Professional Documents

Culture Documents

Aluminum 1100 Information

Uploaded by

axatpgmeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum 1100 Information

Uploaded by

axatpgmeCopyright:

Available Formats

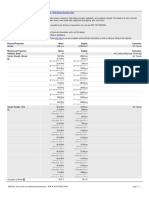

Aluminum 1100-0

Categories: Material Notes: Metal; Nonferrous Metal; Aluminum Alloy; 1000 Series Aluminum This is a common commercial grade sold when "aluminum" is specified. As with other unalloyed aluminum grades, it is used where the intrinsic formability and corrosion resistance of aluminum is needed while high strength is not. Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN. The aluminum content for unalloyed aluminum not made by a refining process is the difference between 100.00% and the sum of all other analyzed metallic elements present in amounts of 0.010% of more each, expressed to the second decimal before determining the sum. For alloys and unalloyed aluminum not made by refining process, when the specified maximum limit is 0.XX, an observed value or a calculated value greater than 0.005 but less than 0.010% is rounded off and shown as "less than 0.01%". Composition information provided by the Aluminum Association and is not for design. Aluminum 1100-O; UNS A91100; ISO AI99.0Cu; NF A45 (France); CSA 990C (Canada); AA1100-O Metric English Comments 2.71 g/cc 0.0979 lb. / in AA; Typical Metric English Comments 23 23 AA: Typical; 500 g. load; 10 mm ball. 89.6 MPa 13000 psi AA; Typical 34.5 MPa 5000 psi AA; Typical 35.00% 35.00% AA; Typical @ Thickness 1.59 mm @ Thickness .0625 mm 45.00% 45.00% AA; Typical @ Diameter 12.7 mm @ Diameter 0.500 mm AA; Typical: Average of tension and compression. 68.9GPa 10000 ksi Compression modulus is about 2% greater than tensile modulus. 90.0 MPa 131000 psi 2.5 cm width x 0.16 cm thick side-notched specimen, Kt = 17 159 MPa 23100 psi Edge distance/pin diameter = 2.0 55.0 Mpa 7980 psi Edge distance/pin diameter = 2.0 0.33 0.33 34.5 MPa 5000 psi Completely reversed stress; RR Moore machine/specimen @# of cycles 5.00e+8 @# of cycles 5.00e+8 10.00% 10.00% 0 - 100 Scale of Aluminum Alloys 26.0 GPa 3770 ksi Calculated 62.1 MPa 9000 psi AA; Typical Metric English Comments 0.00000299 ohm-cm 0.00000299 ohm-cm AA; Typical @ Temperature 20.0 C @ Temperature 68.0 F Metric English Comments 390 J/g 168 BTU/lb 23.6 m/m-C 13.1 in/in-F AA; Typical; @Temp 20.0 -100 C @ Temp 68.0 - 212 F 25.5 m/m-C @Temp 20.0 - 300 C 0.904 J/g-C 222W/m-K 643 - 657.2 C 643 C 657.2C Metric 343 C Metric >= 99.0 % <= 0.000800 % 0.050 - 0.20 % <= 0.050 % <= 0.050 % <= 0.15 % <= 0.95 % <= 0.10 % 650 F English >= 99.0 % <= 0.000800 % 0.050 - 0.20 % <= 0.050 % <= 0.050 % <= 0.15 % <= 0.95 % <= 0.10 % Comments Welding Electrode and filler wire only. 14.2 in/in-F @ Temp 68.0 - 572 F 0.216 BTU /lb-F 1540 BTU-in/hr-ft-F 1190 - 1215 F 1190F 1215 F English Average AA; Typical at 77F AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. AA; Typical AA; Typical Comments

Composition Notes:

Key Words: Physical Properties Density Mechanical Properties Hardness, Brinell Ultimate Tensile Strength Tensile Yield Strength Elongation at Break

Modulus of Elasticity Notched Tensile Strength Ultimate Bearing Strength Bearing Yield Strngth Poissons Ratio Fatigue Strength Machinability Shear Modulus Shear Strength Electrical Properties Electrical Resistivity Thermal Properties Heat of Fusion

CTE, linear

Specific Heat Capacity Thermal Conductivity Melting Point Solidus Liquidus Processing Properties Annealing Temperature Material Components Properties Aluminum, Al Beryllium, Be Copper, Cu Manganese, Mn Other, each Other, total Si+Fe Zinc, Zn

INFORMATION TO BE USED AS A GUIDE ONLY.

