Professional Documents

Culture Documents

SCADA Architecture For Natural Gas Plant

Uploaded by

Wajid Khattak0 ratings0% found this document useful (0 votes)

86 views6 pagesThe main purpose of SCADA system is remote monitoring ana controlling of any inaustrial plant. The SCADA haraware architecture is basea on multi-aropping system allowing connecting a large number of aifferent fiela aevices. The main benefit of using SCADA is real time aisplaying of gas plant state.

Original Description:

Original Title

SCADA Architecture for Natural Gas Plant

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe main purpose of SCADA system is remote monitoring ana controlling of any inaustrial plant. The SCADA haraware architecture is basea on multi-aropping system allowing connecting a large number of aifferent fiela aevices. The main benefit of using SCADA is real time aisplaying of gas plant state.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

86 views6 pagesSCADA Architecture For Natural Gas Plant

Uploaded by

Wajid KhattakThe main purpose of SCADA system is remote monitoring ana controlling of any inaustrial plant. The SCADA haraware architecture is basea on multi-aropping system allowing connecting a large number of aifferent fiela aevices. The main benefit of using SCADA is real time aisplaying of gas plant state.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Scientific Bulletin of the Petru Maior University of Tirgu Mures

Vol. 6 (XXIII), 2009

ISSN 1841-9267

Keywords: natural gas plant, SCADA, HMI-User interface

SCADA Architecture for Natural Gas Plant

Traian Turc

'Petru Maior` University of Targu Mures

traian.turcengineering.upm.ro

Horatiu GriI

'Petru Maior` University of Targu Mures

hgrifengineering.upm.ro

Abstract

The paper aescribes the Natural Gas Plant SCADA

architecture. The main purpose of SCADA system is

remote monitoring ana controlling of any inaustrial

plant. The SCADA haraware architecture is basea on

multi-aropping system allowing connecting a large

number of aifferent fiela aevices. The SCADA Server

gathers aata from gas plant ana stores aata to a

MySQL aatabase. The SCADA server is connectea to

other SCADA clients through Ethernet-LAN. The

SCADA client application offers an intuitive ana user-

frienaly HMI. The main benefit of using SCADA is real

time aisplaying of gas plant state. The main

contribution of the author consists in aesigning

SCADA architecture basea on multi-aropping system

ana Human Machine Interface.

1. Introduction

SCADA is an acronym that stands Ior Supervisory

Control and Data Acquisition. It reIers to a system that

collects data Irom various sensors at a Iactory, plant or

in other remote locations and then sends it to a central

computer, which manages and controls the data.

A SCADA system includes signal hardware (input

and output), controllers, networks, user interIace

(HMI), communications equipment and soItware.

The SCADA provides real-time control and

optimizes exploitation management systems.

Figure 1 shows typical hardware architecture.

Figure 1. Typical SCADA hardware

architecture

2. RTU (Remote Terminal Unit)

The RTU is installed at a remote location and

collects data Irom PLCs, acting as data concentrator.

Figure 2. Typical SCADA hardware

architecture, using RTU

79

The SCADA Server request data Irom the RTU,

which codes the data into a Iormat that is transmittable

and then the RTU, transmits data to SCADA Server.

The RTU also collects inIormation Irom the

SCADA Server and implements processes that are

directed by the SCADA Server.

The RTU is also equipped with input channels Ior

sensing or metering, output channels Ior control,

indication or alarms and a communications port.

3. Connecting multiple RTU

In order to connect multiple RTU or other

instruments to the SCADA Server trough serial port, a

new BUS is needed. A RS 485 serial line allows

multiple devices connection.

The SCADA Server has only RS-232 interIace, so a

serial data converter RS-232/RS-485 is required.

Figure 3 shows a typical hardware architecture using

multiple RTU.

Figure 3. Typical SCADA hardware

architecture, using multiple RTU

4. Redundancy

For increasing the integrity oI the system, multiple

servers are occasionally conIigured in hot-standby or

dual-redundant Iormation, providing monitoring and

continuous control during server Iailure. For increasing

integrity oI Iield bus, dual RTU in master slave

conIiguration and redundant Iield bus is used.

II the plant processes are critical, or the downtime

costs are high, redundancy must be incorporated into

the system to eliminate Iailures caused by equipment

Iailure.

Figure 4 shows a typical hardware architecture

using dual redundant server and dual RTU in master

slave conIiguration.

Figure 4. Typical SCADA hardware

architecture, using dual RTU in master slave

configuration

5. Multi dropping

In many cases, the RTU and other instruments are

RS-232 interIace equipped. In this case, each oI them

has to be connected through RS-232/RS-484 serial data

converter in order to connect all devices in the same

bus.

Finally, even the SCADA Server has to be

connected through serial data converter R-

S484/RS-232.

