Professional Documents

Culture Documents

Supercharging and Turbocharging

Uploaded by

Mudassir HussainCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supercharging and Turbocharging

Uploaded by

Mudassir HussainCopyright:

Available Formats

NUST

SUPERCHARGING AND TURBOCHARGING IN TERMS OF ISENTROPIC EFFICIENCY

SUBMITTED TO LEC MUBASHIR GULZAR

SUBMITTED BY NS MUDASSAR HUSSAIN DE-32(MECHANICAL ENGINEERING)

SYNDICATE:B

DATE: MARCH 25TH, 2012

SUPERCHARGING AND TURBOCHARGING INTRODUCTION

Turbocharging or supercharging is a method of increasing engine volumetric efficiency by forcing the air-fuel mixture into the intake rather than merely allowing the pistons to draw it in naturally. Supercharging and turbocharging in some cases will push volumetric efficiencies over 100 percent. Engines must be modified to operate properly in some cases, because the extra airfuel mixture will cause higher compression pressures, resulting in detonation. Superchargers: To increase the output efficiency of any engine we have to burn more fuel and make bigger explosion in every cycle. We have two options for this. One way to add power is to build a bigger engine. But bigger engines, which weigh more and cost more to build and maintain, are not always better. Another way to add power is to make a normal-sized engine more efficient. We can accomplish this by forcing more air into the combustion chamber. More air means more fuel can be added, and more fuel means a bigger explosion and greater horsepower. This can be done with the help of a supercharger. A supercharger is basically an air compressor used for forced induction of an internal combustion engine. It does the same work as that of a compressor, i.e. it compresses the air being delivered to the combustion chamber of an engine. The greater mass flow-rate provides more oxygen to support combustion than would be available in a naturally-aspirated engine, which allows more fuel to be provided and more work to be done per cycle, increasing the power output of the engine. Thus a supercharger is extra equipment provided in an engine so as to boost the capacity and the torque of an engine. Benefits of using superchargers: A supercharger is used in an engine for various reasons. Some of the advantages of superchargers are as follows: Increases the power of an engine. A supercharger spinning at 50,000 RPM translates to a boost of about six to nine pounds per square inch (psi). Increases the torque produced. An efficiently working engine with supercharger can achieve the same speed in one third of the time taken by the same engine without supercharger. Necessary in airplanes and jets as they have less oxygen at high altitudes. So they provide the sufficient amount of air by compressing it to higher pressure. And ensures complete combustion. Higher amount of oxygen in compressed air from supercharger ensures complete combustion of the fuel. Complete combustion reduces pollution to some extent.

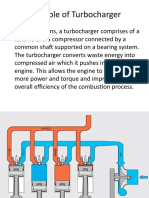

Diagram of a working engine equipped with a Supercharger. Turbochargers: A turbocharger uses the force of the engine exhaust stream to force the air-fuel mixture into the engine. It consists of a housing containing two chambers. One chamber contains a turbine that is spun as hot exhaust gases are directed against it. The turbine shaft drives an impeller that is located in the other chamber. The spinning impeller draws an air-fuel mixture from the carburetor and forces it into the engine. Because the volume of exhaust gases increases with engine load and speed, the turbocharger speed will increase proportionally, keeping the manifold pressure boost fairly uniform. A device known as a waste gate is installed on turbocharged engines to control manifold pressure. It is a valve that, when open, allows engine exhaust to bypass the turbocharger turbine, effectively reducing intake pressure. The waste-gate valve is operated by a diaphragm that is operated by manifold pressure. The diaphragm will open the waste-gate valve whenever manifold pressure reaches the desired maximum.

