Professional Documents

Culture Documents

Experimental Study On The Characteristics of Polymer Concrete With Epoxy Resin

Uploaded by

Brwa OsmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental Study On The Characteristics of Polymer Concrete With Epoxy Resin

Uploaded by

Brwa OsmanCopyright:

Available Formats

BULETINUL INSTITUTULUI POLITEHNIC DIN IAI Publicat de Universitatea Tehnic Gheorghe Asachi din Iai Tomul LIV (LVIII),

Fasc. 1, 2008 Secia CONSTRUCII. ARHITECTUR

EXPERIMENTAL STUDY ON THE CHARACTERISTICS OF POLYMER CONCRETE WITH EPOXY RESIN

BY

MARINELA BRBU1,* and MARIA HARJA2

Abstract. In the paper are presented the results of some experimental researches concerning polymer mortars and concretes realized of epoxy resin, silica fume and crushed aggregates. The mechanical characteristics of hardened concrete were determined. The silica fume content varied between 6.5% and 30% to polymer mortar and 6.4% and 9.6% to polymer concrete. The obtained results show maximum characteristics for a dosage of 24% resin and maximum dosage of silica fume to the polymer mortar, and for the polymer concrete the mechanical characteristics are influenced by all mixture factors: the compressive strength increases with the increase of silica fume dosage, and the flexure strength and split strength increase with the decreasing of silica fume dosage. Key words: epoxy resin, silica fume, polymer mortar, polymer concrete.

1. Introduction In the constructions industry new building materials with improved properties are required for satisfying the new utilization domains for modern construction or for repair works. The application of polymer on concrete has significantly progressed in the last 30 years. Polymers are either incorporated in a cement-aggregate mix or used as single binder. The composites made by using polymer along with cement and aggregates are called polymer-modified mortar or polymer-modified concrete, while composites made with polymer and aggregates are called polymer mortar or polymer concrete, depending on the maximum size of aggregate granule [1]. In the composition of polymer concrete there is not cement: the aggregates are bonded by the resin. Function of the type of polymer it can obtain concretes with synthetic resin, concretes with plastic resin or simple concrete with resin [2]. The composite does not contain hydrated cement paste. Polymer concrete presents some advantages compared to the cement Portland concrete such as: rapid hardening, high mechanical strengths, improved resistance to chemical attack, durability, etc. [3] [4]. One of the most

*

Corresponding author. E-mail address: barbuta@ce.tuiasi.ro (M. Barbu)

54

Marinela Brbu and Maria Harja

important disadvantages is the high cost of resin that limited the use domains of polymer concrete. The performances of polymeric concrete depend on the polymer properties, type of filler and aggregates, curing temperature, components dosage, etc. The aggregates can be silicates, quartz, crushed stone, gravel, limestone, calcareous, granite, clay, etc. Near the aggregate, the filler is very important. Different types of fine materials can be used such as fly ash, silica fume, phosphor-gypsum, cinder, etc. [5], [6]. In this paper, the experimental results made for polymer concrete are presented. The properties of polymer mortar and polymer concrete were studied. 2. Experiment

2.1. Materials

For the experimental researches of polymer mortar and concrete properties, the following materials were used: polymer, silica fume (SUF) as filler and crushed aggregates. The polymer was type epoxy resin, called ROPOXID, made in Romania by POLICOLOR, Bucureti [7]. The hardener was type ROMANID 407, also made by POLICOLOR, Bucureti [7]. The filler was type silica fume and was added to the composition without replacing the fine part of aggregate. The principal characteristics of SUF are: gray color, particles sizes between 0.010.03 and 0.3...0.5 m; the shape of particles is spherical, specific surface is between 13,000 and 23,000 m2/kg, the density is between 2,100 and 2,250 kg/m3 [8]. The aggregates were used in two sorts: 04 mm and 48 mm, with continuous granulosity, obtained from crushed river gravel by S.C. EMBERON SRL, Iai.

2.1. Experimental Samples

Two types of compositions were studied in the experimental program: a) Type I (noted MP) - polymer mortar (or micro-concrete), for which the maximum size of aggregate was 4 mm, b) Type II (noted BPS) - polymer concrete for which the maximum size of aggregate was 8 mm. There were studied six mixtures for concrete type I and seven mixtures for concrete type II. The mixtures are given in Table 1. For mixtures type MP with one sort of aggregate 04 mm the polymer was reduced from maximum 58.87% (composition MP1) to a minimum of 24.2% (composition MP5). The aggregate percentage varied from minimum 29.4% to maximum 59.8%.