Copyright 2010 HM Wire International, Inc.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Aluminio 2024-T3Document2 pagesAluminio 2024-T3IbsonhNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 6061 Vs 6063Document9 pages6061 Vs 6063SrRonNo ratings yet

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- Aluminum 6061-O: To View All Available Suppliers For This MaterialDocument2 pagesAluminum 6061-O: To View All Available Suppliers For This MaterialAlonso ReynaNo ratings yet

- Aluminum 6063Document2 pagesAluminum 6063Laurence SarmientoNo ratings yet

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudNo ratings yet

- Aluminum 6061Document3 pagesAluminum 6061Ali FahemNo ratings yet

- Al 7075 T651Document2 pagesAl 7075 T651Michael HarrellNo ratings yet

- Aluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg AlloyDocument3 pagesAluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg Alloyvishwanadh kNo ratings yet

- 7050Document1 page7050yasvanth_m1493No ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetShankar PranavNo ratings yet

- ASM Material Data SheetDocument3 pagesASM Material Data SheetMadhu MithaNo ratings yet

- Aluminum 6061 Data SheetDocument2 pagesAluminum 6061 Data SheetASHOK100% (1)

- Aluminum 2024-T4-2024-T351Document3 pagesAluminum 2024-T4-2024-T351Raj EklureNo ratings yet

- Aluminum 1050-H14 PropertiesDocument2 pagesAluminum 1050-H14 PropertiesCarlos Andres Garcia MuñozNo ratings yet

- Aluminio 6061-T6 6061-T651Document2 pagesAluminio 6061-T6 6061-T651leroniusNo ratings yet

- ASM Material Data Sheet (Aluminium Beam)Document2 pagesASM Material Data Sheet (Aluminium Beam)Mohammed AdnanNo ratings yet

- Aluminium 7075 t6 7075 t651Document3 pagesAluminium 7075 t6 7075 t651VassiliNikolaiWolnitzkyElguetaNo ratings yet

- Aluminio 3105 H16Document2 pagesAluminio 3105 H16Cesar Zarate100% (1)

- Aluminum 6351-T6, Aluminium DatasheetDocument2 pagesAluminum 6351-T6, Aluminium DatasheetvikrantNo ratings yet

- Aluminum 5052Document6 pagesAluminum 5052lalfredoperezNo ratings yet

- Aluminum 5052Document3 pagesAluminum 5052Luis EstevesNo ratings yet

- Aluminum 5052 H38Document2 pagesAluminum 5052 H38Vishal VaishnavNo ratings yet

- Aluminum 6061Document3 pagesAluminum 6061Achmad Rizal MustaqimNo ratings yet

- 7178-T6511 Property - ASM Material Data SheetDocument2 pages7178-T6511 Property - ASM Material Data SheetptrfmNo ratings yet

- ASM Material Data SheetDocument3 pagesASM Material Data SheetrenjithaeroNo ratings yet

- Aluminum 2024 PropertiesDocument3 pagesAluminum 2024 Propertiesbotan_mihaiNo ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- Data Sheet Aluminium 6061 t6 Group (H)Document7 pagesData Sheet Aluminium 6061 t6 Group (H)احمد نعيمNo ratings yet

- Aisi 1030 SteelDocument2 pagesAisi 1030 SteelKhairul KaiNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Alluminium SheetsDocument7 pagesAlluminium SheetsVaibhav ShuklaNo ratings yet

