Professional Documents

Culture Documents

Best Practice: Load Management For Energy Efficiency: Heat Transfer Equipment

Uploaded by

sethu1091Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Best Practice: Load Management For Energy Efficiency: Heat Transfer Equipment

Uploaded by

sethu1091Copyright:

Available Formats

Best Practice

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment Document Responsibility: CSD/ESD/Energy Systems Unit 5 July 2006

Load Management for Energy Efficiency: Heat Transfer Equipment

Developed by: Energy Systems Unit Consulting Services Department Issue Date: 5 July 2006

Previous issue: None Next Planned Update: 5 July 2009 Primary Contact: jimmy.kumana@aramco.com, phone +966 (3) 874-6157

Page 1 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Table of Contents

1.0 Introduction 1.1 Purpose 1.2 Scope 1.3 Intended Users 1.4 References and Related Documents General 2.1 Definitions 2.2 Principles and Concepts 2.3 Degrees of Freedom 2.4 Process Variability 2.5 HX Design and Simulation 2.6 Fouling Monitoring & Mitigation Process Heating Trains 3.1 Single Process Stream Heated in Series 3.2 Single Process Stream Heated in Network of Parallel HX Trains 3.3 Avoid Un-Necessary Heating Process Cooling Trains 4.1 Single Process Stream Cooled in Series 4.2 Single Process Stream Cooled in Network of Parallel HX Trains 4.3 Multiple process Streams Cooled with a Single Cooling Utility 4.4 Avoid Un-Necessary Cooling 4.5 Load Shedding versus Process Modifications Heat Exchanger Networks 5.1 Simple HENs 5.2 Complex HENs 5.3 HEN Operability Considerations and Constraints Boiler Networks 6.1 Boiler Sparing Philosophy for Optimum Reliability 6.2 Load Allocation among Multiple Parallel Boilers 6.3 Load Management of Boiler Auxiliaries 6.4 Steam Balance Optimization Furnace Networks 7.1 Heater Sparing Philosophy 7.2 Load Allocation among Multiple Parallel Heaters 7.3 Load Allocation in Hot Oil Loops 7.4 Load Management of Furnace Auxiliaries 7.5 WHB Opportunities Page 5 5 5 5 6 6 6 6 7 7 8 20 20 22 24 26 26 27 30 31 32 34 34 38 43 47 47 50 54 59 64 65 66 66 70 74

2.0

3.0

4.0

5.0

6.0

7.0

Page 2 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

List of Exhibits

Number

2-1

Title

Feed Rate Profile for Fractionation Plant

Page

9

2-2 2-3 2-4 2-5 2-6 2-7 2-8 2-9 2-10 2-11 2-12 2-13 3-1 3-2 3-3 3-4 3-5 3-6 3-7 4-1 4-2 4-3 4-4 4-5 4-6 4-7 4-8 4-9 5-1 5-2a 5-2b 5-3 5-4 5-5 5-6a 5-6b

Steam Demand Profile for Fractionation Plant Savings Potential from Improved Process Stability Correlation between Feed to Plant and Feed to Fractionation Example of Control Strategy Change to Improve Process Stability Counter-current Temperature Profile Stage-wise Construction Procedure for NTU Experimental Measurement Fouling Rate (Field Data) Predicted Fouling Rates for a Particular HX Typical Composition of Fouling Deposits in Crude Oil Refineries Fouling Threshold Plot Hydro-blasting versus Foam Cleaning of Fin-Fan Coolers Results of Foam Cleaning Before and After Alternative Sequences for Process Heating in Series Energy Cost of Alternative Process Heating Sequences Control Strategy for Optimal Load Distribution in a Preheat Train Energy Cost of Alternative Process Heating Sequences Process Heating in Parallel HX Trains Comparison of Operating Policies for Process Heating in Parallel Bypass Line Avoids Un-Necessary Heating & Cooling Alternative Sequences for Process Cooling in Series Energy Cost of Alternative Process Cooling Sequences Process Cooling in Parallel HX Trains Comparison of Operating Policies for Process Cooling in Parallel Historical (12 month) Flow Profile of Stream Being Cooled Estimated Savings from Optimum Cooler Management Cooling Water Circuit with Series-Parallel HEN Power Conservation by Minimizing Compressor Discharge Pressure Shedding Fan Load vs Minimizing Compression Ratio Example of Simple HEN Simulation Results for Simple HEN Flow Deviation Only Simulation Results for Simple HEN Both Flow + Temp Deviations Recommended Control Strategy for Trim Cooler Simplified Flowsheet of NHT Plant Simulation Model of HEN for NHT Process (Design Case) Simulation Model for Shell & Tube Heat Exchanger Overall Temperature Profile for Simulated HX Operation

9 10 10 11 12 15 16 17 17 18 18 19 20 20 21 22 23 23 24 26 26 28 29 30 30 31 32 33 34 35 36 37 38 39 40 41

Page 3 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

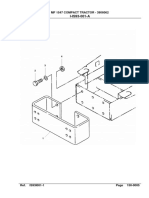

5-7 5-8 5-9 5-10 5-11 6-1 6-2 6-3 6-4 6-5 6-6 6-7 6-8 6-9 6-10 6-11 6-12 6-13 6-14 6-15 6-16 6-17 6-18 7-1 7-2 7-3 7-4 7-5 7-6 7-7 7-8 7-9 7-10 7-11 7-12 7-13 7-14 7-15 7-16 7-17

