Professional Documents

Culture Documents

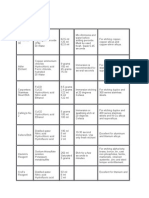

Stainless steel corrosion resistance technical table

Uploaded by

Thitipong RukkhotOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless steel corrosion resistance technical table

Uploaded by

Thitipong RukkhotCopyright:

Available Formats

dacapo

Technical information

stainless

Corrosion resistance table

Stainless steels can be susceptible to certain localised corrosion mechanisms,

namely crevice corrosion, pitting, intercrystalline corrosion, stress corrosion cracking and bimetallic (galvanic)

corrosion. Localised corrosion is often associated with chloride ions in aqueous environments.

Corrosion resistance relies on a good supply of oxygen. Higher levels of chromium, nickel, molybdenum and

nitrogen increase resistance to localised corrosion.

The corrosion table is not a exact reproduction of reality, it is a first determination.

The criterion for corrosion in the case of general corrosion is expressed as weight loss

by unit of time and surface area, for example grammes by square meter and per hour, or loss

of thickness per unit of time, for example mm per year.

The loss of weight by unit of time and surface area is commonly used for laboratory tests,

the loss of thickness per unit of time is commonly used in practice.

The general accepted practical limit within a material is considered corrosion resistant, is 0.1mm per year.

Note! Remember that corrosion is a complicated issue, depending on the combinations of materials and the fluids,

the fluid temperatures, the surrounding environment and the galvanic currents in the constructions.

The corrosion table must be used with care.

Conversion Factors

Composed entity

Coversion factors

g/m h

g/m/h

mm / year

mills / year

1.0

8,64: s.g.

340: s.g.

g/m/24h

0.042

0,360: s.g.

14,2: s.g.

g/dm/24h

4.17

36,0: s.g.

1420: s.g.

mg/dm/24h

0.004

0,036: s.g.

1,42: s.g.

mg/cm/24h

0.417

3,60: s.g.

142: s.g.

lbs/ft/24h

203

1760: s.g.

69200: s.g.

lbs/ft/year

0.564

4,88: s.g.

192: s.g.

- 18.01 -

dacapo

Technical information

stainless

Corrosion resistance table

Corrosion criteria

Conversion factors

Combined unit

mm/year

mm/year

mills/year

0,116 x s.g.

1.0

1,39 x s.g.

12

479

20,80 x s.g.

180

7185

tum/year (ipy)

2,95 x s.g.

25.4

100.00

tum/month (imp)

35,3 x s.g.

305

12000

mills/year (mpy)

0,003 x s.g.

0.025

1.0

mills/month (mpm)

0,035 x s.g.

0.305

12

mm/month

mm/48h

s.g. =

g/m h

39.4

Specific gravity

mills (thousandth of an inch) per year penetration

Corrosion criteria based on laboratory tests are commonly expressed in grams per square meter per hour.

For all metals this entity correspondents with approximately mm/per year (1 g/mh = 1,1 mm/year)

beacause the specific gravity (7.7 to 8.1) for all metal is similar.

Titanium has a specific gravity of 4.5 the entity is 1g/mh =1,9 mm year.

Specific gravity stainless steels and other metals

Combined unit

W.N

Specific gravity

13 Cr

1.4000

7.7

17 Cr

1.4016

7.7

18 Cr - 2 Mo

1.4521

7.7

25 - 5 - 1,5 Mo

1.4460

7.7

18 - 9

1.4301, 1.4306, 1.4311, 1.4541

7.9

17 - 12 - 2,5 Mo

1.4401, 1.4404, 1.4571, 1.4436,

8.0

1.4435, 1.4429, 1.4438

18 - 14 - 3,5 Mo

17 - 15 - 4,5 Mo

20 - 25 4,5 Mo - 1,5 Cu

1.4438

8.0

8.0

1.4539

8.1

Carbon steel

7.8

Titanium

4.5

- 18.02 -

dacapo

Technical information

stainless

Corrosion resistance table

In the table on the next pages the following symbols are used meaning:

0

Corrosion rate less than 0.1 mm/year.

The material is corrosion proof.

Corrosion rate 0.1 - 1.0 mm/year.

The material is not corrosion proof, but useful in certain cases.

Corrosion rate over 1.0 mm/year.

Serious corrosion. The material is not usable.

Risk (Severe risk) of pitting and crevice corrosion.

Risk (Severe risk) of stress corrosion cracking.

Boiling solution.

All concentrations are in the percentage weight loss, the solvent is water unless differently indicated.

The information applies for annealed materials with a normal structure and a surface that is clean.

- 18.03 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Chemical

formula

Concentration

Temp.

