Professional Documents

Culture Documents

Artículo Oleaginosas 5-9

Uploaded by

Gonzalo ParedesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Artículo Oleaginosas 5-9

Uploaded by

Gonzalo ParedesCopyright:

Available Formats

Amylose from cereal starches can form gels on cooling from a hot solution.

We have been interested to find out whether a general structure can be found for amylase gels. Studies have therefore been performed on purified amylose, and Fig. 6 shows a TEM micrograph of a thin section of an amylose gel. One plane of the gel is in view, and the micrograph reveals a gel structure composed of stiff rod-like strands. We then thought it would be interesting to carry out the same investigation of the continuous phase of a wheat starch gel. Figure 7 shows part of such a continuous phase; a similar type of stiff rod-like gel structure as observed in the pure amylase gels is indeed evident. In addition, spherical particles can be seen. These are small hydrated particles, probably composed of hydrated amylopectin, that have a stabilizing effect on the amylose network. The structures found in dispersions of pure wheat starch affect the structure and functionality of complex food products. For example, both types of starch swelling are important in determining the texture of pasta. In the outer layers of cooked pasta, the granules are in the second stage of swelling, as shown in Fig. 8. The granules have lost their original shape, and substantial amounts of amylose have leached out of the granules and can be seen as blue-stained pools outside the amylopectin-rich brownish granules. This gel-like outer layer controls the diffusion of water into the central parts of the pasta, where the granules are in their first stage of swelling. If the pasta is heated at a lower temperature and all of the granules are in the first stage of swelling, the pasta will be judged as spongy rather than 'al dente' regardless of the duration of heating. Apart from the elongated A-starch granules, this plastic section reveals numerous small B-starch granules embedded in the yellow-stained gluten matrix. A cryo-section would be too thick to reveal such details. Electron microscopy has been used to show that amylose leaches out into the gluten phase and fills small pores in the gluten network. The aggregated amylose in the pores can be expected to have a stabilizing effect on the gluten network and to add to the firmness of the pasta. Released amylose has a strong tendency to interact and aggregate at the surfaces of other particulate materials in foods. Amylose is known to interact with aroma compounds, emulsifiers, lipids, proteins and other polysaccharides in a manner that can affect the stability and the sensory perception of a product. For this reason, an understanding of the interactions among starch and other components is important for product development. Sometimes, the tendency of amylose to interact with lipids can give rise to quality problems, such as cloudiness in sauces, whereas starch-gluten interaction can have a positive effect on pasta texture. Potato starch: a close-packed system or a macromolecular dispersion? Potato starch is an example of a high-swelling starch system. Phosphate groups covalently linked to the amylopectin in potato starch increase its hydrophilic nature. Potato starch gives high viscosity and high waterbinding capacity, and it has a low swelling temperature. Compared with cereal starches, it retrogrades less, is more transparent and has a blander taste. Owing to its slightly higher price and limited supply in some parts of the world, potato starch is not normally used for bulk applications, but used for its special properties. A substantial amount of potato starch is used in papermaking: as a cationic derivative, it improves the binding of fillers and fibres as well as the paper strength. During gelatinization, the granules flfSt swell like balloons, which may subsequently collapse and become folded23. The volume of a swollen granule is -100-fold greater than that of an ungelatinized granule. Cereal starch granules swell up to 30-fold their original volume during the second stage of swelling at 90C (Refs 24 and 25). The large size of potato starch granules and their high swelling capacity lead to swollen granules that are exceptionally large in volume, which not only result in a high viscosity but also give rise to a less smooth texture. At concentrations greater than 4%, the gel phase of the swollen granules occupies practically the entire volume, and the structure will be that of a close-packed system26, as depicted schematically in Fig. Ib. The granule shown in Fig. 9 is in the course of gelatinization; it can be seen that swelling has started with an influx of water into the amorphous middle of the granule, the hilum. The granules swell first in the middle and then rupture as a result of internal pressurel3. A fully gelatinized starch paste is shown in Fig. 10. The structures stained violet are the gel phase of the swollen granules, consisting mainly of amylopectin; the structures stained dark blue are the aqueous phase into which the amylose has diffused. The granular gel phase is the dominant structure, as shown in the schematic representation in Fig. Ib. The swollen granules are folded, intertwined and fractured. It is therefore difficult to identify individual swollen granules. Most of the blue-stained leached amylose is found in the middle of swollen granules. Potato and tapioca starches, which have a high swelling capacity, also form gels much more slowly than cereal starches. The higher amylose content and lower molecular weight of amylose in cereal starches than in potato starch cannot fully explain the higher rate of gel formation of cereal starches. Insufficient release of amylose from potato starch granules might also be an important factor. One characteristic of potato starch is the fragility of the swollen granules, which makes them prone to disperse or solubilize on heating and shearing, resulting in a macromolecular dispersion, as depicted in Fig. lc. The processing of potato starch therefore readily results in overcooking. Crosslinking to various degrees is used to tailor the starch to a particular process. Figure II shows a macromolecular solution of an 8% starch paste that has been heated at 90C and heavily sheared until no remnants of swollen granules remained.

