Professional Documents

Culture Documents

Steel Moment Frames

Uploaded by

Leonardo PimentelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Moment Frames

Uploaded by

Leonardo PimentelCopyright:

Available Formats

1

Published in Structural Engineer magazine February 2009

Steel Moment Frames History and Evolution

By Paul McEntee, S.E., R & D Engineer for Simpson Strong-Tie Steel-frame structures were developed during the 19th century in response to the limitations of masonrybearing wall structures, which were the common method of commercial construction at the time. These bearing wall structures were limited to about 10 stories high and allowed for only small openings because of the strength of the masonry materials. Since property owners back then wanted the same things that developers and architects want todaythe maximum amount of rentable space on their land and plenty of natural lightnew solutions were explored. Steel-frame building construction using rigid frames, or moment frames, was the answer to these demands. While originally intended for use in high-rise construction, the use of steel moment frames has evolved to encompass a large number of residential and light-framed, mixed-use projects because of the flexibility they give designers. A Brief History The earliest steel moment frame buildings used riveted connections with angles or T-sections connecting the beam flanges to the columns to create moment connections. The development of new welding technologies throughout the 20th Century and the introduction of high-strength bolts in the 1950s ended the use of riveting in building and bridge construction in the United States. The Welded Flange connection became one of the most common moment frame joints, using either a bolted or welded shear tab for vertical loads, and complete joint penetration welds for the beam flange-to-column flange moment connection. (See Figure 1) Steel moment frames are expected to achieve ductility through yielding beams or columns, and the connections must be capable of remaining intact through several cycles of inelastic rotation due to seismic loading. The 1994 Northridge Earthquake demonstrated that the standard connection (shown in Figure 1) did not perform as expected, in many cases fracturing at low levels of plastic deformation. Failures in the moment frame connections were attributed to multiple causes and are well documented, but are beyond the scope of this article to discuss. In mid-1994, the SAC Joint Venture was established, bringing together SEAOC, ATC and CUREE. Funded by FEMA, SAC was tasked with developing new design recommendations for welded steel moment frames. Several documents were published to address the design of moment frames in new structures, repair and evaluation of existing structures, and quality control guidelines.

Simpson Strong-Tie Company Inc.

5956 W. Las Positas Boulevard

Pleasanton, CA 94588

Phone: 925.560.9000

Fax: 925.847.1605

www.strongtie.com

The period after the Northridge Earthquake held some uncertainty for structural engineers. Many new design requirements were developed in a relatively short time frame and were not uniformly adopted by building jurisdictions. Fortunately, the recommendations for design and quality control contained in the numerous FEMA publications have been incorporated into the current 2005 AISC Seismic Design Provisions. In addition, the American Welding Society has published AWS D1.8, a supplement to AWS D1.1, that addresses welding requirements for high seismic applications. With these two documents, engineers now have clear seismic design requirements in one place. So Moment Frame Design is Simple Now? The code requirements are clearly given in the AISC and AWS specifications, but the application of these design requirements remains a difficult task. This can be especially true for engineers who specialize in light-frame construction, where structural steel is sometimes required to resist high lateral loads in a small space. While the actual design and detailing of a moment frame may only take a few hours to a days work, this is only the first stage of the process. In addition to designing the foundation anchorage, the engineer will need to produce steel and welding specifications, and also review steel shop drawings and welding procedure specifications. A steel sub-contractor will need to install the frame, and the general contractor will need to coordinate between the iron workers and the framers to make sure everything fits together. To save all this additional design work for the engineer and coordination effort for the general contractor, several manufacturers are now selling pre-fabricated moment frames that are geared specifically toward light-frame construction (See Figure 2). The use of pre-fabricated, load-rated components in building designs has been evolving for the past decade, primarily with narrow shear panels that are tested to exceed code height-to-width ratios. The introduction of moment frames to resist higher loads in lightframed structures is the logical progression for pre-manufactured products. The specification of pre-manufactured moment frames can be simplified to selecting a frame model from a catalog that meets the vertical and lateral loading requirements. This is a tremendous benefit for engineers who do not have the time or budget to design a custom frame. However, there are still important design considerations that engineers must be aware of when using a moment frame (premanufactured or not) in light-frame construction.

