Professional Documents

Culture Documents

Directional Seat Valves

Uploaded by

Miron GabrielOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Directional Seat Valves

Uploaded by

Miron GabrielCopyright:

Available Formats

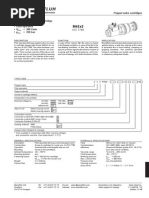

Directional seated valves with various actuations

These directional seated valves use spring loaded balls as valve elements and therefore do not show any leakage. They are manifold mounting and are available with various actuations which always act on an angled lever pushing the valve element in the desired switching position. The basic versions are designed as 2/2- and 3/2-way directional valves. 3/3- , 4/3-way functions are possible, if two valves are housed in one valve body, whereas 4/2-way functions require an additional intermediate plate. The enforced versions size G..-22 are intended for pulsating, permanent load with frequent switching operations in the high pressure range. These valves may be directly installed in pipe systems, when equipped with subplates enabling pipe connection. Many optional functions can be incorporated in these sub-plates e.g. pressure limiting valve or restrictor check valve for widen the field of application for this valve type. Valve banks of these valves are also available featuring several valves connected in parallel (see type VB). Features and benefits: Zero leakage ball seated design with high functional safety Actuations: Solenoid, pressure, mechanical or manually Low switching forces, smooth shifting without pressure surges Operating pressure up to 700 bar Intended applications: Machine tools (chipping and non-chipping) Clamping, punching and jigs Rubber and plastic machinery General hydraulics Design and order coding example G R2 - 3 R - 1/2 - G24 Solenoid voltage 12V DC, 24V DC, 110V AC, 230V AC Additional versions: Connection blocks with by-pass check valve or pressure limiting valve between P and R Connection block with bridge rectifier circuit. Check valves in "GRAETZ"-circuitry ensure flow direction through the valve

Nomen- Directional seated valve, zero leakage clature: Design: Individual valve, manifold mounting combination with subplates for pipe connection Actuation: Solenoid Pressure actuated (hydraulic, pneumatic) Mechanical (roller, pin) Manual (hand lever, adjusting knob) pmax: 350 ... 700 bar Qmax: 6 ... 120 lpm

Indiv. connection blocks for pipe connection

Additional elements

With check valve insert for port P With check valve insert for port P With return pressure stop for port R Lift monitoring (size 3 and 4)

Size Function

Size 0 to 4

Size 1 also available with industrial connection hole pattern NG 6 (CETOP), type NG 2/2-way directional valve (R2, S2) 3/2-way directional valve (3, Z3) 3/3-way directional valve (21, 39) 4/3-way directional valve (22, 48, 49) 4/2-way directional valve (4, Z4) Solenoid (G, WG) Hydraulic (H) Pneumatic (P) Mechanical (K, T, F, D)

Actuation

www.hawe.de | 2011 | 1

Function 2/2-way directional valve R2 S2 3/2-way directional valve 3 Z3 3/3-way directional valve 21, 39 4/3-way directional valve 22, 48, 49 4/2-way directional valve 4 Z4

SEATED VALVES

Simplified symbols for 3/3-, 4/3- and 4/2-way functions Type 21, 22 not in size 4 Type 39, 48, 49 only in size 22 Type 4, Z4 only in size 1

Actuation: Solenoid Pressure Hydraulical G WG H Pneumatical P Mechanically Roller K Pin T Manually Hand lever F Turn knob D

Solenoid voltage: 12V DC, 24V DC (type G) 230V AC (type WG)

Control pressure pcontr max [bar]: 400 ... 700 15

Shifting force [N]: 25 ... 80 Shifting travel [mm]: 10.5 ... 30 4 and 5 51 ... 20

Shifting force [N]: 25 ... 80 Shifting travel [mm]: 20.5 ... 45

Shifting torque [Ncm]: 45 ... 98

Control pressure pcontr min [bar]: 9 ... 16 2.5 ... 4

- Directional seated valve with actuation solenoids 24V DC also available conforming ATEX