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANNo ratings yet

- AMS 4640 - MatwebDocument1 pageAMS 4640 - Matwebanil610No ratings yet

- Aluminum 1060-O alloy data sheetDocument2 pagesAluminum 1060-O alloy data sheetMaruda8382No ratings yet

- MaterialData 11240 PDFDocument1 pageMaterialData 11240 PDFPengelana KehidupanNo ratings yet

- Aluminum 6082-T4: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument1 pageAluminum 6082-T4: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloydeepscubNo ratings yet

- CuAg0,1P PDFDocument8 pagesCuAg0,1P PDFirajfarji2481No ratings yet

- Aluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum AlloyDocument3 pagesAluminum 5052-O: Metal Nonferrous Metal Aluminum Alloy 5000 Series Aluminum Alloyrezaeibehrouz100% (1)

- Aluminum 7075 SpecsDocument3 pagesAluminum 7075 SpecsZakaria MuhammadNo ratings yet

- Aluminum 2024-O Data SheetDocument2 pagesAluminum 2024-O Data SheetAnonymous mq0U43UsPNo ratings yet

- Astm A228Document2 pagesAstm A228Rakesh S IndiaNo ratings yet

- Alumina 6061 T6Document1 pageAlumina 6061 T6Imdadul MilonNo ratings yet

- Astm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Document1 pageAstm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Federico RevelloNo ratings yet

- Aluminum6061DataSheet PDFDocument2 pagesAluminum6061DataSheet PDFhardik033No ratings yet

- P 9000Document6 pagesP 9000Jeff Gomez PerezNo ratings yet

- SAE1018Document1 pageSAE1018arunas1081No ratings yet

- Aluminum 6063Document1 pageAluminum 6063이영준No ratings yet

- 6061 T6 MaterialDocument2 pages6061 T6 Materialtravis8zimmermannNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- MCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080Document13 pagesMCF 0.5W 1M MCF 0.5W 470K MCF 0.5W 820R MCF 1W 1R5 MCF 1W 330K MCF 1W 33K MCF 1W 680K MCF 1W 68K MCF 1W 68R MCF 2W 150K MCF 2W 470K MCF 2W 680K 287-11040 287-11050 287-11080willian GaldinoNo ratings yet

- Tabela ResistoreDocument13 pagesTabela Resistorewillian GaldinoNo ratings yet

- 316L SS CrucibleDocument2 pages316L SS CrucibleARUNKANNANNo ratings yet

- Sae 5160 VBDocument2 pagesSae 5160 VBBarron ValentinNo ratings yet

- MIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsDocument11 pagesMIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsgamillosNo ratings yet

- Zamak 5Document1 pageZamak 5san moedanoNo ratings yet

- Imtm Turbine Meters 2" - 16" For Custody Transfer: High LightsDocument6 pagesImtm Turbine Meters 2" - 16" For Custody Transfer: High LightsaliNo ratings yet

- FEA-Academy Course On-Demand - Practical Basic FEADocument35 pagesFEA-Academy Course On-Demand - Practical Basic FEAaxatpgmeNo ratings yet

- Solar Power Primer - Panel QtiltDocument2 pagesSolar Power Primer - Panel QtiltaxatpgmeNo ratings yet

- Employee List RevisedDocument39 pagesEmployee List RevisedaxatpgmeNo ratings yet

- Post Crimp Assembly : Dynalloy, IncDocument1 pagePost Crimp Assembly : Dynalloy, IncaxatpgmeNo ratings yet

- 7th Sem ME Backlog ListDocument6 pages7th Sem ME Backlog ListaxatpgmeNo ratings yet

- Test Checklist For Dark RoomDocument1 pageTest Checklist For Dark RoomaxatpgmeNo ratings yet

