Professional Documents

Culture Documents

RT Vol. 9, No. 4 Clear Field Technology Clears Out Red Rice

Uploaded by

Rice TodayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT Vol. 9, No. 4 Clear Field Technology Clears Out Red Rice

Uploaded by

Rice TodayCopyright:

Available Formats

Clearfield technology clears out red rice

The adoption of Clearfield technology brings positive changes to the U.S. rice industry

ice production is an important part of the agricultural industry in the southern United States, especially in the major producing states of Arkansas, Louisiana, Mississippi, Missouri, and Texas. The mechanized production of rice began in the 1880s in southwest Louisiana, when farmers started to use some of the new agricultural implements invented during this period. From the earliest beginning of this industry, production was plagued by a weedy relative of commercial rice called red rice, which came in with the first seed used by the fledgling industry. Most red rice biotypes are characterized by a red pericarp or outer covering. Thus, if the grain is harvested, and makes it through the milling process, it reduces the quality of milled white rice. However, much of the red rice produced in a commercial rice field will never make it through the combine harvester because red rice tends to shatter as it matures. Also, its seed can be dormant for a longer time. Because of its shattering and dormancy traits, once a field is infested with red rice, the seed will remain viable and problematic for many years. Since commercial rice and red rice are so closely related, it has been difficult to develop a conventional herbicide that can control red rice without significantly damaging the commercial rice crop. However, work initiated by Dr. Tim Croughan and his associates in the 1980s at the Rice Research Station in

1

red riCe, a close relative of rice, is a noxious weed that can be controlled very effectively with the Clearfield production system.

by Steve Linscombe

Crowley, Louisiana, USA, eventually led to the development of Clearfield1 rice production technology, which can control red rice in commercial rice production.

Developing Clearfield rice

As it was not feasible to develop a rice herbicide to control red rice without harming the commercial rice, the idea was to develop a new type of rice plant that would be genetically resistant to a herbicide that would control red rice. This was accomplished by a process known as induced mutation breeding, in which many seeds are subjected to an agent that causes a high level of mutations or changes to the genetic makeup of the seed. The agent used was a chemical called ethyl methane sulfonate (EMS). After treatment with EMS, the seeds were planted, and the resulting plants were sprayed with imazethapyr, a herbicide known to control red rice (as well as conventional rice) effectively. After several years of repeating this process with billions of rice seeds, success was finally achieved when a lone plant survived the imazethapyr treatment. This single plant, along with several more resistant plants, which were developed in the same way a few years later, led to the birth of the successful Clearfield rice technology. We finally had rice that could be safely sprayed with a chemical that would kill red rice. Then, through conventional rice breeding, new varieties were developed that have high

yields and superior traits and at the same time are resistant to imazethapyr and to a related chemical called imazamox, which is also used with the technology. Thus, we could now effectively control red rice while growing high-yielding, highquality rice varieties. The technology was first used on a limited area in 2002. This area has steadily grown through the years, and, in 2010, Clearfield rice is being grown on more than 60% of the rice area in the southern United States. This includes varieties developed by both the Louisiana State University Agricultural Center and the University of Arkansas breeding programs, as well as hybrids developed by RiceTec, a private rice breeding company. Moreover, the breeding programs of Mississippi State University and Southeast Missouri State University are actively working to develop new Clearfield lines.

practices that prevented red rice seed from germinating. Water in soil keeps oxygen away from the seed and prevents germination. A typical system involved flooding a rice field in the early spring and then working the field in the water to destroy any red rice seedlings present. After this operation, pregerminated seeds were scattered over the field. Shortly after seeding, the field was drained briefly to help seeds establish their root system. The trick was to leave the field drained only long enough for the root to anchor,

but not too long for the soil to crack and for oxygen to find its way to the red rice seed below the soil surface. This system suppressed only red rice, and its success depended on weather conditions as well as pumping capabilities that would allow a field to be quickly re-flooded. Another major problem with this system was, when fields were drained after seeding, the water left in the field contained a high sediment load from the water tillage operation. This led to soil erosion as well as water quality problems in receiving streams. The advent of the Clearfield technology meant that these fields would no longer have to be worked in the water and could now be dry-seededin many cases, using no-till or minimum-till techniques. So, in addition to improving weed control, Clearfield technology has greatly reduced soil erosion and improved water quality and overall environmental stewardship.