C

304

cr 18

ni 9

316

cr 17

ni 12

mo 2,5

Acetone

(CH3)2CO

20-K

Acetylchloride

CH3COCI

100% dry

wet

1

P1S

0

P0S

2.5%

90

2.5%

5.5%

5.5%

20-90

K

0

1

0

1

10%

20

10%

50

10%

80

10%

15%

50

15%

saturated

700

saturated

5%

50

0

P0S

0

P0S

Alum

KAL(SO4)2

Aluminium acetate

AL

Al (OOCCH3)3

Aluminiumchloride

ALCL3

Aluminium melted

5%

100

P2S

P2S

10%

100

10%

150

20%

100

20%

150

25%

20

25%

60

27.5%

110

Aluminium nitrate

AL(NO3)3

all conc.

20

Aluminium sulphate

AL2(SO4)3

0.50%

50

1%

20

2.30%

101=K

5%

101=K

10%

20

10%

50

10%

102=K

23%

20

23%

100

27%

20

27%

102=K

saturated by 20C

105=K

Ammonium

NH4OH

all conc.

20-K

Ammonium bifluoride

NH4HF2

10%

25

Ammonium bicarbonate

(NH4)HCO3

all conc.

20

- 18.04 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Ammonium chloride

Ammonium carbonate

Chemical

formula

NH4CL

(NH4)2CO3H2O

Concentration

Temp.

C

304

cr 18

ni 9

316

cr 17

ni 12

mo 2,5

1%

20

P0

P0

1%

100

P0S

P0S

P0S

5%

P0S

10%

20-50

P0

P0

10%

90-100

P0S

P0S

10%

10%

K

135

P1S

P1S

P0S

P0S

20%

20-50

P0

P0

20%

90

P1S

P0S

20%

P1S

P1S

50%

115

P2S

P1S

all conc.

20

100

Ammonium nitrate

NH4NO3 + (NH4)2SO4

100

60

100

120

Ammonium oxalate

in elke verhouding

(NH4)2C2O4

1-8%

20

5-20%

100

10%

20

10%

20%

30

10%

0

P0S

0

P0S

Ammoniumperchlorate

NH4CIO4

20%

30

P0

P0

Ammonium sulfphate

(NH4)2SO4

all conc.

20-K

Ammonium sulphite

(NH4)2SO3

saturated

20-K

Aniline unrefined

C6H5NH2

100%

20

Aniline hydrochloride

C6H5NH2HCI

all conc.

20

0

P2

0

P2

5%

100

P2S

P2S

Anitimonium, melted

Sb

CH3COOH

650

1%

90

1%

100K

5%

20

5%

50

5%

75

5%

100=K

10%

20

10%

75

10%

100=K

20%

20

20%

80

20%

90

Acetic acid

-18.05 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Acetic acid

Bariumchloride

Chemical

formula

CH3COOH

BaCI22H20

Temp.

C

20%

100=K

50%

20

50%

80

50%

90

50%

100

80%

80%

20

40

0

0

0

0

Na2B4O710H2O

cr 18

ni 9

85

200

100%

20

100%

80

100%

100

6%

100

1

P0S

0

P0S

P0S

100

P0S

melted

20-K

20-K

all conc.

20-K

0

P0

melted

melted

Blood

20

37

Boric acid

Bromine moist

B(OH)3

Br2

Aqueous solution of bromine

Butryic acid

Calciumbisulphite

C3H7COOH

Ca(HSO3)2

Calciumchloride

CaCI26H2O

Calciumhypochloride

Ca(CIO)2

316

80%

Beer yeast

Borax: in solution

304

99.5%

23%

Petrol

cr 17

ni 12

mo 2,5

Concentration

all conc.

100%

20

0.03%

20

2

P0

2

P0

0.30%

20

P1

P0

100%

20

100%

10%

20

10%

cold saturated

1%

20

P1

P0

2%

100

P1S

P1S

6%

20

P1

P1

6%

100

P2S

P1S

Calcium sulphate

CaSO4

all conc.

100

Chloride

CL2

dry gas

70

0

P2

P2S

100%

20-60

0

P2

moist gas

60-100

P2S

- 18.06 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Chlorobezene

Chemical

formula

C6H5CI

Concentration

Temp.

C

Chloride of lime ,dry

CH2CICOOH

CaOCI2

moist

Chloroform

Sulpher chloride

Chloric acid

Hydrogen chloride, gas

CHCI3

S2CI2

HCIO3

HCI

CrO3

316

cr 17

ni 12

mo 2,5

100%

20%

132-K

0

P0S

0

P0S

30%

80

50%

20

100%

100%

100

100

2

2

2

2

0.8%

20

P1

1%

20%

35

30%

20

all conc.

