Professional Documents

Culture Documents

Mechanism of Shaper

Uploaded by

Anuj KrOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanism of Shaper

Uploaded by

Anuj KrCopyright:

Available Formats

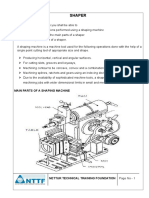

INTRODUCTION TO SHAPER MACHINE The shaper is a reciprocating type of machine tool intended primarily to produce flat surfaces.

These surfaces may be horizontal, vertical, or inclined. In general, the shaper can produce any surface composed of straight line ele ments. Modern shapers can generate contoured surface. The metal working shaper was developed in the year 1836 by James Nasmyth an, Englishman. TYPES OF SHAPERS Shapers are classified in number of ways depending upon the general features of design or the purpose for which they are intended.

According to the type of mechanism used for g i v i n g r e c i p r o c a t i n g m o t i o n t o t h e r a m : - (a) Crank type (b) Geared type (c) Hydraulic type

1. CRANK SHAPER: This is the most common type of shaper in which a single point cutting tool is given a reciprocating equal to the length of the stroke desired while the work is clamped in position on an adjustable table. In construction, the crank shaper employs a crank mechanism to change circular motion of a large gear called bull gear incorporated

in the machine to reciprocating motion of the ram. The bull gear receives power either from an individual motor or from an overhead line shaft if it is a belt driven shaper.

2. GEARED TYPE: The reciprocating motion of the ram in some type of shaper is effected by means of a rack and pinion. The rack teeth which are cut directly below the ram mesh with a spur gear. The pinion meshing with the rack is driven by a gear train. The speed and the direction in which the machine will traverse depend on the number of gears in the gear train. This type of shaper in not very widely used

3. HYDRAULIC SHAPER: In a hydraulic shaper, reciprocating movement of the ram is obtained by hydraulic power. Oil under high pressure is pumped into the operating cylinder fitted with a piston. The end of the piston red is connected to the ram. The high pressure oil first acts on one side o f t h e p i s t o n a n d t h e n on the other causing the piston to reciproca te and t h e m o t i o n i s t5ransmitted to the ram. The piston speed is changed by varying the amount of liquid delivered by the pump. One of the most important advantages of this type of shaper is that the cutting speed and force of the ram drive are constant from the very beginning to the end of the cut. It also offers great flexibility of speed and feed control., eliminates shock and permits slip or slowing up of motion when the cutting tool is overloaded,

protecting the parts or the tools from breakage. Another advantage is that the machine does not make any noise and operates very quietly.

You might also like

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Mitsubishi SU series marine engines 1,007-3,580 kWmDocument4 pagesMitsubishi SU series marine engines 1,007-3,580 kWmDikiNo ratings yet

- Machine Tools (Workshop Technology) PDFDocument11 pagesMachine Tools (Workshop Technology) PDFvenkateshyadav2116100% (1)

- Actuator PDFDocument62 pagesActuator PDFpdealers100% (2)

- Selection of Presses and Its SettingDocument21 pagesSelection of Presses and Its SettingVipul MetaNo ratings yet

- CNG Kit ExperimentDocument2 pagesCNG Kit ExperimentAnuj KrNo ratings yet

- Blanking and Piercing FundamentalsDocument8 pagesBlanking and Piercing FundamentalsK C Vara PrasadNo ratings yet

- Shaper MachineDocument18 pagesShaper MachineSanyam JainNo ratings yet

- 1.8 ltr./110 KW Motronic, Engine Code AGU,: Current Flow DiagramDocument13 pages1.8 ltr./110 KW Motronic, Engine Code AGU,: Current Flow DiagramsergioNo ratings yet

- Progress in Aeroengine Technology (1939-2003) : University of Dayton, Dayton, Ohio 45469-0102Document8 pagesProgress in Aeroengine Technology (1939-2003) : University of Dayton, Dayton, Ohio 45469-0102ArashNo ratings yet

- Shaper Planer N SlotterDocument23 pagesShaper Planer N SlotterAtif WahidNo ratings yet

- Pin ConnectionDocument5 pagesPin ConnectionnicamarcosNo ratings yet

- RT Flex SulzerDocument59 pagesRT Flex SulzerEmurhohwo Jeremiah75% (4)

- Conventional Thickener SystemsDocument13 pagesConventional Thickener SystemslucianotigreNo ratings yet