An inherent setback

It is important to note, however, that the Clearfield technology is not without its shortcomings. Because rice and red rice are so closely related, pollen can flow between the two types of rice. Thus,

Clearfield rice can pollinate red rice and vice versa. Either way can lead to red rice plant types with resistance to the herbicides used with the technology. Stewardship programs have been designed to minimize this problem that is inherent with the technology. Another problem is the contamination of adjacent fields of conventional (non-Clearfield) rice with herbicides used in Clearfield rice, which can cause severe injury. These are very real issues, and every effort must be made to minimize their occurrence. Despite the problems, this technology has been rapidly adopted across the southern United States and has led to high-yielding, higherquality rice being produced using more environmentally sound production practices. The reduction of red rice has also greatly benefited the milling industry as well as consumers and other end users. Clearfield rice is also being grown today in a number of other riceproducing countries. Dr. Linscombe is a senior rice breeder and director of the Louisiana State University Agricultural Center.

Bruce Schultz (2)

The Clearfield system allows farmers to produce crops free of red riceeven in fields with a significant level of red rice seeds in the soil.

Controlling red rice

The Clearfield technology has dramatically improved rice producers ability to control red rice. Imazethapyr and imazamox excellently control many other problematic weeds in rice production. Also, the Clearfield technology has changed the production systems used in rice farming. Before Clearfield rice, the only approach to minimize red rice on severely infested fields was by combining water-seeding and water management

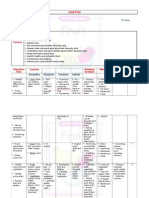

Percentage of Clearfield rice area in southern U.S. (2010) Total Clearfield Clearfield rice (ha) rice (ha) % Arkansas 721,360 Louisiana 212,750 Mississippi 122,030 Texas 101,820 Missouri 75,430 Southern 1,233,390 U.S. 432,800 164,000 75,650 36,600 27,150 736,200 60 77 62 36 36 60

Data sources: USDA Farm Services Agency and LSU AgCenter.

Clearfield rice is a technology owned by BASF.

44

Rice Today October-December 2010

Rice Today October-December 2010

45

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Dukan Diet: 2 Steps To Lose The Weight, 2 Steps To Keep It Off Forever - Pierre DukanDocument5 pagesThe Dukan Diet: 2 Steps To Lose The Weight, 2 Steps To Keep It Off Forever - Pierre Dukanfikojatu100% (1)

- Rice Today Vol. 14, No. 2Document37 pagesRice Today Vol. 14, No. 2Rice TodayNo ratings yet

- Chris Acceto Carb LoadingDocument4 pagesChris Acceto Carb LoadingMilana Milanovic92% (12)

- Bare GuideDocument71 pagesBare GuideLaura IsopNo ratings yet

- Breadman RecipeDocument10 pagesBreadman RecipeCharles ChanNo ratings yet

- Business Plan Group 1 (Example)Document19 pagesBusiness Plan Group 1 (Example)STEPHEN JAMES RONCESVALLES LIZANo ratings yet

- PRACTICAL TRAINING REPORT AishahDocument34 pagesPRACTICAL TRAINING REPORT AishahAishah LatepNo ratings yet

- Rice Today Vol. 14, No. 2 A Schoolboy at Heart: Celebrated Indian Scientist Speaks His MindDocument3 pagesRice Today Vol. 14, No. 2 A Schoolboy at Heart: Celebrated Indian Scientist Speaks His MindRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 What Latin America's Rice Sector Offers The WorldDocument2 pagesRice Today Vol. 14, No. 2 What Latin America's Rice Sector Offers The WorldRice TodayNo ratings yet