Sample Driving Force Plot from Integrity Sample Exchanger Response Plot from Integrity Network Performance with Over-sized HX Simulation Results for HEN of Exhibit 5-9 Propagation of Disturbances along Downstream Paths Typical Design of Field-erected Water-tube Boiler for Clean Fuels Comparison of Boiler Sparing Policies Boiler Fuel Use and Efficiency versus Steam Rate Effect of Turndown on Boiler Fuel Consumption Load Allocation Algorithm based on Least Cost Effect of Turndown on Boiler Fuel Consumption Excess Air versus Boiler Load, Typical Curve HHV and Stoichiometric Air Requirement for Common Fuels Fuel and Air Distribution Control for Multi-Burner Boilers Flame Similarity with Good Burner Control FD Fan Load Management: (a) 3 running; (b) 2 running Typical Fan Performance Curves Estimation of Savings from FD Fan Load Management BFW Pumps Load Management: (a) 3 running; (b) 2 running Refinery Steam Balance with GTs running at Full Capacity Refinery Steam Balance with GTs Off, Boilers Equally Loaded Refinery Steam Balance with GTs Off, Boilers Optimally Loaded Comparison of CHP Scenarios Principal Fired Heater Applications in Oil Refining Schematic of a Typical Process Heater Common Mechanical Configurations of Fired Heaters Optimum Flow Distribution for Hot Oil Loops Existing Process and Heater Configuration Process Heating Duty Histogram Proposed Heater Configuration for Optimum Load Management Furnace Data Savings Potential from Furnace Load Sharing Policy Savings Potential from Load Sharing plus Shifting Average Burner Number and Size in Fired Heaters Optimum Excess Air Ranges for Common Fuels Adiabatic Flame Temperatures with 15% Excess Ambient Air Adiabatic Flame Temperature vs Air Preheat (for Stoichiometric Air) Furnace Capacity Control System Based on Combustion Air Preheat Improved Furnace Efficiency with Combustion Air Preheat Improved Furnace Efficiency by Addition of a WHB

42 42 44 44 45 48 49 50 52 52 53 55 55 56 56 57 58 58 59 60 61 62 59 64 64 65 66 67 68 69 69 70 70 71 71 71 72 72 73 74

Page 4 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

1.0

1.1

Introduction

Purpose

Large industrial plants commonly use multiple parallel equipment trains for improved reliability. Very often, installed equipment capacity far exceeds normal production requirements. This excess capacity can often be translated into energy cost savings. Also, the heating and cooling objectives for the process can be met in a variety of alternative ways, using different types and amounts of utilities. There is a certain utilities mix that results in the lowest overall operating costs. The purpose of this new Best Practice is to describe ways in which energy cost can be minimized through optimum allocation of load among existing heat transfer equipment.

1.2

Scope

Many types of equipment commonly used in Saudi Aramco plants are significant energy consumers and amenable to operational optimization through Load Management, including: Steam heaters Fired Heaters (furnaces) Process Coolers air, water, refrigerant Complex Heat Exchanger Networks Boilers fired and unfired Pumps and compressors Steam and Gas Turbines

This Best Practice manual provides guidelines on methods to determine the optimum load management policies for heat transfer equipment only. Other types of energy consuming and converting equipment are covered in complementary Best Practice manuals. It is also important to note and understand what this manual is not: It is not a text book on heat transfer theory. It is not a Design Procedure for heat exchangers or for optimum design/retrofit of Heat Exchanger Networks (HENs). It is not a Design Procedure for boilers or fired heaters. It is not a procedure for calculating boiler or furnace efficiency. It is not a course. It is not a Saudi Aramco equipment design standard.

Although some of the topics covered in this manual may overlap with those found in the foregoing texts, they have been included only to provide background, and to make the reader aware that these subjects have a bearing on the determination of operational optimization via Load Management. For detailed information on these subjects, the reader should consult the reference books and related documents cited in section 1-4.

Page 5 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

1.3

Intended Users

This Best Practice manual is intended for use by the engineers working in Saudi Aramco plants, who are responsible for energy efficient operation of their facility. It provides guidelines for developing optimum load management policies, and estimating the cost savings therefrom. It is not intended to serve as a comprehensive treatise or design manual for heat exchangers, heat exchanger networks, boilers, or fired heaters.

1.4

Related Documents and References

SABP-A-002: Load Management for Energy Efficiency: Pumps and Compressors, Saudi Aramco Engineering Standard (2005) SABP-A-005: Quick Energy Assessment Methodology for Energy Efficiency Optimization, Saudi Aramco Engineering Standard (2006) SABP-A-007: Steam Trap Management for Energy Efficiency, Saudi Aramco Engineering Standard (2006) Handbook of Heat Transfer, 3rd ed, W. M. Rohsenow, J. P. Hartnett, and Y. I. Cho, McGrawHill Inc, New York (1998), Ch 18. Fundamentals of Heat Exchanger Design, R. P. Shah and D. P. Sekulic, John Wiley & Sons Inc, Hoboken, NJ (2003), Chs 3 and 11. Heat Transfer, 8th ed., J. P. Holman, McGraw-Hill Inc, New York (1997), Ch 10. Heat Exchanger Network Synthesis, U. V. Shenoy, Gulf Publishing Co, Houston, TX (1995) Thermal Design of Heat Exchangers, E. M. Smith, John Wiley & Sons Ltd, Chichester, UK (1997), Ch 2. Steam Plant Operation, 7th ed, E. B. Woodruff, H. B. Lammers, and T. F. Lammers, McGrawHill Inc, New York (1998). The Control of Boilers, S. G. Dukelow, ISA Press, Research Triangle Park, NC (1986). The John Zink Combustion Handbook, .C. E. Baukal, ed., CRC Press, Boca Raton, FL (2001), Chs 2, 16. Combustion System Design, Y. Khavkin, PennWell Books, Tulsa, OK (1996). No conflict is expected between the optimum load management policy and other Saudi Aramco standards with respect to reliability, safety, etc. If any such conflict should arise, the standard shall take precedence.