Simpson Strong-Tie Company Inc.

5956 W. Las Positas Boulevard

Pleasanton, CA 94588

Phone: 925.560.9000

Fax: 925.847.1605

www.strongtie.com

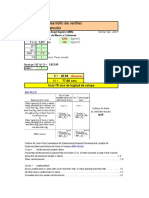

All Moment Frames are Not Created Equal Dylan Richards article Steel Moment Frames 101 (Structural Engineer Magazine, June 2008) addressed the differences in Ordinary Moment Frames (OMF), Intermediate Moment Frames (IMF) and Special Moment Frames (SMF), however, it is worth repeating the difference in the design requirements between OMF and SMF when mixing different lateral-force resisting systems. First, Response Modification Coefficients (R-values), Deflection Amplification Factors (Cd), and System Overstrength Factors (0) used for seismic design shall be reviewed. ASCE 7-05 and other model building codes acknowledge that structures will be loaded beyond their elastic range during seismic events. Damping and ductile yielding make it unnecessary to design for the full inelastic design force, so the code divides the seismic response by the R-factor to get a lower elastic design force or base shear. Higher R-factors represent more ductile systems and, therefore, yield a lower seismic design force. Deflections must be amplified by the Deflection Amplification Factor, Cd, to obtain the expected inelastic deflections. Similarly, the System Overstrength Factor is another amplification factor that is applied to the elastic design forces for specific elements where it is necessary to prevent a brittle failure in the system.

A properly detailed SMF is among the most ductile lateral-force resisting systems. This ductility is recognized in ASCE 7 by the relatively high R-value of 8, which yields lower design forces, smaller foundation forces and reduced diaphragm forces in the system. However, the lower design forces for SMF come with a relatively high Deflection Amplification Factor, Cd, which can result in frames that need to be much heavier to meet drift limits than if just designed for strength. In addition, the AISC Seismic Provisions have special beam bracing requirements which are not simple to satisfy, especially in lightframe construction. The beam bracing and the additional steel weight required to meet drift requirements for an SMF in light frame can outweigh the potential cost savings in the foundation and diaphragms. OMF is a less ductile system than SMF, being described in the 2005 AISC Seismic Provisions as a system expected to withstand minimal inelastic deformations in their members and connections when subjected to forces resulting from the design earthquake. ASCE 7 addresses the lower ductility of OMF by assigning it an R-factor of 3.5, resulting in an increased seismic design force compared to SMF. OMF is allowed for use in high seismic regions, but the code places some limits on allowable structure heights

Simpson Strong-Tie Company Inc.