2 | www.hawe.de | 2011

General parameters and dimensions Individual valve Valve with sub-plate

Dimensions Size Hmax H1max B 2/2- and 3/2-way 0 1 2, 22 3 4 90.5 115 126.5; 134.5 162 226 110.5 145 156.5; 161.5 202 226 36 45 56; 56 70 80 3/3- and 4/3-way 75 92 116; 116 144 162 41.5 50 62.5; 67.5 91.5 127 40.0 50 56; 56 70 125 0.8/1.0 1.4/1.9 2.9/3.9; 3.0/4.0 5.7/7.1 16.3/20.1 Tmax T1 mmax [kg]

Qmax [lpm] Size

pmax [bar] Solenoid G WG Pressure H 500 500 ... 700 500 400 P Mechanical K 400 ... 700 400 ... 500 350 T Manual F 400 ... 700 400 ... 500 350 D 500

Ports

P, R, A, B G 1/4 G 1/4 and G 3/8 G 3/8 and G 1/2 G 1/2 and G 3/4 G 3/4 and G 1

0 1 2, 22 3 4

6 12 25 65 120

300 ... 500 350 ... 500 (700) 350 ... 500 (700) 350 ... 400 350

www.hawe.de | 2011 | 3

Circuit example: RZ 4,0/2-12,3-B 75-V 5,5 - 3 x 690/400V 50 Hz VB 22 AM 1/500 -G 49/U 22-8 E-2-G 24 GR 2-1-1-3/8 C-G 24

Associated technical data sheets: Directional seated valves: D 7300 Directional seated valves with industrial standard connection pattern (CETOP3, NG 6): D 7300 N Directional valves with lift monitoring: D 7300 H Valve banks: Valve banks type VB: page

Plugs: With LED etc.: D 7163 With economy circuit: D 7813, D 7833 See also section Devices for special applications: Devices for explosion hazardous areas, conforming ATEX Devices for up to 700 bar

www.hawe.de | 2011 | 4

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Netstal SYNERGY 800-230: Injection Moulding MachineDocument9 pagesNetstal SYNERGY 800-230: Injection Moulding MachinePiman MiriNo ratings yet

- Hydraulic Directional Control and Check ValvesDocument28 pagesHydraulic Directional Control and Check ValvestunradotNo ratings yet

- A10VSODocument40 pagesA10VSOJulio Carrero100% (1)

- Hawe Rapid RangeDocument16 pagesHawe Rapid RangecinbrekNo ratings yet

- RE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMDocument8 pagesRE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMAhmed Abd ElhakeemNo ratings yet

- Hydraulic directional control valves guideDocument112 pagesHydraulic directional control valves guideAldo Alonso GuemezNo ratings yet

- 5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Document8 pages5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Hdhm TdhNo ratings yet

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- FP 730-59 Data Sheet PDFDocument4 pagesFP 730-59 Data Sheet PDFCarlos TarquinoNo ratings yet

- Directional control valves guideDocument108 pagesDirectional control valves guidemgkalfas100% (2)

- PV 48Document12 pagesPV 48thierrylindoNo ratings yet

- Directional Seated Valves Type VPDocument2 pagesDirectional Seated Valves Type VPli geneNo ratings yet

- SDM140EDocument36 pagesSDM140Eseaqu3stNo ratings yet

- Guth VSR Modulating ValvesDocument8 pagesGuth VSR Modulating ValvesRaul Guevara TorresNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Yuken DSHGDocument28 pagesYuken DSHGDian PramadiNo ratings yet

- Electro Válvula Del CompresorDocument4 pagesElectro Válvula Del CompresorneumaticoNo ratings yet

- Ra 22058 PDFDocument12 pagesRa 22058 PDFmanjappahNo ratings yet

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991No ratings yet

- 3/2 Directional Control Valves for Single-Acting CylindersDocument9 pages3/2 Directional Control Valves for Single-Acting CylindersMohan ArumugavallalNo ratings yet

