Professional Documents

Culture Documents

Chapter 6 Electrical: A1200 Control Systems

Uploaded by

Juan MartinezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 6 Electrical: A1200 Control Systems

Uploaded by

Juan MartinezCopyright:

Available Formats

Chapter 6 Electrical

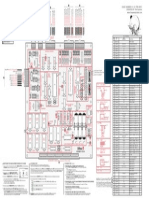

A1200 Control Systems Input/output Keypad & Dip Switch Card Dip Switch 1 Dip Switch 2

Dip Switch 3 Dip Switch 4 Typical Switch layout Off On A1 A2 A3 A4 A5 A6 A7 A8 Page 6 - 1

Note 1: DIP Switch

1=A 2=B 3=C 4=D

Note 2:

On DIP Switch A switches A5 through A8 most always be off as show on the preceding page.

Page 6 - 2

Maximum Angle Adjustment Switch 128 degrees 130 132 134 136 138 140 142 144 146 (K25) 148 150 152 154 156 (15) 158 A1 off on off on off on off on off on off on off on off on A2 off off on on off off on on off off on on off off on on A3 off off off off on on on on off off off off on on on on A4 off off off off off off off off on on on on on on on on

page 6 - 3

Default up-value 0 1 2 3 4 5 6 7 8 9 (normal)

B1 B2 B3 B4 off on off on off on off on off on off off on on off off on on off off off off off off on on on on off off off off off off off off off off on on

Up adjustment switch 5 (shortest time) 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 (longest time)

B5 B6 B7 B8 off on off on off on off on off on off on off on off on off off on on off off on on off off on on off off on on off off off off on on on on off off off off on on on on off off off off off off off off on on on on on on on on

page 6 - 4

Clamp pressure adjustment 40 (shortest time) 48 56 64 72 80 88 96 104 112 120 128 136 144 152 160 (longest time) C1 off on off on off on off on off on off on off on off on C2 off off on on off off on on off off on on off off on on C3 off off off off on on on on off off off off on on on on C4 off off off off off off off off on on on on on on on on

page 6 - 5

Hemming pressure adjustment 8 (shortest time) 24 40 56 72 88 104 120 136 152 168 184 200 216 232 248 (longest) A8 off on off on off on off on off on off on off on off on A8 off off on on off off on on off off on on off off on on A8 off off off off on on on on off off off off on on on on A8 off off off off off off off off on on on on on on on on

page 6 - 6

Backgauge maximum speed 2 (Max output freq) 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 (min output freq) D1 off on off on off on off on off on off on off on off on D2 off off on on off off on on off off on on off off on on D3 off off off off on on on on off off off off on on on on D4 off off off off off off off off on on on on on on on on

page 6 - 7

Backgauge ramp time 2 (shorest ramp time) 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 (longest ramp time) D5 off on off on off on off on off on off on off on off on D6 off off on on off off on on off off on on off off on on D7 off off off off on on on on off off off off on on on on D8 off off off off off off off off on on on on on on on on

page 6 - 8

Trouble Shooting from the LED Relay Card 4321 X6 X7 D28 D29 D30 D31 D32 D33 D10 D11 D12 D13 D14 D15 D22 D23 D24 D25 D26 D27 D16 D17 D18 D19 D20 D21 X9 X11 X10 RE1 RE2 RE3 RE4 RE5 RE6 X12 X3 X4 X5 654321 654321 X8 X1 X2

Harness Connection X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 X12 Serial port communication to I.O. Board 9 vac input power control output sugnal to C1 & C2 relays, (Clamping Beam) control output to C3 & C4 relays, (Bending Apton) control output to backgauge soleniod fingers bending apron encoder input signals clamping pressure input signal backgauge home position switch not used 4/ 5 mm position inputs foot pedal input, clamping beam up, down and bend command. Bending beam return command from right foot pedal; bending beam home; 6 mm.

Page 6 - 9

The LEDs the I/O relay card are visual indicators that provide a visual means of trouble shooting the electrical control system. By observing the LEDs the operator can determine if the correct input commands are being received from the foot pedals, the back gauge home switch, encoder, clamping beam position and bending apron position Switchs. In addition, it is possible to determine if the microprocessor is sending out the correct signals to the various control relays used to operate the bending and clamping beams. All the LEDs on the board are not used, some are reserved for future expansion or functions your unit may not have. Below is a list of the functioning LEDs and what they indicate. D10 Microprocessor is sending an output command to RE1 to open the upper clamping beam.