P0

P0S

P0

20

1

P0

1

P0

P0S

P0S

dry 100%

62=K

dry 100%

20

dry 100%

136=K

nat

20

0

P1

0

P1

10%

20

100%

20

P2

P2

dry

20-40

100

250

1

2

dry

Chromic acid

pure, H2SO4 free

cr 18

ni 9

100%

with moisture

Chloroacetic Acid (mono)

304

400-500

2%

75

2%

100=K

5%

80

5%

100=K

10%

40

10%

20%

20

20%

50

20%

40%

20

40%

40

50%

20

- 18.07 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Citric acid

Hydrocyanic acid

Dichloroethylene

Chemical

formula

C3H4(OH)(COOH)3

HCN

C2H2CI2

cr 17

ni 12

mo 2,5

Concentration

Temp.

C

1%

20

1%

5%

20-50

5%

85-K

5%

140

10%

10%

20-40

85-K

0

0

0

0

25%

20

25%

40

25%

85

25%

100

25%

50%

20

50%

40

50%

100

50%

70%

100%

20

100%

20-K

0

P0S

0

P0S

wet

304

cr 18

ni 9

316

Ethyl chloride

C2H5CI

wet

20-K

0

P0S

0

P0S

Ethyl alcohol

C2H5OH

all conc.

20-K

Ethyl ether

(C2H5)2O

20-K

Ethyl chloride

C2H4CI2

100%

20-K

Hyposulphite

Na2S2O3+K2S2O4

40%, 2,5%

20

0

P0

Hyposulphite +

Na2S2O3+Na2SO3

19%, 4,7%

20

P0

Sulphuric acid

+H2SO4

Hydrogen fluoride

HF

Formaldehyde

Galic acid

HCHO

C6H2(OH)3COOH

-0.50%

1%

20

10%

20

75%

20

100%

20

all conc.

20-K

op 100C

all conc.

20

conc. 25%

saturated

Glycerine

C3H5(OH)3

- 18.08 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Iodine, dry

Chemical

formula

I2

moist

Concentration

Temp.

C

304

cr 18

ni 9

316

cr 17

ni 12

mo 2,5

dry

20

moist

20

0

P2

0

P2

water solution 1%

20

P0

P0

+ 1% KI

20

P0

P0

crystal

damp

20

50

P0

P0

P0

P0

20%

90

25%

20

25%

all conc.

20

P0

P0

7-10%

50

10%

100

36%

PS

PS

water solution 2%

Idioform, liquefied

vaporous

CHI3

Potassium dichromate

K2Cr2O7

Potassium bifluoride

KHF2

Potassium bitartrate

KH(OOC(OH)CH)2

cold saturated

saturated

bij 100C

Potassium bromide

Potassium chlorate

KBr

KCIO3

met CI

Potassium chlorate

KCIO3

Potassium cyanide

KCNO

Potassium cyanide

KCN

all conc.

all conc.

20

K

Potassium ferricyanide

Potassium hydroxide

Potassium hypochlorite

K3(Fe(CN)6)

KOH

KCIO

until 20 g as cl/liter

all conc.

20

10%

20%

20

25%

50%

20

50%

0

1S

1S

70%

120

1S

1S

melted

300-365

2S

2S

<2%

20

P1

P0

>20%

20

P2

P1

P0

Kaliumjodide

KI

all conc.

P0

Potassium carbonate

K2CO3

all conc.

900-1000

Potassium nitrate

Potassium oxalate

KNO3

all conc.

(C OOK)2 x H2O

- 18.09 -

20-K

550

780

20

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Potassium permanganate

Chemical

formula

KMnO4

Potassium sulphate

K2SO4

Silicic acid

HF

Nitrohydrochloric acid

HCI+HNO3

Copper acetate

Cu(CH3COO)2

Copper chloride

CuCI2

Copper cyanide

Cu(CN)2

cr 17

ni 12

mo 2,5

Concentration

Temp.

C

5-10%

20

10%

all conc.

1%

20

304

cr 18

ni 9

316

10%

20

75%

100%

30

20

2

1

2

1

all conc.

0.05%

100=K

0

P0

0

P0

saturated

at 100C

Copper nitrate

Cu(NO3)2

all conc.

20-K

Copper sulphate

CuSO4

all conc.

20-K

Kwik

Hg

HgCI2

20-400

0.1%

20

0

P1

0

P0

0.1%

P1S

P0S

0.7%

20

P1

P0

0.7%

P2S

P2S

1-10%

100

1-10%

135

0

Mercuric chloride

Mercuric cyanide

Hg(CN)2

5%

20

Mercuric nitrate

Hg(NO3)2

5%

20

Lead, melted

Pb

melted

400

900

Lead acetate

(CH3COO)2Pb3H2O

all

20-90

concentrations

Lead acetate, basic

Pb(CH3COO)2

Pb(OH)2

Lead nitrate

Pb(NO3)2

Lysol

Manganese chloride

MgCI2

Manganese sulphate

MgSO4

all conc.

