Professional Documents

Culture Documents

CISE 412 Mechatronics Lab Manual

Uploaded by

karthisanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CISE 412 Mechatronics Lab Manual

Uploaded by

karthisanCopyright:

Available Formats

King Fahd Universit y of Pet roleum & Minerals

Syst ems Engineering Depart ment

CI SE 412: Mechat ronics

Lab Manual

( Term 092)

Dr. Samir Al- Amer

2010

Table of Cont ent s

Lab # 1: Component Information Gathering ................................................................. 3

Lab # 2: Modeling and Controller Design of Magnetic Levitation System .................. 6

Lab # 3-4: Modeling and Controller Design of Magnetic Levitation System ............ 18

Lab # 5: Design and Implementation of Operational Amplifier Circuits .................... 29

Lab # 6: Introduction to Boe-Bot ................................................................................. 41

Lab # 7: Servomotors for the Boe-Bot ........................................................................ 42

Lab # 8: Assembling and Testing the Boe-Bot ........................................................... 43

Lab # 9: Basic Boe-Bot Navigation ............................................................................ 44

Lab # 10: Boe-Bot Navigation with Whiskers ............................................................. 45

Lab # 11: Boe-Bot Navigation with Photoresistors ..................................................... 46

CI SE 412: Mechat ronics

Term 092

LAB # 1: Component I nf or mat i on Gat her i ng

Obj ect i v e:

The obj ect ive of t his lab is t o pract ice gat hering t echnical

informat ion about different t ypes of component s used in

Mechat ronic Syst ems.

I nt r oduct i on:

An import ant st ep in t he design of mechat ronic syst ems is t o gat her

t echnical informat ion about component s t hat can be used in design

of a syst em. I n t his lab session you will pract ice collect ing

informat ion and select ing component s t o sat isfy some const raint s.

This involves reading dat a sheet s and ext ract ing informat ion from

t hem.

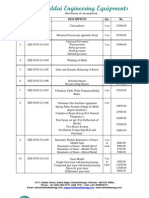

Part 1:

Using I nt ernet search, obt ain t he dat a sheet s for t he following

component s. Use t he dat a sheet t o provide t he required dat a.

1. Provide t he following informat ion about TTL 7400 ( or 74ACT00)

The purpose of t his I C

Sket ch t he I C pin- out ( DI P if available)

Temperat ure operat ing range

Supply volt age ( min max)

I nput Volt age level for OFF ( low)

I nput Volt age Level for ON ( high)

Out put Volt age level for OFF ( low)

Out put Volt age Level for ON ( high)

High level input current

Low level input current

Typical propagat ion delay

A company t hat produce such I C. ( Name- address)

2. Provide a CMOS I C t o do t he funct ion similar t o t he TTL 7400 and

provide t he same informat ion asked for in ( 1) .

Par t 2

I n t he following, you need t o search for and provide informat ion

about several component s. I n some cases a specific name

( component number) is provided. I n ot her cases a general name

indicat ing t he funct ion of t he component is provided. You are asked

t o do a search on t he int ernet t o get more det ails about t hose

component s.

There could be many component s t o do t he required j ob. Provide

informat ion about one such component .

Required informat ion include t he company providing t he

component , URL locat ion for specificat ion sheet if available , Pin-

out diagram, component number

How does it work? How much does it cost ?

1. 4- digit LED display unit t hat can be used t o display 0,1, 2, .. 9.

2. SN7490 Decay Count er

3. LM7414 Schmit t Trigger ( How does i t w or k ?)

4. NE555 t imer. ( How does i t w or k ?)

5. Opt ical I solat or TTL, DI P format

6. 0. 25 W resist ors DI P resist or ( 8 resist ors, 10 M ohm if

available)

7. Pot ent iomet er ( rot ary t ype , power rat ing < 5 W, Rot at ion

Angle> 200 degrees)

8. 12- bit DAC

9. Toggle Swit ches ( lower power, volt age < 20V, small size,

ON- OFF)

10. Keypads ( 4X4 , small size)

11. Speed and posit ion t ransducer ( Shaft Encoder) ( < 100

pulse/ rev)

Groups of 2 can work on t his lab proj ect

Soft copy of t he report can be submit t ed t hrough webCT.

Due dat e for submission is t he beginning of t he next lab.

CI SE 412: MECHATRONI CS

( Term 092)

Lab # 2: Model i ng and Cont r ol l er Desi gn of

Magnet i c Levi t at i on Sy st em

Equi pment Needed

+ PC w i t h MATLAB and SI MULI NK

I nt r oduct i on:

Magnet ic levit at ion syst em finds applicat ions in engineering

including aerospace, high speed t ransport at ion syst em, levit at ed

micro- robot ics, magnet ic levit at ed aut omot ive engine valves,

magnet ic bearings. Cont rol and ident ificat ion of magnet ic levit at ion

syst em physical syst em is challenging research problem as t he

syst em is nonlinear and unst able [ 1- 4] . From educat ional point of

view t he magnet ic levit at ion provides a t est bed for learning

cont roller design as it is unst able and nonlinear and must be

operat ed in a closed loop [ 1] . There are a number of ot her physical

syst ems which are unst able and must be operat ed in closed loop

such as an aircraft , helicopt er, invert ed pendulum ( e. g. Segway) ,

posit ion cont rol syst em, liquid level process cont rol. However t he

maglev syst em has poles st rict ly in t he right half plane syst em

whereas t he above st at ed syst ems have poles at t he origin ( each

behaves as an int egrat or) and hence poses difficult ies in t he design

of a robust cont roller and it s implement at ion.

Obj ect i ve:

The obj ect ive of t his lab is as follows:

- Model t he maglev syst em using t he physical laws governing

t he elect ro- magnet ic circuit s, and Newt on laws laws of

mot ion.

- Design an analog/ digit al cont roller.

- Evaluat e t he performance of t he closed loop cont rol syst em in

t ime domain ( set t ling t ime, overshoot and cont rol input

magnit ude, and in frequency domain including t he

bandwidt h, resonance frequency and resonance peak.

- I t erat e t he design t ill t he cont roller performance is accept able

for implement at ion

Model i ng of a Magnet i c Levi t at i on Sy st em

We will use physical laws governing t he at t ract ive force generat ed

by t he int eract ion of t he elect romagnet ic field and an iron ball, and

t he result ing mot ion by t he Newt ons Law. Consider a magnet ic

levit at ion shown in Fig. 1. I t consist s of an elect romagnet which

produces a magnet ic field t hat at t ract s an iron ball. The vert ical

mot ion of t he ball is measured by an opt ical syst em.

Fig. 1. MAGLEV syst em

Elect romagnet ic force

A magnet ic mat erial such as an iron ball placed in t he magnet ic field

will experience a force, f, due t o at t ract ion bet ween t he magnet ic

poles, one in t he elect romagnet ic and t he ot her induced in t he

magnet ic mat erial as shown in t he Fig. 2.

Fig. 2. Force in t he magnet ic mat erial placed in a magnet ic field

The at t ract ive force on t he iron ball, F, is

( )

2 2

2

0

2

N Ai

F

X

=

+

where N is t he number of t urn of t he coil, A is t he area of t he

elect romagnet ic, i is current in t he coil which creat es t he magnet ic

field,

0

X = + is t he lengt h of t he magnet ic pat h, X is t he dist ance

bet ween t he iron ball and t he elect romagnet and

0

is t he lengt h of

t he magnet ic pat h in t he magnet ic mat erials of t he elect ro- magnet ic

and t he iron ball.

The direct ion of t his force is vert ically upwards.

Comment s: Applicat ions of t he force bet ween t he flux and a

magnet ic mat erial include t he following:

- Magnet ic levit at ion t rain ( t he t rain levit at es t hanks t o t he

force experience by t he elect romagnet at t ached t o t he t rain

and t he ferrous rail) .