- Presses and Equipment For SheetMetal DiesDocument153 pagesPresses and Equipment For SheetMetal Diessamurai7_77No ratings yet

- Metal Forming Machines: PressesDocument35 pagesMetal Forming Machines: PressesMohammed Alnashar0% (1)

- TankerDocument60 pagesTankerlopezdestructionNo ratings yet

- Chapter 7 Shaper Operation-1Document22 pagesChapter 7 Shaper Operation-1علاءإدريسNo ratings yet

- C9 - GrindingDocument7 pagesC9 - GrindingHans PinonNo ratings yet

- Technology Development, Design and Safety Features of PHWR and Their Operating PerformanceDocument57 pagesTechnology Development, Design and Safety Features of PHWR and Their Operating PerformanceLuptonga100% (2)

- Hot Oil Heaters and Thermal Fluids - The Complete Guide - PiroblocDocument51 pagesHot Oil Heaters and Thermal Fluids - The Complete Guide - PiroblocasdrumelNo ratings yet

- See More. Lift More. Do MoreDocument6 pagesSee More. Lift More. Do MoreElvis Eberth Huanca Machaca0% (1)

- Shaper Machine SeminrDocument20 pagesShaper Machine SeminrSoumya Banerjee80% (5)

- Piping system design basisDocument6 pagesPiping system design basisDeden SobirinNo ratings yet

- The Cleaning Operations Study of Gas Wells Blowing Lines From Fluid Sand Mechanical ContaminationDocument19 pagesThe Cleaning Operations Study of Gas Wells Blowing Lines From Fluid Sand Mechanical ContaminationNazarii HedzykNo ratings yet

- Working Principle of ShaperDocument9 pagesWorking Principle of ShaperSamir BoseNo ratings yet

- MC-MT R16 - Unit-3Document63 pagesMC-MT R16 - Unit-3Anonymous GEHeEQlajbNo ratings yet

- of ShaperDocument59 pagesof ShaperKishan Siddhpura56% (9)

- Dual Direction Gera MechanisumDocument61 pagesDual Direction Gera Mechanisumpaul_jaikumarm2753No ratings yet

- 4-Shaper, Planer & SlotterDocument43 pages4-Shaper, Planer & SlotterkaushiksoniNo ratings yet

- Shapermachine 160920133823Document17 pagesShapermachine 160920133823deepesh guptaNo ratings yet

- Shaping Machine GuideDocument25 pagesShaping Machine GuidevinayakNo ratings yet

- Shaper MachineDocument9 pagesShaper MachineAqib Zaman100% (1)

- Shaping: OrkingDocument6 pagesShaping: OrkingDevesh TiwariNo ratings yet

- Shaping and PlaningDocument30 pagesShaping and Planingmantana11No ratings yet

- Capacity Enhancement Project Without Any Capital Investment by Prime Turning in Stamping DivisionDocument6 pagesCapacity Enhancement Project Without Any Capital Investment by Prime Turning in Stamping DivisiondharmeshNo ratings yet

- Shaper MachineDocument7 pagesShaper MachineJames_45100% (1)

- C, One of The Most Important Material Removal Methods, Is A Collection of Material-WorkingDocument27 pagesC, One of The Most Important Material Removal Methods, Is A Collection of Material-Workinghackmelike1No ratings yet

- Sheet Metal Stamping Presses: Training ObjectiveDocument6 pagesSheet Metal Stamping Presses: Training ObjectiveSileno DiasNo ratings yet

- ShapingDocument17 pagesShapingShardaNo ratings yet

- Press Tool Design Press Tool Design Press Tool Design Press Tool DesignDocument34 pagesPress Tool Design Press Tool Design Press Tool Design Press Tool DesignAbhiEnd AdevILLNo ratings yet

- ShaperDocument5 pagesShaperRAFIULALAM75% (4)

- Unit 3Document80 pagesUnit 3bmm16957No ratings yet

- Suez Canal University Faculty of Engineering Production and Design Dept. 4 YearDocument13 pagesSuez Canal University Faculty of Engineering Production and Design Dept. 4 YearViolet RoseNo ratings yet

- Everything You Need to Know About Shaping Machines and Scotch Yoke MechanismsDocument36 pagesEverything You Need to Know About Shaping Machines and Scotch Yoke Mechanismsvijay vijay33% (3)