2%

20

conc.

20-K

2.50%

20

0

P0

0

P0

5%

P0S

P0S

5%

20

5%

60

10%

20

10%

60

20%

20%

26%

- 18.10 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Mangaan chloruur

Manganese sulphate

Chemical

formula

MnCI2

MnSO4

Concentration

Temp.

C

304

cr 18

ni 9

316

cr 17

ni 12

mo 2,5

5%

100

P0S

P0S

10%

P0S

P0S

10%

135

P0S

P0S

20%

100

P1S

P0S

50%

P1S

P0S

alle conc.

23%

20

K

0

0

0

0

0

Methyl alcohol

CH3OH

100%

65-K

Methyl chloride

CH3CI

droog 100%

20

Fresh

20

sour

20

10-50%

2

P0

Milk

Lactic acid + sulphuric acid

(C2H4COH)COOH

+ H2SO4

25%

20

P0

Sodium carbonate

NaHCO3

all conc.

20-100

Sodium bisulphate

NaHSO4

1%

85

2%

20

2%

85

4%

20

4%

5%

20

5%

85

10%

20

10%

50

10%

15%

85

20

Mustard

Sodium bisulphate

NaHSO3

10%

10%

Natriumchloraat

NaCIO3

10-20%

30%

20

30%

5-10%

20-100

10%

20

Sodium fluoride

NaF

Sodium hydorxyde

NaOH

10%

90

10%

103=K

20%

20

20%

90

25%

20

25%

112=K

30%

20

- 18.11 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Sodium hydorxyde

Sodium hypochlorite

Sodium carbonate

Chemical

formula

NaOH

NaCIO

Na2CO3

Concentration

Temp.

C

304

cr 18

ni 9

316

cr 17

ni 12

mo 2,5

30%

100

30%

116=K

1S

0S

40%

80

40%

90

40%

100

40%

50%

128=K

60

1S

1S

50%

90

50%

100

50%

120

50%

140=K

1

1S

1S

60%

90

60%

120

60%

160=K

1

2S

2S

70%

90

70%

130

70%

180=K

1

2S

2S

90%

300

2S

1S

melted

320

2S

2S

5%

20

P1

P1

5%

P1S

P1S

all conc.

20-K

melted

900

sodium nitrate

NaNO3

all conc.

20-K

melted

360

Sodium nitrite

NaNO2

alle conc.

Sodium perchlotae

NaCIO4

10%

Sodium phosphate

Na3PO4

all conc.

Sodium sulphate

NaSO4

all conc.

20

Sodium sulphade

NaSS

Sodium sulphite

Sdodium thiosulphate

Na2SO3

Na2S2O3

Nickel chloride

NiCI2

Nickel nitrate

Ni(NO3)2

Nickel sulphate

NiSO4

5%

10%

20

10-50%

50%

20

50%

50%

20

50%

10%

20

0

P0

0

P0

10%

100

P0S

P0S

5-10%

all conc.

Mineral oil

- 18.12 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Chemical

formula

Temp.

C

K

10%

25

10%

50

10%

60

10%

10%

80

101=K

2

2

1

1

25%

60

25%

75

25%

103=K

40%

75

20-100

0

0

Oil (spice oil)

Oxalic acid

Paraffin, melted

Petrol

Phenol

Phosphoric acid

C6H5OH

H3PO4

cr 17

ni 12

mo 2,5

Concentration

304

cr 18

ni 9

316

20-K

all conc.

20-50

70-100%

1%

20

1%

100=K

1%

140

3%

100=K

5%

20-60

5%

85

5%

100=K

10%

40

10%

60

10%

80

10%

101=K

20%

35

20%

60

20%

102=K

30%

20-35

30%

60

30%

100

40%

35

40%

50

40%

100

40%

106=K

50%

20

50%

35

50%

50

50%

85

50%

100

- 18.13 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Phosphoric acid

Phosphorus pentoxide

Chemical

formula

H3PO4

P2O5

dry and moist

Nitric acid

HNO3

cr 17

ni 12

mo 2,5

Concentration

Temp.

C

50%

110=K

60%

20

60%

35

60%

100

60%

116=K

70%

70%

35

90

0

2

0

1

70%

126=K

80%

20

80%

35

80%

80

80%

100

80%

146=K

85%

20

85%

50

85%

95

85%

156=K

droog

20

304

cr 18

ni 9

316

vochtig

20

alle conc.