D11 Microprosser is sending an ouput command to RE2 to close the upper beam. D12 Microprosser is sending an output command to RE3 to move the bending beam up. D13 Microprosser is sending an output command to RE4 to send the bending beam back to home position. D14 Microprosser is sending an output command to RE5 to activate the first set of back gauge fingers. D15 Microprosser is sending an output command to RE6 to activate the second set of back gauge fingers. D16 Normally on, goes off when right foot pedal is activated, works in conjunction with D19, command signal for clamping beam to open up. D17 Normally off, comes on when left foot pedal is activated. Command signal for clamping beam to clamp down. D18 Normally off, comes on when the middle petal is depressed. Is command signal for bending beam to move up. D19 Normally off, works in conjunction with D16, comes on when the right foot petal is activated. Command signal for bending apron to return to home position. Page 6 -10

D20 Bending apron home switch. Normally closed contact, LED is off in the home position, comes on when bending apron is not home. D21 6mm safety switch. LED is on when clamping beam is open more then 3/8 inches. Note: D21 should extinguish before D27 (4 mm switch) when clamping. If the sequence is reversed the microprosser will lock up. The reverse also applies when un-clamping. D22 Not used D23 Not used D24 Not used D24 Not used

D26 Not used D27 4mm position switch. On above 0.200 inches and off below. This is the minimum open height after a bending operation has been completed. D28 & D29 One or both may be on when the bending apron is home. The lights will appear to flicker rapidly during the bending operation. This is the bending apron encoder sending information back to the microposser which determines the bending angle. D30 Not used D31 Clamping pressure switch. Normally open contacts. The switch is activated when the beam is un-clamped.. During the clamping process the switch opens up and this starts a timing sequence for developing clamping pressure. D32 Not used D33 Back gauge home position sensor. Off when the back gauge is forward of 9.5 inches, approximately. On when behind 9,5 inches.

Page 6 - 11

You might also like

- CT V900 A DiagrammDocument1 pageCT V900 A Diagrammsxn69c2703No ratings yet

- TB6560AHQ 4-Axis CNC Driver PDFDocument7 pagesTB6560AHQ 4-Axis CNC Driver PDFMai HuyNo ratings yet

- LG (Cl-11) Lg881y Fpd1800 LCDDocument34 pagesLG (Cl-11) Lg881y Fpd1800 LCDGregory Adolfo AlvarezNo ratings yet

- C 4 WTP 150Document16 pagesC 4 WTP 150Jose Alfredo VillarroelNo ratings yet

- DGR360 Digital Gyro Repeater Operating ManualDocument6 pagesDGR360 Digital Gyro Repeater Operating ManualSeamen 777No ratings yet

- Digital Weighing Indicator: Dacell Co.,LtdDocument56 pagesDigital Weighing Indicator: Dacell Co.,Ltdايمن الهدامNo ratings yet

- Botones Killark PDFDocument59 pagesBotones Killark PDFnikodemis100% (2)

- D-FORCE300S ManualDocument19 pagesD-FORCE300S ManualWladek PNo ratings yet

- Druid LCD 13 and 15 Installer ManualDocument23 pagesDruid LCD 13 and 15 Installer Manualdjiceman33% (3)

- HT9200A/HT9200B DTMF Generators: FeaturesDocument14 pagesHT9200A/HT9200B DTMF Generators: FeaturesNOTIS64No ratings yet

- SAMSUNG TFT-LCD 933HD (LS19CFE) - TroubleshootingDocument28 pagesSAMSUNG TFT-LCD 933HD (LS19CFE) - TroubleshootingJoão Lopes100% (1)

- W3000Document46 pagesW3000Ron FerraroNo ratings yet

- Digital Weighing Indicator: Instruction ManualDocument55 pagesDigital Weighing Indicator: Instruction Manualايمن الهدامNo ratings yet

- 2005 Plasma Field Service Guide: Technical Training Department 1925 E. Dominguez Street Long Beach, CA 90810Document48 pages2005 Plasma Field Service Guide: Technical Training Department 1925 E. Dominguez Street Long Beach, CA 90810jvrsolNo ratings yet