Bul. Inst. Polit. Iai, t. LIV (LVIII), f. 1, 2008

55

Types MP1 MP2 MP3 MP4 MP5 MP6 BPS1 BPS2 BPS3 BPS4 BPS5 BPS6 BPS7

Table 1 Composition of Polymer Concrete, [%] Aggregate, Aggregate, Resin SUF sort I sort II 58.8 11.8 29.4 40 30 30.0 34.8 6.5 58.7 44.5 6.6 48.9 24.2 17.5 58.3 25.6 14.6 59.8 18.8 6.4 37.4 37.4 12.4 6.4 43.8 37.4 15.6 9.6 37.4 37.4 15.6 6.4 40.6 37.4 16.4 7.2 38.2 38.2 13.2 7.2 41.4 38.2 14.0 8.0 39.0 39.0

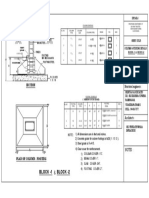

Fig. 1. Samples of polymer concrete

For mixtures type BPS with two sorts of aggregates 04 mm and 48 mm the polymer was reduced from maximum 18.8% (composition BPS1) to a minimum of 12.4% (composition BPS2). The aggregate percentage varied from minimum 37.4% to maximum 43.8%. For all MP and BPS compositions types, the mechanical characteristics were experimentally determined: compressive strength on cube samples of 70.7 mm sizes, flexural strength and split tensile strength on prismatic samples of sizes 2107070 mm, (Fig. 1) according to standard prescriptions [9]. 3. Results and Discussions The following mechanical characteristics of polymer mortar and polymer concrete were experimentally determined: compressive strength (fc), flexural strength (fti) and split tensile strength (ftd). The results are given in Table 2.

56

Marinela Brbu and Maria Harja

Table 2 Mechanical Characteristics of Experimental Composition Composition fc, [Mpa] fti, [Mpa] ftd, [MPa] MP1 63.2 10.6 8.78 MP2 62.1 9.32 5.80 MP3 45.3 11.4 5.20 MP4 50.4 9.96 4.72 MP5 69.1 12.7 12.1 MP6 51.1 10.3 4.90 BPS1 59.2 15.9 6.76 BPS2 59.6 16.8 7.67 BPS3 64.1 15.8 7.62 BPS4 58.6 17.6 6.27 BPS5 58.8 15.6 7.28 BPS6 65.3 14.8 7.02 BPS7 57.8 14.9 6.49

70 66

fc, MPa

62 58 54 50 11 13 15 17 19 21

Resin dosage, %

Fig. 2. Variation of the compressive strength for BPS

The experimental results concerning polymer concrete lead to the following conclusions: a) The values of compressive strengths for mortar MP vary between 51.1 MPa (for MP6) and 69.1 MPa (for MP5) that means: until 25.1% resin dosage the compressive strength decreases and up to this value, compressive strength increases. Mortar MP5 (with 24% polymer) shows the biggest values for all mechanical strengths. b) The values of compressive strengths for concrete BPS (Fig. 2) vary between 65.32 MPa (for BPS6) and 57.75 MPa (for BPS7); in this case it

Bul. Inst. Polit. Iai, t. LIV (LVIII), f. 1, 2008

57

cannot specify how much the resin dosage or silica fume dosage influence the compressive strength; c) The values of flexure strengths for mortar MP vary between 12.7 MPa (for MP5) and 9.32 MPa(for MP2) that signifies a value of about 24% resin to increase the flexure strength; d) The values of flexure strengths for concrete BPS (Fig. 3) vary between 17.57 MPa (for BPS4) and 14.81 MPa (for BPS6), so, the decrease of resin dosage results in the increase of flexure strength; e) The values of split tensile strengths for mortar MP vary between 12.1 MPa (for MP5) and MPa (for MP4), that signifies a value of about 24% resin to increase the split tensile strength, but for this mechanical characteristic the values are varying from a percentage to the other; f) The values of split tensile strengths for concrete BPS (Fig. 4) vary between 7.67 MPa (for MP5) and 4.72 N/mm2 (for MP4) so, the decrease of resin dosage results in the increase of split tensile strength.