20

0.5%

250

1%

20

1%

50

1%

100=K

5%

20

5%

50

5%

100=K

5%

150

5%

290

10%

20

10%

50

10%

101=K

10%

145

20%

20

20%

50

20%

103=K

20%

120

30%

20

30%

70

30%

106=K

- 18.14 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Nitric acid

Chemical

formula

HNO3

Nitrous acid

HNO2

Tin, melted

Sn

cr 17

ni 12

mo 2,5

Concentration

Temp.

C

30%

120

50%

20

50%

70

50%

90

50%

110

50%

60%

117=K

20

1

0

1

0

60%

60

60%

100

60%

121=K

65%

20

65%

60

65%

70

65%

90

65%

121=K

65%

175

80%

20

80%

50

80%

80

80%

106=K

90%

20

90%

80

90%

94=K

94%

30

97%

25

99%

25

99%

40

99%

84=K

all conc.

20

melted

300

400

500-700

20

2

P2

2

P1

304

cr 18

ni 9

316

350

Stannous (II) chloride

SnCl2

5-24%

18-24%

P2

P2

Toluene

C6H5CH3

100%

Trichloroethylene

C2HCl3

100%

20

0-60

P0

P0

180

(technical grade)

Urine

Urea

CO(NH2)2

- 18.15 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Chemical

formula

Concentration

Temp.

C

304

cr 18

ni 9

316

cr 17

ni 12

mo 2,5

Fatty acid, oil acid

100%

20

Stearic acid

100%

80-130

100%

150

100%

180

100%

235

100%

1-2%

300

50

2

0

0

0

5%

20

5%

40-50

10%

23

10%

40

10%

60-80

15%

22

15%

30-40

15%

50-80

30%

27

30%

40-80

50%

40

4-5%

20

1%

90

1%

100=K

20%

70

20%

100

30%

60

30%

90

30%

102=K

50%

50

50%

70

50%

90

50%

106=K

60%

80

60%

100

70%

114=K

75%

100

Hydrogen peroxide

H2O2

Fruit juices, Wines

Wine vinagar

Tataric acid

Iron (III) chloride

C2H2(OH)2(COOH)2

75%

118=K

FeCI3

0,5-50%

20-100

2

P2

1

P2

Fe(NO3)3

all conc.

20

Fe2(SO4)3

10%

20-K

all conc.

(ferric chloride)

Iron (III) nitrate

(ferric nitrate)

Iron (III) sulphate

(ferric sulphate)

Xylene

C6H4(CH3)2

- 18.16 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Silver nitrate

Hydrochloric acid

Sulpher

Sulpher chloride

Chemical

formula

AgNO3

HCI

S2CI2

cr 17

ni 12

mo 2,5

Concentration

Temp.

C

all conc.

20-K

melted

250

0.1%

20-50

0

P1

0

P0

304

cr 18

ni 9

316

0.1%

100=K

P1S

P0S

0.2%

20

P1

P0

0.2%

0.2%

50

130

P1

P0

0.5%

20

P1

P0

0.5%

50

P1

P0

0.5%

100=K

1%

20

2

P1

2

P0

1%

50

P1

1%

60

1%

80

1%

100=K

2%

20

2

P1

2%

60

2%

100=K

3%

20

2

P1

3%

60

3%

70

3%

80

3%

100

3%

101=K

5%

20-70

5%

102=K

8%

60

10%

20-35

10%

60

20%

20-35

30-37%

20

melted

240

melted

445=K

boiling

570

dry 100%

20

dry 100%

136=k

moist

20

0

P1

0

P1

- 18.17 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Sulphuric acid

Chemical

formula

H2SO4

cr 17

ni 12

mo 2,5

Concentration

Temp.

C

0.1%

100

0.5%

20

0.5%

50

0.5%

100

1%

20

1%

1%

50

70

1

1

0

0

304

cr 18

ni 9

316

1%

85

1%

100

2%

20

2%

50

2%

60

3%

20

3%

35

3%

50

3%

85

3%

100

5%

20

5%

35

5%

60

5%

75

5%

85

5%

101=K

10%

10%

50

10%

60

10%

80

10%

102=K

20%

20

20%

40

20%

50

20%

60

20%

100

30%

20

30%

40

30%

60

40%

20

40%

40

40%

60

40%

90

50%

20

- 18.18 -

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Sulphuric acid

Hydrogensulphide

Chemical

formula

H2SO4

H2 S

cr 17

ni 12

mo 2,5

Concentration

Temp.