- Angle Seat Valve: High Cycle-Life On/Off Control ValveDocument6 pagesAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyNo ratings yet

- Lincoln W-115-ENDocument24 pagesLincoln W-115-ENakangucaiNo ratings yet

- SDM 141 eDocument28 pagesSDM 141 eseaqu3stNo ratings yet

- Bomba Hidraulica A7VODocument52 pagesBomba Hidraulica A7VOanon_491700336100% (2)

- D631 Series Servo Control Valves ISO 4401 Size 05Document12 pagesD631 Series Servo Control Valves ISO 4401 Size 05José OlaveNo ratings yet

- 2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedDocument16 pages2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedOgulcan CafNo ratings yet

- DGMPC 5 Check Valve Eaton Vickers PDFDocument10 pagesDGMPC 5 Check Valve Eaton Vickers PDFsandyread4uNo ratings yet

- Re92105 2003-11Document32 pagesRe92105 2003-11Madhu RajagopalanNo ratings yet

- HPB Brochure 0708Document12 pagesHPB Brochure 0708musaluddinNo ratings yet

- Festo Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Document66 pagesFesto Solenoid Valve model MFH โซลินอยด์วาล์วเฟสโต้Parinpa Ketar100% (1)

- Hawe Directional Seated Valves Type WN and WHDocument2 pagesHawe Directional Seated Valves Type WN and WHMarek SłowikNo ratings yet

- Bom A4VG - REXROTHDocument44 pagesBom A4VG - REXROTHnamduong368100% (4)

- Hydraulic TechnologyDocument76 pagesHydraulic TechnologyOgulcan CafNo ratings yet

- Directional Seated Valve Type G With Interchangeable SolenoidDocument34 pagesDirectional Seated Valve Type G With Interchangeable SolenoidebraNo ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Reductores - d140 - HG KGDocument4 pagesReductores - d140 - HG KGDANIZACHNo ratings yet

- 62 Series Servovalves Technical OverviewDocument8 pages62 Series Servovalves Technical OverviewDevendra BangarNo ratings yet

- Re64354 2003-06Document20 pagesRe64354 2003-06thierrylindoNo ratings yet

- Rexroth 4WE6D6X-G24 Directional ValveDocument12 pagesRexroth 4WE6D6X-G24 Directional ValveCosma Petru-RaulNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- SDM 080 eDocument28 pagesSDM 080 eseaqu3stNo ratings yet

- PCT 473731Document20 pagesPCT 473731pissiniNo ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- Solinoid Popet ValveDocument3 pagesSolinoid Popet ValvesaqureshNo ratings yet

- Flow Control Valves Pressure Compensated Cartridge TypeDocument6 pagesFlow Control Valves Pressure Compensated Cartridge TypevrgohilNo ratings yet

- A10VSO18 Bomba HidraulicaDocument16 pagesA10VSO18 Bomba HidraulicaGuilherme RodriguesNo ratings yet

- Rexroth FDDocument116 pagesRexroth FDIvan GudeljNo ratings yet

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- LX325 (New Hi-Cyclic Low-ResDocument24 pagesLX325 (New Hi-Cyclic Low-ResGianna FrolaNo ratings yet

- C72H NorgrenDocument4 pagesC72H NorgrenHernando HerreraNo ratings yet

- VZPR enDocument14 pagesVZPR enoanzarNo ratings yet

- Pump A4vgDocument68 pagesPump A4vgbiabamanbemanNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Cone Ranger: Mobile Cone Crushing UnitsDocument2 pagesCone Ranger: Mobile Cone Crushing UnitsYousef AlipourNo ratings yet

- Electric Motors, USADocument15 pagesElectric Motors, USAVanessa MendozaNo ratings yet

- Sop Normally Opened Ball Valve Functionality TestDocument13 pagesSop Normally Opened Ball Valve Functionality Testapi-538504186No ratings yet