- magnet ic bearing ( rot at ing shaft is suspended in a circular

magnet ic field so t hat t he rot at ing shaft does not t ouch any

component t hereby eliminat ing frict ion)

- Elect romagnet ic swit ches, e. g. solenoids , relays. Solenoids

are inexpensive and are used in lat ching, locking. Examples

include aut omobile door lat ches and st art er solenoids,

opening and closing of valves in washing machines, relays in

power syst ems. I t has advant age over semiconduct or

swit ches as it can handle very large current s, and t he circuit

cont rolling t he elect romagnet ic swit ches is isolat ed

- St epper mot or and reluct ance mot ors

x

magnet

ic

magnet ic

flux

coil

current ,

Model of t he coil: curr ent I and t he volt age V

=

Fig. 3 RL circuit

Consider t he coil of t he elect romagnet shown in Fig. 3. Let R be t he

resist ance and L be t he induct ance.

Ver i f y t hat t he different ial equat ion governing applied volt age t o

t he coil and t he current t hrough t he coil is

di

L Ri V

dt

+ =

Ver i f y t hat t he t ransfer funct ion relat ing V and i is given by

( ) 1 1/

( ) 1

i s R L

where

V s Ls R s R

t

t

= = =

+ +

The elect romagnet ic coil is generally designed t o have very low

resist ance t o reduce t he power loss

2

i R and t hereby reduce t he heat

generat ed. I n pract ical syst ems such as magnet ron part icle

accelerat ors and magnet ic levit at ion syst ems very low t emperat ure

( cryogenic) is creat ed t o reduce t he resist ance and hence t he heat

loss.

As / L R is negligible t he induct ance may be neglect ed, and t hus t he

relat ion bet ween t he volt age and t he resist ance, R is a simple st at ic

equat ion

V

i

R

=

R

L

i

+

V

_

+

V

_

Comment : The model of a RL circuit of an elect romagnet is a first

order syst em wit h a t ime const ant

L

R

t = since t he t ime const ant t is

very small, it is neglect ed. I n modeling of syst ems and in cont roller

design, neglect ing very low t ime const ant syst ems is t ermed as

unmodelled dynamics or model reduct ion. I n ot her words t he

t ransfer funct ion of t he coil is approximat ed:

( ) 1/ 1

( ) 1

i s R

V s s R t

= ~

+

I n pract ice it is common t o neglect fast dynamics and an

approximat e reduced order model so as t o simplify t he design of

cont roller wit hout affect ing t he performance.

Wit h t his approximat ion, t he vert ical force on t he iron ball becomes

( )

2 2

2 2

0

2

N A V

F

R

X

=

+

Model of t he maglev syst em using Newt ons law of mot ion

Consider t he iron ball. Let m be t he mass of t he ball. Using

Newt ons law of mot ion ( mass t imes t he accelerat ion equals t he net

force) , t he force and t he dist ance are relat ed by t he following

different ial equat ion

mX F mg =

Subst it ut ing for t he force F and simplifying we get

( )

2

2

0

V

X k g

X

=

+

where

2

2

2

N A

k

mR

=

Equilibrium point

There is a upward force, F, on t he iron ball and t here is a downward

force due t o gravit y, mg. The quest ion arises as t o where will t he

iron ball go. Will it fall down, will it be at t ract ed upwards and crash

on t he elect romagnet or it will remain at some locat ion where t he

upward force will balance t he downward force. The answer t o t his

quest ion will depend upon t he equi l i br i um poi nt also t ermed t he

si ngul ar poi nt of t he different ial equat ion. The equilibrium point is

obt ained by set t ing all t he derivat ives, first order, second and

higher order derivat ives t o zero. I n t his case we only have second

order derivat ive. Set t ing it t o zero yields t he equilibrium point ,

0

X ,

is obt ained from

( )

2

0

2

0 0

0

V

k g

X

=

+

where

0

V is t he volt age applied.

( )

2

0

2

0

0

V

k g

X

=

+

The equilibrium point ,

0

X , is given by

0 0

k

X L V

g

+ =

Subst it ut ing for k we get

0

2

VR A

X L

N mg

+ =

Linearizat ion of t he Differ ent ial Equat ion

Consider t he different ial equat ion model

( , ) X f X V g =

where

2

2

( , )

V

f X V k

X

=

I t is second order nonlinear syst em. For designing a cont roller, a

linear approximat e model is employed as it is very difficult t o design

a cont roller for a nonlinear syst em. A linear approximat ion is

obt ained by linearizing t he nonlinear funct ion, ( , ) f X V about t he

equilibrium point ,

0

x and t he nominal volt age input ,

0

V , using

Taylors series

( ) ( )

0 0 0

0 0 0 0

, ,

( , ) ( , )

o

X X V V X X V V

df df

f X V f X V X X V V

dX dV

= = = =

~ + +

This approximat ion is valid for small variat ions of X about

0

X ,

0

X X se, and V V se.

Ver i f y t hat t he expression for linear approximat ion

of ( , ) f X V becomes

( ) ( )

( )

( )

( )

2 2 2

0 0 0

0 0 2 3

0

0 0

2

( , ) 2

kV V kV

f X V k X X V V

X L

X L X L

= +

+

+ +

Let us define

0

x X X = and

0

u V V = ,. Using t his definit ion we get

( ) ( ) ( )

2 2

0 0 0

2 3 2

0 0 0

2

( , ) 2

kV V kV

f X V k x u

X L X L X L

= +

+ + +

Since

( )

2

0

2

0

V

g k

X L

=

+

we get

( , ) f X V g x u o | = +

where

( ) ( )

2

0 0

2 2

0 0

2

2 ,

V kV

k

X L X L

o | = =

+ +

Subst it ut ing t he nonlinear funct ion by it s linear approximat ion in

( , ) X g f X V =

we get

x x u o | =

The above is a linear approximat ion model of t he nonlinear maglev

syst em. This approximat ion is valid for excursion in t he

neighborhood of

0

X and

0

V ,

x se and u se

Taking t he Laplace t ransform, t he t ransfer funct ion relat ing x and u

becomes

2

( )

( )

( )

x s

G s

u s s

|

o

= =

The syst em is unst able as t here is pole in t he right half of t he s-

plane. The poles, p, of t he plant are real and are symmet rically

locat ed about t he imaginary axis

p o =

Analysis of t he open loop syst em

St abilit y analysis

The syst em is unst able as t here is pole in t he right half of t he s-

plane. The poles, p, of t he plant are real and are symmet rically

locat ed about t he imaginary axis

p o =

The poles are symmet rically locat ed about t he imaginary axis in t he

s- plane.

St ep response

Ver i f y t hat t he st ep response will be unbounded and is given by

( )

1 1

( ) 1

2

t t

x t e e

o o

o

(

= +

(

The st ep response is unbounded.

=

) ( lim t x

t

Frequency response

Consider t he t ransfer funct ion, ( ) G s . Set t ing s je = t he frequency

response becomes

2

( ) 1

( )

( )

x j

G j

u j

e

e

e e o

= =

+

The frequency response is real and posit ive for all frequencies

t hanks t o t he symmet ric locat ion of t he poles.

This shows t hat one can analyze t he maglev syst em using

frequency response and not st ep response.

Design of cont r oller

Cont roller st ruct ure and cont roller design approach

There are a number of choices of cont roller st ruct ures including,

proport ional int egral derivat ive ( PI D) cont roller, lead- lag

compensat or, and st at e feedback cont roller and number of

approaches for designing a cont roller.

The maglev syst em in t he laborat ory has lead- lag compensat or.

Hence we will choose a lead- lag compensat or. As for t he design

approach we will choose a simple approach based on pole-

placement .

The lead- lag compensat or, C( s) , t akes t he general form

( )

s b

C s k

s a

+ | |

=

|

+

\ .