5956 W. Las Positas Boulevard

Pleasanton, CA 94588

Phone: 925.560.9000

Fax: 925.847.1605

www.strongtie.com

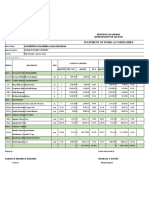

and building weights in Seismic Design Categories D, E, and F. The AISC Seismic Provisions do not have OMF beam bracing requirements beyond what is required by the AISC Specification, which allows engineers to design beams as unbraced. Combination of Systems While steel moment frames are generally less cost effective than shearwall or braced-frame systems, the open space and design flexibility they provide continue to drive their demand in modern structures. This holds true in light-frame construction as well. Moment frames can accommodate the demand for more windows and grander, taller entryways in custom single-family homes that simply would not work with code aspect ratio shearwalls. Steel moment frames also are needed for mixed-use developments where several stories of light-frame housing are constructed over retail space and require open storefronts and open floor plans. ASCE 7-05 addresses combinations of lateral systems that commonly occur in many designs. Sections 12.2.3.1 and 12.2.3.2 provide direction for dealing with vertical and horizontal combinations of lateral force resisting systems, but each of these sections requires interpretation and judgment when establishing design loading requirements. For both vertical and horizontal combinations in the same direction, the code is clear that the lowest R factor for calculating seismic loading is used. For example, for structural panel shearwalls (R=6.5, Cd=4.0) and ordinary moment frames (R=3.5, Cd=3.0), the design shear would be based on the R=3.5 in that direction. However, in detached 1- and 2-family dwellings of light-frame construction two-stories or less, the respective R-values along each wall line can be used, so an R=6.5 along the shear wall line and an R=3.5 along the OMF line are permitted. What becomes less clear is what to do for the deflection amplification, Cd. The language in 12.2.3.1 and 12.2.3.2 is somewhat unclear and could be interpreted in two ways: 1) The largest Cd and 0 values of all the individual structural systems shall be used. 2) The Cd and 0 values shall correspond to the least R-value of all the individual structural systems. While the first interpretation is conservative, the second interpretation is more appropriate since, fundamentally, as the design R-factor goes down, so too does the ratio between the calculated elastic design displacement and the expected inelastic displacement, which the code refers to as Cd. Therefore, the Cd factor should always be linked to the R-factor used for calculation of the design forces. Beam Bracing Special Moment Frames are expected to withstand significant inelastic deformation during a design earthquake. To preclude undesirable beam buckling failure modes that may occur during the formation of plastic hinges in the beam, Section 9.8 of the AISC Seismic Provisions has the following requirement for SMF: Both flanges of beams shall be laterally braced, with a maximum spacing of Lb = 0.086ryE/Fy. Braces shall meet the provisions of Equations A-6-7 and A-6-8 of Appendix 6 of the Specification.

Simpson Strong-Tie Company Inc.

5956 W. Las Positas Boulevard

Pleasanton, CA 94588

Phone: 925.560.9000

Fax: 925.847.1605

www.strongtie.com

This section goes on to require bracing at concentrated forces, changes in cross section or other locations where plastic hinges may occur. It also has higher brace strength requirements for bracing adjacent to plastic hinges. These requirements are summarized in Figure 4.

In structural steel buildings, additional steel beams connected to full-depth shear tabs with slip-critical bolts have little difficulty in satisfying SMF bracing strength and stiffness requirements. (See Figure 5) However, meeting the code prescribed bracing requirements is far more problematic when installing SMF in light-framed construction. There are deflections in the brace due to oversized holes in the wood, vertical deflection of the floor beam and horizontal deflection of the floor diaphragm. Each of these sources of deflection added in series make it unlikely to achieve the minimum bracing stiffness mandated by the AISC for an SMF. (See Figure 6) The challenges of meeting the code beam bracing requirements should be carefully considered when specifying SMFs in lightframed construction for seismic designs. While the lower R-factor for OMF results in higher design forces that may increase costs due to a larger foundation or higher diaphragm forces, the benefit is that OMF can be designed without beam bracing. Engineers should weigh the added foundation and diaphragm costs associated with OMFs against the costs of trying to provide the SMFs beam bracing that is required by the AISC Seismic Provisions. Conclusion Moment frames provide tremendous flexibility in meeting building lateral-load demands and are the lateral systems of choice when design constraints require a small structural footprint to accommodate large

Simpson Strong-Tie Company Inc.

5956 W. Las Positas Boulevard

Pleasanton, CA 94588

Phone: 925.560.9000

Fax: 925.847.1605

www.strongtie.com

openings. Traditionally, moment frames have been time intensive to design and labor intensive to install. The introduction of pre-manufactured, load-rated moment frames offers designers and contractors very effective alternatives to site-built frames, especially for use in light-frame construction. However, while a manufacturer has taken care of the frame design and fabrication, the engineer-of-record must address several key issues to meet the code requirements. These include seismic force calculations using the appropriate design coefficients for the combination of systems used, chord and collector design as well as providing the required beam bracing if SMF is used.

References: ASCE 7-05 Minimum Design Loads for Buildings and Other Structures 2005 Manual of Steel Construction (ANSI/AISC 360-05) 2005 AISC Seismic Provisions (ANSI/AISC 341-05) FEMA 267, 350, 351, 352, 353, 354

Simpson Strong-Tie Company Inc.