- Firewall III Single Shielded PairDocument2 pagesFirewall III Single Shielded PairRenato BarbarićNo ratings yet

- High-torque starter motors for diesel enginesDocument2 pagesHigh-torque starter motors for diesel enginesosobaxNo ratings yet

- Artikel Bersama 6Document6 pagesArtikel Bersama 6Ngô Thịnh DuyNo ratings yet

- Iwaki: Magnetic Drive PumpDocument4 pagesIwaki: Magnetic Drive PumpFranklin RochaNo ratings yet

- Grove GMK 4075-1 Crawler Crane for Sale in PhilippinesDocument1 pageGrove GMK 4075-1 Crawler Crane for Sale in PhilippinesMiguel Avella BelloNo ratings yet

- Types of GearsDocument5 pagesTypes of GearsKarthikNo ratings yet

- Miniature Circuit Breakers: Din-T15 Series 15 Ka, 20 Ka, 25 Ka McbsDocument11 pagesMiniature Circuit Breakers: Din-T15 Series 15 Ka, 20 Ka, 25 Ka McbsSchaum001No ratings yet

- Eaton - 93PM - 30-200 - Datasheet - LOW 724Document2 pagesEaton - 93PM - 30-200 - Datasheet - LOW 724keyurNo ratings yet

- Three Phase Induction MotorDocument21 pagesThree Phase Induction MotorNavdeep KaurNo ratings yet

- High Power 1P1T Switch SpecsDocument3 pagesHigh Power 1P1T Switch SpecsAfzal ImamNo ratings yet

- Daikin Altherma 3 H EPGA-D 11-14-16 KW: Product Catalogue 2020Document40 pagesDaikin Altherma 3 H EPGA-D 11-14-16 KW: Product Catalogue 2020wiwiNo ratings yet

- Generators and Transformers: Prepared by M.Aruna / EeeDocument11 pagesGenerators and Transformers: Prepared by M.Aruna / EeegssasiNo ratings yet

- Transformer Concepts ReportDocument15 pagesTransformer Concepts ReportJoel ThomasNo ratings yet

- DA0X81MB6E0Document66 pagesDA0X81MB6E0Asterman SaidiNo ratings yet

- Physics For Scientists and Engineers, 6e: Chapter 28 - Direct Current CircuitsDocument29 pagesPhysics For Scientists and Engineers, 6e: Chapter 28 - Direct Current CircuitsFaiza AliNo ratings yet

- 1504805126-HPI - CR-Series Copper Crusher - 04-2021ENDocument1 page1504805126-HPI - CR-Series Copper Crusher - 04-2021ENCaio BittencourtNo ratings yet

- Reflective Optical Beam Smoke Detector User GuideDocument8 pagesReflective Optical Beam Smoke Detector User GuidejolymolyNo ratings yet

- Capacitor Trip Device CTD-3Document2 pagesCapacitor Trip Device CTD-3DAS1300No ratings yet

- Spec FVZ FVY 240 300 2304RDocument4 pagesSpec FVZ FVY 240 300 2304RSitichoke SemamonNo ratings yet

- Pic18f IntroDocument25 pagesPic18f IntroElena Gilbert100% (1)

- Brother P-Touch PT-2420PC Parts List PDFDocument16 pagesBrother P-Touch PT-2420PC Parts List PDFMaxim100No ratings yet

- Bevel and Worm GearsDocument1 pageBevel and Worm GearsDevansh ChhajlaniNo ratings yet

- Ficha Tecnica JLG E600Document2 pagesFicha Tecnica JLG E600David GordilloNo ratings yet

- Excavator Attachment Operation Manual - CompressedDocument13 pagesExcavator Attachment Operation Manual - CompressedRobin Sanchez100% (1)

- Lexus NX 200tDocument28 pagesLexus NX 200tSopheak LimNo ratings yet

- B&S 161400-161499Document22 pagesB&S 161400-161499Bruno MarianoNo ratings yet