Benefits of using Turbochargers: One of the surest ways to get more power out of an engine is to increase the amount of air and fuel that it can burn. One way to do this is to add cylinders or make the current cylinders bigger. Sometimes these changes may not be feasible. A turbo can be a simpler, more compact way to add power, especially for an aftermarket accessory. Turbochargers allow an engine to burn more fuel and air by packing more into the existing cylinders. The typical boost provided by a turbocharger is 6 to 8 pounds per square inch (psi). Since normal atmospheric pressure is 14.7 psi at sea level, you can see that you are getting about 50 percent more air into the engine. Therefore, you would expect to get 50 percent more power.

How a turbocharger is plumbed in a car

Inside a turbocharger

Turbocharger

Turbocharger Efficiency: The isentropic efficiencies of the compressor and the turbine can be found using the following equations. Eq. (A) given below shows the efficiency of the compressor: . (A) Eq. (B) shows the efficiency of the turbine: . (B)

Note that the isentropic efficiency of a turbocharger is usually a good method to compare the real work of the turbine to the actual work produced from the system. The isentropic efficiency of a radial flow turbocharger is usually 75 percent for the compressor and 70-85 percent for the radial flow system. Performance: The performance of a particular turbocharger can be determined by looking at a turbocharger compressor map. The compressor flow map gives the amount of air compression as a function of the mass (or volume) flow of the uncompressed air entering the turbo itself. At first glance, these charts may seem quite difficult to read. The curved lines on the map with numbers ranging from 46,050 and 125,650 represent the rotational speed of the turbine in RPM. The isentropic efficiency of the compressor is represented by the elliptical curved lines which range from 50 percent to 73 percent for this particular turbocharger. The pressure ratio on the vertical axis is the ratio of the exiting air pressure to the incoming ambient air pressure. The air flow rating on the horizontal axis gives an output of . An interesting side note concerning the wheel speed of the compressor is that at Turbocharger compressor map certain high wheel speed values, it becomes very difficult to raise the output pressure of the turbine. At these speeds (which are faster than the speed of sound), the diffuser in the housing becomes choked and does not permit notable increases in flow. At this point, the turbine has become inefficient and a larger unit may be required. In addition, when the turbine is spun to a very high speed, engine damage may occur.

This danger is usually overcome through the use of a waste-gate valve. Waste-gate operation may vary depending on its design. One of the simple and common mechanical waste-gate designs involves the use of a calibrated spring which regulates manifold pressure by directing flow around the turbine wheel and directly into the exhaust system. Turbocharger-related Sources of Engine Failure: The damage that may occur from a turbocharger usually concerns pre-ignition or engine knock. This sometimes occurs from setting the timing of the spark ignition system at a value which is too far advanced. The combination of increased cylinder pressure and early ignition causes combustion substantially before the piston has reached TDC. This early ignition produces a knocking sound and is accompanied by very high pressures. This high pressure causes high stress on the piston and ring assembly as well, and has been known to crack ring lands and severely damage piston assemblies, along with other internal parts. In addition to advanced spark timing, a high compression engine will be less effective at making power than a lower compression engine if a turbocharger is applied. This stems from pre-ignition due excessively high cylinder pressures. A lower compression motor will accept a larger amount of the highly dense intake charge produced by the turbocharger. It is important to also note that an engine running lean will also be susceptible to knock and pre-ignition. Besides reducing the compression ratio and retarding the timing, it is also effective to reduce the probability of knock and increase performance through the use of an intercooler to reduce the temperature of the incoming intake charge. The power level of the engine may be increased with an intercooler since the density of the incoming charge may be increased substantially. If the inlet temperature is reduced, there will be less thermal loading on the engine. The equation showing the efficiency associated with an intercooler is shown below as Eq. (C).

(C)

The cooling medium used in intercoolers is usually air or water. Sometimes water in the form of ice for high performance applications such as drag racing where the car will travel short distances. In some cases, engine coolant is used; however, due to its high temperature, it is not the best choice as a cooling medium. Note that with an intercooler, some losses in flow might be present through the intercooler. As such, it is sometimes necessary to increase the output pressure of the turbocharger itself to compensate. Also, due to the increased mass flow rate of air into the engine, the fueling system must be altered to provide more fuel to the engine.