Closed loop syst em

Since t he plant , G( s) is unst able it must be operat ed in a closed

loop configurat ion formed of t he plant G( s) and t he cont roller, C( s)

as shown in Fig. 4 below.

e u x r

C( s G( s

Fig. 4. Closed loop syst em formed of t he plant G( s) and t he

cont roller, C( s)

The close loop t ransfer funct ion relat ing t he reference input , r and

t he plant out put , x is given by

( ) ( ) ( )

( ) 1 ( ) ( )

x s G s C s

r s G s C s

=

+

Subst it ut ing for G( s) and C( s) t he closed loop numerat or

polynomial, N( s) and denominat or polynomial ( also t ermed

charact erist ic polynomial) , D( s) become

( ) ( ) N s k s b | = +

( )( ) ( )

2

( ) D s s a s k s b o | = + +

Consider t he charact erist ic polynomial, D( s) . Simplifying yields

3 2

( ) ( ) D s s as s k a k b o | o | = + +

Design using pole- placement approach

We will use pole- placement approach t o design t he cont roller, C( s) ,

t hat is obt ain t he cont roller paramet ers, k, a and b.

- Choice of desired pole locat ion

The closed loop syst em is of t hird order. Let us choose for

convenience all poles t o be equal t o p.

Ver i f y t hat t he desired charact erist ic polynomial, ( ) s

becomes

( )

3

3 2 2 3

( ) 3 3 s s p s s p sp p = + = + + +

- Equat e t he act ual charact erist ic polynomial and t he desired

charact erist ic polynomial

( ) ( ) D s s =

Subst it ut ing for D( s) and ( ) s yields

3 2 3 2 2 3

( ) 3 3 s as s k a k b s s p sp p o | o | + + = + + +

- Solve for t he unknown cont roller paramet ers, k, a, and b by

equat ing t he coefficient s of t he equal powers of s.

Ver i f y t hat t he solut ion of t he equat ions yields

3

2

2

3

3

3

a p

p p

b

p

p

k

o

o

o

|

=

+

=

+

+

=

Del i ver abl es

Each st udent should submit a word file cont aining t he following:

- Verificat ion of marked expressions.

- The mat hemat ical model of maglev syst em

- Analysis of t he linear approximat ion model of t he Maglev

syst em in t ime and frequency domain using SI MULI NK.

- Evaluat ion of t he performance

REFERENCES

[ 1] Galvo, R. K. H. , Yoneyama, T. , Araj o, F. M. U., Machado, R.

G. A Simple Technique for I dent ifying a Linearized Model for a

Didact ic Magnet ic Levit at ion Syst em . I EEE Transact ions on

Educat ion, v. 46, n. 1, p. 22- 25, 2003.

[ 2] K. Pet erson, J. W.Grizzle, and A.G. St efanpolou, Nonlinear

magnet ic levit at ion of aut omot ive engine valves

[ 3] David Craig and Mir Behrad Khamesee, Black box model

ident ificat ion of a magnet ically levit at ed microrobot ic syst em Smart

Mat erials and St ruct ures, 16, 2007, pp. 739- 747

CI SE 412: MECHATRONI CS ( Term 082)

Lab # 3: Model i ng and Cont r ol l er Desi gn of

Magnet i c Levi t at i on Sy st em

I nt r oduct i on:

Magnet ic levit at ion syst em finds applicat ions in engineering

including aerospace, high speed t ransport at ion syst em, levit at ed

micro- robot ics, magnet ic levit at ed aut omot ive engine valves,

magnet ic bearings. Cont rol and ident ificat ion of magnet ic levit at ion

syst em physical syst em is challenging research problem as t he

syst em is nonlinear and unst able [ 1- 4] . From educat ional point of

view t he magnet ic levit at ion provides a t est bed for learning

cont roller design as it is unst able and nonlinear and must be

operat ed in a closed loop [ 1] . There are a number of ot her physical

syst ems which are unst able and must be operat ed in closed loop

such as an aircraft , helicopt er, invert ed pendulum ( e. g. Segway) ,

posit ion cont rol syst em, liquid level process cont rol. However t he

maglev syst em has poles st rict ly in t he right half plane syst em

whereas t he above st at ed syst ems have poles at t he origin ( each

behaves as an int egrat or) and hence poses difficult ies in t he design

of a robust cont roller and it s implement at ion.

Obj ect i ve:

The obj ect ive of t his lab is as follows:

- Model t he maglev syst em using t he physical laws governing

t he elect ro- magnet ic circuit s, and Newt on laws laws of

mot ion.

- Design an analog/ digit al cont roller.

- Evaluat e t he performance of t he closed loop cont rol syst em in

t ime domain ( set t ling t ime and overshoot , cont rol input

magnit ude, and in frequency domain including t he

bandwidt h, resonance frequency and resonance peak.

- I t erat e t he design t ill t he cont roller performance is accept able

for implement at ion

Model i ng of a Magnet i c Levi t at i on Sy st em

We will use physical laws governing t he at t ract ive force generat ed

by t he int eract ion of t he elect romagnet ic field and an iron ball, and

t he result ing mot ion by t he Newt ons Law. Consider a magnet ic

levit at ion shown in Fig. 1. I t consist s of an elect romagnet which

produces a magnet ic field t hat at t ract s an iron ball. The vert ical

mot ion of t he ball is measured by an opt ical syst em.

Fig. 1. MAGLEV syst em

Elect romagnet ic force

A magnet ic mat erial such as an iron ball placed in t he magnet ic field

will experience a force, f, due t o at t ract ion bet ween t he magnet ic

poles, one in t he elect romagnet ic and t he ot her induced in t he

magnet ic mat erial as shown in t he Fig. 2.

Fig. 2. Force in t he magnet ic mat erial placed in a magnet ic field

The at t ract ive force on t he iron ball, F, is

( )

2 2

2

0

2

N Ai

F

X

=

+

where N is t he number of t urn of t he coil, A is t he area of t he

elect romagnet ic, i is current in t he coil which creat es t he magnet ic

field,

0

X = + is t he lengt h of t he magnet ic pat h, X is t he dist ance

bet ween t he iron ball and t he elect romagnet and

0

is t he lengt h of

t he magnet ic pat h in t he magnet ic mat erials of t he elect ro- magnet ic

and t he iron ball.

The direct ion of t his force is vert ically upwards.

Comment s: Applicat ions of t he force bet ween t he flux and a

magnet ic mat erial include t he following:

- Magnet ic levit at ion t rain ( t he t rain levit at es t hanks t o t he

force experience by t he elect romagnet at t ached t o t he t rain

and t he ferrous rail) .

- magnet ic bearing ( rot at ing shaft is suspended in a circular

magnet ic field so t hat t he rot at ing shaft does not t ouch any

component t hereby eliminat ing frict ion)

- Elect romagnet ic swit ches, e. g. solenoids , relays. Solenoids

are inexpensive and are used in lat ching, locking. Examples

include aut omobile door lat ches and st art er solenoids,

opening and closing of valves in washing machines, relays in

power syst ems. I t has advant age over semiconduct or

swit ches as it can handle very large current s, and t he circuit

cont rolling t he elect romagnet ic swit ches is isolat ed

- St epper mot or and reluct ance mot ors

x

magnet

ic

magnet ic

flux

coil

current ,

Model of t he coil: current I and t he volt age V

V

i

R

L

Fig. 3 RL circuit

Consider t he coil of t he elect romagnet shown in Fig. 3. Let R be t he

resist ance and L be t he induct ance. The different ial equat ion

governing applied volt age t o t he coil and t he current t hrough t he

coil is

di

L Ri V

dt

+ =

The t ransfer funct ion relat ing V and i is given by

( ) 1 1/

( ) 1

i s R L

where

V s Ls R s R

t

t

= = =

+ +

The elect romagnet ic coil is generally designed t o have very low

resist ance t o reduce t he power loss

2

i R and t hereby reduce t he heat

generat ed. I n pract ical syst ems such as magnet ron part icle

accelerat ors and magnet ic levit at ion syst ems very low t emperat ure

( cryogenic) is creat ed t o reduce t he resist ance and hence t he heat

loss.

