Professional Documents

Culture Documents

2 1-CommonStForms

Uploaded by

Ken KaHo YuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 1-CommonStForms

Uploaded by

Ken KaHo YuCopyright:

Available Formats

Topic : Common Structural Forms for High-rise Buildings in Hong Kong

Prepared by Raymond Wong

Building bends or deflects under lateral force The more rigid of a building structure, the less it deflects

wind

Deflection is a comfort consideration for building users. Building regulation has a basic criteria on deflection. The structure of a building should be so designed to have a deflection less than 1/500 of its height

The problems of tall and slim building

Various deflection modes under wind tunnel test

Structural forms suitable for buildings in HK

1.

Column and beam (framed) structure in RC sometimes called framed buildings which are structures formed by the framed elements usually in the form of columns and beams, as well as further strengthened as necessary by the introduction of rigid floor membranes and external walls. - Simple formwork is required - lower cost of construction - easy to satisfy various spatial arrangement and shapes - may not be very able to cater for the structural needs of tall and slim buildings - more suitable to construction low-rise or horizontalspread buildings such as schools, podium or carpark structures

Example of layout design evolution from a 5 x 3 grid system

Example of In-situ RC frame building

Structural forms suitable for buildings in HK

2. Load bearing wall (shear wall) structure in RC - More complicated formwork is required - cost of construction may increase especially for building with more internal walls or in complicated shape - the load bearing walls can strengthen the rigidity of the building and able to resist building against deflection - building examples: public buildings such as the Harmony Blocks

Example of load-bearing wall structures

Structural forms suitable for buildings in HK

3. Load bearing wall plus core wall structure - Complicated formwork is often required especially in forming the core - cost of construction is higher, especially for buildings with complicated shape (e.g. lots of set-back or light wells - has very strong rigidity to resist deflection - this is the most common structural form for use in HKs residential buildings due to: . walls between residential flats can be best used as a load bearing wall (fire resistance is one reason) . To fulfill building regulation for prescribed window areas . To satisfy the rigidity of high-rise buildings

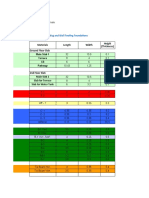

Example of load-bearing wall structures with building area below 500 sq m

Example of load-bearing wall structures of building area around 800 1000 sq m

Example of load-bearing wall structures with several blocks linked together to form a connected structure

Structures in load-bearing wall with a RC core

Structural forms suitable for buildings in HK

4. RC Centre core plus a RC frame structure - Confine to more regularly shaped or building with simpler layout, such as usual tower type buildings - fair rigidity performance but may not be sufficient for building higher than, say 50 storeys. - rigidity can be improved by the adding in of other stiffening members - plenty of window areas (it is only a frame in the external face the building) - The internal core may have difficulty in getting natural ventilation or sunlight.

Example of cored structure with an external frame for towertype office building

Various layout arrangement for building using core and outer frame structure

Various layout arrangement for building using core and outer frame structure

It is sometimes quite difficult and costly to construct the RC core

Structural forms suitable for buildings in HK

5. Center core plus a outer core structure (tube in tube) - Formwork usually very complicated with the floor added in at a second stage - building shape confined to tubular forms - area of windows limited due to the provision of a structurally strong external tube (wall) - quite strong in rigidity and be able to construct to very tall structure - building examples Hopewell Center (HK) or the previous World Trade Center in New York

Examples of tube-in-tube structures

Examples of a framing plan showing the location/layout of walls, columns and beams

Structural forms suitable for buildings in HK

6. Steel frame structure - building is lighter than usual RC structure due to the relative higher weight/strength ration of steel - construction cost is lower especially for buildings adopting high level of standardization - building is weak in rigidity due to steel is a more flexible (elastic) material when compare to RC - additional stiffening elements in the form of internal/external trusses, out-rigger or bracing members are often required to make the building structure more rigid - addition work is required to fire-protect the steel structure - building examples: The Center, China Bank Building

Examples of building constructed in pure structural steel frame

Construction of Structural steel frame building

Structural forms suitable for buildings in HK

7. Composite structure (RC Core plus steel frame, hybrid structure) - building can be lighter than usual RC structure but with a more acceptable rigidity than pure steel buildings - construction cost is higher for the adding in of a RC core which requires a complicated formwork system - it is time consuming and more complicated to make connections between the RC and steel elements - It is even more difficult and costly if stiffening members are introduced into the building in order to make it more rigid to resist deflection - Building examples: Time square, Manual Life Tower, Cheung Kong Center, IFC 1 and 2