C

50%

40

50%

70

60%

20

60%

40

60%

70

70%

70%

20

40

2

2

2

2

70%

70

80%

20

80%

40

80%

60

85%

20

85%

30

85%

40

85%

50

90%

20

90%

30

90%

40

90%

70

94%

20

94%

30

94%

40

94%

50

96%

20

96%

30

96%

40

96%

50

98%

30

98%

40

98%

50

98%

80

100%

70

dry gas

100

4%

200

moist gas

20

0

P1S

- 18.19 -

304

cr 18

ni 9

316

dacapo

Technical information

stainless

Corrosion resistance table

Medium

Sulphurous acid

Chemical

formula

H2SO3

(SO2 dissolved in water)

Sulpher dioxide

SO2

Concentration

Temp.

C

2% SO2

50

5% SO2

20

304

cr 18

ni 9

0

316

cr 17

ni 12

mo 2,5

0

0

10% SO2

160

20% SO2

20

saturated

with SO2

saturated

20

with SO2

135

saturated

with SO2

200

dry gas

100

25

moist gas

20

oxigen free

100

100%

dry gas

liquid

100%

- 18.20 -

You might also like

- GISL2Document14 pagesGISL2Abdullah Sabry AzzamNo ratings yet

- Sa 266Document5 pagesSa 266Alejo ZabalaNo ratings yet

- Dalma Mall's Industrial Plastic Pipes and FittingsDocument24 pagesDalma Mall's Industrial Plastic Pipes and FittingsashishNo ratings yet

- Gas Industry Standard: GIS/E34:2007Document36 pagesGas Industry Standard: GIS/E34:2007nedalinaNo ratings yet

- Age-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsDocument4 pagesAge-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsGustavo SuarezNo ratings yet

- Specification For Carbon Structural Steel: SA-36 /SA-36MDocument7 pagesSpecification For Carbon Structural Steel: SA-36 /SA-36MBowo Edhi Wibowo100% (2)

- Weld 2507Document8 pagesWeld 2507kyaw369No ratings yet

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServicemarykongNo ratings yet

- NCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FacilDocument131 pagesNCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FaciliagpconceNo ratings yet

- HS Exwill - 01 Marine Pneumatic FenderDocument8 pagesHS Exwill - 01 Marine Pneumatic FenderetenuelNo ratings yet

- Critical Surface Preparation for Steel CoatingsDocument2 pagesCritical Surface Preparation for Steel CoatingsHIPAPNo ratings yet

- Prefabrication Primer Range Prefabrication Primer Range: A PPG BrandDocument8 pagesPrefabrication Primer Range Prefabrication Primer Range: A PPG BrandengindmecNo ratings yet

- Plain Washers - Extra Large Series - Product Grade C: Technical Corrigendum 1Document1 pagePlain Washers - Extra Large Series - Product Grade C: Technical Corrigendum 1Anonymous DTzckONo ratings yet

- Astm A815-A815m-22Document8 pagesAstm A815-A815m-22ali ahmad100% (1)

- ISO 7040 Material A4-80Document1 pageISO 7040 Material A4-80rijalharunNo ratings yet

- PVC Waterstop - Design Guide: Suggested Master SpecificationDocument4 pagesPVC Waterstop - Design Guide: Suggested Master Specificationarvin jay santarinNo ratings yet

- Gas Industry Standard: GIS/PL2-3:2006Document27 pagesGas Industry Standard: GIS/PL2-3:2006HassanNo ratings yet

- Heat GuideDocument77 pagesHeat GuideLeonichevNo ratings yet

- Internal Resistance To Corrosion in Structural Hollow Sections PDFDocument48 pagesInternal Resistance To Corrosion in Structural Hollow Sections PDFjemanuelvNo ratings yet

- Class Programme: Type ApprovalDocument21 pagesClass Programme: Type ApprovalShih-Bou Wang100% (1)

- Bisalloy Technical Manual SectionsDocument65 pagesBisalloy Technical Manual Sectionsramaus100% (1)

- Structural Steel Specification for G&P GeotechnicsDocument0 pagesStructural Steel Specification for G&P GeotechnicsGnabBangNo ratings yet

- Din 8075 PDFDocument11 pagesDin 8075 PDFAndrei SimionNo ratings yet

- Understanding DecarburizationDocument6 pagesUnderstanding Decarburizationoquintero990% (1)

- Steel Springs, Helical, Heat-Treated: Standard Specification ForDocument6 pagesSteel Springs, Helical, Heat-Treated: Standard Specification Forsharon blushteinNo ratings yet

- AISI 12L14 Steel Analysis and PropertiesDocument2 pagesAISI 12L14 Steel Analysis and PropertiessyuepiNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- Gis-Te P6.3 2021Document16 pagesGis-Te P6.3 2021Ashraf Ismail HassenNo ratings yet

- Fpa Australia - Ps 06 v1 Water Tanks For Fire Protection SystemsDocument11 pagesFpa Australia - Ps 06 v1 Water Tanks For Fire Protection Systemsyogesh0% (1)