18 17

fti, MPa

16 15 14 13 11 13 15 17 19 21

Resin dosage, %

Fig. 3. Variation of flexural strength for BPS

8.5

7.5

ftd, MPa

6.5

5.5

4.5 11 13 15 17 19 21

Resin dosage, %

Fig. 4. Variation of split tensile strength for BPS

58

Marinela Brbu and Maria Harja

The compressive strengths and split tensile strengths resulted bigger in the case of mortar MP (with aggregate sort 04 mm and SUF dosage between 6.5% and 30%); the flexure strengths resulted with bigger values in the case of BPS (with aggregates of two sorts, 04 mm and 48 mm, and SUF dosage between 6.4% and 9.6%). The experimental researches showed the following: a) The use of one sort of aggregate (04 mm) results in high values of compressive strengths for a resin dosage of about 24%, b) The use of two sorts of aggregates (04 mm and 48 mm) results in smaller values of compressive strengths compared to polymer mortar, but the flexure strengths are bigger, c) Epoxy resin was used as binder, the principal objective being the reduction of its dosage for obtaining an optimum cost. d) Silica fume had improved the mechanical characteristics of the polymer concrete. The high values of mechanical strengths obtained from experimental researches showed that the polymer concretes are concretes of high strength. 4. Conclusions The experimental researches concerning the polymer concrete had as principal objectives the decreasing the epoxy resin dosage and improving the mechanical characteristics by using the silica fume as fine filler. The polymer mortar obtained showed good mechanical properties that are necessary for repair works. The high silica fume dosage in the mortar improved the strengths and reduced the cost of the composite. The values for mechanical strengths showed that polymer concrete with silica fume is a high strength concrete. This concrete can be used for realizing the rehabilitation of structures by coating or for realizing structural elements such as beams, columns, foundation beams, etc.

Received, September 14th, 2008 Gheorghe Asachi Technical University, Jassy, 1 Department of Concrete, Materials, Technology and Organization and 2 Department of Chemical Engineering

REFERENCES 1. Aggarwal L.K., Thapliyal P.C., Karada S.R., Constr. Build. Mater., 21, 379-383, 2007. 2. Fowler D.W., Cem. Concr. Comp., 21, 449-452, 1999. 3. Abdel-Fattah H., El-Hawary M., Constr. Build. Mater., 13, 253-262, 1999. 4. Blaga A., Beaudoin J.J., Building Digest, CBD 242, Ottawa, 1985.

Bul. Inst. Polit. Iai, t. LIV (LVIII), f. 1, 2008

59

5. Mirza J., Mirza M.S., Lapointe R., Constr.Build. Mater., 16, 365-374, 2002. 6. Mutukumar M., Mohan D., J. Polymer Res., 12, 231-241, 2004. 7. Brbu M.,. Decher E., International Conference VSU 2005, Sofia, I, II-249-252, (2005). 8. Decher E., Brbu M., Buletinul Institutului Politehnic Iai, L (LIV), 5, Constr. Arhit., 25-28, 2004. 9. *** Testing Hardened Concrete EN 12390/2001 European Committee for Standardization, Brussels, Belgium, 2001.

STUDIU EXPERIMENTAL PRIVIND CARACTERISTICILE BETOANELOR POLIMERICE CU RIN EPOXIDIC (Rezumat) Se prezint rezultatele unor studii experimentale efectuate pe mortare i betoane polimerice obinute din rin epoxidic, silice ultrafin i agregate concasate. Au fost studiate proprietile mecanice ale betonului ntrit. Coninutul de silice ultrafin a variat, la mortarele polimerice, ntre 6,5% i 30%, iar la betoanele polimerice, ntre 6,4% i 9,6%. Rezultatele indic caracteristici maxime la mortarele polimerice pentru un dozaj de 24% rin epoxidic i dozaj maxim de silice ultrafin (17%), iar la betoanele polimerice caracteristicile mecanice sunt influenate de toi factorii de compoziie; rezistenele la compresiune cresc cu creterea dozajului de silice ultrafin iar rezistenele la ntindere din ncovoiere i prin despicare cresc cu scderea dozajului de silice ultrafin.

