Professional Documents

Culture Documents

Cornu Article 1907

Uploaded by

Lex Nunes FPireauxOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cornu Article 1907

Uploaded by

Lex Nunes FPireauxCopyright:

Available Formats

Author: A.

Bracke Series Title: Monograph of Aviation 3 Title: The Helicopters, Paul Cornu Published by: The Library of Aeronautic Sciences Translation: Bernard Mettler _________________________________________________

The efficiency of propellers/rotors depends on the air resistance on the branches rods and the friction of air molecules against the surfaces. These losses of work can be reduced by a careful construction. There is another loss that is not due to the construction. The propeller is a motion transformation device that works like a screw. The screw advances with a quantity that equals the pitch multiplied by the number revolutions made. This analogy would lead to the thinking that a propeller would drive the machine to which it is attached with a speed determined by these two factors. However, this is not the case: the actual speed is smaller; the difference is due to the slippage. This loss which shows great variability depending on the case is unavoidable. A propeller build perfectly in all its details cannot be applied to any type of vehicle with the justification that it has, as a propeller, a perfect efficiency. The point of support of the propeller is a fluid, and this fluid has the sole tendency to slip away. The greater the resistance in the vehicle motion is, the easier the fluid will slip away. In this case, the vehicle will show little motion, while the fluid will be pushed backwards, creating an enormous set back, and as a result we will spend a great amount of the engine work in form of a pure loss. In these vehicles that we call helicopters, the vertical lift is obtained thanks to propellers. Since these propellers cannot move, the slippage is 100% and all the available work, subtracting the efficiency of the construction, is absorbed. These propellers which have the function to produce a maximum thrust while reducing the speed as much as possible distinguish themselves from the propulsive propellers. The speed is the pitch as described by the propeller during a unit of time. The first quality of a lifting propeller is a small pitch. The smaller the better. Since all the work is absorbed by the slip, the latter will have to be reduced as much as possible. The way this is achieved is by taking a propeller with a large diameter.

The question of construction efficiency sets a limit to this increase in diameter, since the construction of wings that are lightweight and strong would be difficult, moreover, large branches? are subject to a high sensitivity in rotation resistance, and the friction of the air on the surface of the branches increases very significantly. For helicopters it is necessary to make the slip as small as possible. However, we can also leave it very large and make use of it. This is what Mr. Cornu and his sons did in 1906. They used the slip of a lifting propeller to obtain the horizontal displacement of the helicopter. The mechanism which enables this result is made of a series of surfaces that can be tilted. These surfaces are positioned bellow the propellers in such a way that the air mass displaced by the propellers is forced to pass through the intervals between the surfaces. The action of this air mass has a horizontal component which was used by the inventors to obtain the advancing motion of the entire machine. p.4 In essence, the volume of air that flow through these intervals act on these in a same way as the wind on the wings of a windmill. With the only difference that the motion is rectilinear instead of rotary. Therefore the engine is entirely used to drive the propeller and the horizontal propulsion is produced by the slip, which in an ordinary vehicle is a force that is lost entirely. Figure 1 represents the schematic of a generic machine based on the principle that we just exposed. The propulsion surfaces c are mounted between two rods l . The latter are connected via small moving parts e that are attached around fixed hinges f . A lever g, mounted in the same line as the central part e, makes it possible to give the surfaces a varying inclination. Hence a by simple action of the lever g it is possible to make the machine move forward or backward at a speed that will depend on the inclination of the surfaces. To obtain this forward or backward motion it is absolutely unnecessary to vary the speed of the lifting propellers. p.5 The first trial made by Paul Cornu and sons, demonstrated that the horizontal thrust equaled to 2/3 of the total vertical force of the lifting propellers. The resistance produced by the surfaces to the passage of the air pushed by these propellers is always three times less than the thrust given by the surfaces. In a machine equipped with such surfaces, and with propellers producing a vertical lifting force of 100kg, the properly tilted surfaces will produce a horizontal thrust of 60kg.,