Page 6 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

2.0

2.1

General

Definitions

Best Practice: A process or method that, when correctly executed, leads to enhanced system performance. Load Management: An operating policy that distributes the load among multiple machines or equipment installed as series-parallel networks in a way that minimizes their energy (fuel + power) consumption, without compromising safety or reliability.

2.2

Principles and Concepts

When a process plant is designed, it is common practice for the engineering contractor to build some fat into the equipment sizes and piping, as a contingency factor to compensate for uncertainties in future operating conditions. Consequently, equipment is invariably over-sized for the task at hand. When equipment is being operated at rates below the installed capacity, it is often possible to extract some operating cost savings in the form of reduced energy consumption from the capital that has already been invested in surplus equipment capacity, but is not being utilized for additional production. On the other hand, over-sizing can also cause reduced overall system efficiency, because excessive heat transfer in a non-pinch HX could potentially reduce driving forces in a more critical pinch HX. The objective is to operate the equipment at the lowest total cost while still meeting the production objective. Several general principles and strategies apply in all cases: Minimize number of equipment items being operated in parallel (load sharing). Use heat recovery in preferences to utilities, and use the lower cost utilities in preference to higher cost utilities (load shifting). Allocate heat transfer duties to the different heat exchangers in a series/parallel network in such a way that minimizes the total cost of the various utilities required. Operate equipment at conditions that will maximize the system efficiency, even if it means that individual items may have to operate away from their maximum efficiency points. Assign maximum duty to the most efficient equipment (in a parallel set), and use the least efficient equipment as the swing machine. For parallel equipment with efficiency profiles of different shapes, assign incremental load according to incremental efficiency gradient (slope of curve).

The analytical procedures outlined in this manual will help establish the quantitative relationship between operating flexibility and energy costs, thereby enabling plant engineers and foremen to jointly make intelligent decisions about the optimum operating policy.

2.3

Degrees of Freedom

Optimization implies that one has multiple choices to accomplish the desired objective, and the only problem remaining is to choose the best option. The range of options available is limited by constraints which can be either hard or soft. A hard constraint is one which we cannot

Page 7 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

or are unprepared to violate at any cost e.g. the laws of physics, market realities, or the directives of senior management. A soft constraint is one that we have imposed on ourselves, and which could be relaxed at our discretion upon penalty of incurring some additional costs elsewhere. An example of a soft constraint is the requirement for redundancy in installed equipment in order to increase the level of operator comfort. It follows that the range of available options can be increased by relaxing soft constraints, and by finding some other way to alleviate the problem that the constraint was intended to prevent/mitigate. One way of highlighting the nature of a constraint is to set bounds for the acceptable temperature range. Process plants seldom operate under fixed condition . For instance, as discussed below, throughput can vary significantly, which gives rise to variations in process temperatures. We can identify the hardness of a constraint by specifying both a normal (eg. design point) value and maximum and minimum acceptable values. In this way we can define the flexibility inherent within the plant, and exploit it to reduce operating costs. The key to increased flexibility is introducing new Degrees of Freedom, which are parameters or design features over which one has some control. For example, a process heater that operates under varying load can be piped up to use two alternative sources of steam LP and HP, so that the cheapest one can be used depending on operating conditions requirements. Basically, one must keep an open mind. Think out-of-the-box. Do not accept the existing plant configuration as inviolate; try to think of the ideal solution, and then systematically add features to the existing design that will help to reach that ideal solution. Learn to recognize the difference between hard and soft constraints.

2.4

Process Variability

Process variability is a major cause of operating equipment at sub-optimal conditions. The smother the process flow rate, the greater the potential for stable and efficient operation. Consider the feed rate profile of experienced by one of our condensate fractionation plants. As seen from Exhibit 2-1, it is highly variable, with a max/min flow ratio of roughly 630/350 = 1.8 and a peak/avg ratio of about 630/450 = 1.4. The plant is clearly capable of being operated at a throughput of 630 MBD while still maintaining temperatures within acceptable bounds. This suggests that if the throughput were controlled closely within narrow bounds, the investment that has already been made would permit a 40% increase in production. That is the inherent power of reducing process variability. Now consider the impact of the variable fractionation feed rate on plant energy costs. The steam production rate will typically follow the feed flow rate. The ratio of peak/average flow is seen to be approx 2200/1530 = 1.44, consistent with the feed flow profile. The benefits of reduced process variability apply to utility systems as well. Consider the case of a plant whose operating policy is to run N+1 boilers, where N is the minimum number of boilers required to satisfy peak process demand. Suppose that the boilers are equal sized, with a maximum sustained capacity of 530 Klb/h each. The estimated potential savings from reducing process variability to 1.0 is shown in Exhibit 2-3. Note that these are free savings, requiring minimal capital investment in process revamp.