As / L R is negligible t he induct ance may be neglect ed, and t hus t he

relat ion bet ween t he volt age and t he resist ance, R is a simple st at ic

equat ion

V

i

R

=

Comment : The model of a RL circuit of an elect romagnet is a first

order syst em wit h a t ime const ant

L

R

t = since t he t ime const ant t is

very small is very small, it is neglect ed. I n modeling of syst ems and

in cont roller design, neglect ing very low t ime const ant syst ems is

t ermed as unmodelled dynamics or model reduct ion. I n ot her

words t he t ransfer funct ion of t he coil is approximat ed:

( ) 1/ 1

( ) 1

i s R

V s s R t

= ~

+

I n pract ice it is common t o neglect fast dynamics and an

approximat e reduced order model so as t o simplify t he design of

cont roller wit hout affect ing t he performance.

Wit h t his approximat ion, t he vert ical force on t he iron ball becomes

( )

2 2

2 2

0

2

N A V

F

R

X

=

+

Model of t he maglev syst em using Newt ons law of mot ion

Consider t he iron ball. Let m be t he mass of t he ball. Using

Newt ons law of mot ion ( mass t imes t he accelerat ion equals t he net

force) , t he force and t he dist ance are relat ed by t he following

different ial equat ion

mX F mg =

Subst it ut ing for t he force F and simplifying we get

( )

2

2

0

V

X k g

X

=

+

where

2

2

2

N A

k

mR

=

Equilibrium point

There is a upward force, F, on t he iron ball and t here is a downward

force due t o gravit y, mg. The quest ion arises as t o where will t he

iron ball go. Will it fall down, will it be at t ract ed upwards and crash

on t he elect romagnet or it will remain at some locat ion where t he

upward force will balance t he downward force. The answer t o t his

quest ion will depend upon t he equilibrium point also t ermed t he

singular point of t he different ial equat ion. The equilibrium point is

obt ained by set t ing all t he derivat ives, first order, and second and

higher order derivat ives t o zero. I n t his case we only have second

order derivat ive. Set t ing it t o zero yields t he equilibrium point ,

0

X ,

is obt ained from

( )

2

0

2

0 0

0

V

k g

X

=

+

where

0

V is t he volt age applied.

( )

2

0

2

0

0

V

k g

X

=

+

The equilibrium point ,

0

X , is given by

0 0

k

X L V

g

+ =

Subst it ut ing for k we get

0

2

VR A

X L

N mg

+ =

Linearizat ion of t he Differ ent ial Equat ion

Consider t he different ial equat ion model

( , ) X f X V g =

where

2

2

( , )

V

f X V k

X

=

I t is second order nonlinear syst em. For designing a cont roller, a

linear approximat e model is employed as it is very difficult t o design

a cont roller for a nonlinear syst em. A linear approximat ion is

obt ained by linearizing t he nonlinear funct ion, ( , ) f X V about t he

equilibrium point ,

0

x and t he nominal volt age input ,

0

V , using

Taylors series

( ) ( )

0 0 0

0 0 0 0

, ,

( , ) ( , )

o

X X V V X X V V

df df

f X V f X V X X V V

dX dV

= = = =

~ + +

This approximat ion is valid for small variat ions of X about

0

X ,

0

X X se, and V V se. Using t he expression for linear

approximat ion of ( , ) f X V becomes

( ) ( )

( )

( )

( )

2 2 2

0 0 0

0 0 2 3

0

0 0

2

( , ) 2

kV V kV

f X V k X X V V

X L

X L X L

= +

+

+ +

Let us define

0

x X X = and

0

u V V = ,. Using t his definit ion we get

( ) ( ) ( )

2 2

0 0 0

2 3 2

0 0 0

2

( , ) 2

kV V kV

f X V k x u

X L X L X L

= +

+ + +

Since

( )

2

0

2

0

V

g k

X L

=

+

we get

( , ) f X V g x u o | = +

where

( ) ( )

2

0 0

2 2

0 0

2

2 ,

V kV

k

X L X L

o | = =

+ +

Subst it ut ing t he nonlinear funct ion by it s linear approximat ion in

( , ) X g f X V =

we get

x x u o | =

The above is a linear approximat ion model of t he nonlinear maglev

syst em. This approximat ion is valid for excursion in t he

neighborhood of

0

X and

0

V ,

x se and u se

Taking t he Laplace t ransform, t he t ransfer funct ion relat ing x and u

becomes

2

( )

( )

( )

x s

G s

u s s

|

o

= =

The syst em is unst able as t here is pole in t he right half of t he s-

plane. The poles, p, of t he plant are real and are symmet rically

locat ed about t he imaginary axis

p o =

Analysis of t he open loop syst em

St abilit y analysis

The syst em is unst able as t here is pole in t he right half of t he s-

plane. The poles, p, of t he plant are real and are symmet rically

locat ed about t he imaginary axis

p o =

The poles are symmet rically locat ed about t he imaginary axis in t he

s- plane.

St ep response

The st ep response will be unbounded and is given by

( )

1 1

( ) 1

2

t t

x t e e

o o

o

(

= +

(

The st ep response is unbounded.

=

) ( lim t x

t

Frequency response

Consider t he t ransfer funct ion, ( ) G s . Set t ing s je = t he frequency

response becomes

2

( ) 1

( )

( )

x j

G j

u j

e

e

e e o

= =

+

The frequency response is real and posit ive for all frequencies

t hanks t o t he symmet ric locat ion of t he poles.

This shows t hat one can analyze t he maglev syst em using

frequency response and not st ep response.

Design of cont r oller

Cont roller st ruct ure and cont roller design approach

There are a number of choices of cont roller st ruct ures including,

proport ional int egral derivat ive ( PI D) cont roller, lead- lag

compensat or, and st at e feedback cont roller and number of

approaches for designing a cont roller.

The maglev syst em in t he laborat ory has lead- lag compensat or.

Hence we will choose a lead- lag compensat or. As for t he design

approach we will choose a simple approach based on pole-

placement .

The lead- lag compensat or, C( s) , t akes t he general form

( )

s b

C s k

s a

+ | |

=

|

+

\ .

Closed loop syst em

Since t he plant , G( s) is unst able it must be operat ed in a closed

loop configurat ion formed of t he plant G( s) and t he cont roller, C( s)

as shown in Fig. 4 below.

Fig. 4. Closed loop syst em formed of t he plant G( s) and t he

cont roller, C( s)

The close loop t ransfer funct ion relat ing t he reference input , r and

t he plant out put , x is given by

e u x r

C( s G( s

( ) ( ) ( )

( ) 1 ( ) ( )

x s G s C s

r s G s C s

=

+

Subst it ut ing for G( s) and C( s) t he closed loop numerat or

polynomial, N( s) and denominat or polynomial ( also t ermed

charact erist ic polynomial) , D( s) become

( ) ( ) N s k s b | = +

( )( ) ( )

2

( ) D s s a s k s b o | = + +

Consider t he charact erist ic polynomial, D( s) . Simplifying yields

3 2

( ) ( ) D s s as s k a k b o | o | = + +

Design using pole- placement approach

We will use pole- placement approach t o design t he cont roller, C( s) ,

t hat is obt ain t he cont roller paramet ers, k, a and b.

- Choice of desired pole locat ion

The closed loop syst em is of t hird order. Let us choose for

convenience all poles t o be equal t o p. The desired

charact erist ic polynomial, ( ) s becomes

( )

3

3 2 2 3

( ) 3 3 s s p s s p sp p = + = + + +

- Equat e t he act ual charact erist ic polynomial and t he desired

charact erist ic polynomial

( ) ( ) D s s =

Subst it ut ing for D( s) and ( ) s yields

3 2 3 2 2 3

( ) 3 3 s as s k a k b s s p sp p o | o | + + = + + +

- Solve for t he unknown cont roller paramet ers, k, a, and b by

equat ing t he coefficient s of t he equal powers of s

2

3

3

3

a p

k p

a k b p

o |

o |

=

+ =

=

Solving t he above equat ions yields

3

2

2

3

3

3

a p

p p

b

p

p

k

o

o

o

|

=

+

=

+

+

=

Del i ver abl es

Each st udent should submit a word file cont aining t he following:

- The mat hemat ical model of maglev syst em

- Analysis of t he linear approximat ion model of t he Maglev

syst em in t ime and frequency domain using SI MULI NK.

