

- Ruling:: 2. REPUBLIC V. BAGTAS, 6 SCRA 262 (1962)Document16 pagesRuling:: 2. REPUBLIC V. BAGTAS, 6 SCRA 262 (1962)Bluebells33100% (2)

- Reliance Retail Limited: Sr. No. Item Name Hsn/Sac Qty Price/Unit Discount ValueDocument3 pagesReliance Retail Limited: Sr. No. Item Name Hsn/Sac Qty Price/Unit Discount ValuemukeshNo ratings yet

- Tutsheet 7Document2 pagesTutsheet 7Vikas Kumar PooniaNo ratings yet

- Bangladesh's Net Financial Account, Capital Flows, Balance of Payments and Trade Deficit Trends from 2014-2020Document4 pagesBangladesh's Net Financial Account, Capital Flows, Balance of Payments and Trade Deficit Trends from 2014-2020FahimHossainNitolNo ratings yet

- TestDocument14 pagesTesthonest0988No ratings yet

- Cambridge Master of Finance (MFin) 2013 BrochureDocument13 pagesCambridge Master of Finance (MFin) 2013 BrochureCambridgeJBSNo ratings yet

- Choose Letter of The Correct Answer.Document3 pagesChoose Letter of The Correct Answer.Peng GuinNo ratings yet

- Salary Advances and Staff LoansDocument3 pagesSalary Advances and Staff LoansomarelzainNo ratings yet

- ABM - Specialized Subject: Fundamentals of Accountancy, Business and Management 1Document14 pagesABM - Specialized Subject: Fundamentals of Accountancy, Business and Management 1Jupiter Whiteside100% (6)

- Model Portfolio: DBS Group Research - EquityDocument12 pagesModel Portfolio: DBS Group Research - EquityFunk33qNo ratings yet

- Differences Between An Executor, Administrator and Special AdministratorDocument3 pagesDifferences Between An Executor, Administrator and Special AdministratorALee BudNo ratings yet

- Business Fundamentals BSC Curriculum IntegrationDocument36 pagesBusiness Fundamentals BSC Curriculum IntegrationsuryatnoNo ratings yet

- Payment guarantee letter for €100B transactionDocument13 pagesPayment guarantee letter for €100B transactionEsteban Enrique Posan BalcazarNo ratings yet

- Online BankingDocument35 pagesOnline BankingShanzaiNo ratings yet

- Chapter Three: Interest Rates and Security ValuationDocument40 pagesChapter Three: Interest Rates and Security ValuationOwncoebdiefNo ratings yet

- Cpa 1Document2,011 pagesCpa 1mwanziaNo ratings yet

- Review QuestionsDocument2 pagesReview QuestionsHads LunaNo ratings yet

- 06 ReceivableDocument104 pages06 Receivablefordan Zodorovic100% (4)

- PT INDOFOOD CBP SUKSES MAKMUR TBK DAN ENTITAS ANAKNYADocument3 pagesPT INDOFOOD CBP SUKSES MAKMUR TBK DAN ENTITAS ANAKNYARama fauziNo ratings yet

- Easypaisa-All Pricing and CommissioningDocument17 pagesEasypaisa-All Pricing and Commissioningqaisar_murtaza50% (4)

- Elliot Advisors 2020 Q1 LetterDocument10 pagesElliot Advisors 2020 Q1 LetterEdwin UcheNo ratings yet

- Rta - Price List Agro July 2023Document9 pagesRta - Price List Agro July 2023Saniya ShaikhNo ratings yet

- Tenancy AgreementDocument3 pagesTenancy AgreementseunoyebanjiesqNo ratings yet

- Delegated Regulation Annex enDocument20 pagesDelegated Regulation Annex enNickNo ratings yet

- NOTESDocument12 pagesNOTESBhea Irish Joy BuenaflorNo ratings yet

- Debt Vs EquityDocument10 pagesDebt Vs EquityKedar ParabNo ratings yet

- Accountancy Class XII Practice PaperDocument7 pagesAccountancy Class XII Practice PaperмŕίȡùĻ νέŕмάNo ratings yet