The same type of structure can be obtained by autoclaving or jet cooking at 120C. One interesting feature is the phase separation; the amylopectin and the amylase can be seen separately within the phase of the macromolecular dispersed starch. The amylopectin appears to form a continuous phase (stained red or violet), whereas the amylose appears to be dispersed as droplets (stained blue). Figure 12 shows a starch paste that has also been cooked at 90C but sheared less heavilyl8. The system is a mixture of fragments of swollen granules and a macromolecular dispersion of amylose and amylopectin. In some application areas in paper-making, the remnants of swollen granules may be detrimental. Potato starch for use in paper-making is therefore jet cooked at 120C, so that no remnants of granules remain. Results from mixed amylose-amylopectin model systems have shown that amylopectin forms the continuous phase below a relative ratio of 22% amylose28.29P.o tato starches contain -20% amylosel,2, and the micrographs in Figs II and 12 imply that amylopectin does form a continuous phase. Interestingly, cereal starches normally have a relatively high content of amylose (-28%)1,2, which is greater than the inflection point at which amylose becomes the continuous phase in model mixed systems. This phenomenon has not been studied in the context of real starch systems, although it could underlie some effects seen during both swelling and phase separation. Rheology as related to microstructure The effects of the structural states can be clearly seen from the changes in the rheological behaviour .Oscillatory viscoelastic measurements can be performed in such a manner that the structure is not influenced mechanically by the measurement. Figure 13 shows the differences in rheological behavior between wheat starch and potato starchI8,30T. he greatest difference is the increase in shear modulus due to the formation of the continuous amylose gel phase in wheat starch on cooling. Shear does not influence the general rheological behaviour of wheat starch, but the shear modulus of the gel is decreased. The probable reason for this is that the highly hydrated outer amylopectin layers of the swollen granules are sheared off, as mentioned earlier. The close-packed potato starch dispersion does not gel directly on cooling. The potato starch depicted in Fig. 13 was subjected to a minimum degree of shear during preparation. The effects of shear on the rheological properties are far more drastic for potato starch dispersions than for wheat starch dispersions. This is illustrated in Fig. 14 by the viscoelastic behaviour of a 5% potato starch paste sample that had been subjected to a minimum degree of shear and another 5% paste sample that had been sheared before making the viscoelastic measurements31. The continuous line shows how the shear modulus changes on heating and cooling under a minimum degree of shear. The squares represent sheared samples, and illustrate a drastic decrease in the shear modulus relative to that of the low-sheared sample. At the point where the shear modulus reaches the low plateau value, amylopectin makes up the continuous phase surrounding the remaining fragments of the granules, as shown in Fig. 12 (Ref. 18). The continuous amylopectin phase determines the rheological behaviour of sheared potato starch dispersions, and the continuous amylose phase of wheat starch gels determines the behaviour of wheat starch systems. Potato amylopectin: a new type of starch A completely new type of starch has recently been developed by Lyckeby Starkelsen (Kristianstad, Sweden) and Svalof Weibull (Svalof, Sweden) using genetic engineering. The synthesis of amylose in potatoes has been suppressed using an antisense technique. The alterations in the biosynthesis of this starch type are basically the same as in the waxy genotypes of, for example, maize and barley. The potato amylopectin granules are ordered as in normal starch granules, with the amylopectin forming microcrystallites. There is little change in the gelatinization temperatures or degree of crystallinity of the starch granules (K. Svegmark et al., in preparation). The storage stability of potato amylopectin is high, as is the case for other amylopectin starches. The high molecular weight of potato starch and the very low content of lipids and proteins give this starch the unique properties of being both stable and viscous and capable of producing exceptionally clear solutions. The consistency is long and similar to that of overcooked potato starch. The absence of amylose completely alters the swelling pattern described previously for starch granules. Figure 15 shows an amylopectin granule in the course of gelatinization. Nothing is stained blue, because no amylose is present. The part of the granule that is still ungelatinized is clearly seen in brown. The main structural alteration is that the gelatinized part does not form the structures typical of swollen granules. Instead, it immediately transforms into a macromolecular solution. The immediate dissolution of the granules following gelatinization is an advantage in all applications in which swollen granules and fragments of swollen granules are unwanted. Amylose is believed to act as a restraint on swelling, and cereal starch granules do not show complete swelling until amylose has been leached out of the granule. One proposed mechanism that might explain this is that amylose-lipid complexes within cereal starch granules dissolve at temperatures higher than the gelatinization temperature. The swelling pattern of potato amylopectin granules proves that amylose also restrains swelling and maintains the integrity of swollen starch granules in the case of starches with a low lipid content.