You might also like

- Polymer Concrete Dosage With EpoxiDocument8 pagesPolymer Concrete Dosage With Epoxirogerio rosaNo ratings yet

- Literature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. HeDocument9 pagesLiterature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. Henutan acharyaNo ratings yet

- Effect of Superplasticizer Type On The PerformanceDocument14 pagesEffect of Superplasticizer Type On The PerformanceKevin ChumánNo ratings yet

- Concrete Quality Control During ConstructionDocument7 pagesConcrete Quality Control During Constructionpaul machariaNo ratings yet

- Irjet - Effect of Addition of Crumb Rubbe PDFDocument5 pagesIrjet - Effect of Addition of Crumb Rubbe PDFKlisman A. Flores DurandNo ratings yet

- Behaviour of Concrete Partially Replacement of Cement by Steatite and Polypropylene FibreDocument4 pagesBehaviour of Concrete Partially Replacement of Cement by Steatite and Polypropylene FibreijaertNo ratings yet

- Research Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaDocument4 pagesResearch Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaahmedanyNo ratings yet

- ICPIC2018 122 Final v4Document7 pagesICPIC2018 122 Final v4Long An DoNo ratings yet

- Elixir2016115450Document5 pagesElixir2016115450Nick YogaNo ratings yet

- Sathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036Document11 pagesSathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036henryNo ratings yet

- Effects of Polymer-Cement Ratio and Accelerated Curing On Flexural Behavior of Hardener-Free Epoxy-Modified Mortar PanelsDocument11 pagesEffects of Polymer-Cement Ratio and Accelerated Curing On Flexural Behavior of Hardener-Free Epoxy-Modified Mortar PanelsJoseph ChenNo ratings yet

- Construction and Building Materials: Reza Saleh Ahari, Tahir Kemal Erdem, Kambiz RamyarDocument11 pagesConstruction and Building Materials: Reza Saleh Ahari, Tahir Kemal Erdem, Kambiz RamyarReny AkmaliaNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument4 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- A Study On Use of WastFilename: A STUDY ON USE OF WASTE POLYETHYLENE - Docx e PolyethyleneDocument64 pagesA Study On Use of WastFilename: A STUDY ON USE OF WASTE POLYETHYLENE - Docx e PolyethyleneNirmal PrasathNo ratings yet

- Polymer CementDocument15 pagesPolymer CementfaheemqcNo ratings yet

- Effects of Use of Metakaolin and Pond Ash in Different Types of ConcreteDocument5 pagesEffects of Use of Metakaolin and Pond Ash in Different Types of ConcreteNalina Amith VijayanandNo ratings yet

- Concrete Quality Control During ConstructionDocument5 pagesConcrete Quality Control During ConstructionanmoljassalNo ratings yet

- Mechanical Properties of Carbon Fiber Reinforced ConcreteDocument44 pagesMechanical Properties of Carbon Fiber Reinforced Concretecien18111051 KFUEITNo ratings yet

- Mechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarDocument6 pagesMechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarIJAERS JOURNALNo ratings yet

- E09122629 With Cover Page v2Document5 pagesE09122629 With Cover Page v2shivanand hippargaNo ratings yet

- Review Article: Mechanical Properties of Polymer ConcreteDocument13 pagesReview Article: Mechanical Properties of Polymer ConcreteDTech ExtraNo ratings yet

- Alunno Rossetti-Di Palma-Ferraro JMCE REVISEDDocument20 pagesAlunno Rossetti-Di Palma-Ferraro JMCE REVISEDAntonella FerraroNo ratings yet

- Construction and Building Materials: M. Nepomuceno, L. Oliveira, S.M.R. LopesDocument10 pagesConstruction and Building Materials: M. Nepomuceno, L. Oliveira, S.M.R. LopesTarek ChikerNo ratings yet

- 91 Effect of Fiber Type On Freeze Thaw Durability of SifconDocument4 pages91 Effect of Fiber Type On Freeze Thaw Durability of SifconMsheer Hasan AliNo ratings yet

- Effect of Graphite Filler Content On The Mechanical and Wear Properties of Epoxy Matrix CompositeDocument12 pagesEffect of Graphite Filler Content On The Mechanical and Wear Properties of Epoxy Matrix CompositeIAEME PublicationNo ratings yet

- He Effect of Using Polypropylene Fiber On Deformation Resistance of Asphalt ConcreteDocument6 pagesHe Effect of Using Polypropylene Fiber On Deformation Resistance of Asphalt ConcreteAaron VillasanteNo ratings yet

- J Matdes 2014 05 009Document32 pagesJ Matdes 2014 05 009Shovon HalderNo ratings yet

- Experimental Program and Mechanical Properties of Reactive Powder ConcreteDocument25 pagesExperimental Program and Mechanical Properties of Reactive Powder ConcreteMir Masood ShahNo ratings yet

- 4N5 Ijeset0202520 PDFDocument8 pages4N5 Ijeset0202520 PDFBia MughalNo ratings yet

- Properties of Sulfur-Extended Asphalt ConcreteDocument6 pagesProperties of Sulfur-Extended Asphalt Concretefusionit0No ratings yet