REFERENCES

[1]. Balich, G. W., & Aschenbach, C. R. (2004). The gasoline 4-stroke engine for automobiles, Department of Aerospace and Mechanical Engineering, University of Notre Dame, Paris, France. Retrieved from http://nd.edu/~msen/Teaching/DirStudies/Gas4Stroke.pdf [2]. Department of the US Army. (1985). Principles of Automotive Vehicles, TM 9-8000. Washington, DC.

[3]. Harris, W. (2006). How Superchargers Work. Retrieved from http://auto.howstuffworks.com/supercharger.htm [4]. Karim, N. (2000). How Turbochargers Work. Retrieved from http://auto.howstuffworks.com/turbo.htm [5]. Lucius, J. Turbocharger compressor flow maps for 3000gt and stealth owners. Retrieved from http://www.stealth316.com/2-3s-compflowmaps.htm [6]. Panda, A. (2010). A technical seminar report on supercharger. (Visvesvaraya Technological University, Belgaum, India.) Retrieved from http://www.scribd.com/doc/29016581/supercharger-pdf

You might also like

- Turbocharger and Supercharger ReportDocument18 pagesTurbocharger and Supercharger ReportMayank Burman100% (3)

- Geothermal Heat PumpDocument17 pagesGeothermal Heat PumpMudassir Hussain83% (6)

- Turbo Charger LectureDocument6 pagesTurbo Charger LectureAbdelrhman Essam AttiaNo ratings yet

- Turbo Charger - ProjectDocument36 pagesTurbo Charger - ProjectSam Sams100% (2)

- TurbochargerDocument17 pagesTurbochargerAravindhRaj100% (1)

- Gear PumpDocument21 pagesGear PumpMudassir Hussain83% (6)

- Description: Necessity of Turbocharger and SuperchargerDocument16 pagesDescription: Necessity of Turbocharger and SuperchargerNazrul Aizat ZunaidiNo ratings yet

- What Is Forced Induction?Document15 pagesWhat Is Forced Induction?Fugaru Paul - AlexandruNo ratings yet

- Earth and Life Science DLLDocument6 pagesEarth and Life Science DLLGsoon Sibulan100% (3)

- Turbocharger Basics - What is a TurbochargerDocument18 pagesTurbocharger Basics - What is a TurbochargerShrwan Gyawali100% (3)

- Allen Bradley Power Monitor 3000 Manual PDFDocument356 pagesAllen Bradley Power Monitor 3000 Manual PDFAndrewcaesar100% (1)

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- TurbochargerDocument17 pagesTurbochargerdinucv83% (6)

- Functions of an Exhaust ManifoldDocument5 pagesFunctions of an Exhaust Manifoldjameel babooram100% (1)

- Edexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginesDocument9 pagesEdexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginescataiceNo ratings yet

- Internal Combustion Engine Turbocharger and Supercharger GuideDocument65 pagesInternal Combustion Engine Turbocharger and Supercharger Guidezia malikNo ratings yet

- Page Tables 1to16 CDocument1 pagePage Tables 1to16 CMudassir HussainNo ratings yet

- Hybrid TurbochargersDocument7 pagesHybrid Turbochargersanon_47328873429% (7)

- Four-Stroke Diesel EngineDocument18 pagesFour-Stroke Diesel Enginebs esliye me aap ka fan ho gya100% (2)

- Super ChargingDocument23 pagesSuper Charginghirenbabaji100% (2)

- Power Tube Biasing Operation Manual 15-01-08Document2 pagesPower Tube Biasing Operation Manual 15-01-08MitchNo ratings yet

- FSC Area Triangle FormulasDocument1 pageFSC Area Triangle FormulasMudassir HussainNo ratings yet

- Air and Fuel Induction - FiveDocument35 pagesAir and Fuel Induction - FiveasfsaedgarNo ratings yet