Examples of composite structures

The IFC 2

Complicated stiffening elements incorporated in steel or composite building to improve the rigidity of the structure

Cheung Kong Center

Outrigger system used in Cheung Kong Center

The Cheung Kong Center

Complicated stiffening elements incorporated in steel or composite building to improve the rigidity of the structure

Cost idea of using RC, Steel and composite method in constructing tall buildings

How to construct various forms of Buildings

Buildings can be constructed or formed in a number of ways, such as: 1. In-situ manner using formwork for all reinforced concrete buildings 2. Prefabricated manner for using part or all in precast concrete elements 3. Prefabricated manner using structural steel elements 4. Hybrid manner making combination of any of the above systems

Construction of in-situ RC buildings

Forming the wall structure using aluminum moulds

Forming the wall structure using manual-type timber formwork

Construction of in-situ RC buildings

Forming the structure using large panel-type forms for walls or columns

Construction of in-situ RC buildings

Forming the wall structure using mechanical-operated formwork systems

Construction of in-situ RC buildings

Forming the floor structure using timber formwork systems

Construction of in-situ RC buildings

Forming the floor structure using table formwork most suitable for office buildings

Construction of in-situ RC buildings

Forming the floor structure using table formwork floor being strengthened by tensioning technique

Construction of prefabricated frame building

Headquarters building of Hong Kong Jockey Club

Podium KCR Kowloon Station

Construction of prefabricated frame building

Using precast elements as part of the external walls as well as the permanent formwork for load-bearing walls

An external view of building majority of external walls are constructed in precast manner

Advantageous features of framed structure

1.

Speedy construction due to simplicity in geometry consist of only columns and beams (or partially by the floor slab) as the main structural elements Very rigid and stable able to resist tremendous vertical (dead load) and lateral loads (wind) Reduced dead load absent of thick shear wall etc. Roofed over at an earlier stage every floor slab being finished becomes an cover to protect the lower floors from sun and rain Offer large unobstructed floor areas without obstacle between columns Flexible utilization of space

2.

3. 4.

5.

6.

Advan. features of framed structure (continued)

7. 8.

9.

10. 11. 12.

Adaptable to almost any shape Easily altered within limits of frame regular or non-regular grid system is very adaptable in spatial arrangement Offsite preparation possible especially for prefabricated construction using precast concrete or structural steel elements May be designed to accommodate movement Acceptable distribution of natural light window openings can be provided easily on eternal walls Easy to design structurally including computer design again, due to simple geometry

Principle factors affecting choice of frame

Production consideration

Availability of materials, labour and plant Speed of construction Availability of mechanical plants

Architectural Design consideration

Size and shape of site Conditions of site Integration of mechanical elements Architectural or aesthetic requirements

Principle factors affecting choice of frame

Structural Design consideration

Foundation consideration Standardization of members or design Span and floor loads Fire resistance requirement Maintenance consideration Integration of architectural & structural elements

Features of In-situ concrete frame construction

Construction aspects

1.

2.

3. 4.

Insitu concrete is inconsistent in quality in performance mixing, delivery, placing and compacting of concrete require very tight quality control Overlapping formwork, steel fixing and concreting process make site operations more difficult these works are to be done almost at the same time at the same location Formwork erection is often timely, expensive, environmental unfriendly and labour intensive Increase a lot of wet-work difficult to maintain site in a clean and tidy environment

Features of In-situ concrete frame construction

Construction aspects examples of problem

Improper placing and compaction will serious lower the strength of concrete

Features of In-situ concrete frame construction

Construction aspects examples of problem

Finishing the concrete surface after placing improper finish will affect the size and dimension of member

Features of In-situ concrete frame construction

Construction aspects examples of problem

Exterior environment

Interior environment

It is difficult to maintain a clean and tidy site using in-situ concrete structure for the casting process is wet and dirty

Features of In-situ RC frame construction

Construction aspects (continue)

5.

6. 7.

8.

Easier to allow for dimensional discrepancy formwork can relatively easy to provide any ready dimension and shape Concrete is cheap, easy available and can be cast into complicated shape Frame erection affected seriously by climatic condition in windy day it is difficult to erect formwork nor to place concrete Durability affect by heat, moisture or environmental factors concrete is not so durable as most person think

Features of in-situ RC frame construction (cont.)

Structural characteristics and design aspects

1. 2. 3. 4. 5. 6. 7. 8.