- Ijciet 08 03 057 PDFDocument8 pagesIjciet 08 03 057 PDFucsproject2017No ratings yet

- P - 31 - Synthetic Granite Composite For Precision Equipment StructuresDocument9 pagesP - 31 - Synthetic Granite Composite For Precision Equipment StructuresFlavia GialorencoNo ratings yet

- Study On Properties of Polymer Modified Mortars Used As Repair MaterialsDocument6 pagesStudy On Properties of Polymer Modified Mortars Used As Repair MaterialsIJSTE100% (1)

- Study The Effectiveness of The Different Pozzolanic Material On Self-Compacting ConcreteDocument7 pagesStudy The Effectiveness of The Different Pozzolanic Material On Self-Compacting ConcreteramNo ratings yet

- Basalt Fiber Reinforced ConcreteDocument15 pagesBasalt Fiber Reinforced ConcreteSusheel KumarNo ratings yet

- Mechanical Properties of Modified Reactive Powder Concrete: January 1997Document17 pagesMechanical Properties of Modified Reactive Powder Concrete: January 1997Ahmed EsamNo ratings yet

- Reactive Powder Concrete: An Ultra-High Strength MaterialDocument33 pagesReactive Powder Concrete: An Ultra-High Strength MaterialSHAIK HUMAYUNNo ratings yet

- Mechanical Properties of Polymer ConcreteDocument12 pagesMechanical Properties of Polymer ConcreteSamuelSzeNo ratings yet

- Compatibility Issues of Nsf-Pce Superplasticizers With Several Lots of Different Cement Types (Long-Term Results)Document17 pagesCompatibility Issues of Nsf-Pce Superplasticizers With Several Lots of Different Cement Types (Long-Term Results)Alfredo landaverde GarciaNo ratings yet

- Effect of Superplasticizer On Compressive Strength On Compressive Strength of Self Compating ConcreteDocument7 pagesEffect of Superplasticizer On Compressive Strength On Compressive Strength of Self Compating ConcreteMuthu KumarNo ratings yet

- Recent Progress in Concrete-Polymer CompositesDocument10 pagesRecent Progress in Concrete-Polymer Compositesswathi1105No ratings yet

- Effects of Metakaolin on Strength Properties of ConcreteDocument5 pagesEffects of Metakaolin on Strength Properties of ConcreteLokesh MechNo ratings yet

- Reactive Powder Concrete: An Ultra-High Strength MaterialDocument33 pagesReactive Powder Concrete: An Ultra-High Strength MaterialSHAIK HUMAYUNNo ratings yet

- Compatibility Between Polycarboxylate-Based Admixtures and Blended Cement PasteDocument12 pagesCompatibility Between Polycarboxylate-Based Admixtures and Blended Cement Pasteshihab44No ratings yet

- Construction and Building Materials: Jamshid Esmaeili, Keyvan Andalibi, Osman GencelDocument11 pagesConstruction and Building Materials: Jamshid Esmaeili, Keyvan Andalibi, Osman GencelTuğçe VuralNo ratings yet

- Lightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiDocument6 pagesLightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiAfzalNo ratings yet

- Experimental Study on Use of Fly Ash in ConcreteDocument22 pagesExperimental Study on Use of Fly Ash in ConcreteVincent VivekNo ratings yet

- Opc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Document15 pagesOpc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Abdul RashidNo ratings yet

- Effects of Polypropylene Fibers on Properties of High-Strength ConcreteDocument18 pagesEffects of Polypropylene Fibers on Properties of High-Strength ConcreteRaviwan IntaratNo ratings yet

- S. Orak (Damping Ratio)Document4 pagesS. Orak (Damping Ratio)fatinNo ratings yet

- DX 24785787Document3 pagesDX 24785787Jithesh.k.sNo ratings yet

- Replacing Cement with Fly Ash for Sustainable ConcreteDocument22 pagesReplacing Cement with Fly Ash for Sustainable Concretekaushal yadavNo ratings yet

- Term Paper 109Document16 pagesTerm Paper 109Satya PydisettiNo ratings yet

- M.M. Reda (1999)Document7 pagesM.M. Reda (1999)kashifNo ratings yet

- Jurnal Beton Busa PDFDocument8 pagesJurnal Beton Busa PDFIqbalArifkyNo ratings yet

- Effect of Mineral Admixtures On Properties of Self-Compacting ConcreteDocument6 pagesEffect of Mineral Admixtures On Properties of Self-Compacting ConcreteNeeraj Mondia0% (1)