The amylopectin in a completely gelatinized paste, as shown in Fig. 16, forms unusual structures. These uniform structures in the shape of small 'cushions' fill the whole section. Amylopectin in normal potato starch has not been shown to develop such structures. However, as mentioned above, normal potato starch has to be heated to temperatures much higher than the gelatinization temperature to remove the remnants of swollen granules. At such temperatures, phase separation is enhanced in potato starch and the amylose is released from the amylopectin. This example illustrates the enormous potential of combining knowledge of structure-function relationships together with new technology to achieve the performance required of starch-containing products. The development of potato amylopectin starch has been driven by a need for improved functionality in the paper industry .In the food industry , too, an increased understanding of starch functionality and how it is affected by other ingredients and processing methods should lead to improvements in the quality of both new and traditional food products. Acknowledgements The authors would like to express their appreciation to Siw Kidman for skilful microscopy work.

You might also like

- Starch GranuleDocument9 pagesStarch GranuleKay Buchorchor JnrNo ratings yet

- 4 Starch Solutions ViscosityDocument4 pages4 Starch Solutions ViscositySiddhartha PachisiaNo ratings yet

- Physically Modified Starches A ReviewDocument3 pagesPhysically Modified Starches A ReviewSantosh MishraNo ratings yet

- (Doi 10.1007/978!1!4613-0671-9 - 8) Skeist, Irving - Handbook of Adhesives Starch Based AdhesivesDocument14 pages(Doi 10.1007/978!1!4613-0671-9 - 8) Skeist, Irving - Handbook of Adhesives Starch Based Adhesivesguptarahul1992No ratings yet

- RetrogradationDocument16 pagesRetrogradationChaitra H MNo ratings yet

- Karbohidrat IIDocument64 pagesKarbohidrat IIdestikrismalolaNo ratings yet

- Colloids Study!Document19 pagesColloids Study!Alyssa RomeroNo ratings yet

- Egg Yolk Proteins Gels and EmulsionsDocument6 pagesEgg Yolk Proteins Gels and EmulsionsGeesurihani Ibrahim IbrahimNo ratings yet

- Effects of Enzymes on Bread StalingDocument5 pagesEffects of Enzymes on Bread StalingJUAN JOSE ESCOBARNo ratings yet

