Professional Documents

Culture Documents

Pradhan and Dey

Uploaded by

Sriharsha AinampudiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pradhan and Dey

Uploaded by

Sriharsha AinampudiCopyright:

Available Formats

Journal of Engineering and Technology Research Vol. 1 (6), pp.

115-121, September, 2009

Available online at http:// www.academicjournals.org/JETR

2009 Academic Journals

Full Length Research Paper

Rock cutting with surface miner: A computational

approach

Premananda Pradhan and Kaushik Dey*

Department of Mining Engineering, National Institute of Technology, Rourkela, India.

Accepted 6 July, 2009.

Surface miner is proved to be an efficient rock excavation technique in surface mines. However, till date,

mining industry is facing a problem in selecting best surface miner model suitable to their conditions

amongst the models available in the market. The readily available models are purchased by the mine

authority and then, are deployed in the mines. This results into the increase in mining cost and

reduction in performance. The field engineers are also unable to operate the surface miner in the

optimum mode of operation. This paper has reported an investigation carried out to identify the factors

affecting performance of surface miner. Computer software has also been developed to assist the mine

management in selecting the most suitable surface miner. This also assists the field engineers to select

the optimum mode of operation to arrive at the maximum possible production.

Key words: Surface miner, operating mode, software, cuttability.

INTRODUCTION

Surface miner was first used in mining sector in mid 70s.

Indian mining industry introduced surface miner in the

year 1996 in a limestone mines of Gujrat Ambuja Cement

Ltd (Dey and Sen, 2001). Among the 400 surface miners

working over the world, more than 100 are working in

Indian coal and limestone mines (Dey and Ghose, 2008).

Though surface miner was introduced as a technology to

avoid the difficulties of blasting near the inhabitancy, but

it became a cost-effective surface mining system. To

reduce the cost of mining by surface miner, judicial

planning and its proper implementations are essentially

required. Deployment of surface miner in any surface

mine requires three decisions to be made:

i) Whether the mine is suitable for deploying surface

miner or not?

ii) If suitable, then which surface miner model should be

used to achieve optimum production?

iii) How the selected model can be judicially deployed in

the surface mine?

The first two decisions are taken by the mine planner and

top management, where as the third decision is the

responsibility of the field engineers. Performance of sur-

face miner depends largely on the operating mode in

*Corresponding author. E-mail: kausdey@yahoo.co.uk.

which surface miner has to work and the cuttability index

of the rock or material. Thus, it becomes a critical

decision for the mine planner to adopt a suitable surface

miner. Once the most suitable miner is decided, then it

becomes a challenge for the field engineer to utilise the

machine in appropriate operating mode. To assist the

mine planner, a computer programme for selection of

surface miner based on cuttability index is developed. To

assist the field engineer, a computer programme for

selection of optimum operating mode of surface miner is

also developed. These computer programmes are

combined to become a software.

Factors affecting performance of surface miner

Performance of surface miner depends on cuttability

index, as the cuttability index increases performance of

surface miner decreases. If the cuttability index exceeds

greater than 80 surface miner should not be deployed

(Anon, 2008). Cuttability of a surface miner depends on

a number of influencing parameters. These parameters

can be categorized as rock/rockmass parameters,

machine parameters and the type of application. The

Parameters influencing performance of surface miner are

detailed in Table 1.

Rockmass is a natural component in the earths crust

and is thus immutable. Machine configuration is the one

116 J. Eng.Technol. Res.

Table 1. Parameters influencing performance of surface miner (Pradhan and Dey, 2009).

Rock/rockmass parameters Machine configuration Type of application

Moisture content, density, brittleness,

unconfined compressive strength, point

load index, Youngs modulus, fracture

energy, toughness index, Brazilian tensile

strength, sonic velocity, abrasivity (Schi-

mazek-F, Cerchar) volumetric joint count,

stickiness of material, specific energy of

cuttability .

Cutting tool configuration

(rake angle, attack angle,

clearance angle and tip angle,

pick lacing, type of pick (point

attack) number of picks, (tip

material), drum weight, engine

power, nature of coolant for

tips.

Mode of operation (windrowing/

conveyor loading), length and

width of operating area (select

machine travel method), opera-

tor skill, specific requirements

(dry/wet, fragmentation desired

and output).

Figure 1. Possible modes of operation of a surface miner.