- Compar A TieDocument12 pagesCompar A TieSorin SorinNo ratings yet

- Mestrovic RPC MaterialDocument8 pagesMestrovic RPC Materialriski.230110019No ratings yet

- Geopolymer For PavementDocument13 pagesGeopolymer For PavementSo Thu DaiNo ratings yet

- LG AHU CatalogueDocument48 pagesLG AHU CatalogueKiran Kumar Nethrakere/EMD/UAENo ratings yet

- MepDocument80 pagesMepABDELLAHNo ratings yet

- NYC 1922 Building CodeDocument364 pagesNYC 1922 Building CodeJohn Doe100% (1)

- Design and Acceptability of a Universal Concrete SpacerDocument74 pagesDesign and Acceptability of a Universal Concrete SpacerJohn Aries Almelor SarzaNo ratings yet

- Review of Composite Materials and Applications: M.K.S.SaiDocument7 pagesReview of Composite Materials and Applications: M.K.S.SaiTejas shastrakarNo ratings yet

- Revised Standard Data For ElectrificationDocument120 pagesRevised Standard Data For ElectrificationKishore Ainavilli100% (1)

- Content of ReportDocument52 pagesContent of ReportZaim AdliNo ratings yet

- SasoDocument3 pagesSasodeepuNo ratings yet

- Rice Husk AshDocument2 pagesRice Husk AshBart KwanNo ratings yet

- Valv Retencion Daroc PDFDocument14 pagesValv Retencion Daroc PDFMiguel AngelNo ratings yet

- كتالوج الاعمال الجبسيهDocument60 pagesكتالوج الاعمال الجبسيهHoussem MelakhessouNo ratings yet

- Curtain RodDocument4 pagesCurtain RodAnonymous 9b8vCz1WNo ratings yet

- Solvent-Free, Low Viscosity Epoxy ResinDocument2 pagesSolvent-Free, Low Viscosity Epoxy ResinYASHICA VAITTIANATHANNo ratings yet

- Supreme VBS HomesDocument2 pagesSupreme VBS HomesHarish SNo ratings yet

- 84 Design of JointsDocument13 pages84 Design of JointsHasumati SolankiNo ratings yet

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- C.05 SL - SLW Girder Inspection ReportDocument5 pagesC.05 SL - SLW Girder Inspection ReportSami AjNo ratings yet

- Column & Footing Details Block-1 & Block-2Document1 pageColumn & Footing Details Block-1 & Block-2Sandeep VarmaNo ratings yet

- WR2 Electrical Submersible Pump: Wear Resistant Wide Range ESP For Operation in Ultra Demanding ApplicationsDocument2 pagesWR2 Electrical Submersible Pump: Wear Resistant Wide Range ESP For Operation in Ultra Demanding ApplicationsIsmael GuamaniNo ratings yet

- Pds Sikaceram flx23Document5 pagesPds Sikaceram flx23mertelululalalolo23No ratings yet

- Internal Gas Piping Design and Installation GuidelinesDocument27 pagesInternal Gas Piping Design and Installation Guidelinesvirtech67% (3)

- Asme Questions and Answers Part IIIDocument6 pagesAsme Questions and Answers Part IIIYan FerizalNo ratings yet

- Effect of Cooling Rate On The Microstructure and Mechanical Properties of Medium Carbon SteelDocument4 pagesEffect of Cooling Rate On The Microstructure and Mechanical Properties of Medium Carbon SteelIsrar EqubalNo ratings yet

- Welding Wire Diameter CHARTDocument1 pageWelding Wire Diameter CHARTZamriNo ratings yet

- What Is VeneerDocument45 pagesWhat Is Veneeraliyah khalidNo ratings yet

- Mil STD 403c RivetDocument32 pagesMil STD 403c RivetFaizy NohNo ratings yet

- History of Cement IndustryDocument6 pagesHistory of Cement Industrypraveenkv_keskarNo ratings yet

- PART 166 What Is Spot WeldingDocument4 pagesPART 166 What Is Spot Weldingravindra_jivaniNo ratings yet

- Piping Standard and SpecificationDocument27 pagesPiping Standard and SpecificationSunil Kumar100% (2)

- MWTE58 Vs Solarban 90-Triple Silver Low e Glass PerformanceDocument2 pagesMWTE58 Vs Solarban 90-Triple Silver Low e Glass PerformanceHAN HANNo ratings yet