Page 8 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 2-1: Feed Rate Profile for Fractionation Plant

700 C2+ Feed 600 C3+ Feed Combined Feeds 500

Flow, MBD

400

300

200

100

0 5/1/01 6/8/01 7/16/01 8/23/01 9/30/01 11/7/01 12/15/01 1/22/02 3/1/02 4/8/02

Exhibit 2-2: Steam Demand Profile for Fractionation Plant

Boiler Steam Gen

2500

2000 Total HP Stm Gen, Klb/h

1500

1000

500

0

4/1/2001 5/21/2001 7/10/2001 8/29/2001 10/18/2001 12/7/2001 1/26/2002 3/17/2002

Page 9 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 2-3: Savings Potential from Improved Process Stability

How can we reduce process variability? Generally by revamping the control strategy and introducing additional surge capacity at critical pinch points in the process scheme. In the example cited, it is clear that the data clearly show that swings in steam demand follow (and therefore are most likely a consequence of) variations in feed flow rate. By increasing the amount of feed surge capacity through addition of a couple of storage tanks, the feed to fractionation was able to be changed from level control (as obvious from Exhibit 2-4) to flow control, per Exhibit 2-5, thus eliminating the hourly swings. Exhibit 2-4: Correlation between Feed to Plant and Feed to Fractionation

Feed to Fractionation 12000

10000

8000 Total Flow, BPH

6000

4000 C3+ from BGP 2000 C3+ feed to Mods

0 4/1 4/25 5/19 6/12 7/6 7/30 8/23 9/16 10/10 11/3 11/27 12/21 1/14 2/7 3/3 3/27

Page 10 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 2-5: Example of Control Strategy Change to Improve Process Stability

2.5

Heat Exchanger Design and Simulation

There are many types of heat exchanger (HX) designs, with the most common design being the Shell-and-Tube type. All indirect contact heat transfer equipment designs, however, are governed by a common set of design considerations. The most fundamental relationship in heat transfer is the heat balance, which derives from the first law of thermodynamics, and can be expressed as follows: q = Mass flow rate of cold stream x specific heat cold stream x (t2 t1) = Mass flow rate of hot stream x specific heat of hot stream x (T1-T2) The heat transferred by a HX is given by the equation: q = U x A x CMTD where and q = heat transfer duty, MMBtu/h U = overall heat transfer coefficient, Btu/ft2-h-F A = heat transfer area, ft2 CMTD = corrected mean temperature difference

The overall heat transfer coefficient is related to the film heat transfer coefficients for the hot and cold fluids by the equation: 1/U = 1/h1 + 1/h2 where h1 and h2 are the film heat transfer coefficients, inclusive of fouling allowances, for the hot and cold fluids respectively, and which are a function of the fluid flow regime (proportional to Reynolds number raised to the power 0.8), exchanger geometry (equivalent diameter of

Page 11 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

cross-sectional flow area), and fluid properties (specific heat, thermal conductivity, density, viscosity). The CMTD is a complex function of the exchanger geometry and fluid flow profiles, and is generally expressed as CMTD = Ft x LMTD where and LMTD = log mean temperature difference for true countercurrent flow, Ft = correction factor for non-countercurrent temperature profile

Consider Exhibit 2-6, which shows the schematic representation of a HX with a true countercurrent temperature profile. The Logarithmic Mean Temperature Difference, or LMTD, is defined as (T t ) (T2 t1 ) LMTD = 1 2 T t ln 1 2 T2 t 1 The correction factor Ft adjusts the LMTD for cases where the temperature profiles of the hot and cold stream are not true counter-current. Detailed procedures for calculating Ft are beyond the scope of this Best Practice manual. The reader is instead referred to basic college text books on heat transfer theory and heat exchanger design, such as Holmans Heat Transfer, 8th ed, McGraw-Hill Book Co, New York (1997), or Kerns Process Heat Transfer, McGraw-Hill Book Co, New York (1950) Exhibit 2-6: Counter-current Temperature Profile

For economic reasons, the HX is normally designed is such a way that the value of Ft is between 0.75 and 1.0 (Saudi Aramco standard is 0.8). For multi-pass shell & tube HX with t2 < T2 (ie. no temperature cross), the approximations of Gulyani & Mohanty [Chem Eng, (Nov 1996) p127] can be used with an error of less than 1%:

T t Ft = A + B 2 2 T t 1 1

Page 12 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

HX Effectiveness Relationships

Source: J. P. Holman, Heat Transfer, 8th ed, p 581. Note that C = Cmin/Cmax, and N = NTU. For a more comprehensive list, see Table 17.6, Handbook of Heat Transfer, Rohsenow et al, op. cit.

Except when C (more commonly denoted as R) = 0, the hot and cold outlet temperatures can be calculated from the known hot and cold stream inlet temperatures T1 and t1 as:

T2 = T1 (T1 t1), and t2 = t1 + R(T1 t1)

Page 13 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

HX Configuration 1-2+ 2-4+ 4-8+

A 0.8037 0.961 0.991

B 1.208 0.237 0.0661

Using the Ft method, the number of minimum shells in series can only be determined by trial and error. Shenoy [Ref. Heat Exchanger Network Synthesis, Gulf Publishing Co, Houston (1995), pp 260-264] has described a more direct method using two parameters P and R:

=P=

T1 T2 T t 1 1

and R =

(M .Cp )H (M .Cp )C

The minimum number of shells required (in multiple tube-pass configuration) in order to have Ft 0.75 is obtained by

1 R.P (NS)min = ln 1 P

(NS)min = 0.9P/(1-P), where PC =

1 R.PC ln 1 PC

for R = 1

, for R 1

2. 1 0.1 exp[0.5(log R) 2 ] 1+ R + R2 +1

(NS)min usually turns out to be a fractional number, and must be rounded up to the next integer. The design is considered acceptable when P PC. The Ft method can be used only when the inlet and outlet temperatures are specified, or otherwise known. For heat load management, that is not generally the case. Normally we know only two of the four terminal temperatures, with the other two having to be determined by simulation. Because the equations involved are non-linear, the solution requires trial and error. For simulating the performance of existing heat exchangers of known geometry under different operating conditions, the effectiveness-NTU method is much more convenient. The effectiveness is defined as:

T of fluid with lower heat capacity actual heat transfer = maximum possible heat transfer Max temp difference in HX

= (t2-t1)/(T1-t1), if cold fluid heat capacity < hot fluid = (T1-T2)/(T1-t1), if hot fluid heat capacity < cold fluid =

1 exp[ NTU .(1 C min / C max )] for true counter-current flow 1 (C min / C max ) exp[ NTU .(1 C min / C max )]

Page 14 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

where and

NTU = Number of Transfer Units = UA/Cmin Cmin = heat capacity of smaller stream, Btu/h-F Cmax = heat capacity of larger stream, Btu/h-F

A quick approximate estimate for the number of shells-in-series required for a given duty can obtained by stepping down the hot and cold duty lines (see Exhibit 2-7). This is equivalent to applying a temperature meet condition to each shell. Since the number of shells must be an integer, fractional solutions are rounded up. Exhibit 2-7: Stage-wise Construction Procedure for NTU

These are the critical relationships that will be required to perform HEN simulations, from which we can derive the optimum HX load management policies.

2.6

Fouling Monitoring & Mitigation

One of the problems that plague most heat exchangers is fouling, which degrades the ability of the equipment to transfer the desired amount of heat. Fouling can be due to a number of factors. Polley et al [Evaluation of Crude Oil Fouling Data for Application to Refinery Preheat Trains, Applied Thermal Engineering, vol 22 (2002), pp 777-788] showed that for oil refining processes, the fouling mechanism consists of a competition between scale deposition (thermal effect) and removal (shear effect), which can be adequately modeled by the equation

dR f

E = Re 0.8 Pr 0.33 exp RT dt w

k Re 0.8 ,

Page 15 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

where TW = tube wall temperature, which can be estimated as = (hoTo + hiti) / (ho + hi) To = bulk temperature of hot fluid (shell side), and ti = bulk temperature of cold fluid (tube side). Fouling rates are determined through HX performance monitoring under actual field conditions, as illustrated in Exhibit 2-8. The activation energy E is a key variable which must be empirically adjusted to fit the data, and usually falls in the range 16.8 - 18.9 Btu/lbmole (3944 kJ/kg-mole) for most crude oil streams. The removal constant k has a value of 3 x 10-8. Exhibit 2-8: Experimental Measurement Fouling Rate (Field Data)

0.011 0.01 0.009 Overall Fouling Factor 0.008 0.007 0.006 0.005 0.004 0.003 0.002 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 Time since last cleaning (hours)

Source: G. T. Polley (gtpolley@aol.com), personal communication (2006)

Activation Energy (E) and Removal Constant (k) are best obtained through the analysis of the performance of an existing plant. Exhibit 2-9 shows a screen shot from ESDUs EXPRESS computer program. The plot is derived for chosen E and k. The upper line (red) shows fouling rate predicted for the hottest point in the exchanger, the lower line (blue) shows the rate predicted for the crude inlet, the middle line (magenta) gives a prediction of the overall fouling rate (derived from an integral equation), the short (grey) line is the rate measured on the plant. It is possible to get the integral rate and the measured rate to coincide through judicious selection of E and k. The best values for E and k are obtained by analyzing the performance of a range of exchangers each operating at different velocity and bulk temperatures. At high temperatures, the deposition rate increases. At high velocities, the scale removal rate increases. It is therefore possible to construct a chart, as in Exhibit 2-11, that shows the flow regimes and temperatures in which deposition rates exceed removal rates, and vice versa. Such fouling threshold plots should be developed for each exchanger (shell-side as well as tube-side), and the HX must be operated in the appropriate temp-flow regime to minimize fouling. The fouling threshold identifies the flow and temperature conditions at which it becomes impossible to eliminate fouling through exchanger design. Above this point either a cleaning schedule should be introduced or fouling controlled through the use of tube inserts.

Page 16 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 2-9: Predicted Fouling Rates for a Particular HX

Source: G. T. Polley, Saudi Aramco Course Notes , lecture 7 (July 2006)

Exhibit 2-10: Typical Composition of Fouling Deposits in Crude Oil Refineries

Source: H. Lemke, Fouling in Refinery Equipment an Overview, AIChE Spring Mtg (March 1999)

The fouling problem is equally important for fin-fan to air coolers, which are the predominant type of utility coolers in Saudi Arabia. Fortunately, they are relatively easy to clean.

Page 17 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 2-11: Fouling Threshold Plot

340 320 300

Temperature (C)

280 260 240

Epstein Model Polley Model

220 200 0 0.5 1 1.5 2 2.5

No Fouling Positive Fouling Negative Fouling

3.5

Velocity (m/s)

Source: B. L. Yeap et al, Chem Eng Res Des, vol 82A (2004), pp 53-71

The conventional cleaning method is to use hydro-blasting. However, this tends to damage the fins, causing a permanently high flow resistance on the air aide, and corresponding loss of capacity. A newer and preferred method is foam cleaning. This has been successfully used in some Saudi Aramco refineries, and is recommended as a best practice. Since cleaning costs are low, the optimum cleaning cycle is much shorter than for shell & tube HX cleaning. Exhibit 2-12: Hydro-blasting versus Foam Cleaning of Fin-Fan Coolers

Gentle Foam Drainage through Fins

Low Pressure Foam Aerates and Protects Fins Source: www.northernindustrialcleaners.com (2006)

Page 18 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 2-13: Results of Foam Cleaning Before and After (a) Before Cleaning

(b) After Foam Cleaning

Source: www.northernindustrialcleaners.com (2006)

Page 19 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

3.0

Process Heating Trains

When a process stream has to be heated from its supply temperature to its target temperature, this can be accomplished in a variety of ways. For example, all of the heat could be supplied through utilities, or some could be supplied via heat recovery from other process streams, and the balance through utilities. There is also the option of allocating load between utilities.