(a) Windrowing (b) Conveyor loading

Figure 2. Loading modes of surface miner.

time decision of the mine management. Thus, perfor-

mance of a surface miner, generally, depends on cutting

in edges, curves, turning radius and length of working

area, truck changing time, which can be controlled by the

field engineers. Field engineer can choose operating

modes of surface miner to achieve the maximum pro-

duction based on the onsite requirement. The operating

modes can be classified based on the travelling and

loading options. The possible modes of operation are

depicted in Figures 1 and 2.

User of the surface miners always finds difficulty in

selecting suitable machines (for a mine) and also in

choosing their operating mode in short term (day to day

operation) and long term basis (for a particular face). For

the ready guidance to them, surface miner manufacturers

provide performance graphs (Performance vs. compres-

sive strength) derived based on their experience.

Though, the reliability of these charts varies due to two

main reasons: (a) manufacturer assumes ideal conditions

(b) geo-mining differences in applications. Further, these

Pradhan and Dey 117

Table 2. Rating of the parameters of new rockmass cuttability classification (Dey and Ghose, 2008).

Class I II III IV V

Point load index (Is50) < 0.5 0.5 1.5 1.5 2.0 2.0 3.5 > 3.5

Rating (Is) 5 10 15 20 25

Volumetric joint coun (no/m

3

) > 30 30 10 10 3 3 1 1

Rating (Jv) 5 10 15 20 25

Abrasivity < 0.5 0.5 1.0 1.0 2.0 2.0 3.0 > 3.0

Rating (Aw) 3 6 9 12 15

Direction of cutting respect to

major joint direction

720 - 900 540 - 720 360 - 540 180 - 360 00 - 180

Rating (Js) 3 6 9 12 15

Machine power (kW) > 1000 800 1000 600 800 400 600 < 400

Rating (M) 4 8 12 16 20

charts are also not available for all the manufacturers. To

overcome this problem, software has been developed to

select the suitable surface miner and their operating

mode.

THE SOFTWARE

Cuttability index developed by Dey and Ghose (2008)

had been utilised in selection of surface miner model.

The model has been considered the key influencing

parameters, namely; point load strength index, rock

abrasivity, volumetric joint count, direction of machine

operation with respect to joint direction and the cutting

power of surface miner. The ratings of these parameters

are tabulated in Table 2.

Utilising this theory, software has been developed in C

language to select the suitable surface miner model. The

flow sheet of the software is given in Figure 3. Similarly,

the mathematical relationship proposed for computation

of surface miner performance in different operating mode

is utilised for selecting the optimum operating mode of

surface miner. The flow sheet for this module is given in

Figure 4.

Thus, the cuttability index (CI) is the sum of the rating of

above five parameters

M J A J I CI

S W V S

+ + + + =

(1)

Utilising this cuttability index production rate of a surface

miner can be estimated as follow

C

*

M k

100

CI

- 1 L

=

(2)

Where;

L

*

= production or cutting performance (bcm/h).

M

c

= Rated capacity of the machine (bcm/h).

CI = Cuttability index.

k = A factor for consideration of influence of specific

cutting condition and is a function of pick lacing (array),

pick shape, atmospheric condition etc. and varies from

0.5 1.0.

Thus, the flow sheet of the software can be established

as given below (Pradhan, 2008).

Theoretical production formulae for surface miner (Dey,

1999) are utilised to find out performance of a surface

miner for different mode of operations. The operating

mode gives the maximum production is selected as the

optimum mode of operation. Thus, the flow sheet of the

software can be established as given below (Dey and

Sen, 2001).

The software is being developed to select suitable

surface miner and its operating mode. The software is

presently under development in Visual Basic but it is

completed in C language and is presented in this section.

The developed module can select the suitable surface

miner for a particular condition from the available models

and also the operating mode for the surface miner to

achieve optimum production under following geo mining

conditions:-

i) Compressive strength of the rock is less than 120 MPa,

ii) Abrasivity should be less than 3.

iii) The effect of gradient of the working bench on the

production is not considered, thus it is considered to be

flat or gently inclined.

iv) Special applications like, selective mining of thin

seams/dirt bands, ramp construction etc., are not

considered.

v) No financial calculation has been incorporated

presently.

The step by step procedure to use the software is as

follows

Step 1: The basic information like rock properties and

118 J. Eng.Technol. Res.

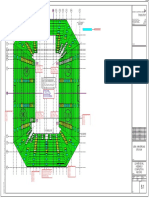

Figure 3. Flow sheet for selection of surface miner based on cuttability index.

machine configuration has to give.