- Eula 1033Document2 pagesEula 1033Taurus_PereaNo ratings yet

- SatgrhygsdrDocument1 pageSatgrhygsdraxatpgmeNo ratings yet

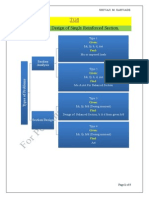

- Result V: No Series Connection Paralle Connection 10 VAB VBC VAC VPN VAC 2.24 2.24 4.48 Vac Vab +VBC 4.23 4.23Document2 pagesResult V: No Series Connection Paralle Connection 10 VAB VBC VAC VPN VAC 2.24 2.24 4.48 Vac Vab +VBC 4.23 4.23axatpgmeNo ratings yet

- Nptel Copying Course ListDocument33 pagesNptel Copying Course ListaxatpgmeNo ratings yet

- Requiring This Telescope For The Student Project Perpose - Axatpatel - Me@ecchanga - AcDocument1 pageRequiring This Telescope For The Student Project Perpose - Axatpatel - Me@ecchanga - AcaxatpgmeNo ratings yet

- 7th BE ME-1 Attendance - Odd Sem 2013-2014Document132 pages7th BE ME-1 Attendance - Odd Sem 2013-2014axatpgmeNo ratings yet

- Celestron 8 - Schmidt-Cassegrain OTA With CGE Mount Plate - All Telescopes - Telescopes - OPT TelescopesDocument1 pageCelestron 8 - Schmidt-Cassegrain OTA With CGE Mount Plate - All Telescopes - Telescopes - OPT TelescopesaxatpgmeNo ratings yet

- Computer Desk Dimensions GuideDocument1 pageComputer Desk Dimensions GuideaxatpgmeNo ratings yet

- Phone NumbersDocument2 pagesPhone NumbersaxatpgmeNo ratings yet

- Odd Sem Acedemic Calender 2013 - 14Document1 pageOdd Sem Acedemic Calender 2013 - 14axatpgmeNo ratings yet

- Journal Impact FactorDocument1 pageJournal Impact FactoraxatpgmeNo ratings yet

- 1st Sem CLDocument3 pages1st Sem CLaxatpgmeNo ratings yet

- New Consolated Time Table - 14!6!13Document9 pagesNew Consolated Time Table - 14!6!13axatpgmeNo ratings yet

- SyallabusDocument4 pagesSyallabusaxatpgmeNo ratings yet

- Ed DiplomaDocument5 pagesEd Diplomahari1008108No ratings yet

- Sno STN Code STN Name Route No. Arrival Time Dep. Time Halt Time (In Minutes) Distance Day RemarkDocument1 pageSno STN Code STN Name Route No. Arrival Time Dep. Time Halt Time (In Minutes) Distance Day RemarkaxatpgmeNo ratings yet

- M Tech 2012 Charusat Acedemic CalenderDocument1 pageM Tech 2012 Charusat Acedemic CalenderKedar PatilNo ratings yet

- SyallabusDocument4 pagesSyallabusaxatpgmeNo ratings yet

- ME322 Module 6iDocument43 pagesME322 Module 6iaxatpgmeNo ratings yet

- IIT Kanpur's Technical Details of Jugnu Nanosatellite MissionDocument5 pagesIIT Kanpur's Technical Details of Jugnu Nanosatellite MissionaxatpgmeNo ratings yet

- Control EngineeringDocument1 pageControl Engineeringaxatpgme100% (1)

- Control EngineeringDocument1 pageControl Engineeringaxatpgme100% (1)

- Control EngineeringDocument1 pageControl Engineeringaxatpgme100% (1)

- Guide To Understanding Your Form-16Document3 pagesGuide To Understanding Your Form-16axatpgmeNo ratings yet

- KIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITDocument2 pagesKIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITSorinNo ratings yet

- Lecture2 Semiconductor StatisticsDocument13 pagesLecture2 Semiconductor StatisticsRakib KhanNo ratings yet

- Levee Drain Analysis in SlideDocument12 pagesLevee Drain Analysis in SlideAdriRGNo ratings yet