- Design of a lead- lag compensat or

- Evaluat ion of t he performance

CI SE 412: MECHATRONI CS

( Term 092)

Lab # 5:

Desi gn and I mpl ement at i on of Oper at i onal

Ampl i f i er Ci r cui t s

Equi pment Needed

+ Oper at i onal Ampl i f i er s ( LM 741, LM 311, or equi v al ent )

+ Resi st or s ( 500 O, 1k O, 1M O, )

+ Var i abl e Resi st or

+ Capaci t or s ( 22 pF, 33 pF, )

+ Mul t i - met er

+ Osci l l oscope

+ Si gnal Gener at or

+ Pow er Suppl y

I nt r oduct i on:

Operat ional Amplifiers ar e import ant devices t hat can be used for

signal condit ioning and int erfacing sensor s and act uat ors. I n t his lab,

you will pract ice using t he op- amp in different ways. LM 741 in a

classical oper at ional amplifier t hat is widely used. I t comes in DI P or

met allic package. The one used in t his lab is an 8- Pin DI P package.

Pr el ab Act i v i t y 0:

Dow n l oad t he Op- Amp dat a sheet s f r om t he

manuf act ur e' s w eb si t e.

I dent i f y t he mai n char act er i st i cs of t he LM 741.

St ep 1:

Par t 1: How t o connect t he LM

741

I f you have not already done so, wire t he bus st rips on

your breadboard t o provide posit ive power, negat ive

power and ground buses. What ever color scheme you

have chosen for your wires, you should use t he green

binding post for ground, t he black for - 15 V, and t he red

for + 15 V.

St ep 2:

Connect a 0. 1F capacit or bet ween t he + 15 V power bus

and ground. Connect anot her 0. 1F capacit or bet ween

t he - 15 V power bus and ground. The power buses for

your board should look like t his:

These capacitors are the first of several bits of "magic" we will employ

to try to avoid amomolous behavior. As we will see when we study

control systems, feedback also has a dark side. In particular, feedback

which becomes positive at some frequency can cause instabilities.

Although we have not deliberately introduced any positive feedback,

feedback can occur where we don't intend it. The purpose of these

capacitors is to prevent it from occurring via the power supply, which at

high frequencies is not a very ideal voltage source.

St ep 3:

Plug an op- amp int o t he breadboard so t hat it st raddles

t he gap bet ween t he t op and bot t om sect ions of t he

socket st rip. I f you have wired t he power buses as

suggest ed above, Pin 1 should be t o t he left .

War ni ng

Do not t ry t o unplug t he op- amp wit h your

t humb and forefinger. Use I C puller.

St ep 4:

Connect Pin 4 ( Vcc- ) t o t he negat ive power supply bus ( -

15 V) . Connect Pin 7 ( Vcc+ ) t o t he posit ive power supply

bus ( + 15 V) .

St ep 5:

Set t he METER SELECTOR on t he power supply t o +20V. Wit h

t he power supply disconnect ed from t he breadboard,

t urn on t he supply and adj ust t he left - hand volt age

cont rol unt il t he met er reads 15 volt s.

St ep 6:

Turn off t he supply and connect t he supply t o t he

breadboard wit h banana plug pat ch cables. Connect t he 0

to -20V t erminal ( black) t o t he black binding post on your

breadboard, t he 0 to +20V t erminal ( red) t o t he red

breadboard binding post , and t he COMMON t erminal ( light

blue) t o t he green breadboard binding post . Not e t hat

none of t he power supply out put t erminals are connect ed

t o ground. I f we want t he power supply zero volt

reference connect ed t o ground, we must make t he

connect ion ourselves.

Par t 2: Non- i nv er t i ng Ampl i f i er

Pr e- l ab Act i v i t y 2 :

Design a non- invert ing Amplifier circuit . The closed loop gain of t he

amplifier is required t o be 2.

Lab Act i v i t y 2:

1. Select t he resist ors needed t o implement t he designed non-

invert ing amplifier.

2. Connect t he circuit

3. Use t he signal generat or t o provide t he input t o t he amplifier.

Use sine wave wit h Peak t o peak value of 2Volt s. Use

Frequencies of 1 Hz, 100 Hz and 1000Hz.

4. Use t he oscillat or t o display t he out put of t he amplifier

Observat ions and Comment s:

Part 3: I nvert ing Amplifier

Pr e- l ab Act i v i t y 3 :

Design an I nvert ing Amplifier circuit . The closed loop gain of t he

amplifier is required t o be 2.

Lab Act i v i t y 3:

5. Select t he resist ors needed t o implement t he designed

invert ing amplifier.

6. Connect t he circuit

7. Use t he signal generat or t o provide t he input t o t he amplifier.

Use sine wave wit h Peak t o peak value of 2Volt s. Use

Frequencies of 1 Hz, 100 Hz and 1000Hz

8. Use t he oscillat or t o display t he out put of t he amplifier

Observat ions and Comment s:

St ep 1:

Par t 3: The Op Amp as a Compar at or

Wit h t he power t urned off, wire t he following circuit . This

will compare t he funct ion generat or out put wit h an

adj ust able t hreshold proficed by t he 0- 6V supply.

St ep 2:

Set t he funct ion generat or t o produce a 4 V p- p, 100 Hz

t riangle wave.

St ep 3:

Pull out t he DC OFFSET cont rol and adj ust it so t hat t he

waveform has an average value of 2. 5 V ( i. e. t he

negat ive peaks have a value of + 0. 5 V) .

St ep 4:

Connect t he funct ion generat or out put t o Vi n of t he

circuit above. Connect CH1 of t he scope t o Vi n and CH2 t o

Vout . Set t he CH2 VOLTS/DIV t o 5. Make sure bot h

channels of t he scope are on DC.

St ep 5:

Turn on t he power supply and set t he 0-6V out put t o

zero.

St ep 6:

Slowly increase t he 0-6V cont rol unt il Vout begins t o

change. Sket ch t he waveform.

St ep 7:

I ncrease V

2

in st eps of 0. 4 V unt il Vout st ops changing.

At each st ep sket ch Vout , not ing t he posit ive and

negat ive peak values and t he durat ion of t he high and

low st at es.

St ep 8:

Set V

2

t o zero and push t he DC OFFSET cont rol back in.

Vout should be approximat ely a square wave. I s t his

what you expect ?

Quest ion

Explain t he waveforms observed in t his Part . Develop an

expression for t he dut y cycle ( t he percent age of t he t ime

t hat t he waveform is in t he "high" st at e) as a funct ion of

1:

V

2

.

Balancing the Input Offset

I nt roduct ion

In the previous experiment (The Basic Op Amp Inverter), we learned that there are at

least three basic limitations on the accuracy of an op amp circuit: the tolerance of the

resistors, input offset voltage and current, and output saturation. We can't do anything

about output saturation, and we can only deal with resistor tolerances by selecting

resistors of the degree of precision required for a specific application. However, in

those cases where it is necessary, we can make use of a feature of the basic 741 op

amp to balance out the input offsets and thus remove their influence on the output

voltage.

Fortunately, in most applications this is not necessary. This permits the construction

of dual- and quad-op amp packages, where the offset adjustment connections are not

available outside the package. However, there are some cases where the input offset

must be balanced as closely as possible. Therefore, we will examine the required

method in this experiment.