Step 2: Check the UCS and abrasivity of rock than

calculate the cuttability index.

Step 3: Calculate the estimated production than check

whether the production is acceptable or not. If not go for

other model otherwise show the production.

Step 4: To choose operating mode the basic inputs like

machine parameters has to give and the calculation

option for travel and loading combinations mode has to

select.

Step 5: Check the mode of travel and loading

combinations inserted.

Step 6: Read the relevant input parameters required for

production analysis.

Step 7: Calculate the production for the selected mode of

travel and loading combination.

Step 8: Check and calculate for other modes.

Step 9: Compare the productions and find out the mode

Pradhan and Dey 119

Figure 4a. Reading the inputs to determine optimum mode of operation

of maximum production and print.

The software has the feature to give the output in text

format.

A trial of the software

The software has been tested for a case of coal mines of

MCL. The data are taken from Lakhanpur Opencast

Project of Mahanadi Coal Fields Limited.

Point load index = 1.1 that is rating I

s

= 10

Surface Miner used == 2100 SM

Rated machine capacity = 400 m

3

/h

Machine power = 448 kW that is rating M

c

= 16

Volumetric joint count = 32 that is rating J

v

= 5

Abrasivity = 0.4 that is rating A

w

= 3

Direction of machine operation with respect to joint plane

= 800 that is rating J

s

= 3

Thus, cuttability index (CI) = 37 (thus very easy cutting

condition for surface miner)

Expected production (for k = 0.6) = (1 37/100) 400

0.6 = 151 m

3

/h

Density = 1.4 t/m

3

Expected production achieved = 210 t/h

Truck exchange time=24 s

Length required to fill a truck = 51 m

Drum width = 2.1 m

Cutting depth = 160 mm

120 J. Eng.Technol. Res.

Figure 4b. Calculation for empty travel back - conveyor loading and widrowing mode

/

Calculate Production rate (p)

F{CF)

F

INPUT RELEVANT PARAMETERS

Length of cut to fill a truck(Lt) Truck

exchange time(Tc), Drum width (S) Cut

depth(D), face length (L), Cutting speed (V),

Empty travel speed (VE)

+ +

=

t

c

E

L

T

V

1

V

1

60

1000

D S

p

8

INPUT RELEVANT PARAMETERS

Cut depth(D), Effective face length(L),

Cutting speed (V), Drum width (S)

Empty travel speed (VE)

Calculation Production rate (p)

F{CF)=F

F

+

=

E

V

L

V

L

60

1000

D L S

p

Figure 4c. Calculation for turn back - conveyor loading and widrowing mode

D

INPUT RELEVANT PARAMETERS cut

depth (D), Effective face length (L), Drum

width (S) Cutting speed(V), Turning time(T)

Calculate Production rate(p)

P(OP)=P

F

C

INPUT RELEVANT PARAMETERS

Length of cut to fill a truck (Lt) Drum width (S)

Truck exchange time(Tc) cut depth (D)

Effective face length(L) Cutting speed(V)

Turning time(T)

Calculate Production rate(p)

P(OP)=P

F

+ +

=

t

c

L

T

L

T

V

1

60

1000

D S

p

+

=

T

V

L

60

1000

D L S

p

Pradhan and Dey 121

Figure 4. Flow sheet of the software used for developing the programme.

Cutting speed = 22 m/min

Empty travel speed = 25 m/min

Turning time = 4.6 min

Length of face = 212 m

Production for empty travel back and conveyor loading

is=216.08 tonnes/h

Production for empty travel back and windrowing is =

235.91 tonnes/h

Production for turn back and conveyor loading is =

268.81 tonnes/h

Production for turn back and windrowing is = 300.21

tonnes/h.

Conclusion

The developed software is user-friendly and easily to

operate. Thus, it can be used to select the suitable

surface miner model and also the optimum mode of

operation. Software may suggest a mode of operation as

the optimum (windrowing in this case). The software is

tested successfully for a case of coal mine, where a

SM2100 Surface miner has been introduced successfully.

The estimated production and actual productions are also

quite similar. However, it is strongly recommended to

carry out financial analysis prior to deployment of surface

miner. In future, all those (including financial assessment)

would be given in a nutshell in the software.