- Rice Today Special Supplement For The Philippine Department of Agriculture Management Committee Meeting, 6-8 April 2015Document48 pagesRice Today Special Supplement For The Philippine Department of Agriculture Management Committee Meeting, 6-8 April 2015Rice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Celebrating 50 Years of Impact Through Rice Research in IndiaDocument1 pageRice Today Vol. 14, No. 2 Celebrating 50 Years of Impact Through Rice Research in IndiaRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Regional Cooperation Speeds Up The Release of Rice VarietiesDocument1 pageRice Today Vol. 14, No. 2 Regional Cooperation Speeds Up The Release of Rice VarietiesRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Home-Made Noodles From GhanaDocument1 pageRice Today Vol. 14, No. 2 Home-Made Noodles From GhanaRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 GOTDocument2 pagesRice Today Vol. 14, No. 2 GOTRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Rice Scientists From India Helping AfricaDocument1 pageRice Today Vol. 14, No. 2 Rice Scientists From India Helping AfricaRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Indian Farmer Kick-Starts Two Green RevolutionsDocument1 pageRice Today Vol. 14, No. 2 Indian Farmer Kick-Starts Two Green RevolutionsRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 India Reaches The Pinnacle in Rice ExportsDocument3 pagesRice Today Vol. 14, No. 2 India Reaches The Pinnacle in Rice ExportsRice TodayNo ratings yet

- Rice Today Vol 14, No. 2 Averting Hunger in Ebola-Hit CountriesDocument1 pageRice Today Vol 14, No. 2 Averting Hunger in Ebola-Hit CountriesRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Yield Rises With WeRiseDocument1 pageRice Today Vol. 14, No. 2 Yield Rises With WeRiseRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Revisiting 50 Years of Indian Rice ResearchDocument2 pagesRice Today Vol. 14, No. 2 Revisiting 50 Years of Indian Rice ResearchRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Nuggets of Planetary TruthDocument1 pageRice Today Vol. 14, No. 2 Nuggets of Planetary TruthRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 DRR Rice Museum Features Traditional Wisdom and Scientific BreakthroughsDocument1 pageRice Today Vol. 14, No. 2 DRR Rice Museum Features Traditional Wisdom and Scientific BreakthroughsRice TodayNo ratings yet

- GRiSP: Partnerships For SuccessDocument1 pageGRiSP: Partnerships For SuccessRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 What Kind of Rice Do Consumers Want?Document1 pageRice Today Vol. 14, No. 2 What Kind of Rice Do Consumers Want?Rice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 Uruguayan Rice The Secrets of A Success StoryDocument2 pagesRice Today Vol. 14, No. 1 Uruguayan Rice The Secrets of A Success StoryRice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 Where's My GM RiceDocument1 pageRice Today Vol. 14, No. 1 Where's My GM RiceRice TodayNo ratings yet

- Rice Today Special SupplementDocument27 pagesRice Today Special SupplementRice TodayNo ratings yet

- Rice Today Vol. 14, No. 2 Striking A Balance Through Ecologically Engineered Rice EcosystemsDocument2 pagesRice Today Vol. 14, No. 2 Striking A Balance Through Ecologically Engineered Rice EcosystemsRice TodayNo ratings yet

- Rice Today Special Supplement For Farmers' DayDocument23 pagesRice Today Special Supplement For Farmers' DayRice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 Unleashing The Rice MarketDocument2 pagesRice Today Vol. 14, No. 1 Unleashing The Rice MarketRice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 The Rise of Rice On Peru's Sacred GroundDocument2 pagesRice Today Vol. 14, No. 1 The Rise of Rice On Peru's Sacred GroundRice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 Trends in Global Rice TradeDocument2 pagesRice Today Vol. 14, No. 1 Trends in Global Rice TradeRice Today100% (1)