Schemat ic Diagram

The recommended circuit for balancing out the input offset is quite simple, as shown

here. The offset null pins (1 and 5) give direct access to the 1K emitter resistors in the

input stage, and the offset null circuit is simply a 10K potentiometer connected

between them, with its slider connected to the negative power supply. This is

equivalent to putting a 5K resistance in parallel with each of the 1K resistors inside

the IC. The difference is that we can vary the external resistances by adjusting the

potentiometer, until the voltage offset becomes zero.

Since we're dealing with the input stage of a high-gain amplifier, the output voltage

will be very sensitive to potentiometer changes. Therefore, we'll use a 15-turn trimpot

here.

So how do we tell when we have exactly balanced out the offset? After all, the input

offset is internal to the IC, and is rated to be no more than 6.0 millivolts (0.006 V) and

0.2 milliamps (0.0002 A). These require very accurate and sensitive measuring

equipment, and are inaccessible in any case.

What we can do is select R

in

and R

f

to amplify an input voltage of zero. We'll make

R

in

= 1K and R

f

= 100K, and connect the input end of R

in

to ground. This will give the

overall circuit a gain of 100, and assure us that the correct output voltage should

nevertheless be 0.000 volt. Any output voltage will be due to offsets in the op amp

itself, and we will use the 10K trimpot to balance them out as closely as possible.

Part s List

To construct and test the offset balancing circuit on your breadboard, you will need

the following experimental parts:

- ( 2) 1K, 1% resist ors ( brown- black- black- brown) .

- ( 1) 100K, 1% resist or ( brown- black- black- orange) .

- ( 1) 10K t rimmer pot ent iomet er.

Performing t he Experiment

Turn on your voltmeter and set it to measure voltages in the range of 20 volts, and

connect it to monitor the output voltage of the 741 op amp at pin 6 (the top end of the

100K resistor). Turn on power to your experimental circuit, and note the output

voltage of this circuit. If the trimpot is still at one end of its range from the last

experiment, the output voltage may well be quite high. This is not a problem; simply

note it for now.

Adjust the trimpot over its range and note the effect on the output voltage. Then,

readjust the trimpot to reduce the output voltage to below 1.00 volt.

Reduce the range on your voltmeter to measure voltages up to 2 volts, and then

continue to adjust the trimpot to reduce the output voltage to zero.

If your voltmeter has a 200 mV range, switch down to that and use the trimpot to

adjust the output voltage to as close to zero as you can. By now the adjustment will be

very sensitive to slight changes, so you may have difficulty balancing out the last

millivolt. If so, don't worry about it; just do the best you can.

When you have reduced the output voltage as closely as possible to zero, leave the

trimpot alone and simply observe the output voltage for a few minutes. What does this

observation show you?

Finally, remove the trimpot from the breadboard socket and set it aside. What is the

output voltage now? Keeping in mind the op amp gain of 100, what was the effective

initial input offset voltage?

When you have made your determinations, turn off the power to your experimental

circuit and voltmeter and compare your results with the discussion below.

Discussion

1. Why balancing is needed?

2. How can we balance t he LM 741 op- amp?

Part 5: Design and implement a summing amplifier.

The required equation is

) 2 (

2 1

V V Vout + =

The inputs are two constant voltages

+ Draw the circuit diagram

+ Connect the circuit

+ Turn on the power supply

+ Check the result and comment on it.

Part 6: Design and implement a low pass first order active

filter. The required equation is

The input is a sign wave with frequencies 10Hz, 100Hz and 10000Hz.

+ Draw the circuit diagram

+ Connect the circuit

+ Turn on the power supply

+ Check the result and comment on it.

+

When you have completed this experiment, make sure power to your experimental

circuit and voltmeter is turned off. Remove all of your experimental components from

the breadboard socket and put them aside for use in later experiments.

Tur n t he pow er suppl y of f dur i ng t he

connect i on of t he ci r cui t

Lab # 6: I nt r oduct i on t o Boe- Bot

Obj ect ives:

Get t ing and inst alling t he BASI C STAMP Edit or

Set t ing up hardware and t est ing t he syst em

Writ ing t he first program for t he Boe- Bot

Lab act ivit ies:

I n t his lab session, st udent s are expect ed t o do t he following six

act ivit ies. Det ails of t he act ivit ies are available in Chapt er 1 of t he

Boe- Bot manual

1. Get t i ng t he sof t w ar e: The inst ruct or will provide t he CD t o

be used in inst alling t he BASI C STAMP Edit or. You can follow

t he st eps in pages 4- 8 t o download most recent version of

t he soft ware.

2. Sof t w ar e I nst al l at i on: t o inst all t he BASI C STAMP Edit or,

you need t o follow t he procedure in pages 10- 12.

3. Set t i ng up Har dw ar e and Test i ng t he Sy st em: Follow

t he det ails given in page 13- 20.

4. Wr i t i ng t he Fi r st Pr ogr am: Follow t he det ails given in

page 22- 36.

5. Pr oj ect s: Each st udent group must do Proj ect s 1 and 2.

The inst ruct or need t o check t hat all act ivit ies are done correct ly.

Del i ver abl es:

Lab report summarizing what was done in t he lab.

Short descript ion and program list ings for Proj ect s 1 and 2.

Lab # 7: Ser vomot or s f or t he Boe- Bot

Obj ect ives:

Connect , adj ust and t est ing t he servomot ors

Lab act ivit ies:

I n t his lab session, st udent s are expect ed t o do t he following six

act ivit ies. Det ails of t he act ivit ies are available in Chapt er 2 of t he

Boe- Bot manual

1. Ti me Tr ack i ng and Repeat Act i ons: To pract ice soft ware

inst ruct ions for t ime t racking and t imed loops.

2. Test i ng LEDs: Pract ice inst ruct ions of t he microcont roller t o

send out put s. Do t he st eps in page 48 t o connect t he LEDs

and writ e a program t o t urn t he LEDs ON and OFF.

3. Usi ng Pul seout and Pause Follow t he det ails given in

page 52- 58 t o generat e specific t iming diagrams.

4. Connect i ng Ser vomot or s: Follow t he det ails given in page

58- 66.

5. Cent er i ng t he Ser vos: Follow t he det ails given in page 66-

70.

6. Test i ng t he Ser vos:

7. Pr oj ect s: Each st udent group must do Proj ect s 1 and 2

given in page 87

The inst ruct or need t o check t hat all act ivit ies are done correct ly.

Del i ver abl es:

Lab report summarizing what was done in t he lab.

Short descript ion and program list ings for Proj ect s 1 and 2.

Lab # 8: Assembl i ng and Test i ng t he Boe- Bot

Obj ect ives:

Build t he Boe- Bot

Test t he servomot ors

Connect t he speaker and t est it

Use Debug t o cont rol and t est t he servo speed

Lab act ivit ies:

I n t his lab session, st udent s are expect ed t o do t he following six

act ivit ies. Det ails of t he act ivit ies are available in Chapt er 2 of t he

Boe- Bot manual

1. Assembl i ng t he Boe- Bot : Follow t he st eps in 91- 100 t o

assemble t he Boe- Bot .

2. Re- Test i ng t he Ser vos: t o t est t he servos, Follow t he st eps

in 101- 105.

3. St ar t / Rest I ndi cat or and pr ogr am

4. Test i ng Speed Cont r ol

5. Pr oj ect s: Each st udent group must do Proj ect s 1 and 2

given in page 119.

The inst ruct or need t o check t hat all act ivit ies are done correct ly.

Del i ver abl es:

Lab report summarizing what was done in t he lab.

Short descript ion and program list ings for Proj ect s 1 and 2.

Lab # 9: Basi c Boe- Bot Navi gat i on

Obj ect ives:

Program t he Boe- Bot t o do t he basic maneuvers: Move forward,

backward, rot at e left , rot at e right , pivot t urn

Calculat e required t ime t o move Boe- bot precise dist ances.