3.1

Single Process Stream Heated in Series

Three examples of alternative heating sequences are illustrated in Exhibit 3-1, each of which has a different energy cost as shown in Exhibit 3-2. Exhibit 3-1: Alternative Sequences for Process Heating in Series

Exhibit 3-2: Energy Cost of Alternative Process Heating Sequences

Page 20 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

In case 1, all heat is supplied using high-pressure (HP) steam, at a cost of $58.3 per hour. In case 2, the heating load is split between low-pressure (LP) and HP steam, for a total cost of $52 per hour. This reduction in operating cost was possible because we shifted some of the heating duty from a more expensive (HP steam) utility to a less expensive utility (LP steam). Now let us consider case 3a. Here, some of the heating duty is provided by recovery of waste heat from another process stream, one which requires cooling. The cost drops further, and rather dramatically, from $52 per hour to $37.5 per hour. If we do more heat recovery, as in case 3b, the cost drops to $36 per hour. Obviously, our goal is to minimize the total utility cost, which corresponds to case 3b. However, unless the design of the existing train conforms to the configuration shown in case 3, we will not have the flexibility to trade-off LP steam versus HP steam, and LP steam versus process heat recovery. These three cases illustrate the essential principle of load management. viz., when we have the option to use multiple utilities, we should maximize the duty of the cheapest utility, and minimize the duty of the most expensive utility. Thus, in Cases 2 and 3, the control system should be designed to maximize the process stream temperature out of the LP steam heater, as illustrated in Exhibit 3-3, rather than setting LP steam on direct flow control. Exhibit 3-3: Control Strategy for Optimal Steam Load Distribution in a Preheat Train

In general, we will not have the freedom to do all of the heating with free waste heat. Nor will we be able to eliminate use of the most expensive utility. This is because we have certain design constraints. One is the temperature of the heat source, another is the available quantity of the heat source, and the third is the capacity of the heat exchange equipment itself. The first two constraints are obvious. It is not possible to heat a cold stream to a temperature higher than the temperature of the hot stream (heat source). This is known as the driving

Page 21 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

force constraint. Similarly, the cold stream cannot be supplied more heat than is available in the heat source. This is known as the heat balance constraint. The third constraint has to do with heat transfer capacity of the HX, which could become limiting because at flow rates below design, U, LMTD, and Ft all fall, and the multiplicative effect of the combined reduction could over-ride the reduced requirement for Q. While the Case 3 configuration shown in Exhibit 3-1 may give the lowest operating cost, it should be recognized that the capital cost of this design will be higher than that of Case 1. Suppose we are faced with a Case 1 configuration. What can be done to minimize operating cost at minimal expense of capital cost? A possible solution is illustrated in Exhibit 3-4. The basic principle is to introduce a new degree of freedom by adding a new LP supply connection, and blend LP steam with HP steam through an ejector. The discharge pressure from the ejector will be an intermediate value between that of LP steam and HP steam. The cost savings derive from the fact that some of the HP steam is substituted with LP steam. Some additional capital will be required for an ejector and for additional process controls, but it would be substantially less than adding a new LP steam heater. Exhibit 3-4: Energy Cost of Alternative Process Heating Sequences

3.2

Single Process Stream Heated in Network of Parallel HX Trains

Flow rates in many Saudi Aramco facilities are so great that it is not possible to build singletrain equipment large enough to accomplish the desired heat transfer. In these situations, banks of parallel heat exchangers are used, as illustrated in Exhibit 3-5. What is the optimum load management policy when the actual flow rate is less than design? Should be reduce all flows equally, or should we valve off some of the HX and run the rest at closer to design capacity? The two options are compared in Exhibit 3-6.

Page 22 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 3-5: Process Heating in Parallel HX Trains

Exhibit 3-6: Comparison of Operating Policies for Process Heating in Parallel

Page 23 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

What is very interesting is that even though the heat transfer duty on the inter-changer goes down substantially at lower operating rates, the feed outlet temperature stays about the same. This is not an aberration; but has a theoretical basis: LMTD is roughly proportional to r0.2, where r = actual throughput design throughput. Thus LMTD remains substantially constant over the normal range of operating rates. A 50% reduction in throughout will cause LMTD to suffer only a 13% decrease. As LMTD falls, the feed outlet temperature rises, and steam requirement per unit of feed flow goes down. This observation is generically true. The simulation results show that it is better to run the network with all units, although the difference is very slight. This is based on the assumption that lower velocities will not result in increased fouling rates (per Exhibit 2-10). However, if the lower velocities at reduced operating rates cause the HX to fall into the fouling zone, then it would be better to run the network with fewer trains, and accept the small increase in steam costs. The model should check that HX duty q = M.Cp.(T1-T2) is q = U.A.CMTD, as this constraint cannot be violated. What the simulation model also shows is that a very small energy cost penalty (< 1%) is incurred if the plant elects to shut down one train (during low-rate operation) for HX cleaning or repair while the rest of the trains pick up the slack.