whilst they will only absorb a vertical force of 28kg, a force which is absorbed by the resistance they offer to the air flow from top to bottom, produced by the lifting propellers. Therefore, if a machine weighs 80kg in working state, with propellers having a vertical force of 100kg, this machine if it surfaces are properly adjusted will be able to be in balance and its surfaces will provide a horizontal thrust of 60kg. Based on these data, the inventors established a model machine of ordinary construction. They describe in the following terms: We make use of a Buchet engine model 190 of 2HP, costing 125fr, which weight 14kg when we bought it, which was reduced to 7kg. This engine drives, via a special transmission, two propellers of 2m25 in diameter, placed one besides the other. The frame of these propellers is made of tubular steel welded with ETAIN. Besides the transmission there is nothing special in this there at the exception of a mechanical assembly disposed in a manner that appeared the best after multiple trials. p.6 Here are the results obtained with this machine which weighs 13kg complete in working state. It lifts easily 16kg with only half of the ignition advance. At this time, the engine develops 1 and _ HP. Hence we lift on average about 10kg per HP. This remarkable result, given the small dimension of the propellers, we attribute to our transmission which we patented. The vertical lift trials where stopped and the inventors were concerned about the realization of the propulsion using the slippage of the lifting propellers. To this end, they say, we installed only 14 surfaces, weighing, including their mounts and the inclination system, 400g; they made it possible to obtain a horizontal traction of 1.500g, enough to move our helicopter. At this time, the surfaces absorb btw. 500 and 600g of ascending force. The theoretical (horizontal translational) speed is of 25 to 30km/hour. The practical speed is a little less due to the slippage; however the machine moves easily at a speed of 15 to 20km/hour. The machine is not equipped with a rudder since it is suspended by a special beam which provides guidance during the ascension. In the first models that were built and tested, the 14 surfaces were arrange in a symmetrical fashion with respect to the vertical passing through the engine, and the two bladed propellers were attached to bicycle wheels with their axis set vertically. The JANTES served as gorges for the transmission belts. This arrangement was later

modified and the (p.7) picture Figure 2 shows the surface providing the propulsion placed at the center of the machine. Public experiments crowned with success took place at Lisieux, in October 1906. Their success had the consequence that an machine capable of lifting a human was started. Friends of the inventor offered as a gift a subvention of 12,500 francs. On October 30, the 24 HP Antoinette engine was ordered. The inventor had first the idea to build a helicopter with small, fast spinning blades. But concerned to engage in an unknown path, he applied the contraptions and data provided by his experimental models. The main structure of the definitive machine, shown on the large plate, has a very open V shape, and it is made of a large central pipe and reinforced by 6 star-shaped soldered steel pipes armed by Bowden cables that were properly intertwined. This way we achieve a high stiffness. The length of this machine, mounted on four wheels, is 6m 20, the weight is 50kg. The engine and the pilot seat are at the center. With the help of an endless flat belt of 22meters in length and 100mm wide, the engine drives two two-bladed propellers of 6 meters in diameter, attached at the extremities of the structure. Close to the aviator, we find: left a tightening clutch; right, the lever used to lift off (the ignition advance). The central board which is visible above the aviator is made of aluminum. Held by four tubes, it caries two return pulleys and guiding pulleys. All the spinning pieces, including the propellers, are fitted with ball bearings. p.8 and 9: main plate. p.10 The water and fuel tanks are placed symmetrically at the front and back third of the structure. The water tank has a capacity of 12 liters, with a circulation enabled by thermo-siphon; the fuel tank has a capacity of 7 liters. The oil tank is above, the batteries and the engine spool bellow the engine. The propellers are composed of a 1 mm thick sheet metal pulley measuring100mm in width, and 1m80 in diameter.