- Cumulative List of Notices to MarinersDocument2 pagesCumulative List of Notices to MarinersResian Garalde Bisco100% (2)

- FSC Trigonometric FormulasDocument1 pageFSC Trigonometric FormulasMudassir HussainNo ratings yet

- Chapter 3 SuperchargingDocument16 pagesChapter 3 Superchargingmustafa1011100% (1)

- 4 Stroke Petrol EngineDocument11 pages4 Stroke Petrol EngineAnkit Joshi50% (4)

- 03 Principle of TurbochargerDocument19 pages03 Principle of TurbochargerSky RNo ratings yet

- SuperchargerDocument24 pagesSuperchargerpravat dalai100% (1)

- Turbochargers, Final Report of The SeminarDocument19 pagesTurbochargers, Final Report of The SeminarMuddukrishna C Shetty91% (22)

- BS en 12201 5 2011Document20 pagesBS en 12201 5 2011fatjon31100% (4)

- ICE Turbocharger BasicsDocument18 pagesICE Turbocharger Basicssafwansd750% (2)

- AOAC 2012.11 Vitamin DDocument3 pagesAOAC 2012.11 Vitamin DPankaj BudhlakotiNo ratings yet

- Solid Waste ManagementDocument26 pagesSolid Waste ManagementPamela MendozaNo ratings yet

- BCMEDocument9 pagesBCMEVenkateshwaran VenkyNo ratings yet

- Turbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Document25 pagesTurbochargers: BY: Muddukrishna C Shetty USN:4AL08ME023Vinod SubramaniamNo ratings yet

- Boost engine power with turbochargersDocument18 pagesBoost engine power with turbochargerscleousNo ratings yet

- 2.16.1 Principles of Forced InductionDocument8 pages2.16.1 Principles of Forced Inductionstefanovicana1No ratings yet

- Supercharger VS TurbochargerDocument25 pagesSupercharger VS TurbochargerAllen CastorNo ratings yet

- Super ChargingDocument24 pagesSuper ChargingGagan KaushikNo ratings yet

- TURBOCHARGERDocument5 pagesTURBOCHARGERAnand Raju100% (1)

- Ic Engine: Assignment#02Document9 pagesIc Engine: Assignment#02Jawad ZafarNo ratings yet

- Turbo ChargerDocument28 pagesTurbo ChargerCharles ChivengahNo ratings yet

- Turbocharger and SuperchargerDocument16 pagesTurbocharger and SuperchargerPrajwal ZinjadeNo ratings yet

- Turbocharging of Ic EnginesDocument5 pagesTurbocharging of Ic EnginesKrishna MurthyNo ratings yet

- 6 TURBOCHARGING v2Document27 pages6 TURBOCHARGING v2Tuan Linh VoNo ratings yet

- Ch-12 - Turbocharger & Super MecDocument29 pagesCh-12 - Turbocharger & Super Mecahmed jemalNo ratings yet

- 8 1turbochargerDocument24 pages8 1turbochargerkedir67No ratings yet

- Supercharging. The Friction Losses in A Supercharged Engine Are Greater, But Because of The Rise in TheDocument9 pagesSupercharging. The Friction Losses in A Supercharged Engine Are Greater, But Because of The Rise in TheVicki NurrizkyNo ratings yet

- Chapter 12 Supercharging TurbochargingDocument33 pagesChapter 12 Supercharging Turbochargingdesie yalewNo ratings yet

- Final Turbohargr ReportDocument32 pagesFinal Turbohargr ReportPooja BanNo ratings yet

- Turbo ChargerDocument13 pagesTurbo ChargerSwaraj TodankarNo ratings yet

- Operating PrincipleDocument6 pagesOperating PrincipleGedan CristianNo ratings yet

- 17ME655-Module 4 PDFDocument40 pages17ME655-Module 4 PDFVinayakNo ratings yet

- Etm 08 TurbochargingDocument58 pagesEtm 08 TurbochargingjashokjackNo ratings yet