REFERENCES

Dey K (1999). Performance analysis of surface miner in Indian surface

coal mine. Unpublished M. Tech thesis, ISM Dhanbad: 10-32.

Dey K, Sen P (2001). Selection of optimum mode of continuous surface

miner operation- A methodology. The Indian Mining Eng. J.

May/June: 21-24.

Dey K, Ghose AK (2008). Predicting Cuttability with Surface Miners

A Rockmass Classification Approach. J. Mines Metals Fuels 56(5 -6):

85 - 92.

Pradhan P, Dey K (2009). Productivity Improvement through Selection

of Operating Mode of Surface Miner - A Computational Approach.

National Seminar on Productivity improvement in surface mines and

quarries role of new technology and ancillary equipment. Kolkata.

January 03-04.

Pradhan P (2008). Development of a computer programme for selection

of mode of operation for continuous surface miner. B.Tech

dissertation: 37 - 48.

Anon (2008). Surface miner manual of Wirtgen Gmbh: 2 -100.

You might also like

- Gate Scorecard 2019Document19 pagesGate Scorecard 2019Sandeep Saket100% (1)

- Longwall Mining Is A Form of UndergroundDocument31 pagesLongwall Mining Is A Form of UndergroundNaniNo ratings yet

- Mining Methods - Opencast Working M201: Duration of Year Is Considered 28 WeeksDocument4 pagesMining Methods - Opencast Working M201: Duration of Year Is Considered 28 WeeksPawan SahuNo ratings yet

- Horizon Mining Level Mining: Longwall & Other Methods of WorkingDocument14 pagesHorizon Mining Level Mining: Longwall & Other Methods of WorkingVamshiNo ratings yet

- Coal India LTD - 2017 MT Mining Interview Experience - Adarsh SahayDocument5 pagesCoal India LTD - 2017 MT Mining Interview Experience - Adarsh SahayRanjan KumarNo ratings yet

- Selecting Methods of Extraction of Steeply Dipping Coal SeamDocument24 pagesSelecting Methods of Extraction of Steeply Dipping Coal SeammanikantaNo ratings yet

- Mining Theory Q&ADocument48 pagesMining Theory Q&ARahul patelNo ratings yet

- Final Strata Monitoring InstrumentsDocument42 pagesFinal Strata Monitoring InstrumentsSushantNo ratings yet

- Are You Looking For .: WWW - Promining.inDocument18 pagesAre You Looking For .: WWW - Promining.inANKIT DEOGADENo ratings yet

- Practice Test 2 For GATE MiningDocument3 pagesPractice Test 2 For GATE MiningBishnu Sharma100% (1)

- Behaviour of Shield Support in Longwall MiningDocument68 pagesBehaviour of Shield Support in Longwall MiningHimanshu SharmaNo ratings yet

- Class Notes PDFDocument5 pagesClass Notes PDFKumar RajanNo ratings yet

- Hoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundryDocument3 pagesHoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundrySumedha Sawni100% (2)

- Are You Looking For .: WWW - Promining.inDocument27 pagesAre You Looking For .: WWW - Promining.inANKIT DEOGADENo ratings yet

- Code Subject L Ts MN 302 Mine Development 3 0 0Document2 pagesCode Subject L Ts MN 302 Mine Development 3 0 0Subhankar GhoshNo ratings yet

- Mine Asset Management AssignmentDocument23 pagesMine Asset Management AssignmentMilthon Chambi0% (1)

- MINE LEGISLATION One LinerDocument68 pagesMINE LEGISLATION One Linerersunilsingh1No ratings yet

- Macrel Report (HCL)Document39 pagesMacrel Report (HCL)Santhosh100% (1)

- Contiguous WorkingDocument8 pagesContiguous WorkingAjeet KumarNo ratings yet

- Mining in IndiaDocument13 pagesMining in IndiaVenkata Nagabhushana ShastryNo ratings yet

- GATE Mining Engineering PDFDocument2 pagesGATE Mining Engineering PDFSandeep SinghNo ratings yet

- Department of Mining EngineeringDocument15 pagesDepartment of Mining EngineeringsrawannathNo ratings yet

- NMDC Vocational Training ReportDocument34 pagesNMDC Vocational Training ReportEđđy Åadi ßãrsàNo ratings yet

- Important Legislation Section For Cil MT (Mining) Exam PDFDocument169 pagesImportant Legislation Section For Cil MT (Mining) Exam PDFSatyam Gupta0% (1)