3.3

Avoid Un-Necessary Heating

Sometimes, it is possible to save steam load merely by looking at the overall process scheme to identify opportunities for avoiding steam use in the first place. Most process units are designed to be self-contained, with storage tanks in between them to provide surge capacity for intermediate products. Exhibit 3-7: Bypass Line Avoids Un-Necessary Heating & Cooling

Page 24 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Typically the intermediate product from process A must be cooled before storage, both to prevent material loss due to evaporation, as well as consequent environmental emissions. Typically this intermediate product must then be reheated before it is fed to process B. Once we recognize the inter-relationship, it becomes obvious that both heating and cooling duties could be eliminated (or at least minimized) by by-passing the intermediate storage tank during regular operation, and using it only to compensate for flow imbalances between the operating rates of processes A and B.

Page 25 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

4.0

Process Cooling Trains

Load management policies for process coolers follow the same general rules as for process heaters.

4.1

Single Process Stream Cooled in Series

Three examples of alternative heating sequences are illustrated in Exhibit 4-1, each of which has a different energy cost as shown in Exhibit 4-2. Exhibit 4-1: Alternative Sequences for Process Cooling in Series

Exhibit 4-2: Energy Cost of Alternative Process Cooling Sequences

Page 26 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

In case 1, all cooling is done with refrigerant, at a cost of $34.9 per hour. In case 2, a significant portion of the cooling duty has been shifted to lower cost air cooling, for a total cost of only $14.9 per hour. Process-process heat recovery, while it can reduce total utility cooling duty, does not reduce costs significantly, because all the saving occurs in low-cost air-cooling duty. Therefore Case 2 will in all likelihood have better economics than Cases 3a and 3b. The key optimization parameter here would be the outlet temperature from the air cooler (120F in the example). All efforts should be made to minimize this temperature. The appropriate operating policy whenever refrigerant is being used would therefore include some or all of the following:

Run all the air-cooler (fin-fans) at full speed all the time Clean the fin-fans frequently to maintain high U (must set up a monitoring program) Use water spray on fin-fans to boost heat transfer capacity through evaporative cooling. Water quality must be very high, though, to prevent scale formation and/or corrosion. Cooled boiler blowdown may a suitable candidate for this application.

It would be a mistake to control the air-cooler outlet temperature to some set design value by cutting back on the fans. Depending on the economics, it might also be worth introducing another degree of freedom, eg. cooling water as an additional utility to off-load the refrigerant duty. The best way to determine the optimum load management strategy is to construct a simulation model for each application as illustrated in Exhibit 4-2, and focus on optimizing the operating parameters that have the greatest impact on energy total cost.

4.2

Single Process Stream Cooled in Network of Parallel HX Trains

The general procedure for determining the optimum operating policy for cooling trains in parallel is the same as described for heating trains. The simulation results for the network of parallel cooling trains shown in Exhibit 4-3 are presented in Exhibit 4-4, for the following data:

Observe that the previous conclusion about running all trains in preference to fewer trains is no longer correct. The previous conclusion is valid only if the utility cost is a continuous function of capacity; eg for steam, for which the cost per MMBtu is constant within narrow bands. In the case of air cooled (fin-fan) HX that is generally not so. Air coolers are usually equipped with fixed speed fans which can be either ON or OFF, so that a reduced cooling load does not automatically translate into power savings. Only when the cooling load drops sufficiently can one of the fans in a fin-fan bank be shut off. In other words, fan power is a discrete (step-wise) function of cooling load.

Page 27 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 4-3: Process Cooling in Parallel HX Trains

For the selected design basis conditions, the optimum operating policy is:

It was determined by running the simulation model at various load factors, making sure that the actual capacity of the heat exchangers never exceeds the maximum capacity. In the illustrative example, the cold process stream is being heated against the product and fed directly to a reactor. That may not always be feasible, and a trim heater (or flow bypass) for more precise temperature control may be required. If the air cooler motors were equipped with variable frequency drives, then it would be possible to modulate the fan speed and reduce the air flow rates to exactly match the required duty. In such a case, the cost of operating the air cooler would be more nearly a constant with respect to capacity, and we would have to do the economics differently, as in Exhibit 4-2, with the optimum operating policy probably also being different. So the message is one can only determine the optimum load management policy by constructing a simulation model that accurately reflects the actual capabilities and operating characteristics of the equipment in the field. Generalizations can be dangerously misleading.

Page 28 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 4-4: Comparison of Operating Policies for Process Cooling in Parallel

What Exhibit 4-4 demonstrates is that it is possible to save a significant portion (25%) of the power cost for operating this cooling train if the number of trains being operated is adjusted accordingly to the load. The actual savings potential versus flat out operation with all trains running all the time can be estimated using historical data on the load profile, as illustrated in Exhibits 4-5 and 4-6.

Page 29 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 4-5: Historical (12 month) Flow Profile of Stream Being Cooled

Flow Profile

4500 4000 3500 Hours per year 3000 2500 2000 1500 1000 500 0 200 240 280 320 360 400 Flow, MBD

Exhibit 4-6: Estimated Savings from Optimum Cooler Management

The potential savings in this case are not especially large, but they are FREE, requiring zero capital investment, and are a substantial reduction (about 20%) compared to the base case power cost when running with all four trains all the time. In the example shown, only flow rate variations have been examined. In fact, many other parameters could also be varying, such as supply temperatures of the product and cold process stream, U values (due to fouling), and of course, ambient temperature. These additional complexities can be easily accommodated in a spreadsheet model; the simulation approach remains the same.