- Turbocharger: - Power of A Two Stroke Diesel EngineDocument28 pagesTurbocharger: - Power of A Two Stroke Diesel EngineShraddha Kant SinghNo ratings yet

- SuperchargerDocument27 pagesSuperchargerRamachandran SubburathinamNo ratings yet

- Turbo ChargerDocument23 pagesTurbo Chargerselvaraj9223100% (1)

- IC Engine QuestionsDocument18 pagesIC Engine QuestionswasemNo ratings yet

- Supercharger and TurbochargerDocument11 pagesSupercharger and Turbocharger20bme094No ratings yet

- Kumaran 3Document4 pagesKumaran 3HANUMANT MORENo ratings yet

- Turbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDocument19 pagesTurbo Engine: Mechfest 06 A Technical Paper Presentation On " " Submitted byDeepak Satpathy0% (1)

- TurbochargingDocument7 pagesTurbochargingTsihatesfaNo ratings yet

- HowATurboWorks PDFDocument5 pagesHowATurboWorks PDFNikhil KanojiNo ratings yet

- Supercharging and TurbochargingDocument3 pagesSupercharging and Turbocharging13311A0341 S SHIVA SAI KIRANNo ratings yet

- The TurbochargerDocument19 pagesThe TurbochargerAbdallah MansourNo ratings yet

- AqwsredtDocument18 pagesAqwsredtwillisNo ratings yet

- Performance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol EngineDocument8 pagesPerformance Analysis and Fabrication On A Turbocharger in Two Stroke Single Cylinder Petrol Engineashan19800217No ratings yet

- Gujarat Technological University: L.D. College of Engineering AhmedabadDocument31 pagesGujarat Technological University: L.D. College of Engineering AhmedabadRaumil ManiarNo ratings yet

- Turbo ChargerDocument19 pagesTurbo ChargerHamimi AkmalNo ratings yet

- The Parts of SpeechDocument28 pagesThe Parts of SpeechMudassir HussainNo ratings yet

- Comfortable Viewing Distance For Text On Presentation VisualsDocument1 pageComfortable Viewing Distance For Text On Presentation VisualsMudassir HussainNo ratings yet

- KittredgeDocument26 pagesKittredgeMudassir HussainNo ratings yet

- The War From Afghanistan (1979-1989) in The Memory of Participants From The Republic of Moldova. Official and Oral SpeechDocument21 pagesThe War From Afghanistan (1979-1989) in The Memory of Participants From The Republic of Moldova. Official and Oral SpeechMudassir HussainNo ratings yet

- 8 Parts of SpeechDocument21 pages8 Parts of SpeechMudassir HussainNo ratings yet

- Ignition SysDocument23 pagesIgnition SysMudassir HussainNo ratings yet

- KittredgeDocument26 pagesKittredgeMudassir HussainNo ratings yet

- Parts of Speech: English - Grade 6Document10 pagesParts of Speech: English - Grade 6Luthfi CahyaNo ratings yet

- 8 Parts of SpeechDocument20 pages8 Parts of Speechnora tika100% (2)

- Assignment No 1 - Program SecurityDocument2 pagesAssignment No 1 - Program SecurityMudassir HussainNo ratings yet

- List of Practical of All Subjects HSSCDocument11 pagesList of Practical of All Subjects HSSCMudassir HussainNo ratings yet

- Genigraphics Poster Template 24x48eDocument1 pageGenigraphics Poster Template 24x48eMudassir HussainNo ratings yet

- Department of Pediatrics, Eastern Virginia Medical School, Norfolk, VADocument1 pageDepartment of Pediatrics, Eastern Virginia Medical School, Norfolk, VAMudassir HussainNo ratings yet

- Homework 151 A MainDocument22 pagesHomework 151 A MainMudassir HussainNo ratings yet

- Genigraphics Poster Template 44x44CDocument1 pageGenigraphics Poster Template 44x44CMudassir HussainNo ratings yet