5956 W. Las Positas Boulevard

Pleasanton, CA 94588

Phone: 925.560.9000

Fax: 925.847.1605

www.strongtie.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Diseno de Conecciones Apoyos BajantesDocument1 pageDiseno de Conecciones Apoyos BajantesLeonardo PimentelNo ratings yet

- Mat FoundationsDocument10 pagesMat FoundationsKamran KhurshidNo ratings yet

- Bentley Software Manual (Geo5)Document1,127 pagesBentley Software Manual (Geo5)Leonardo PimentelNo ratings yet

- LOSADocument1 pageLOSALeonardo PimentelNo ratings yet

- Casa en MaderaDocument20 pagesCasa en MaderaLeonardo PimentelNo ratings yet

- HSS Brochure PDFDocument9 pagesHSS Brochure PDFAntonioNo ratings yet

- GEO5 v16 Software ManualDocument1,127 pagesGEO5 v16 Software ManualBza ZaBug100% (1)

- Diseno de Conecciones Apoyos BajantesDocument1 pageDiseno de Conecciones Apoyos BajantesLeonardo PimentelNo ratings yet

- Clip ConnDocument42 pagesClip ConnLeonardo PimentelNo ratings yet

- PalDuct PIR Datasheet ME EN 04 15Document2 pagesPalDuct PIR Datasheet ME EN 04 15Leonardo PimentelNo ratings yet

- Ansys WorkbookDocument62 pagesAnsys WorkbookbharathNo ratings yet

- Autodesk 2016 Product KeysDocument7 pagesAutodesk 2016 Product KeysLeonardo Pimentel100% (2)

- STEEL STAIR DESIGNDocument4 pagesSTEEL STAIR DESIGNNikki RobertsNo ratings yet

- PaperDocument9 pagesPaperDhaval AdvaniNo ratings yet

- Programa Logitud de Desarrollo en ColumnasDocument6 pagesPrograma Logitud de Desarrollo en ColumnasLeonardo PimentelNo ratings yet

- Earthquake EngineeringDocument34 pagesEarthquake EngineeringLeonardo PimentelNo ratings yet

- Loading Conditions: Strength Design Max. MinDocument6 pagesLoading Conditions: Strength Design Max. MinLeonardo PimentelNo ratings yet

- STEEL STAIR DESIGNDocument4 pagesSTEEL STAIR DESIGNNikki RobertsNo ratings yet

- Peak Ground AccelerationDocument7 pagesPeak Ground AccelerationLeonardo PimentelNo ratings yet

- Earthquake Tips IITDocument2 pagesEarthquake Tips IITTarun GoelNo ratings yet

- Mechanical ResonanceDocument8 pagesMechanical ResonanceLeonardo PimentelNo ratings yet

- Base Plate AnalysisDocument2 pagesBase Plate AnalysisLeonardo PimentelNo ratings yet

- Truss Analysis With FEMDocument1 pageTruss Analysis With FEMLeonardo PimentelNo ratings yet

- Peak Ground AccelerationDocument7 pagesPeak Ground AccelerationLeonardo PimentelNo ratings yet

- Clip ConnDocument42 pagesClip ConnLeonardo PimentelNo ratings yet

- Clip Conn TableDocument10 pagesClip Conn TableLeonardo PimentelNo ratings yet

- Design of isolated footing for pipe supportDocument9 pagesDesign of isolated footing for pipe supportLeonardo PimentelNo ratings yet

- Truss 070505Document147 pagesTruss 070505Leonardo PimentelNo ratings yet

- Floor DeckDocument1 pageFloor DeckLeonardo PimentelNo ratings yet

- BaseplateDocument3 pagesBaseplateDushyantha JayawardenaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Installing Seismic Restraints For Mechanical EquipmentDocument158 pagesInstalling Seismic Restraints For Mechanical EquipmentinitbashNo ratings yet

- Construction Technology Course OutlineDocument8 pagesConstruction Technology Course Outlineapi-268401961No ratings yet