- Paper No. 01 Paper Title: Food Chemistry Module - 5: Food Polysaccharides-1: StarchDocument7 pagesPaper No. 01 Paper Title: Food Chemistry Module - 5: Food Polysaccharides-1: StarchMaruthi Kadamuddi KHNo ratings yet

- Draft PackagingDocument2 pagesDraft PackagingTaruna AggarwalNo ratings yet

- Interesting Facts About Starch in FoodDocument4 pagesInteresting Facts About Starch in FoodKuldeep KumarNo ratings yet

- T.P. Lyons - The Alcohol Textbook (1999 Cap 2-6)Document81 pagesT.P. Lyons - The Alcohol Textbook (1999 Cap 2-6)Rodolfo RivadeneyraNo ratings yet

- Gelatinization and Rheological Properties of Native and Modified StarchesDocument12 pagesGelatinization and Rheological Properties of Native and Modified StarchesMerRasiaNo ratings yet

- TLE 10 Cookery - Part 1 Prepare Cereal and StarchDocument18 pagesTLE 10 Cookery - Part 1 Prepare Cereal and StarchKatrina Cassandra EscovillaNo ratings yet

- Properties and Applications of Starch-Converting Enzymes of The A-Amylase FamilyDocument19 pagesProperties and Applications of Starch-Converting Enzymes of The A-Amylase Familya1805352No ratings yet

- Latinisation of Starch and Wheat Flour Starch - A Review (1978)Document25 pagesLatinisation of Starch and Wheat Flour Starch - A Review (1978)Kiefer YuNo ratings yet

- Controlled Release of Encapsulated Agents from Starch MatricesDocument5 pagesControlled Release of Encapsulated Agents from Starch MatricesAngela KopperNo ratings yet

- Texture and Staling of Wheat Bread Crumb - Effects of Water Extractable Proteins and 'Pentosans'Document10 pagesTexture and Staling of Wheat Bread Crumb - Effects of Water Extractable Proteins and 'Pentosans'Emil Emmanuel EstiloNo ratings yet

- 070971Document15 pages070971Carlo Maiko MabezaNo ratings yet

- 2017 Properties of Starch After Extrusion - A ReviewDocument35 pages2017 Properties of Starch After Extrusion - A Reviewalcy reneNo ratings yet

- Borregaard - How the type of starch can influence pelleting_2020Document8 pagesBorregaard - How the type of starch can influence pelleting_2020leuthenjournalNo ratings yet

- Starch Based Fat SubstitutesDocument4 pagesStarch Based Fat SubstitutesmadbakingNo ratings yet

- Chapter 2 StarchDocument16 pagesChapter 2 StarchAngela mae PanganibanNo ratings yet

- Changes in wheat bread starch on baking and stalingDocument6 pagesChanges in wheat bread starch on baking and stalingEmil Emmanuel EstiloNo ratings yet

- Tle 10Document4 pagesTle 10Kimby VentuzoNo ratings yet

- Experiment No. 5 Starch Hydrolysis by AmylaseDocument10 pagesExperiment No. 5 Starch Hydrolysis by AmylasebobbymayaaNo ratings yet

- Sodium Carboxymethyl Cellulose PDFDocument15 pagesSodium Carboxymethyl Cellulose PDFRezaul RazibNo ratings yet

- Starch Hydrolysis by AmylaseDocument9 pagesStarch Hydrolysis by Amylasegaurav saxenaNo ratings yet

- Bio Deg PolymerDocument19 pagesBio Deg PolymerSivasankar JeyabaskaranNo ratings yet

- Fu - 2014 - Additives On Starch RetrogradationDocument10 pagesFu - 2014 - Additives On Starch RetrogradationDavid LopezNo ratings yet

- Tle10 - Week 4Document13 pagesTle10 - Week 4Lorry ManuelNo ratings yet

- Starch Paste Dilution Effects on Granulations and TabletsDocument2 pagesStarch Paste Dilution Effects on Granulations and TabletsTu TaNo ratings yet