- Request For Issue of Degree (Before Convocation) FConDocument1 pageRequest For Issue of Degree (Before Convocation) FConMudassir HussainNo ratings yet

- Test 1Document3 pagesTest 1Mudassir HussainNo ratings yet

- Test 2Document4 pagesTest 2Mudassir HussainNo ratings yet

- NUST Email Request FormDocument1 pageNUST Email Request FormMudassir HussainNo ratings yet

- Numerical+Analysis+Chapter+3 2Document12 pagesNumerical+Analysis+Chapter+3 2Mudassir HussainNo ratings yet

- Long QuestionsDocument2 pagesLong QuestionsMudassir Hussain100% (1)

- FAQ's ConductDocument8 pagesFAQ's ConductMudassir HussainNo ratings yet

- Top 10 Ssc-I 2015-ADocument1 pageTop 10 Ssc-I 2015-Akareem3456No ratings yet

- Request For Issue of Degree (Before Convocation) FConDocument1 pageRequest For Issue of Degree (Before Convocation) FConMudassir HussainNo ratings yet

- Geothermal Heat PumpDocument84 pagesGeothermal Heat PumpMudassir HussainNo ratings yet

- Techniques for Studying FossilsDocument11 pagesTechniques for Studying FossilsP. C. PandeyNo ratings yet

- Tyfo SDocument2 pagesTyfo SAndi AsNo ratings yet

- Meningitis & EncephalitisDocument7 pagesMeningitis & EncephalitisABAKADANo ratings yet

- Very Low Altitude Drag-Free Satellites: R D UpdatesDocument5 pagesVery Low Altitude Drag-Free Satellites: R D Updatesraa2010No ratings yet

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocument11 pagesDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanNo ratings yet

- Diagram "From-To" Pada Optimasi Tata Letak Berorientasi Proses (Process Layout)Document17 pagesDiagram "From-To" Pada Optimasi Tata Letak Berorientasi Proses (Process Layout)Febrian Satrio WicaksonoNo ratings yet

- Combustion Cat 2008Document32 pagesCombustion Cat 2008Miguel LinaresNo ratings yet

- Gante Iris PPT Pe p006Document20 pagesGante Iris PPT Pe p006Donna Ville GanteNo ratings yet

- UntitledDocument340 pagesUntitledFelipe Batista RetkeNo ratings yet

- Typhoon Ulysses Philippines Deadly StormDocument2 pagesTyphoon Ulysses Philippines Deadly Stormjai mansosNo ratings yet

- Hexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5Document22 pagesHexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5dudecastro1542No ratings yet

- 4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFDocument428 pages4thinternationalconferencetheimportanceofplace Proceedings 2017 PDFnerko86No ratings yet

- CLIC Catalogue PDFDocument28 pagesCLIC Catalogue PDFsangram patilNo ratings yet

- Nitocote WP DDocument4 pagesNitocote WP DdaragNo ratings yet

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 pagesKingspan Spectrum™: Premium Organic Coating SystemNikolaNo ratings yet

- BELL B40C - 872071-01 Section 2 EngineDocument38 pagesBELL B40C - 872071-01 Section 2 EngineALI AKBAR100% (1)

- AMYLOIDOSISDocument22 pagesAMYLOIDOSISMohan ChoudharyNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document9 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Schroedindiger Eqn and Applications3Document4 pagesSchroedindiger Eqn and Applications3kanchankonwarNo ratings yet

- Lesson 1 - Simple StressDocument5 pagesLesson 1 - Simple StressJohn Philip NadalNo ratings yet

- How Does Marijuana Affect The BrainDocument3 pagesHow Does Marijuana Affect The BrainWanNurAtikahNo ratings yet

- Deforestation Management System Using Force and SoundDocument4 pagesDeforestation Management System Using Force and SoundManeesh SvsNo ratings yet

- Datasheet Optris XI 410Document2 pagesDatasheet Optris XI 410davidaldamaNo ratings yet