- Mcqs Preparation For Engineering Competitive ExamsDocument17 pagesMcqs Preparation For Engineering Competitive Examsabhishek sethiNo ratings yet

- Modeling of Synchronous Generators in Power System Studies: October 2016Document12 pagesModeling of Synchronous Generators in Power System Studies: October 2016aswardiNo ratings yet

- Determination of The Diffraction Intensity at Slit and Double Slit SystemsDocument5 pagesDetermination of The Diffraction Intensity at Slit and Double Slit SystemsJose Galvan100% (1)

- Motion of Particles in FluidDocument26 pagesMotion of Particles in FluidSubakti HungNo ratings yet

- Linear Stationary ModelsDocument16 pagesLinear Stationary ModelsKaled AbodeNo ratings yet

- Design Procedure of Centrifugal CompressorsDocument16 pagesDesign Procedure of Centrifugal CompressorsSrujana KandagatlaNo ratings yet

- Sherman Notes PDFDocument213 pagesSherman Notes PDFAbdul Hamid Bhatti100% (1)

- 0901d1968065f1f4 Bearing Preload - TCM - 12 299896Document7 pages0901d1968065f1f4 Bearing Preload - TCM - 12 299896anush_swaminathanNo ratings yet

- 12 Class Physics 1-Chapter Sample Paper PDFDocument9 pages12 Class Physics 1-Chapter Sample Paper PDFharshNo ratings yet

- Four Decades of Research On Thermal Contact, Gap, and Joint Resistance in MicroelectronicsDocument25 pagesFour Decades of Research On Thermal Contact, Gap, and Joint Resistance in MicroelectronicsDaniel MendesNo ratings yet

- Introduction To XAFSDocument270 pagesIntroduction To XAFSEric William CochranNo ratings yet

- Design Guide Handbook For EN 1996 Design of Masonry StructuresDocument46 pagesDesign Guide Handbook For EN 1996 Design of Masonry Structuresbusyspider100% (1)

- Electrical Conductivity of Carbon Blacks Under CompressionDocument7 pagesElectrical Conductivity of Carbon Blacks Under CompressionМирослав Кузишин100% (1)

- LNG SamplingSystemDocument2 pagesLNG SamplingSystemGuillermo Lopez-FloresNo ratings yet

- A Simple Lamina Flow Engine PDFDocument2 pagesA Simple Lamina Flow Engine PDFSelva KumarNo ratings yet

- Notes Singly RF BeamDocument5 pagesNotes Singly RF Beamshivaji_sarvadeNo ratings yet

- Abaqus Analysis User's Manual, 32.15 (User Elements)Document22 pagesAbaqus Analysis User's Manual, 32.15 (User Elements)Elias BuNo ratings yet

- Geometric TolerancesDocument6 pagesGeometric Tolerancesvaibhavgitevaibhav_9No ratings yet

- 2 4228Document13 pages2 4228Huneza AtaNo ratings yet

- Direct Determination of The Flow Curves of NoDocument4 pagesDirect Determination of The Flow Curves of NoZaid HadiNo ratings yet

- Human at Mars PDFDocument55 pagesHuman at Mars PDFVuningoma BoscoNo ratings yet

- The Chronology Protection ConjectureDocument4 pagesThe Chronology Protection ConjectureKrisNo ratings yet

- Filtration of WaterDocument32 pagesFiltration of WaterYusuf Rahmat SidikNo ratings yet

- How Does DCPIP WorkDocument3 pagesHow Does DCPIP WorkIsaac LeeNo ratings yet

- Chapter 6. ThermodynamicsDocument7 pagesChapter 6. Thermodynamicshoney1002No ratings yet

- M04 TemperatureDocument64 pagesM04 TemperatureLê Văn TrườngNo ratings yet

- Ewald SphereDocument57 pagesEwald SphereMohammad Rameez0% (1)