80

Instead oI using many serial data converters, using

a multi-dropping system is a better solution.

Figure 5. Multi-dropping system

The multi-dropping system allows more than one

devices to share a RS-232 common serial (see Figure

5).

Figure 6 shows a multi-dropping system, based on

the IC-232 serial interIace circuit.

In a multi droppings system, all devices are slaves

and can communicate through a serial line only when

the master requests (SCADA Server). All devices can

read the serial line but only the called device can

answer. The SCADA Server scans all subsystems and

collects data using MODBUS RTU protocol. Every

data request includes the address oI the slave. The

slave 'Ieels its own address and answers to the master

request. Every subsystem has its own address.

The multi-dropping system allows more than one

instrument Irom diIIerent manuIacturers to share a

RS-232 common serial.

This approach allows a mixed assortment oI

instrumentation to share a common serial line.

Figure 6. Multi-dropping system, based on IC-232

81

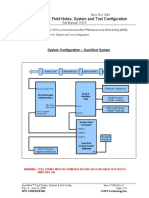

6. SCADA hardware architecture for

Natural gas Industry

In the Iollowing sections a SCADA scalar

architecture used in Natural Gas Industry is described.

Scalability architecture allows the resizing oI

SCADA architecture, without having to modiIy all the

existing hardware or soItware systems. The Scalar

architecture oI SCADA allows the architecture to grow

with new requirements while still preserving the initial

investment.

Figure 7 shows the hardware architecture Ior gas

plant.

Figure 7. Gas plant SCADA hardware architecture

The SCADA servers communicate with devices in

the Iield through the RS-232 serial line. The RTU

(Remote Terminal Unit) and the Base Radio are

connected to RS-485 in multi drop system.

The RTU is installed at a remote location and

collects data Irom actuators, acting as data

concentrator.

On the SCADA server request, the RTU codes the

data into transmittable Iormat and sends data to the

SCADA Server. The RTU also collects inIormation

Irom the SCADA server and implements processes

that are directed by the SCADA Server. RTU is

equipped with input channels Ior sensing or metering,

output channels Ior control, indication or alarms and a

communications port.

The main purpose oI RTU is to interconnect Iield

devices (actuators) with the SCADA server through a

MODBUS RTU interIace card.

RTU transIers all the inIormation Irom the Iield to

the higher level oI the control system (SCADA

sever). This Iunction gives total control oI the plant.

82

Data are transmitted through RS-485serial line

using MODBUS RTU communication protocol.

Data transIerred are relevant to the variables

transmitted with each actuator and to the actuator

physical sequence on MODBUS map.

The RTU is also capable oI executing simple

programs autonomously without involving the

SCADA server to simpliIy deployment, and to

provide redundancy Ior saIety reasons.

The Base Radio collects data Irom wireless

pressure sensors and transmits the data to the SCADA

Server.

An RS-232/RS-485 serial data converter is used to

connect SCADA server to a R-S485 serial line.

The SCADA servers are connected to the SCADA

clients and WEB server stations via an Ethernet LAN.

6. Software user interface-HMI

The HMI (Human Machine InterIace) presents the

processed data to a human operator, and through this

the human operator monitors and controls the

process.

The HMI is a graphical user interIace that

includes controls where the operators can interIace

with the SCADA system.

Figure 8. HMI-User interface and process mimics

By providing inIormation alerts, commands and

other tools, an HMI connects the user with the

process being controlled.

The SCADA clients permanently beneIit the

actualized scheme oI the gas plants.

7. Conclusion and future work

The paper signiIicantly contributes to computer

assisted controlling and monitoring oI the gas plant.

Using a scalar architecture, the resizing oI

SCADA architecture can be done without having to

modiIy all the existing hardware or soItware systems.

Adding new requirements while still preserving

the initial investment.

The Multi-dropping system allows a mixed

assortment oI instrumentation to share a common

serial line.

Using the SCADA system, the SCADA clients

beneIit Irom real time displaying oI gas plant state.

The SCADA clients permanently beneIit the

actualized scheme oI the gas plants.

The SCADA clients are warned about the

incidents and anomalies oI the gas plants.

As a result oI the process oI Iunctioning

parameters monitoring, a notiIication system was

realized.

83

Using Internet connection, SCADA Web clients

can display the gas plant state, the parameters list, the

events list and the alarm list no matter what browser

they use.

The solution that was proposed in this paper was

implemented in two natural gas plants.

The next research includes the using oI intelligent

sensors and intelligent maintenance system based on

neural networks.