- Is.7001.1989 0 PDFDocument14 pagesIs.7001.1989 0 PDFJotheeswaranNo ratings yet

- New materials for sour gas drill pipeDocument2 pagesNew materials for sour gas drill pipeamigofirmNo ratings yet

- Testbars Vs Casting PropertiesDocument36 pagesTestbars Vs Casting Propertiesmaniwel100% (1)

- LNG WeldingDocument12 pagesLNG Weldingrodofgod100% (1)

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Thiago Ribeiro da SilvaNo ratings yet

- Comparison and Validation of Creep-Buckling Analysis MethodsDocument6 pagesComparison and Validation of Creep-Buckling Analysis MethodsalifaramarzNo ratings yet

- Physical Testing of Gypsum, Gypsum Plasters and Gypsum ConcreteDocument8 pagesPhysical Testing of Gypsum, Gypsum Plasters and Gypsum ConcreteRajendra PashteNo ratings yet

- Asme Section II A-2 Sa-453 Sa-453mDocument10 pagesAsme Section II A-2 Sa-453 Sa-453mAnonymous GhPzn1xNo ratings yet

- Steel Grades Properties Global StandardsDocument20 pagesSteel Grades Properties Global StandardsJonald PoquizNo ratings yet

- AGBT07-18 Guide To Bridge Technology Part 7 Maintenance and Management of Existing BridgesDocument239 pagesAGBT07-18 Guide To Bridge Technology Part 7 Maintenance and Management of Existing BridgesRandy BenemeritoNo ratings yet

- AL-6XN SourcebookDocument59 pagesAL-6XN SourcebooklkrzyzanNo ratings yet

- A1018 Hslas GR 50Document1 pageA1018 Hslas GR 50Claudio SampaioNo ratings yet

- Ergonomic Solutions For The Process Industries PDFDocument2 pagesErgonomic Solutions For The Process Industries PDFDougNo ratings yet

- Cmjf?i?l-?i: Technical Supply Conditions FOR Threaded Steel FastenersDocument25 pagesCmjf?i?l-?i: Technical Supply Conditions FOR Threaded Steel FastenersrajupetalokeshNo ratings yet

- En 12451 1999Document24 pagesEn 12451 1999victoraghiNo ratings yet

- Eta-120114 Spax ScrewsDocument84 pagesEta-120114 Spax ScrewsSunnyWongNo ratings yet

- A780 PDFDocument3 pagesA780 PDFMauricio Adame100% (1)

- Technical Information On ISO Shipping Container: IOP Conference Series: Materials Science and EngineeringDocument8 pagesTechnical Information On ISO Shipping Container: IOP Conference Series: Materials Science and EngineeringĐăng ThạnhNo ratings yet

- Aluminium 5083Document2 pagesAluminium 5083Septiana WibowoNo ratings yet

- AWS - WZC D19.0-72 Welding Zinc-Coated SteelDocument148 pagesAWS - WZC D19.0-72 Welding Zinc-Coated Steelarnoldbatista55No ratings yet

- GIB Ceiling Diaphragms Effectively Transfer LoadsDocument4 pagesGIB Ceiling Diaphragms Effectively Transfer Loadsreydudes9156No ratings yet

- ASME 2286-2 Alternative Rules For Determining Allowable External PressureDocument16 pagesASME 2286-2 Alternative Rules For Determining Allowable External PressureMike Dukas100% (1)

- Din en 14399-3 - 2015Document30 pagesDin en 14399-3 - 2015Dato LinNo ratings yet

- TWI Knowledge Summary - Fitness For PurposeDocument5 pagesTWI Knowledge Summary - Fitness For Purposedhurusha100% (1)

- Astm F3125 F3125M 18Document6 pagesAstm F3125 F3125M 18Amine ait talebNo ratings yet

- Corrosion Resistance Table: Conversion FactorsDocument21 pagesCorrosion Resistance Table: Conversion FactorsMutiara PrimasterNo ratings yet

- Corrosion resistance of stainless steels and other metalsDocument20 pagesCorrosion resistance of stainless steels and other metalsDaniel Puello RodeloNo ratings yet

- HASTELLOY® C-22HS™alloyDocument16 pagesHASTELLOY® C-22HS™alloyYudha SatriaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Anshuman RoyNo ratings yet

- Technical Brief Drum ControlDocument3 pagesTechnical Brief Drum ControlThitipong RukkhotNo ratings yet

- Abb Excitation 1Document45 pagesAbb Excitation 1Erbil KeskinNo ratings yet

- 3BSE030430 Advant GraphicLibraryDocument574 pages3BSE030430 Advant GraphicLibraryThitipong RukkhotNo ratings yet

- An Introduction To Functional Safety and IEC 61508Document16 pagesAn Introduction To Functional Safety and IEC 61508glamorous_guy6294100% (3)