- Prepared by S.sanyasirao, Assistant Professor, VITS College of Engg., Sontyam, VizagDocument14 pagesPrepared by S.sanyasirao, Assistant Professor, VITS College of Engg., Sontyam, Vizagsanyasirao1No ratings yet

- Power Press Tools and MachinesDocument60 pagesPower Press Tools and MachinesThulasi RamNo ratings yet

- Modification of Manual Plate Bending MachineDocument12 pagesModification of Manual Plate Bending Machinesuraj dhulannavarNo ratings yet

- Shaping Machine Manual FinalDocument4 pagesShaping Machine Manual FinalBarun DeNo ratings yet

- Shaper MachineDocument23 pagesShaper MachineRayz C.ONo ratings yet

- Ipe Lab Report 4Document11 pagesIpe Lab Report 4Sourav Sutradhar0% (1)

- CNC New Syllabus TopicsDocument51 pagesCNC New Syllabus TopicsVISMAY PATEL100% (1)

- Dual Acting ShaperDocument30 pagesDual Acting ShaperAbhijeet NaikNo ratings yet

- Experiment No.: Experiment Name:: TypesDocument4 pagesExperiment No.: Experiment Name:: TypesMirMdMarufHossainNo ratings yet

- Coal Cutting MachineDocument62 pagesCoal Cutting MachineSaiNo ratings yet

- Shaper, Slotter and Planer MachinesDocument27 pagesShaper, Slotter and Planer Machinessree_guruNo ratings yet

- Dual Side Shaper Machine Increases Productivity Under 39 CharactersDocument22 pagesDual Side Shaper Machine Increases Productivity Under 39 CharactersGopuNo ratings yet

- Shaper and Types of Shaper MachinesDocument6 pagesShaper and Types of Shaper MachinesGeraldNo ratings yet

- Shaper: Al Qadissiya University College of Engineering Mechanical DepartmentDocument12 pagesShaper: Al Qadissiya University College of Engineering Mechanical DepartmentmahaNo ratings yet

- Shaper MachineDocument4 pagesShaper MachineNishit ParmarNo ratings yet

- Die PunchDocument67 pagesDie PunchAbtahee RUETNo ratings yet

- Press Work For BeginnersDocument19 pagesPress Work For Beginnersranarani2013No ratings yet

- Reciprocating, Milling and Gear Cutting Machines: Types and OperationsDocument102 pagesReciprocating, Milling and Gear Cutting Machines: Types and OperationsJohana JoanneNo ratings yet

- Slotting MachineDocument30 pagesSlotting MachineUsman Zubair100% (1)

- List of Contents: 1.1intorductionDocument25 pagesList of Contents: 1.1intorductionBharath Civil116No ratings yet

- Unit-II The LatheDocument14 pagesUnit-II The LatheThulasi RamNo ratings yet

- Shaper MachineDocument81 pagesShaper Machinesam clastineNo ratings yet

- ShaperDocument20 pagesShaperMilan SainiNo ratings yet

- Unit Iii Other Machine ToolsDocument41 pagesUnit Iii Other Machine Toolsrkscad11No ratings yet

- Shaper LAB REPORTDocument3 pagesShaper LAB REPORTVishal JamuarNo ratings yet

- Shaper Machine: TH THDocument20 pagesShaper Machine: TH THLokesh LokiNo ratings yet

- ShaperDocument15 pagesShaperRinku SainiNo ratings yet

- Cleanliness: Important Features of The Railway Budget 2015Document4 pagesCleanliness: Important Features of The Railway Budget 2015Anuj KrNo ratings yet

- SM - BCG MatrixDocument4 pagesSM - BCG MatrixAnuj KrNo ratings yet

- ITOD ProjectDocument3 pagesITOD ProjectAnuj KrNo ratings yet

- Bunge Limited: Global Agribusiness and Food Company ProfileDocument3 pagesBunge Limited: Global Agribusiness and Food Company ProfileAnuj KrNo ratings yet

- Bunge Limited: Global Agribusiness and Food Company ProfileDocument3 pagesBunge Limited: Global Agribusiness and Food Company ProfileAnuj KrNo ratings yet

- CSR ReportDocument9 pagesCSR ReportAnuj KrNo ratings yet

- Tata SteelDocument3 pagesTata SteelAnuj KrNo ratings yet

- India in SpaceDocument1 pageIndia in SpaceAnuj KrNo ratings yet

- 4 Squares: This Was Done in World Record Time of 7 SecDocument1 page4 Squares: This Was Done in World Record Time of 7 SecYashwantChhabraNo ratings yet