8. References

|1| Gavril Toderean, Microprocesoare Univ. Tehnica Cluj,

1994

|2| Mircea Dulau, Automati:area proceselor termice si

chimice- Universitatea ,Petru MaiorTargu Mures, 2002

|3| Traian Turc, Brevet de inventie nr:11863 'Sistem

pentru automatizarea si monitorizarea proceselor

industriale, OSIM, 2003

|4| Munteanu,R., Tarnovan,I.G., Dragomir,N.D.,

Popovici,O, Electrotehnic i convertoare energetice.

Editura MEDIAMIRA, Cluj-Napoca, Romnia, 1997.

|5| R. Hyde, AoA - The Art of Assembly language,

webster.cs.ucr.edu/AoA/DOS/pdI/

|6| S. Nedevschi, Microprocesoare, Editura UTCN, 1994

|7| T. Letia, A. Astilean, Sisteme cu evenimente aiscrete,

Editura albastr, 1998

|8| T. Letia. Programarea avansat in Java. Editura

Albastr (MicroinIormatica), 2002

|9| Riptech, Inc, Unaerstanaing SCADA System, 2001

|10| Schneider Electric Ltd SCADAs Powerful System

Architecture, 2009, Australia

|11| PaciIic Northwest National Laboratory, U.S. Depart-

ment oI Energy, The Role of Authenticatea Communica-

tions for Electric Power Distribution Beyona SCADA,

November 8-9, 2006

84

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- MAN SureShot 12526 RevBDocument46 pagesMAN SureShot 12526 RevBWajid Khattak50% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Spec-11044 Rev CDocument12 pagesSpec-11044 Rev CWajid KhattakNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Well LogsDocument10 pagesWell LogsJorge CervantesNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Data Transmission FormatsDocument20 pagesData Transmission FormatsWajid KhattakNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L LDocument1 pageL L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L L LWajid KhattakNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Gene & Cell Tech CourseDocument58 pagesGene & Cell Tech CourseWajid KhattakNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- How To Remove The System Volume Information Folder From A Flash DriveDocument1 pageHow To Remove The System Volume Information Folder From A Flash DriveWajid KhattakNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Time Management Tips For ProfessionalsDocument1 pageTime Management Tips For ProfessionalsWajid KhattakNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- My First BoardDocument1 pageMy First BoardWajid KhattakNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- My First BoardDocument1 pageMy First BoardWajid KhattakNo ratings yet

- 5 OIL Direction and Inclination 7.0.1 OnlinePDFDocument4 pages5 OIL Direction and Inclination 7.0.1 OnlinePDFWajid KhattakNo ratings yet

- CDC 19446 DS1Document165 pagesCDC 19446 DS1Wajid KhattakNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- APS Rotary PulserDocument2 pagesAPS Rotary PulserWajid KhattakNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Implementation of Control Unit Using SCADA System For Filling Systemv46-13Document5 pagesImplementation of Control Unit Using SCADA System For Filling Systemv46-13Krishna ReddyNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Positive Displacement Motor Increases Drilling Power, Rate of PenetrationDocument2 pagesPositive Displacement Motor Increases Drilling Power, Rate of PenetrationRFVNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 3 Fish ArtDocument0 pages3 Fish ArtMohamad Arif IbrahimNo ratings yet

- Designing and Impli .Menting Scada Subsystem For Textile IndustryDocument4 pagesDesigning and Impli .Menting Scada Subsystem For Textile IndustryWajid KhattakNo ratings yet

- Fatek PLC1Document20 pagesFatek PLC1Engr Dil BagoroNo ratings yet

- 292 E341Document5 pages292 E341Wajid KhattakNo ratings yet

- On-Chip Temperature Control Circuit Using Common Devices: MSEE Project ReportDocument26 pagesOn-Chip Temperature Control Circuit Using Common Devices: MSEE Project ReportWajid KhattakNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 10 1 1 23Document9 pages10 1 1 23Wajid KhattakNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Temporal Pulse Broadening Due To Dispersion and Weak Turbulence in FSO CommunicationDocument6 pagesTemporal Pulse Broadening Due To Dispersion and Weak Turbulence in FSO CommunicationMohamed BouhaddaNo ratings yet

- Beckhoff Bus Coupler BK3100Document95 pagesBeckhoff Bus Coupler BK3100pandhuNo ratings yet

- Digi Etherlite 160 16 Port Rs 232 RJ 45 Terminal Server 70001528 Product DatasheetDocument2 pagesDigi Etherlite 160 16 Port Rs 232 RJ 45 Terminal Server 70001528 Product DatasheetBranko RumoraNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 3GPP LTE Presentation OverviewDocument25 pages3GPP LTE Presentation Overviewธนวรรณ โภคาอนนต์No ratings yet

- Analog Discovery 2 - Pocket Lab for Engineering TestsDocument1 pageAnalog Discovery 2 - Pocket Lab for Engineering TeststomichelNo ratings yet

- h13-511v4 Dump Solved Toaz - InfoDocument48 pagesh13-511v4 Dump Solved Toaz - Infojerome grajalesNo ratings yet