Concrete design more flexible and accurate than steel because of non dependence on standard sections Concrete frame easily damaged by building movements Problems of creep & shrinkage (cause damage to finishes) Higher dead load and bigger structural elements Better fire resistance Durability sensitive to workmanship Overloading cause irreversible structural damages Flexible in layout and shape

Features of structural steel construction

Structural characteristics

1. 2.

3.

4.

Steel has lower dead load (unless encased in concrete) Steel frame can easily to have the layout changed to suit new design than concrete, especially requiring alteration after completion of the building. Easily accommodate building movements for steel is a relatively flexible material and have greater adaptability to take up strain and deformation However, it is weaker in fire resistance for steel will lose strength and deform serious at higher temperature (at 600oC or above). This can be improved by applying fire resistant plaster

Features of structural steel construction

Structural characteristics (continue)

5. 6.

7. 8. 9.

Beams usually shallower in size than for concrete Beams Sections in various convenient type and size thus economical in design and uses refer to standard steel sections Produce larger deflection & deformation (Bend) under wind this will cause uncomfort to users of building Steel has higher thermal expansion value Rusting or corrosion problems very strict anti-corrosion treatment has to be applied

Features of structural steel construction (cont.)

Construction aspects

1.

2. 3. 4.

Quicker to erect and can be prepared offsite in workshop/factory environment with good production and quality control Erection on site less affected by climatic conditions without placing of concrete Longer and highly coordinated planning require long time to make structural design, fabrication and delivery Higher requirement in the control of dimensional accuracy before and during construction (in fabrication and in erection

Features of structural steel construction (cont.)

Construction aspects

5. 6.

7.

8.

9.

Demand greater transportation or cranages provision Complicated quality assurance procedures especially in the control of welding connection Difficult to make connection with rigid structures especially in composite structure in which RC core structure is involved More complex when building become more gigantic and taller due to the huge number of structural members, some may be of very heavy section Induce more works at higher altitude

Features of structural steel construction

Construction aspects highlight of some problems

Delivery of structural steel member by ship

Large member delivery to site waiting to hoisting up for erection

Features of structural steel construction

Construction aspects highlight of some problems

Hoisting of the structural steel member to the upper floor

Features of structural steel construction

Construction aspects highlight of some problems

Connecting steel members with RC element an anchor frame may be required for making strong connection

Features of structural steel construction

Construction aspects highlight of some problems

Constructing the composite floor in steel/RC composite structure

To connect floor to core wall starter bars are to be provided within the core structure

Features of structural steel construction

Construction aspects highlight of some problems

Very large component often in complicated shape

Features of structural steel construction

Construction aspects highlight of some problems

Huge amount of structural members make erection very complicated

Features of structural steel construction

Construction aspects highlight of some problems

Very complex and gigantic framework as stiffening members to the overall structure Belt truss system, the IFC II

Features of structural steel construction

Construction aspects highlight of some problems

Very complex and gigantic framework as stiffening members to the overall structure Outrigger, Cheung Kong Center

Features of structural steel construction

Construction aspects highlight of some problems

The existence of very complicated jointing in steel structure

Features of structural steel construction

Construction aspects highlight of some problems

Required to perform works at very high altitude

Features of structural steel construction

Construction aspects highlight of some problems

Workers work at high altitude

Features of structural steel construction

Construction aspects highlight of some problems

Connecting large and complicate shaped components can be very difficult

Features of structural steel construction

Construction aspects highlight of some problems

Concrete has to be trimmed to allow steel to pass through Examples of location where unmatched dimension causing problem

Features of structural steel construction

Construction aspects highlight of some problems

Roof truss and the decking not on the same level

Examples of location where unmatched dimension causing problem

You might also like

- Bs en 12474Document30 pagesBs en 12474Ken KaHo YuNo ratings yet

- 8 Design of Walls PDFDocument48 pages8 Design of Walls PDFtutulayNo ratings yet

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Hong Kong Construction IndustryDocument6 pagesHong Kong Construction IndustryKen KaHo YuNo ratings yet

- 8 Design of Walls PDFDocument48 pages8 Design of Walls PDFtutulayNo ratings yet

- Analysis of A Reinforced Concrete Shear Wall Bjork - Hauksdottir.2007Document118 pagesAnalysis of A Reinforced Concrete Shear Wall Bjork - Hauksdottir.2007antiacidoNo ratings yet

- Wind Code 2004Document27 pagesWind Code 2004Eric NgNo ratings yet

- ASTM D979 Standard Practice For Sampling Bituminous Paving MixturesDocument3 pagesASTM D979 Standard Practice For Sampling Bituminous Paving MixturesKen KaHo Yu100% (1)