- Sum&avg CPTDocument1 pageSum&avg CPTAnuj KrNo ratings yet

- According To Section 56Document3 pagesAccording To Section 56Anuj KrNo ratings yet

- Important DaysDocument2 pagesImportant DaysmvithiyadharanNo ratings yet

- CoachDocument464 pagesCoachAnuj KrNo ratings yet

- CoachDocument464 pagesCoachAnuj KrNo ratings yet

- Features of A Milling CutterDocument8 pagesFeatures of A Milling CutterAnuj KrNo ratings yet

- AimDocument6 pagesAimAnuj KrNo ratings yet

- India in SpaceDocument1 pageIndia in SpaceAnuj KrNo ratings yet

- NABARDDocument1 pageNABARDAnuj KrNo ratings yet

- Three types of biomass gasifiers and their applications in IC enginesDocument4 pagesThree types of biomass gasifiers and their applications in IC enginesAnuj KrNo ratings yet

- IntegralDocument8 pagesIntegralAnuj KrNo ratings yet

- Famous Books and AuthorsDocument1 pageFamous Books and AuthorsAnuj KrNo ratings yet

- AerodynamicsDocument11 pagesAerodynamicsAnuj KrNo ratings yet

- General KnowledgeDocument1 pageGeneral KnowledgeAnuj KrNo ratings yet

- Features of A Milling CutterDocument8 pagesFeatures of A Milling CutterAnuj KrNo ratings yet

- Area Cir Rec TriDocument1 pageArea Cir Rec TriAnuj KrNo ratings yet

- R.J. Gayler - BG Tuning ManualDocument68 pagesR.J. Gayler - BG Tuning ManualRajat NanchahalNo ratings yet

- Appliec ChemistryDocument3 pagesAppliec ChemistryQueen Ann NavalloNo ratings yet

- Top MonthlyPresentation 201905Document83 pagesTop MonthlyPresentation 201905Aniket SharmaNo ratings yet

- Alat Uji Emsi Solar CosberDocument2 pagesAlat Uji Emsi Solar CosberJuliansyahNo ratings yet

- Module 1 - Introduction - Field Life CycleDocument23 pagesModule 1 - Introduction - Field Life CycleAnimesh ChoudharyNo ratings yet

- Hyundai Accent - Installation - Timing Chain. Repair Procedures - Timing System. - Engine Mechanical SystemDocument10 pagesHyundai Accent - Installation - Timing Chain. Repair Procedures - Timing System. - Engine Mechanical SystemJames LeonNo ratings yet

- Piston Less Pump For RocketDocument24 pagesPiston Less Pump For Rocketpraveenpv7100% (3)

- S. R. ChakravarthyDocument7 pagesS. R. ChakravarthyDevangMarvaniaNo ratings yet

- VSEP Membrane Separation Ethanol Application NoteDocument12 pagesVSEP Membrane Separation Ethanol Application NoteHermawan Dwi AriyantoNo ratings yet

- Petroleum Fraction N UsesDocument36 pagesPetroleum Fraction N UsesWan Afiff100% (1)

- 10th STD Science Lesson Plan Eng Version 2017-18Document43 pages10th STD Science Lesson Plan Eng Version 2017-18sgshekar30No ratings yet

- 2008 Shell Eco Marathon Americas ResultsDocument2 pages2008 Shell Eco Marathon Americas Resultsncwilde43No ratings yet

- AD00691M JISKOOT JetMix System BrochureDocument4 pagesAD00691M JISKOOT JetMix System BrochureMohammad Fahmi Rahmana100% (1)

- Shell Rimula R2 15W-40 Technical Data SheetDocument2 pagesShell Rimula R2 15W-40 Technical Data SheetCernea GabrielNo ratings yet

- VH60-100 Presentation Philippe ChabinDocument46 pagesVH60-100 Presentation Philippe ChabinMohamedMansour50% (2)

- AE8005 Aero Engine Maintenance and Repair LTPC 3 0 0 3 ObjectivesDocument1 pageAE8005 Aero Engine Maintenance and Repair LTPC 3 0 0 3 ObjectivesAERO JPRNo ratings yet

- Lab 6 - Gas TurbineDocument8 pagesLab 6 - Gas TurbinehaziqsajjadNo ratings yet