- SCI ED017 Design and Installation of Light Steel External Wall SystemsDocument36 pagesSCI ED017 Design and Installation of Light Steel External Wall SystemsTiago CastelaniNo ratings yet

- Reportofcayantower 190906010607Document35 pagesReportofcayantower 190906010607Reshay100% (1)

- Design Guide 07 Plywood Box BeamsDocument36 pagesDesign Guide 07 Plywood Box BeamsTaimoo NaseemNo ratings yet

- Steel beam and column connection componentsDocument5 pagesSteel beam and column connection componentsRandistya FahmyNo ratings yet

- Build A Basement Root CellarDocument3 pagesBuild A Basement Root Cellarjonjeys100% (1)

- OverviOverview of Structural Systems Slides 924ew of Structural Systems Slides 924Document11 pagesOverviOverview of Structural Systems Slides 924ew of Structural Systems Slides 924marinkataNo ratings yet

- EXPAMET - Builders - MetalworkDocument32 pagesEXPAMET - Builders - MetalworkMatthew AshworthNo ratings yet

- Techniques For The Seismic Rehabilitation of Existing BuildingsDocument167 pagesTechniques For The Seismic Rehabilitation of Existing Buildingsfasih_baqai4252No ratings yet

- Simulation of IBS Formation For Housing Construction PDFDocument111 pagesSimulation of IBS Formation For Housing Construction PDFHani HusainiNo ratings yet

- Moment Connection For TimberDocument28 pagesMoment Connection For Timberhenrykk2003No ratings yet

- FormDocument2 pagesFormmikailadam656No ratings yet

- 16Document70 pages16Waqar AhmedNo ratings yet

- Technical Bro A4 UK LR NEW v2Document45 pagesTechnical Bro A4 UK LR NEW v2Roxana NegoitaNo ratings yet

- Inviting comments on frozen food processing standardsDocument101 pagesInviting comments on frozen food processing standardsHsamb AbmNo ratings yet

- Carpentry Notes On Basic Roof Ceiling FramingDocument85 pagesCarpentry Notes On Basic Roof Ceiling Framingbekirm175% (4)

- BFD SOP 10 Fires in TaxpayersDocument12 pagesBFD SOP 10 Fires in TaxpayersPEDRO CAPARACHIN PALPANo ratings yet

- ITEM QUANTITY AND DESCRIPTION BILL OF QUANTITIESDocument6 pagesITEM QUANTITY AND DESCRIPTION BILL OF QUANTITIESKarthimeena MeenaNo ratings yet

- Gateway Commons IIIDocument36 pagesGateway Commons IIIRyan SloanNo ratings yet

- Analysis of Open Web Steel JoistsDocument13 pagesAnalysis of Open Web Steel Joistsamokhta100% (1)

- Plywood Manufacturing ProcessDocument40 pagesPlywood Manufacturing Processanon_61481338750% (2)

- Covered Court EstimateDocument255 pagesCovered Court EstimateJoseph DomingoNo ratings yet

- Ladder SafetyDocument27 pagesLadder SafetySantanu Kumar Sahu100% (1)

- Estimating forms, scaffoldingDocument11 pagesEstimating forms, scaffoldingLorna BacligNo ratings yet

- Scope of Work DocumentDocument11 pagesScope of Work DocumentJethNo ratings yet

- High Rise Building Structure SystemDocument35 pagesHigh Rise Building Structure SystemZanyar S. MuhamadNo ratings yet

- Functional Specification: Offshore InstallationsDocument17 pagesFunctional Specification: Offshore Installationshalim_kaNo ratings yet

- Calculating Design Loads For Wood Framing Components in Light Frame ConstructionDocument114 pagesCalculating Design Loads For Wood Framing Components in Light Frame ConstructionThanh Tam NguyenNo ratings yet

- Completion of Barangay Health Center Project in San Luis, AuroraDocument6 pagesCompletion of Barangay Health Center Project in San Luis, AuroraJohn Dale IbaleNo ratings yet