These pulleys are attached with the spokes tangential on aluminum hubs. Although serving in the transmission they are the main body of the propellers. The latter are not adjustable; the blades are made of a tubular frame flattened progressively at the extremities. Their feet are appended to the pulleys through the intermediary of a small aluminum plate. These blades can pivot about themselves; their feet extend through a shaft to the hub, where it is attached on a weakly eccentric ear. The frame of the blades is covered with two layers of rubber coated silk, stretched by a special procedure. Their length is 1m 80 and their width has a maximum of 0.9m. These blades have a very small resistance; the centrifugal forces tend to lift them. To balance this effect, it was necessary to add lead sheets at 2/3rd of their length starting at the center. The blades are driven via the intermediary of cables that are fixed on one end to the pulley and on the other end at 2/3rd of the back branches going through a bridge attached to the front branch. This system is doubled for the purpose of resisting the start-and stop vibrations. With this setup, the blade is pulled as a whole and the tension of the cables, combined with the rotation of the feet, enables the variation of the pitch. The weight of the complete propeller reaches 24.5kg. p. 11: Fig. 2. Study Helicopter p.12 To obtain the propulsion and steering, two surfaces made of a tubular steel frame flattened and covered with silk measuring 2.50m in length and 0.6m in their maximal width, are placed immediately under the propellers. These surfaces can move about a horizontal axis running through their center and are attached on two articulated supports around an extension of the propellers axis. The inclination of these surfaces (propulsion) and their lateral displacement (direction) are adjusted via two levers placed left and right in proximity of the aviator. The air reaction produced by the propellers on the surfaces provides the propulsion the speed of which depends on their inclination. Their lateral displacement provides steering. The weight of the propulsion and steering system is 9kg. The construction of the machine was competed in August 1907 and the testing of the propellers started immediately. From the beginning, it was recognized that it was necessary to balance them with great precision, because as soon as they started spinning a little fast, the machine would jump left and right. It was established that it was sufficient to place a weight of 55g at the extremity of one blade and of 75g on the other to make the

entire system perfectly well. The slippage of the belt was the second issue to prevent; it was necessary to add leather to the small and large pulleys. After a few trials with the diameter of the driving pulley and the pitch of the blade, the machine lifted by itself for the first time on August 31. The propellers were spinning at 70 rpm with a pitch of 2m70. The engine was rotating at 750rpm. The seat of the aviator was loaded with a 50kg sand bag; the slipping of the belt could again be noticed. The diameter of the driving pulley was increased to 18cm and the entire machine including its ballast, which is 235kg, was lifted off the ground on September 27 1907. The engine was rotating at 850rpm and the propellers were spinning at 85 rpm with a pitch of 3m. In what followed, this pitch was kept because if increased, the propeller blades would again have to be leaded to balance the effects of the centrifugal force. Up to this moment, the machine consisted only of the main frame, the engine and the propellers. The inventors went ahead with completing the propulsion surfaces. On November 9, the machine, which was complete, weighing 203kg, carried for the first time its aviator (57kg) and would have lifted off if the slippage in the belts had not resumed. The small pulley was fitted with rubber and four days later the machine lifted his pilot up 30cm high. The same day, the experiment was resumed, and the entire system lifted two people at 1.5m above ground. The weight lifted during these trials reached a total of 328kg. During a trial on December 4, the vertical flight did not last more than one minute because of slippage of the belts even after the large pulley were fitted with rubber. In spite of this, the experiments conducted with the Cornu helicopter seemed conclusive. Moreover, as soon as the month of March 1908, the inventors decided to build a simpler machine. As far as the propulsion was concerned, the experiments demonstrated that when the propellers were spinning at 70rpm, the longitudinal motion took place, as a function of the inclination of the surfaces, at a speed of about 12km per hour. During these experiments, the machine was positioned in a way that prevented it from leaving the ground. In theory, the propellers were spinning at 100rpm with a pitch of 3m, and the surfaces where inclined at 45degrees; the machine was then moving at a speed between 25 and 30 kilometer an hour. p. 14 The results of the experiment can be summarized as follows:

Engine RPM 750 850 900 <900

Propellers Pitch (in meters) 2.7 3 3 3 RPM 70 85 90 ?