- C 3417 MeDocument16 pagesC 3417 Medem_121129No ratings yet

- Chapter 6 - Remove-Replace ProceduresDocument12 pagesChapter 6 - Remove-Replace ProceduresMiguel Angel ValderramaNo ratings yet

- ThinkTop BasicDocument17 pagesThinkTop BasictuyentruongNo ratings yet

- Man Xle Hexe104Document2 pagesMan Xle Hexe104Joao RobertoNo ratings yet

- Interfaz TecnicoDocument45 pagesInterfaz TecnicoPlanos MontacargasNo ratings yet

- Operation Manual of The ParkingDocument21 pagesOperation Manual of The ParkingOsmel RegüeiferosNo ratings yet

- Tp2000 ManualDocument27 pagesTp2000 ManualRizqi AmeryaNo ratings yet

- Samsung Hlr4264wx Xac Chassis l62bDocument81 pagesSamsung Hlr4264wx Xac Chassis l62bDaniboy1994No ratings yet

- Horner He Xe102jkDocument4 pagesHorner He Xe102jkjcudrisNo ratings yet

- DriverDocument5 pagesDriverHanks ZetaNo ratings yet

- Ellix10 Um Eng STDDocument43 pagesEllix10 Um Eng STDHaïthem BEN SALEMNo ratings yet

- Changzhou Wantai Electrical Appliance Co., LTD: Product FeaturesDocument10 pagesChangzhou Wantai Electrical Appliance Co., LTD: Product FeaturesMarcos AndréNo ratings yet

- Cpu BoardDocument0 pagesCpu BoardMauricio RaúlNo ratings yet

- 2500 CryptoDocument14 pages2500 CryptoinsulatedNo ratings yet

- ABS & VSC Diagnostics for 2002 Lexus LX470Document10 pagesABS & VSC Diagnostics for 2002 Lexus LX470Gabriel BalcazarNo ratings yet

- PT-76 Series Temperature Controller Operation Manual - B0Document2 pagesPT-76 Series Temperature Controller Operation Manual - B0jowegNo ratings yet

- Samsung Hlp4663wx Xaa CH l62b-n AtlantisDocument80 pagesSamsung Hlp4663wx Xaa CH l62b-n AtlantisVinicius MarcosNo ratings yet

- G320X REV-10 Manual FormattedDocument7 pagesG320X REV-10 Manual FormattedNghia Nguyen TrongNo ratings yet

- 3 Axis TB6560 3.5A Stepper Motor Driver Board Manual PDFDocument10 pages3 Axis TB6560 3.5A Stepper Motor Driver Board Manual PDFNisar AhmedNo ratings yet

- NEC Format RemoteDocument15 pagesNEC Format RemoteMunish KaundalNo ratings yet

- Notes: Cam Operated Rotary Switches Cam Operated Rotary SwitchesDocument16 pagesNotes: Cam Operated Rotary Switches Cam Operated Rotary Switchesatanumaster1987No ratings yet

- TB6560 3-Axis Driver GuideDocument9 pagesTB6560 3-Axis Driver Guidejulio cesar rosales mendezNo ratings yet

- Warning: Canstart™ 9641/9642Document4 pagesWarning: Canstart™ 9641/9642montoya2333No ratings yet

- Ac 082aDocument18 pagesAc 082aSmehurko SmehurkovNo ratings yet

- TS Mounting InstructionDocument28 pagesTS Mounting InstructionLinweiXiaNo ratings yet

- Kodak Dryview 6800 LASER IMAGER System Block DiagramDocument4 pagesKodak Dryview 6800 LASER IMAGER System Block DiagramDaiane SantosNo ratings yet

- Denon DCD 1650srDocument47 pagesDenon DCD 1650srboroda2410No ratings yet

- LG Color Monitor Flatron l1915sDocument26 pagesLG Color Monitor Flatron l1915ssontuyet82No ratings yet

- DMP3300 Technical ManualDocument16 pagesDMP3300 Technical ManualHr DaniNo ratings yet

- DELTA IA-PLC Mark AN EN 20151022 PDFDocument32 pagesDELTA IA-PLC Mark AN EN 20151022 PDFengrmunirNo ratings yet