- 26th March 2002 Room and Pillar Mechanised MiningDocument59 pages26th March 2002 Room and Pillar Mechanised MiningCraig ThomasNo ratings yet

- Vibration in BlastingDocument21 pagesVibration in Blastingtridev kant tripathiNo ratings yet

- Hoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundryDocument3 pagesHoisting Equipments - Construction & Building Materials Questions and Answers - SanfoundrySumedha SawniNo ratings yet

- Opening of Opencast MineDocument3 pagesOpening of Opencast MineArjun KumarNo ratings yet

- CH 3 - Preparation For ExcavationDocument15 pagesCH 3 - Preparation For ExcavationShubham GuptaNo ratings yet

- 6th Sem Syllabus MiningDocument9 pages6th Sem Syllabus MiningSandeep SaketNo ratings yet

- B.Tech Course Book-12 Mining New With Co PDFDocument40 pagesB.Tech Course Book-12 Mining New With Co PDFMaloth Pramod NayakNo ratings yet

- Earth Excavation - Highway Engineering Questions and Answers - Sanfoundry PDFDocument3 pagesEarth Excavation - Highway Engineering Questions and Answers - Sanfoundry PDFSumedha SawniNo ratings yet

- Unit 4Document6 pagesUnit 4Sai KumarNo ratings yet

- Mechanical Extraction Methods: Rodríguez Lavado Isaac ManuelDocument14 pagesMechanical Extraction Methods: Rodríguez Lavado Isaac ManuelIsaac Manuel Rodriguez LavadoNo ratings yet

- Auxiliary VentilationDocument20 pagesAuxiliary VentilationNikhil Asha JainNo ratings yet

- Success Story of Cil MT (Mining) 2019Document22 pagesSuccess Story of Cil MT (Mining) 2019PRAKASH SUTHAR50% (2)

- B.Tech Diploma Combined MIN - V - Factor of Safety.Document17 pagesB.Tech Diploma Combined MIN - V - Factor of Safety.shivam raiNo ratings yet

- NCL JR Overman Exam-2018Document22 pagesNCL JR Overman Exam-2018Sunnyreddy SandeepNo ratings yet

- 07 Underground Mine MechanisationDocument16 pages07 Underground Mine MechanisationNeha Sharma100% (2)

- Chapter 4 Underground Coal MiningDocument58 pagesChapter 4 Underground Coal Miningrishav baishyaNo ratings yet

- Mining Geology PDFDocument21 pagesMining Geology PDFAbdul JabbarNo ratings yet

- Amie Syllabus Sec B MiningDocument19 pagesAmie Syllabus Sec B MiningSangeet SharmaNo ratings yet

- Numeric in Mine Legislation PC SahooDocument70 pagesNumeric in Mine Legislation PC SahooHari Pidikiti100% (1)

- Application of Millisecond Delays For Improvement of Contour Blastings Results - Case Study BellanicaDocument7 pagesApplication of Millisecond Delays For Improvement of Contour Blastings Results - Case Study BellanicaFrasher Brahimaj100% (1)

- Depillaring With StowingDocument24 pagesDepillaring With Stowingmohit kumar [NIT Rourkela]No ratings yet

- Mine Ventilation LabDocument23 pagesMine Ventilation LabOolasyar KhattakNo ratings yet

- Methane Layering in MinesDocument5 pagesMethane Layering in MinesAnurag TripathyNo ratings yet

- Notes On Coal Mining MethodsDocument39 pagesNotes On Coal Mining MethodsabhilashNo ratings yet

- Blast Design Mathematics - EnaexDocument30 pagesBlast Design Mathematics - EnaexMartin Sanchez BarrientosNo ratings yet

- DL Balancing DiagramDocument7 pagesDL Balancing DiagramJay Yadav100% (1)

- Pillar Design in Coal Mines.Document24 pagesPillar Design in Coal Mines.Waterdrop' 'Dew100% (1)

- Advanced Mine Surveying PDFDocument2 pagesAdvanced Mine Surveying PDFAjay Ajju50% (2)

- Lab 9 - Schmidt Hammer Rebound HardnessDocument7 pagesLab 9 - Schmidt Hammer Rebound HardnessankeshNo ratings yet

- WCL Question Paper PDFDocument100 pagesWCL Question Paper PDFnareshNo ratings yet