Program Boe- Bot t o accelerat e and decelerat e

Lab act ivit ies:

I n t his lab session, st udent s are expect ed t o do t he following seven

act ivit ies. Det ails of t he act ivit ies are available in Chapt er 4 of t he

Boe- Bot manual

1. Basi c Boe- Bot Maneuv er s

2. Tuni ng t he basi c maneuver s

3. Cal cul at i ng di st ances

4. Rampi ng maneuv er s

5. Subr out i nes f or maneuv er s

6. Bui l di ng compl ex maneuver s i n t he EEPROMS

7. Pr oj ect s: Each st udent group must do Proj ect s 1 and 2

given in page 159.

The inst ruct or need t o check t hat all act ivit ies are done correct ly.

Del i ver abl es:

Lab report summarizing what was done in t he lab.

Short descript ion and program list ings for Proj ect s 1 and 2.

Lab # 10: Boe- Bot Navi gat i on w i t h Whi sk er s

Obj ect ives:

Build Tact ile swit ches using whiskers

Program Boe- Bot t o use t he t act ile swit ches in navigat ion

Lab act ivit ies:

I n t his lab session, st udent s are expect ed t o do t he following seven

act ivit ies. Det ails of t he act ivit ies are available in Chapt er 5 of t he

Boe- Bot manual

1. Bui l di ng and Test i ng t he Whi sk er s

2. Test i ng t he Whi sk er s

3. Navi gat i on w i t h Whi sk er s

4. Pr oj ect s: Each st udent group must do Proj ect s 1 and 2

given in page 189.

The inst ruct or need t o check t hat all act ivit ies are done correct ly.

Del i ver abl es:

Lab report summarizing what was done in t he lab.

Short descript ion and program list ings for Proj ect s 1 and 2.

Lab # 11: Boe- Bot Navi gat i on w i t h

Phot or esi st or s

Obj ect ives:

Build and t est phot oresist or circuit

Program Boe- Bot t o use t he phot oresist or in navigat ion

Lab act ivit ies:

I n t his lab session, st udent s are expect ed t o do t he following seven

act ivit ies. Det ails of t he act ivit ies are available in Chapt er 6 of t he

Boe- Bot manual

5. Bui l di ng and Test i ng phot or esi st or ci r cui t

6. Avoi di ng Shadow s

7. Navi gat i on w i t h phot or esi st or

8. Roami ng t ow ar d t he l i ght

9. Pr oj ect s: Each st udent group must do Proj ect 1 given in

page 228.

The inst ruct or need t o check t hat all act ivit ies are done correct ly.

Del i ver abl es:

Lab report summarizing what was done in t he lab.

Short descript ion and program list ings for Proj ect 1.

You might also like

- Mechanics of Materials An Integrated Learning System 4th Edition Philpot Solutions ManualDocument26 pagesMechanics of Materials An Integrated Learning System 4th Edition Philpot Solutions ManualMarkManntjaid95% (20)

- Movement of The EarthDocument21 pagesMovement of The EarthAqilah Taufik100% (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Boundary Wall DesignDocument26 pagesBoundary Wall DesignAtanu Bhattacharya50% (2)

- Microprocessor Lab Experiments - Arrays, Waves, Sensors EC4Document51 pagesMicroprocessor Lab Experiments - Arrays, Waves, Sensors EC4adityaNo ratings yet

- Rogowski Coil Transient Performance and Atp Simulation For Aplications in Protective RelaysDocument6 pagesRogowski Coil Transient Performance and Atp Simulation For Aplications in Protective RelaysJose Alberto RodriguezNo ratings yet

- 1230 PDFDocument46 pages1230 PDFRishabh SharmaNo ratings yet

- Emma Non-Scaling FfagDocument3 pagesEmma Non-Scaling Ffagndiep2No ratings yet

- An On-Line Monitoring System For A Micro Electrical Discharge Machining (micro-EDM) ProcessDocument9 pagesAn On-Line Monitoring System For A Micro Electrical Discharge Machining (micro-EDM) ProcessAnang KatyayanNo ratings yet

- El - Tr-343 Industrial Electronics: 1.1 Understand The Industrial Applications of Switching, Photo Devices and TimersDocument11 pagesEl - Tr-343 Industrial Electronics: 1.1 Understand The Industrial Applications of Switching, Photo Devices and TimersAdeelHashmiNo ratings yet

- EMA Lab1 Note - EM Energy ConversionDocument9 pagesEMA Lab1 Note - EM Energy ConversionArvin Glenn Pagala0% (1)

- Sixth Semester Syllabus: Electrical Machine DesignDocument5 pagesSixth Semester Syllabus: Electrical Machine DesignShamik BhowmikNo ratings yet

- Contact Less Excitation SystemDocument5 pagesContact Less Excitation SystemSalih Ahmed ObeidNo ratings yet

- BT21EE013.Assignment 1Document8 pagesBT21EE013.Assignment 1BT21EE013 PratimaNo ratings yet

- Physics of The Ignition System PDFDocument10 pagesPhysics of The Ignition System PDFmeetbalakumar100% (1)

- Electromagnetic Force WeavingDocument4 pagesElectromagnetic Force WeavingYogesh BalarNo ratings yet

- UploDocument116 pagesUplobashasvuceNo ratings yet

- Lab8 EEDocument4 pagesLab8 EEhaha2012No ratings yet

- Automatic Solar Tracking SystemDocument82 pagesAutomatic Solar Tracking SystemDebashishParidaNo ratings yet

- DCMT - Amin ManualDocument56 pagesDCMT - Amin ManualAmin KharadiNo ratings yet

- An Overview of Spin-Based Integrated CircuitsDocument8 pagesAn Overview of Spin-Based Integrated CircuitsLuis RodriguezNo ratings yet

- A Versatile Window Function Fro Linear Ion Drift Model-A New ApproachDocument10 pagesA Versatile Window Function Fro Linear Ion Drift Model-A New ApproachAmmuNo ratings yet

- AKU Patna Syllabus 3rd YearDocument20 pagesAKU Patna Syllabus 3rd Yearडाँ सूर्यदेव चौधरीNo ratings yet

- Eee312 Eee282 Lab7 Spring2015Document6 pagesEee312 Eee282 Lab7 Spring2015vognarNo ratings yet

- Control System Lab ManualDocument76 pagesControl System Lab ManualYuvaraj Shan50% (2)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- On-Line MCSA To Diagnose Shorted Turns in Low Voltage Stator Windings of 3-Phase Induction Motors Prior To FailureDocument8 pagesOn-Line MCSA To Diagnose Shorted Turns in Low Voltage Stator Windings of 3-Phase Induction Motors Prior To FailureJairo CorimanyaNo ratings yet

- PrabhakaranDocument14 pagesPrabhakaranjananikaran35No ratings yet

- MachineDocument74 pagesMachineTarak BENSLIMANENo ratings yet

- Fault and Abnormal 1Document71 pagesFault and Abnormal 1Mahesh PushpakumaraNo ratings yet

- Static Induction TransistorDocument7 pagesStatic Induction TransistorEnrique Gamez Cardenas50% (2)

- Oscilloscope Experiment FundamentalsDocument5 pagesOscilloscope Experiment FundamentalsMuhammad ZikryNo ratings yet

- Eee-Viii-modern Power System Protection (06ee831) - NotesDocument90 pagesEee-Viii-modern Power System Protection (06ee831) - NotesDilip TheLipNo ratings yet

- Control System Lab ManualDocument56 pagesControl System Lab ManualSrinivas Kondal Rao100% (3)

- Detection of Solder Bump Defects On A Ip Chip Using Vibration AnalysisDocument9 pagesDetection of Solder Bump Defects On A Ip Chip Using Vibration AnalysisArchana MohananNo ratings yet

- Spin Valve TransistorDocument22 pagesSpin Valve TransistorYogesh RmNo ratings yet

- Chapter 8Document9 pagesChapter 8cheraziziNo ratings yet

- Pulse & Digital Circuits Lab Manual 3Document61 pagesPulse & Digital Circuits Lab Manual 3Suda KrishnarjunaraoNo ratings yet