- IMPOTRANT Alcatel Parameters B7.2 0062 17aDocument606 pagesIMPOTRANT Alcatel Parameters B7.2 0062 17aKhandoker FaisalNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Manual Cisco 1200Document158 pagesManual Cisco 1200danilo_sandovalNo ratings yet

- How To Set A Static IP For A Pogoplug and Make It Persistent - Be Cheap and DIY: PDFDocument4 pagesHow To Set A Static IP For A Pogoplug and Make It Persistent - Be Cheap and DIY: PDFjrbuscaNo ratings yet

- Streamline Area Monitoring with the G7 EXO Cloud-Connected Gas DetectorDocument2 pagesStreamline Area Monitoring with the G7 EXO Cloud-Connected Gas DetectorMeesanNo ratings yet

- Poster DVB-T2 en FoldedDocument1 pagePoster DVB-T2 en FoldederdemsecenNo ratings yet

- PartsDocument4 pagesPartsJason CrestwoodNo ratings yet

- OpenScape Personal EditionDocument4 pagesOpenScape Personal EditionKossay Ben AchourNo ratings yet

- DVR5104SDocument3 pagesDVR5104STTB VisionNo ratings yet

- SM G313hu Tshoo 7 PDFDocument69 pagesSM G313hu Tshoo 7 PDFWilliam SequeraNo ratings yet

- Em Trak AIS B100 BrochureDocument4 pagesEm Trak AIS B100 BrochureGiorginoNo ratings yet

- Passenger / Cargo Ship Safety Radio Equipment (GMDSS)Document9 pagesPassenger / Cargo Ship Safety Radio Equipment (GMDSS)Ngô Duy VũNo ratings yet

- DVD MP Board Layout and Pinout GuideDocument5 pagesDVD MP Board Layout and Pinout GuidediordancardosoNo ratings yet

- HomadeDocument11 pagesHomadeJagatheeswari JagaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Alvarion'S Bmax Vision: Bawug Wimax Seminar Aug 5, 2004 Dr. Mo ShakouriDocument29 pagesAlvarion'S Bmax Vision: Bawug Wimax Seminar Aug 5, 2004 Dr. Mo ShakourirobolstadNo ratings yet

- TD-W8968 V3 Datasheet PDFDocument4 pagesTD-W8968 V3 Datasheet PDFSanjeev VermaNo ratings yet

- Java Exam QuestionsDocument5 pagesJava Exam QuestionsselvisasikalaNo ratings yet

- Nokia M2M Platform M2M System Protocol 2 Socket Interface: User ManualDocument50 pagesNokia M2M Platform M2M System Protocol 2 Socket Interface: User ManualEug. Sam.No ratings yet

- KNTECH Product CatalogDocument13 pagesKNTECH Product CatalogArioNo ratings yet

- Hurricane 9000P: 4-Port ADSL Modem/RouterDocument30 pagesHurricane 9000P: 4-Port ADSL Modem/Routersumith_gNo ratings yet

- IT Professionals Setting Up For Remote WorkersDocument2 pagesIT Professionals Setting Up For Remote WorkersCorey MolinelliNo ratings yet

- The Most Precise Overhead Line Fault Locator AvailableDocument8 pagesThe Most Precise Overhead Line Fault Locator AvailablePatriceEmNo ratings yet

- Free Space Optical Communication - CasestudyDocument14 pagesFree Space Optical Communication - CasestudySumesh SundaranNo ratings yet

- Dokumen - Tips - Huawei Smartax Ma5616 Configuration Guide v800r310c0003 PDFDocument717 pagesDokumen - Tips - Huawei Smartax Ma5616 Configuration Guide v800r310c0003 PDFfelckieNo ratings yet

- Smart Home Design For Electronic Devices Monitoring Based Wireless Gateway Network Using Cisco Packet TracerDocument24 pagesSmart Home Design For Electronic Devices Monitoring Based Wireless Gateway Network Using Cisco Packet Tracervicky100% (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- Computer Networking: The Complete Beginner's Guide to Learning the Basics of Network Security, Computer Architecture, Wireless Technology and Communications Systems (Including Cisco, CCENT, and CCNA)From EverandComputer Networking: The Complete Beginner's Guide to Learning the Basics of Network Security, Computer Architecture, Wireless Technology and Communications Systems (Including Cisco, CCENT, and CCNA)Rating: 4 out of 5 stars4/5 (4)

- Designing Data-Intensive Applications: The Big Ideas Behind Reliable, Scalable, and Maintainable SystemsFrom EverandDesigning Data-Intensive Applications: The Big Ideas Behind Reliable, Scalable, and Maintainable SystemsRating: 5 out of 5 stars5/5 (6)