Vertical Thrust Lifted Weight (in kg) 185 235 260 328

In lifting 260 kg with a lifting surface of 6m2, the engine was developing 13HP. On the topic of the power developed, M. Cornu said: The engine power was observed from its speed which never exceeded 900rpm. At this speed, M. Levasseur indicates that his 14 HP Antoinette engine cannot produce more than 12 to 14HP in the best of conditions. Hence, the obtained result is contained in the following numbers: 20 kg lifted per HP, and 45 kg held by square meter of lifting surface. The propulsion produced by the surfaces was on average about 15kg. The helicopters have a serious defect: the air flow during the horizontal motion of the machine has an unfavorable influence on the efficiency of the lifting propellers; it has even a destabilizing effect. During the experiments that we just described, the translation does not exceed 12km/hour and the efficiency of the propellers was better during the translation [contradiction!]. At faster speeds the equilibrium would certainly be affected by the violent air flow which would certainly act on the propeller blades. It is this ideas which prompted a change in the research orientation by M. Paul Cornu. In the mid 1908, he built an experimental machine to study these perturbing effects. The inventors had has goal to lift off the ground a man with the smallest possible propellers. To enclose these propellers in a lenticular envelope made of a silk covered frame. This envelope would be pierced with openings for the intake and exhaust of the air. The openings would be fitted with short pipes. This would prevent perturbation of the propellers from exterior effects and allow them to always function in the same conditions. In the experimental machine, the disposition of the propellers with their axes in parallel was abandoned. This setup required a balancing that was hard to maintain as well as a transmission that was heavy and complicated.

The propulsion system based on oblique surfaces was also abandoned at first, not because it was bad the results that it provided were good but because of the low translational speed it enabled. The increase in speed required an increase in the pitch of the lifting propellers which harmed the lifting performance. This system based on reaction was picked up again later. In an experimental model the translation is provided by a pulling propeller with variable pitch commanded by a flexible transmission. The experiments performed after that by M. Paul Cornu on the lifting propellers demonstrated that in order to lift a weight of 400kg with two propellers of 4m in diameter, a force of 70HP was needed. More than two hundred trials in exact yet practical condition were performed with lifting propellers. The diameter of the tested propellers ranged from 4 to 6m. They were driven by and a bevel wheel and an ordinary transmission with a driving force of 10 to 20HP. From the project on display at the Salon Aeronautique at the end of December 1908 the following has to be considered: The machine was made of a rectangular frame holding in the front the engine and in the back the aviator; the engine was driving, via a clutch and two bevel wheels enclosed in a central CARTER, two concentric shafts fitted with ball bearings; these shafts were spinning in opposite directions and on each of them a propeller was affixed. The gap between the two propellers is 0m.70. Immediately underneath the lower propeller were installed two sets of six surfaces each; one on the right and the other on the left of the frame. These surfaces are mobile, meaning that the arms that carry them can tilt about hinges attached to the frame. Each of these arms is ended by a small lever, the latter are connected though a rod for each set. A lever with equipped with a stop, placed under hand of the aviator sets the travel of the rods. There are two independent levers: one sets the right set of surfaces and the other the left one. The inclination of the surfaces can be adjusted from their vertical orientation to the extreme forward or backward orientation. If one of the set has a steeper inclination we obtain a turn. The experiments demonstrated that there is a loss in speed of 50% on the theoretical speed of the air moved by the lower propeller. In the machine just described, the air was moved at a speed of 72km/hour and it can be expected that an average speed of 40km/hour can be obtained; at that time the surfaces provided a thrust of 50km [per hour ?]. The surfaces inclined at 45%[degrees?] oppose to the vertical lift a resistance that equals one third of the horizontal thrust they produce. But at 60degrees, the forces are equal. The maximal speed is obtained with an inclination of 50degrees. M. Paul Cornu has also studied the hilicoplane; we will probably have the opportunity to discuss it in more lengths.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Parking Stand WIIIDocument11 pagesParking Stand WIIIalena2003No ratings yet

- Empi 2006Document73 pagesEmpi 2006Marcelo Araujo RodriguesNo ratings yet

- Magna-Tyres brochure-USA ConstructionDocument14 pagesMagna-Tyres brochure-USA ConstructionKashyapNo ratings yet