- StarchDocument12 pagesStarchNahusenay TewodrosNo ratings yet

- Surfactants - Emulsifiers Surfactants EmulsifiersDocument62 pagesSurfactants - Emulsifiers Surfactants EmulsifiersUmut Erkılıç100% (1)

- FuE Chances and Limits 01Document14 pagesFuE Chances and Limits 01Dayana AriasNo ratings yet

- Starch Structure, Property, and DeterminationDocument10 pagesStarch Structure, Property, and DeterminationJORDAN ALEXIS APARICIO HUABLOCHONo ratings yet

- Starch and GlycogenDocument20 pagesStarch and GlycogenLaksilu Viduraga Peiris100% (1)

- Modified StarchDocument16 pagesModified StarchRagabAbdoNo ratings yet

- Enzymatic Starch HydrolysisDocument107 pagesEnzymatic Starch HydrolysisManuel Rojas100% (1)

- Starch StructureDocument16 pagesStarch StructureLenLen PeñafloridaNo ratings yet

- Pharmaceuticals, Textiles, Paper, Construction Materials, and Other IndustriesDocument7 pagesPharmaceuticals, Textiles, Paper, Construction Materials, and Other IndustriesClaire BeeNo ratings yet

- Controlling Lactose Crystallization in Ice CreamDocument4 pagesControlling Lactose Crystallization in Ice CreamJuan Jose Escobar P.No ratings yet

- Chapter-2-RELATED LITERATUREDocument10 pagesChapter-2-RELATED LITERATURENizeth Jane Macion CuajotorNo ratings yet

- Galle 2012Document12 pagesGalle 2012dgfNo ratings yet

- Experiment 1Document17 pagesExperiment 1Kelvin Lim100% (3)

- Homogenization of Milk: Course: Dairy and Food EngineeringDocument8 pagesHomogenization of Milk: Course: Dairy and Food Engineering9567592146No ratings yet

- Pharma Tech CapsuleDocument11 pagesPharma Tech Capsulekk4486No ratings yet

- POTIN190510 AppGuide Composition F WebDocument20 pagesPOTIN190510 AppGuide Composition F WebDv MarNo ratings yet

- Amilopektin PDFDocument29 pagesAmilopektin PDFmasdalifahNo ratings yet

- 1997 - Borwankar and Case - Rheology of Emulsions, Foams and GelsDocument6 pages1997 - Borwankar and Case - Rheology of Emulsions, Foams and GelsymiyazyNo ratings yet

- Thermal Behavior of Fat Droplets As RelaDocument6 pagesThermal Behavior of Fat Droplets As RelaPlácidoNo ratings yet

- The Cellulose Derivatives: Cellulose Gum, Methylcellulose, Methylhydroxypropylcellulose, and HydroxypropylcelluloseDocument24 pagesThe Cellulose Derivatives: Cellulose Gum, Methylcellulose, Methylhydroxypropylcellulose, and HydroxypropylcelluloseAnandNo ratings yet

- Literatur CDocument12 pagesLiteratur CZulman EfendiNo ratings yet

- Texturising by Phase Separation: Vladimir TolstoguzovDocument3 pagesTexturising by Phase Separation: Vladimir TolstoguzovJoel PeñaNo ratings yet

- Amylose: IdentifiersDocument5 pagesAmylose: IdentifiersAlaina AmaliaNo ratings yet

- Encapsulation and Controlled Release Technologies in Food SystemsFrom EverandEncapsulation and Controlled Release Technologies in Food SystemsDr Jamileh M. LakkisNo ratings yet

- Biochemistry Applied to the Brewing Processes - Fermentation and the Finished BeerFrom EverandBiochemistry Applied to the Brewing Processes - Fermentation and the Finished BeerRating: 5 out of 5 stars5/5 (1)

- Whey Protein Production, Chemistry, Functionality, and ApplicationsFrom EverandWhey Protein Production, Chemistry, Functionality, and ApplicationsNo ratings yet

- Properties of Construction MaterialsDocument17 pagesProperties of Construction MaterialsYoseph BirruNo ratings yet