- Rice Today Vol. 14, No. 1 Tah Chin Saffron Rice and ChickenDocument1 pageRice Today Vol. 14, No. 1 Tah Chin Saffron Rice and ChickenRice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 Korea The Good BrothersDocument1 pageRice Today Vol. 14, No. 1 Korea The Good BrothersRice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 Making Rice More Competitive in Latin AmericaDocument2 pagesRice Today Vol. 14, No. 1 Making Rice More Competitive in Latin AmericaRice TodayNo ratings yet

- Rice Today Vol. 14, No. 1 Green Revolutions 2.0 & 3.0 No Farmer Left BehindDocument2 pagesRice Today Vol. 14, No. 1 Green Revolutions 2.0 & 3.0 No Farmer Left BehindRice TodayNo ratings yet

- Project Report: Fast Food Restaurant Swot Analysis)Document19 pagesProject Report: Fast Food Restaurant Swot Analysis)deepankar jhaNo ratings yet

- The Mcdonald's Way Case StudyDocument13 pagesThe Mcdonald's Way Case Studyshahnawaz shaikhNo ratings yet

- BOPIS Recipe: Filipino Pork Heart and Lungs DishDocument4 pagesBOPIS Recipe: Filipino Pork Heart and Lungs DishDessa Ruth ReyesNo ratings yet

- Food - Lesson Plan (Can Do)Document5 pagesFood - Lesson Plan (Can Do)claudiamonteirodt5eNo ratings yet

- Sugar Daddy ChurrosDocument6 pagesSugar Daddy Churrosrizaldorodriguez510No ratings yet

- Raidco ProjectDocument21 pagesRaidco ProjectSree Nath0% (1)

- MNT 1 DM Case Study Due 11 29 2016Document3 pagesMNT 1 DM Case Study Due 11 29 2016api-340581896No ratings yet

- FoodsamplingDocument2 pagesFoodsamplingLance OwelNo ratings yet

- 33 Power FoodsDocument21 pages33 Power FoodsTirthankar BhaduryNo ratings yet

- Global Food SecurityDocument7 pagesGlobal Food SecurityMizraim EmuslanNo ratings yet

- Adults Daily Routine - 13545Document2 pagesAdults Daily Routine - 13545hamidNo ratings yet

- Chapter 4 CarbohydratesDocument10 pagesChapter 4 CarbohydratesFendy HamidNo ratings yet

- BM McDonald'sDocument9 pagesBM McDonald'sJessica Jimenez SaltingNo ratings yet

- Lesson 2 Baking Tools and EquipmentDocument38 pagesLesson 2 Baking Tools and EquipmentMatthew Carl DuranNo ratings yet

- Chapter - I, Company ProfileDocument21 pagesChapter - I, Company Profileananthakumar100% (3)

- Reducing Sugar IntakeDocument2 pagesReducing Sugar IntakejenjenNo ratings yet

- Danh Tư Số Ít-NhiềuDocument9 pagesDanh Tư Số Ít-Nhiềudien.nguyen.bbs19No ratings yet

- DSM FEED LabellingDocument29 pagesDSM FEED LabellingIGFAieNo ratings yet

- Nghe 5 No2Document8 pagesNghe 5 No2Ngot NguyenNo ratings yet

- Unit 2 - Answer KeyDocument3 pagesUnit 2 - Answer KeyStyle GeorgieNo ratings yet

- Sprecher's Gluten Free MenuDocument4 pagesSprecher's Gluten Free Menusupport_local_flavorNo ratings yet

- Factors Influencing Agriculture and Types of FarmingDocument2 pagesFactors Influencing Agriculture and Types of FarmingMohammad ImranNo ratings yet

- Quantifiers Schede CompressedDocument19 pagesQuantifiers Schede CompressedMariela Mota HernándezNo ratings yet

- Test For Nutrients in FoodsDocument2 pagesTest For Nutrients in FoodsAdrian Alvinson NazarenoNo ratings yet