- BW7249 Uhb800-CamDocument218 pagesBW7249 Uhb800-CamKeith McCann100% (1)

- 2019 Honda Automatic Scooters 1019Document119 pages2019 Honda Automatic Scooters 1019Octavio PereiraNo ratings yet

- Mercedes Technical Training Srs GC IccDocument5 pagesMercedes Technical Training Srs GC Iccedna100% (47)

- Eaton Performance Differential Application Guide enDocument32 pagesEaton Performance Differential Application Guide enAbhishek BansalNo ratings yet

- No. of Machine CalculationDocument12 pagesNo. of Machine CalculationPranjal JangidNo ratings yet

- Toro WheelHorse Accessories Interchange 2000-1955-2000Document110 pagesToro WheelHorse Accessories Interchange 2000-1955-2000Kevins Small Engine and Tractor Service100% (2)

- Transport Trips of Vehicle During A YearDocument238 pagesTransport Trips of Vehicle During A YearNIRAV JOSHINo ratings yet

- Arrow 2008Document98 pagesArrow 2008ivanmesa.90No ratings yet

- Doc-20230810-Wa0007. (2) - 1Document33 pagesDoc-20230810-Wa0007. (2) - 1Avinash SableNo ratings yet

- MG Genuine Accessories Transform Your Gloster Driving ExperienceDocument18 pagesMG Genuine Accessories Transform Your Gloster Driving ExperienceAjie Mohammad Yuki TakegawaNo ratings yet

- Peugeot 106 Rallye Series 1 vs Series 2: A Technical ComparisonDocument10 pagesPeugeot 106 Rallye Series 1 vs Series 2: A Technical Comparisonxyzqwerty100% (1)

- Complete Product Range (US) Apr 2011Document60 pagesComplete Product Range (US) Apr 2011JCB North America100% (1)

- D275ax 5Document12 pagesD275ax 5josecall100% (1)

- Kubota Mini Excavator SpecsDocument4 pagesKubota Mini Excavator SpecsalfredoNo ratings yet

- DAMEN SLa 4510 Landing VesselDocument2 pagesDAMEN SLa 4510 Landing VesselГригорий ШарунNo ratings yet

- NP200Document6 pagesNP200cunnincnNo ratings yet

- Grove GMK 6350 - 350T PDFDocument24 pagesGrove GMK 6350 - 350T PDFMarco Torres Henrriquez50% (2)

- 4 V 158 TiDocument2 pages4 V 158 TiGeovanny BajañaNo ratings yet

- Autos CanDocument4 pagesAutos Cantibby_1No ratings yet

- Is Ax4n 2Document8 pagesIs Ax4n 20005020100% (1)

- Service Manual En: OSE120, OSE120P, OSE250, OSE250PDocument236 pagesService Manual En: OSE120, OSE120P, OSE250, OSE250PAlfonso Rubio GarciaNo ratings yet

- JLG1850.ky. Parts EnglishDocument880 pagesJLG1850.ky. Parts EnglishkuangyongserviceNo ratings yet

- CRJ-550/700/900/1000 Aom Part 1: Aircraft General / in P3D VOLDocument52 pagesCRJ-550/700/900/1000 Aom Part 1: Aircraft General / in P3D VOLDaniel De AviaciónNo ratings yet

- Volvo 940 Owners Manual 1995Document181 pagesVolvo 940 Owners Manual 1995warriory2kNo ratings yet

- FWD Fiat 127 GearboxesDocument3 pagesFWD Fiat 127 Gearboxesvomit100% (1)

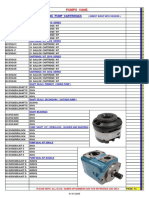

- Model VQ Vane Pump CartridgesDocument7 pagesModel VQ Vane Pump CartridgesglobalindosparepartsNo ratings yet

- 280717-Trent 1000 InfographicDocument1 page280717-Trent 1000 InfographicMaciejNo ratings yet