- BS 6206Document24 pagesBS 6206Ken KaHo Yu100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Procedure For RCC WorksDocument7 pagesProcedure For RCC WorksBhargav BbvsNo ratings yet

- XTRACT30x30 Fi16Document9 pagesXTRACT30x30 Fi16CristiNo ratings yet

- EuroCode 4 - Lecture 3Document19 pagesEuroCode 4 - Lecture 3Tấn Đạt PhanNo ratings yet

- RBG RAM Concept GuideDocument25 pagesRBG RAM Concept GuideRiliToma100% (2)

- Design of Connecting Platform between Centrifuge and SBRDocument29 pagesDesign of Connecting Platform between Centrifuge and SBRepe civil1No ratings yet

- Beam Bending FormulaDocument22 pagesBeam Bending FormulaBeniamine SarmientoNo ratings yet

- Students Project SchemeDocument9 pagesStudents Project SchemeAnonymous i3lI9MNo ratings yet

- Concrete Mix Design Details for P.I IndustriesDocument2 pagesConcrete Mix Design Details for P.I Industriesambrish.bedekarNo ratings yet

- Foundation Engineering Pile Foundation: Luthfi HasanDocument86 pagesFoundation Engineering Pile Foundation: Luthfi HasanYusron JamilNo ratings yet

- Monthly Progress ReportDocument8 pagesMonthly Progress ReportNirajan MarwaitNo ratings yet

- Bridge Analysis & Design ProcedureDocument6 pagesBridge Analysis & Design ProcedurePrakash Singh Rawal80% (5)

- 1st Proposal BeamDocument513 pages1st Proposal BeamCh OuNo ratings yet

- Shear Wall Dengan Menggunakan Microsoft Excel Dan AutocadDocument10 pagesShear Wall Dengan Menggunakan Microsoft Excel Dan AutocadForming CA GondangNo ratings yet

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocument47 pagesColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanNo ratings yet

- Esr 1082 Eagle MetalsDocument9 pagesEsr 1082 Eagle MetalsmurdicksNo ratings yet

- Staad Aashto LRFD ParametersDocument2 pagesStaad Aashto LRFD ParametersMohamad ArrajNo ratings yet

- Exportlayers DWG ISO13567Document6 pagesExportlayers DWG ISO13567Naassom VazNo ratings yet

- ECM 206 CHAPTER 2 Fresh ConcreteDocument4 pagesECM 206 CHAPTER 2 Fresh ConcreteAZUAN BIN AHMAD FAUZINo ratings yet

- Lecture 6 Fracture MechanicsDocument12 pagesLecture 6 Fracture MechanicsAmmar SafwtNo ratings yet

- HSS Copper WeldDocument0 pagesHSS Copper WeldBJERNo ratings yet

- Fibre Reinforced Concrete PDFDocument79 pagesFibre Reinforced Concrete PDFShaik Asif AliNo ratings yet

- SPRAYED CONCRETE SHOTCRETE GUIDEDocument51 pagesSPRAYED CONCRETE SHOTCRETE GUIDEOana GhermanNo ratings yet

- SFD & BMD PDFDocument1 pageSFD & BMD PDFRakesh SapkotaNo ratings yet

- Seismic Behavior of Sheathed Cold-Formed Steel Stud Shear Walls PDFDocument298 pagesSeismic Behavior of Sheathed Cold-Formed Steel Stud Shear Walls PDFAnonymous hprsT3WlPNo ratings yet

- Typical Physical Properties of Vermiculite ConcreteDocument6 pagesTypical Physical Properties of Vermiculite ConcreteUmeshchandra PatilNo ratings yet

- Method Statement For Correcting Crossbeams at KM 18+300 BridgeDocument2 pagesMethod Statement For Correcting Crossbeams at KM 18+300 BridgeOneArmy FrankNo ratings yet

- GuideDocument42 pagesGuideGibral Maulana100% (2)

- SN037a en EU NCCI Design Model For Simple Column Bases Axially Loaded I Section Columns PDFDocument17 pagesSN037a en EU NCCI Design Model For Simple Column Bases Axially Loaded I Section Columns PDF차영근No ratings yet

- Filler SlabDocument4 pagesFiller Slabthusiyanthanp100% (1)

- GO (RT) No 415 PDFDocument50 pagesGO (RT) No 415 PDFmuhammedNo ratings yet