- JET-2022 Mining Sample Paper: - DomainDocument4 pagesJET-2022 Mining Sample Paper: - DomainRaj ShubhamNo ratings yet

- MWNC Sovled PaperDocument45 pagesMWNC Sovled PaperMuhammad Alam KhanNo ratings yet

- " Deepening and Widening of Shafts" .A PresentationDocument18 pages" Deepening and Widening of Shafts" .A PresentationCraig Thomas100% (1)

- Diploma Mining III ToVIDocument45 pagesDiploma Mining III ToVIIrfanMarwanzaNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Reference Paper Literature ReviewDocument5 pagesReference Paper Literature ReviewAani RashNo ratings yet

- OT Initial Assessment (OTIA) 2022-11-15Document2 pagesOT Initial Assessment (OTIA) 2022-11-15funtikarNo ratings yet

- The Palestinian Centipede Illustrated ExcerptsDocument58 pagesThe Palestinian Centipede Illustrated ExcerptsWael HaidarNo ratings yet

- Catheter Related InfectionsDocument581 pagesCatheter Related InfectionshardboneNo ratings yet

- Acting White 2011 SohnDocument18 pagesActing White 2011 SohnrceglieNo ratings yet

- Nikos MIDI Pack - Chord Progression GuideDocument5 pagesNikos MIDI Pack - Chord Progression GuideSamuel ThompsonNo ratings yet

- Institutional Group Agencies For EducationDocument22 pagesInstitutional Group Agencies For EducationGlory Aroma100% (1)

- Johnson & Johnson Equity Research ReportDocument13 pagesJohnson & Johnson Equity Research ReportPraveen R V100% (3)

- Coaxial Cable Attenuation ChartDocument6 pagesCoaxial Cable Attenuation ChartNam PhamNo ratings yet

- SW OSDocument11 pagesSW OSErnest OfosuNo ratings yet

- Jacob Stewart ResumeDocument2 pagesJacob Stewart Resumeapi-250063152No ratings yet

- ICMApprovedCentres - Ghana PDFDocument8 pagesICMApprovedCentres - Ghana PDFPrince Kelly100% (2)

- Registration ListDocument5 pagesRegistration ListGnanesh Shetty BharathipuraNo ratings yet

- The Linguistic Colonialism of EnglishDocument4 pagesThe Linguistic Colonialism of EnglishAdriana MirandaNo ratings yet

- Research FinalDocument55 pagesResearch Finalkieferdem071908No ratings yet

- Optimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsDocument7 pagesOptimized Maximum Power Point Tracker For Fast Changing Environmental ConditionsSheri ShahiNo ratings yet

- AISOY1 KiK User ManualDocument28 pagesAISOY1 KiK User ManualLums TalyerNo ratings yet

- Pioneer 1019ah-K Repair ManualDocument162 pagesPioneer 1019ah-K Repair ManualjekNo ratings yet

- LP32HS User Manual v1Document52 pagesLP32HS User Manual v1tonizx7rrNo ratings yet

- Sap Consultant Cover LetterDocument3 pagesSap Consultant Cover LetterrasgeetsinghNo ratings yet

- ReadingDocument205 pagesReadingHiền ThuNo ratings yet

- J.K. Brimacombe - Design of Continuous Casting MachinesDocument13 pagesJ.K. Brimacombe - Design of Continuous Casting MachinesJavier GómezNo ratings yet

- Session 1Document18 pagesSession 1Akash GuptaNo ratings yet

- The Chemistry of The Colorful FireDocument9 pagesThe Chemistry of The Colorful FireHazel Dela CruzNo ratings yet

- Very Narrow Aisle MTC Turret TruckDocument6 pagesVery Narrow Aisle MTC Turret Truckfirdaushalam96No ratings yet

- The New Order of BarbariansDocument39 pagesThe New Order of Barbariansbadguy100% (1)

- Lady in The House, Her Responsibilities & Ambitions: Amrita DuhanDocument7 pagesLady in The House, Her Responsibilities & Ambitions: Amrita DuhanFitness FableNo ratings yet

- SDSSSSDDocument1 pageSDSSSSDmirfanjpcgmailcomNo ratings yet

- AIIMS 2015 Solved PaperDocument436 pagesAIIMS 2015 Solved PaperSurya TejaNo ratings yet

- Sale Counter List JuneDocument9 pagesSale Counter List Junep6a4nduNo ratings yet