- Uplift PressureDocument10 pagesUplift PressureBurhan AhmadNo ratings yet

- Short CV RJCDocument3 pagesShort CV RJCShivani KhannaNo ratings yet

- ECE 522 IC Fabrication Problems in Film Deposition: HG K - 1.9/kT) C NG N 5X10Document3 pagesECE 522 IC Fabrication Problems in Film Deposition: HG K - 1.9/kT) C NG N 5X10Sahil YadavNo ratings yet

- Aluminum-Alloy Sand Castings: Standard Specification ForDocument14 pagesAluminum-Alloy Sand Castings: Standard Specification Foranurag yadavNo ratings yet

- Glaeser 2nd Chapter OneDocument28 pagesGlaeser 2nd Chapter OneSheri DeanNo ratings yet

- Lesson Plan: Institute of Space TechnologyDocument4 pagesLesson Plan: Institute of Space TechnologyShahZaib AnwarNo ratings yet

- D 4405Document5 pagesD 4405mohsenNo ratings yet

- Industrial Trainning Gladni JammuDocument34 pagesIndustrial Trainning Gladni Jammumohasan aliNo ratings yet

- Reinforced Concrete Road Bridges: Prof. Nirjhar DhangDocument101 pagesReinforced Concrete Road Bridges: Prof. Nirjhar DhangAnonymousNo ratings yet

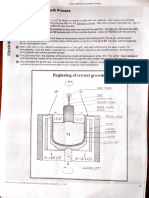

- Czochralski Process POMDocument10 pagesCzochralski Process POMHridisaran PandeNo ratings yet

- Low Density SteelsDocument4 pagesLow Density SteelshuachuliuNo ratings yet

- The Hall Effect-1Document4 pagesThe Hall Effect-1lewyn.socialNo ratings yet

- CHE131 - Module6 Fluid Flow Phenomena (Part 2)Document43 pagesCHE131 - Module6 Fluid Flow Phenomena (Part 2)Jason PacilNo ratings yet

- Shailesh Final ThesisDocument70 pagesShailesh Final Thesisabdulazeez88No ratings yet

- Huang 2019Document10 pagesHuang 2019Robertas ŽilinskasNo ratings yet

- API 510 Exam 5 ClosedDocument4 pagesAPI 510 Exam 5 ClosedweerasinghekNo ratings yet

- Fabric Structures Subjected To Wind and Snow LoadsDocument3 pagesFabric Structures Subjected To Wind and Snow LoadsKhalid Abdel Naser Abdel RahimNo ratings yet

- Lecture6 (CRACKED MOMENT OF INTERTIA)Document38 pagesLecture6 (CRACKED MOMENT OF INTERTIA)RajKumarNo ratings yet

- Review Test Submission - Quiz 08 & Quiz 09 - Solutions and ..Document5 pagesReview Test Submission - Quiz 08 & Quiz 09 - Solutions and ..Thục Ánh Dương NguyễnNo ratings yet

- Honeycomb Design PDFDocument28 pagesHoneycomb Design PDFOmkarKocharekarNo ratings yet

- NDT Techniques for Detecting Surface and Internal DefectsDocument35 pagesNDT Techniques for Detecting Surface and Internal DefectsManan Depala100% (1)

- Alloy CuETPDocument50 pagesAlloy CuETPsahil100% (1)

- DS - 1090 FRT - 25.09.2012Document4 pagesDS - 1090 FRT - 25.09.2012McFlyNo ratings yet

- Civil Engineering Detailed Solution Set A PDFDocument54 pagesCivil Engineering Detailed Solution Set A PDFShravan RathoreNo ratings yet

- Thermoplastic Elastomers-Terminology and Abbreviations: Standard Practice ForDocument3 pagesThermoplastic Elastomers-Terminology and Abbreviations: Standard Practice ForJ MrNo ratings yet

- 3m Converter Markets Selection GuideDocument110 pages3m Converter Markets Selection GuidevivesinjefeNo ratings yet

- KobyDocument1 pageKobyJeanette Bonifacio CorpuzNo ratings yet