- Pulse & Digital Circuits Lab Manual PDFDocument61 pagesPulse & Digital Circuits Lab Manual PDFKarunakar Reddy MNo ratings yet

- Magnetic Components Design and ApplicationsDocument354 pagesMagnetic Components Design and Applicationseugene50% (2)

- 0324AT Hyu PCGDocument55 pages0324AT Hyu PCGLiz BenhamouNo ratings yet

- PROJEKAT ACC04 - Maglev PDFDocument6 pagesPROJEKAT ACC04 - Maglev PDFRandall MillerNo ratings yet

- Actuator Design For Firefighting DroneDocument19 pagesActuator Design For Firefighting DronePrashant SharmaNo ratings yet

- Final Project HDocument33 pagesFinal Project HBenard OchangoNo ratings yet

- 3 Phase Induction MotorDocument48 pages3 Phase Induction Motormsd183wkNo ratings yet

- MRI Physics Course: RAD433 & RAD353 Presented byDocument47 pagesMRI Physics Course: RAD433 & RAD353 Presented byobai AlhwimelNo ratings yet

- Corrugated Waveguide Slow Wave StructureDocument4 pagesCorrugated Waveguide Slow Wave StructureVladimir ShkolnikovNo ratings yet

- A Rotor Condition Monitor For Squirrel CDocument7 pagesA Rotor Condition Monitor For Squirrel CLuiz ArantesNo ratings yet

- Experiment 11Document8 pagesExperiment 11Mihai BogdanNo ratings yet

- Thesis On Switched Reluctance MotorDocument4 pagesThesis On Switched Reluctance Motorbsqxd5g1100% (2)

- Document - Memristor (2010)Document4 pagesDocument - Memristor (2010)Nicolas TorresNo ratings yet

- Ships' Electrical Systems Safety and MaintenanceDocument14 pagesShips' Electrical Systems Safety and MaintenanceBacamarte100% (3)

- Memristor: From Basics To Deployment: Saraju - Mohanty@unt - EduDocument12 pagesMemristor: From Basics To Deployment: Saraju - Mohanty@unt - Edusunilkmch505682No ratings yet

- Of Mameto Motive: Transactions On Energy Conversion, Vol. 7, No. A Se1Document8 pagesOf Mameto Motive: Transactions On Energy Conversion, Vol. 7, No. A Se1Surajit SahaNo ratings yet

- Testing Requirements For Microprocessor RelaysDocument36 pagesTesting Requirements For Microprocessor Relayssaka018891No ratings yet

- Transactions Apparatus and Vol. December A Dynamic State Space Model of Mho Distance RelavDocument7 pagesTransactions Apparatus and Vol. December A Dynamic State Space Model of Mho Distance RelavthavaselvanNo ratings yet

- Design and Implementation of RC OscillatorsDocument11 pagesDesign and Implementation of RC OscillatorsAhmer FarooqNo ratings yet

- Understanding the Yalong YL-335A Automatic Production TrainerDocument15 pagesUnderstanding the Yalong YL-335A Automatic Production TrainerMahtab GhummanNo ratings yet

- UploDocument115 pagesUplobashasvuceNo ratings yet

- FluxDocument6 pagesFluxDobai SzilardNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- 110 Semiconductor Projects for the Home ConstructorFrom Everand110 Semiconductor Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- StepperDocument11 pagesStepperkarthisanNo ratings yet

- Syllabus R2013 PDFDocument105 pagesSyllabus R2013 PDFlogeshboy007No ratings yet

- Unit-2 & 3Document34 pagesUnit-2 & 3karthisanNo ratings yet

- ANNA UNIVERSITY Dts Two MarkDocument7 pagesANNA UNIVERSITY Dts Two MarkkarthisanNo ratings yet

- Dynamics 2011Document2 pagesDynamics 2011karthisanNo ratings yet

- ANNA UNIVERSITY Dts Two MarkDocument7 pagesANNA UNIVERSITY Dts Two MarkkarthisanNo ratings yet

- UNIT-I (Constitution of Alloys and Phase Diagrams) Part-ADocument7 pagesUNIT-I (Constitution of Alloys and Phase Diagrams) Part-AkarthisanNo ratings yet

- KCE Mechanical Engineering Question BankDocument11 pagesKCE Mechanical Engineering Question BankkarthisanNo ratings yet

- Self Assessment Report NBADocument37 pagesSelf Assessment Report NBAkarthisanNo ratings yet

- P355NL2 50mmDocument5 pagesP355NL2 50mmslowmosquitoNo ratings yet

- Anterior Segment OctDocument53 pagesAnterior Segment OctA.c. RaghuNo ratings yet

- Aits 2223 FT Vi Jeem OfflineDocument15 pagesAits 2223 FT Vi Jeem OfflineSuvrajyoti TaraphdarNo ratings yet

- Physics Notes On Elementary ParticlesDocument0 pagesPhysics Notes On Elementary Particleswww.bhawesh.com.npNo ratings yet

- Forensic Engineering of Fire-Damaged StructuresDocument6 pagesForensic Engineering of Fire-Damaged StructuresMartinNo ratings yet

- Bulk and Suspenshion Polynerization of MMA Into PMMADocument5 pagesBulk and Suspenshion Polynerization of MMA Into PMMADavid Meza CarbajalNo ratings yet

- GE6251 Basic Civil and Mechanical Engineering Regulation 2013 Lecture NotesDocument112 pagesGE6251 Basic Civil and Mechanical Engineering Regulation 2013 Lecture NotesSasi Dharan100% (1)

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document15 pagesLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110tttmm100% (1)

- Liebherr Hs DimensionsDocument12 pagesLiebherr Hs DimensionsLiebherrNo ratings yet

- Astm 1500 2012Document5 pagesAstm 1500 2012Hugo MtzaNo ratings yet

- Handbook of Magnetic PDFDocument572 pagesHandbook of Magnetic PDFQassem MohaidatNo ratings yet

- IR sensor operation theory explainedDocument4 pagesIR sensor operation theory explainedSebastin Ashok100% (1)

- Structural Design For ArchitectureDocument274 pagesStructural Design For Architecturedamocca100% (13)

- 1D Advection-Diffusion MATLAB Code SolutionsDocument6 pages1D Advection-Diffusion MATLAB Code SolutionsAnonymous OrhjVLXO5sNo ratings yet

- Lm331 AppnoteDocument8 pagesLm331 AppnoteEward KenNo ratings yet

- AA Holtz & Kovacs - An Introduction To Geotechnical EngineeringDocument23 pagesAA Holtz & Kovacs - An Introduction To Geotechnical EngineeringfaizanNo ratings yet

- BSC Physics Iind SemDocument4 pagesBSC Physics Iind SemDavid JonesNo ratings yet

- Upem Ch-22Document9 pagesUpem Ch-22siddharthsrathor04No ratings yet

- Dokumen - Tips - Cotter Joint PPTX 58f9ab8d3dbc9Document19 pagesDokumen - Tips - Cotter Joint PPTX 58f9ab8d3dbc9Good YagNo ratings yet

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Document1 pageHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyNo ratings yet

- Sales Bulletin American Meter 4510Document12 pagesSales Bulletin American Meter 4510rieza_fNo ratings yet

- Lucas TuningDocument12 pagesLucas TuningMichael RohrNo ratings yet

- 0053 Dynamics of Commodity Forward CurvesDocument25 pages0053 Dynamics of Commodity Forward Curvesamitnp7373No ratings yet

- Photography March 2016Document32 pagesPhotography March 2016ArtdataNo ratings yet

- Experiment 1 Solubility of Organic CompoundsDocument2 pagesExperiment 1 Solubility of Organic CompoundsJamica AmbionNo ratings yet

- The Philosophy of David Hume According to HumeDocument7 pagesThe Philosophy of David Hume According to HumePaul Kallan100% (1)

- Ajmer Vidyut Vitran Nigam LTDDocument1 pageAjmer Vidyut Vitran Nigam LTDKishan MeghwalNo ratings yet