- Proračun I Odabir VentilaDocument20 pagesProračun I Odabir VentilaTenkre Ten0% (1)

- HSE-Better Alarm Handling PDFDocument4 pagesHSE-Better Alarm Handling PDFAlessio DeOsimoNo ratings yet

- Write An Electron Configurations of ElementDocument10 pagesWrite An Electron Configurations of ElementMiccarina Fablina SatirNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument12 pagesCambridge International General Certificate of Secondary EducationZo775 YoutubeNo ratings yet

- Chem VivaDocument12 pagesChem VivaCash Cash CashNo ratings yet

- CHEM 101 Exam 1 Review Spring 2015Document4 pagesCHEM 101 Exam 1 Review Spring 201546bwilsonNo ratings yet

- GAUHATI UNIVERSITY SOPHISTICATED ANALYTICAL INSTRUMENT FACILITYDocument1 pageGAUHATI UNIVERSITY SOPHISTICATED ANALYTICAL INSTRUMENT FACILITYSritam SwapnadarshiNo ratings yet

- SGS Speeds Feeds GPDocument2 pagesSGS Speeds Feeds GPnammarisNo ratings yet

- Science7 Q1 Mod2E Compounds Version3Document24 pagesScience7 Q1 Mod2E Compounds Version3Bryzel Cortes100% (2)

- 2022 - Skema Bab3 - Konsep Mol, Formula Dan Persamaan KimiaDocument17 pages2022 - Skema Bab3 - Konsep Mol, Formula Dan Persamaan Kimiasyed ahmad ansarNo ratings yet

- Clusters and Catenation in P-Block: Allotropes of CarbonDocument15 pagesClusters and Catenation in P-Block: Allotropes of Carbonrajender kumarNo ratings yet

- Pengolahan Bahan Galian Lanjut (1) : DR. Yusuf Rumbino, ST. MT Teknik Pertambangan-FST-UNDANA 2022Document21 pagesPengolahan Bahan Galian Lanjut (1) : DR. Yusuf Rumbino, ST. MT Teknik Pertambangan-FST-UNDANA 2022Paska SorminNo ratings yet

- HidroDocument16 pagesHidroLasandi Affan NurNo ratings yet

- Poly Aluminium Chloride for Drinking Water StandardsDocument25 pagesPoly Aluminium Chloride for Drinking Water Standardsdewi wulansariNo ratings yet

- Acid and BasesDocument15 pagesAcid and Basesharssh adhhiyaNo ratings yet

- Preparation and properties of hydrocarbonsDocument4 pagesPreparation and properties of hydrocarbonsimPERFECTme09No ratings yet

- StoichiometryDocument16 pagesStoichiometryVel MuruganNo ratings yet

- pH Buffer SolutionsDocument5 pagespH Buffer SolutionsDiana ChiscaNo ratings yet

- Co CR Mo AlloyDocument7 pagesCo CR Mo AlloyRe ZanoNo ratings yet

- Jsa Jis K 0101 1998 PDFDocument481 pagesJsa Jis K 0101 1998 PDFRiris Trinartika50% (2)

- Test Report: Destiny Retail Mall Developers Private LimitedDocument3 pagesTest Report: Destiny Retail Mall Developers Private LimitedAbhijit KarpeNo ratings yet

- MIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)Document20 pagesMIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)ccorp0089No ratings yet

- Cambridge Pre-U Revised Syllabus: Atomic and Ionic Radii TablesDocument20 pagesCambridge Pre-U Revised Syllabus: Atomic and Ionic Radii TablesrosestrikesNo ratings yet

- Saltwater Ormus Experiments by Lilac BlackDocument8 pagesSaltwater Ormus Experiments by Lilac BlackTony GaryNo ratings yet

- Chem 1011Document4 pagesChem 1011Arfa Ali KhanNo ratings yet

- Schaeffler Diagram PDFDocument1 pageSchaeffler Diagram PDFyusrilhanafiNo ratings yet

- Chem - Chemical InteractionDocument20 pagesChem - Chemical Interaction현성JacobNo ratings yet

- List of Etchant For MetallographyDocument3 pagesList of Etchant For Metallographyniraj_hwbNo ratings yet

- Manufacture substances in industryDocument20 pagesManufacture substances in industryShazleen SamhanaNo ratings yet

- Catalog2013 PDFDocument24 pagesCatalog2013 PDFVăn Đại - BKHNNo ratings yet

- The D - and F-Block ElementsDocument12 pagesThe D - and F-Block ElementsSHIVANSHU NemaNo ratings yet

- Chemical Equations and Reactions AnswersDocument16 pagesChemical Equations and Reactions AnswersSydney LezamaNo ratings yet