- Casio CE3700 SMDocument61 pagesCasio CE3700 SMSergiu HălăucăNo ratings yet

- JV50-CP Block DiagramDocument67 pagesJV50-CP Block Diagramfdsaq12No ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- Electronic Circuit Design Ideas: Edn Series for Design EngineersFrom EverandElectronic Circuit Design Ideas: Edn Series for Design EngineersRating: 5 out of 5 stars5/5 (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Troubleshooting & Repairing Consumer Electronics Without a SchematicFrom EverandTroubleshooting & Repairing Consumer Electronics Without a SchematicNo ratings yet

- 110 Semiconductor Projects for the Home ConstructorFrom Everand110 Semiconductor Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Ezer or Kinegdo?Document5 pagesEzer or Kinegdo?binhershNo ratings yet

- Language Interrupted Signs of Non Native Acquisition in Standard Language Grammars PDFDocument332 pagesLanguage Interrupted Signs of Non Native Acquisition in Standard Language Grammars PDFjuramentatdo00No ratings yet

- Device DriversDocument18 pagesDevice DriversAnet Augustin100% (1)

- 5 3-6 EALD Progression by Mode SpeakingDocument1 page5 3-6 EALD Progression by Mode SpeakingS TANCREDNo ratings yet

- 1 Chapter 16 Software ReuseDocument52 pages1 Chapter 16 Software ReuseSalah AlaaNo ratings yet

- Bài Tập Về Đại Từ Nhân XưngDocument46 pagesBài Tập Về Đại Từ Nhân XưngVuong PhanNo ratings yet

- PWX 861 Message ReferenceDocument982 pagesPWX 861 Message Referencekomalhs100% (1)

- Hbsc2203 - v2 - Tools of Learning of SciencesDocument10 pagesHbsc2203 - v2 - Tools of Learning of SciencesSimon RajNo ratings yet

- Analytical WritingDocument3 pagesAnalytical WritingLuisa GomezNo ratings yet

- IBM - Mail File Is Slow To ..Document3 pagesIBM - Mail File Is Slow To ..Saravana Kumar100% (1)

- Cambridge International AS & A Level: Further Mathematics 9231/31Document15 pagesCambridge International AS & A Level: Further Mathematics 9231/31Saad HasanNo ratings yet

- Logcat Home Fota Update LogDocument1,715 pagesLogcat Home Fota Update LogMarco AntonioNo ratings yet

- Religion and Politics in EthiopiaDocument26 pagesReligion and Politics in EthiopiaAbduljelil Sheh Ali KassaNo ratings yet

- Starter Architecture For Flutter & Firebase Apps Using RiverpodDocument28 pagesStarter Architecture For Flutter & Firebase Apps Using RiverpodYochay RofeNo ratings yet

- 6-1 Data Set HWDocument1 page6-1 Data Set HWAbeer Arif100% (2)

- 1920-2-PR1-Lesson 4Document30 pages1920-2-PR1-Lesson 4Ivy MuñozNo ratings yet

- 6 (C) The Saints of Medieval IndiaDocument12 pages6 (C) The Saints of Medieval IndiaIAS EXAM PORTALNo ratings yet

- Vilani GrammarDocument51 pagesVilani GrammarpolobiusNo ratings yet

- The Ugly TruthDocument94 pagesThe Ugly Truthgeetkumar1843% (7)

- Adjectives ending in ed or ing describing feelings and causesDocument1 pageAdjectives ending in ed or ing describing feelings and causesGuille RastilloNo ratings yet

- PBL AssignmentDocument2 pagesPBL AssignmentFaseeh HyderNo ratings yet

- Scattering of Scalar Waves From A Schwarzschild Black HoleDocument6 pagesScattering of Scalar Waves From A Schwarzschild Black HoleCássio MarinhoNo ratings yet

- Oral Com 1Document10 pagesOral Com 1Educ AcohNo ratings yet

- 12 - ODI ToolsDocument12 pages12 - ODI ToolsMaheshBirajdarNo ratings yet

- Test scenarios for web application testingDocument21 pagesTest scenarios for web application testingHùng ĐoànNo ratings yet

- Completing Sentences Using Given WordsDocument4 pagesCompleting Sentences Using Given WordsTante DeviNo ratings yet

- Ilp Pat Test On DbmsDocument5 pagesIlp Pat Test On DbmsVijai MoganNo ratings yet

- The Parable of Rainbow Colors - Actual 17Document6 pagesThe Parable of Rainbow Colors - Actual 17Mark Lagorra Perez25% (4)

- M0 11873Document324 pagesM0 11873api-3726475100% (2)