4.3

Multiple Process Streams Cooled with a Single Cooling Utility

This situation arises in cases where a cooling utility such as cooling water, sea water, or refrigerant is used to cool multiple process steams in a network of HX some of which may be in series and others in parallel, as illustrated in Exhibit 4-7.

Page 30 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 4-7: Cooling Water Circuit with Series-Parallel HEN

The optimum distribution of LMTD in each cooler occurs when the coolant flow is controlled to achieve the desired target temperature of the hot process stream, which minimizes the power consumption of the cooling water circulation pumps [Ref. Kumana, A Pre-Design Strategy

for Selecting Near-Optimum Cooling Water Flow Rates, AIChE Symposium Series no. 236, Vol 80, (1984), pp 117-121].

Most often, all coolers are arranged in parallel, between the CW supply and return headers. This is usually not the optimum configuration. Some of the coolers should be in series with respect to coolant flow. The correct cooler network structure (series/parallel arrangement and sequences) should be determined by Pinch Analysis, and the appropriate piping modifications should be made to approach the optimum structure as close as possible. Observe in particular the location of the cooling water makeup and blowdown locations. The make-up must be added at the point in the circuit where coolant temperature is lowest, and the blowdown should be taken from the point in the circuit where the coolant temperature is highest. Usually these are reversed, for mechanical convenience, by vendors and contractors who neither understand nor care about operating efficiency.

4.4

Avoid Un-Necessary Cooling

See section 3.3.

Page 31 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

4.5

Load Shedding versus Process Modifications

Power consumption can also be reduced by minimizing the required discharge pressure. For example most Aramco compressors have a fin-fan cooler in their discharge line, whose cooling capacity varies with ambient temperature. One of the power conservation strategies used by the operators is to shed power load on the fans during cooler weather (a laudable attempt at thermal load management) once the temperature set point downstream of the cooler is being met. However, maintaining a constant condenser temperature is the wrong control objective if the compressor discharge stream is going to a condenser, because the required pressure for condensation is not constant but varies with ambient temperature. In such cases, even greater power savings could be obtained by following a different operating policy viz. to maximize the fin-fan cooling capacity but save even more power by minimizing the discharge pressure (and therefore the compression ratio). A suggested control scheme is shown in Exhibit 4-8, with the supporting calculations presented in Exhibit 4-9. Exhibit 4-8: Power Conservation by Minimizing Compressor Discharge Pressure

The tricky part is being able to determine when exactly we have achieved total condensation, something very difficult to do. The proposed solution is to have two condensers in series. The main condenser would condense only about 90-95% of the vapor, and the vent condenser would condense the balance. The control system would be set up to maintain a fixed flow ratio in the range from 10:1 to 20:1 between the main flow and the vent flow.

Page 32 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 4-9: Shedding Fan Load vs Minimizing Compression Ratio

The required discharge pressure in Case 2 is found by successive iteration until the calculated condenser surface area for cases 1 and 2 are identical. Although process modifications cannot strictly be classified as Load Management, the subject has been presented here because it is a way to introduce new degrees of freedom that enable optimal load allocation between the different energy consumers in the overall system.

Page 33 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

5.0

Heat Exchanger Networks

Process heating and cooling seldom occurs in isolation. Invariably, heating and cooling loads are interlinked though the heat and material balance. Even the simplified examples in sections 3.2 and 3.3 featured both heating and cooling. In this section we are going to focus on how to optimize operating loads in more complex Heat Exchanger Networks (HENs), that are typical of oil, gas and petrochemical processes.

5.1

Simple HEN with HX, Heating and Cooling

Consider the simple HEN shown below. Exhibit 5-1: Example of Simple HEN

The following design data are given, with the flow rate and feed supply temperature known to deviate significantly from design. What should the optimum operating policy be when these two parameters (identified as green-shaded cells) vary over their typical range of values?

Page 34 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Once again, we take the simulation approach, and work out what the performance of the HEN would be under various scenarios. Once we understand the response of the HEN to the expected deviations from design conditions, it becomes possible to determine the optimum load management policy that gives the lowest operating cost. Exhibit 5-2a: Simulation Results for Simple HEN Flow Deviation Only

What if the operation involves a change in both the feed rate and the feed temperature, as shown below?

Page 35 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

The model structure would still be the same, but the optimum set points for operation would be different, as illustrated in Exhibit 5-2b. Exhibit 5-2b: Simulation Results for Simple HEN Combined Flow and Temp Deviations

The simulation models are not difficult to develop, but the following points should be noted: For the Design Case (a) The exchanger minimum approach temperature EMAT is selected to be identical to the minimum approach temperature for the entire network (often referred to as the heat recovery approach temperature, or HRAT). HRAT is normally determined using the optimization algorithm of Pinch Analysis; in this case it is given to be 20F. Once EMAT is specified, the terminal temperatures for all HX can be calculated. (b) For the sake of consistent simulation results, the area of the HX must be adjusted iteratively until the required U matches the available U. (c) For convenience of simulation, exchangers number 1 and 4 have been specified as true counter-flow (1-1 shell & tube) configuration, with Ft = 1. In reality they would probably be either 1-2 or 2-4 configurations, with 0.75 < Ft < 1. The HX effectiveness formulas, in terms of R and N, would have to be modified accordingly.

Page 36 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

For the Operating Case Simulation (a) The HX areas have to be the same as those for the design case (b) HX inlet temperatures are known from the process requirement. Outlet temperatures can be calculated from the effectiveness, viz. T2 = T1 (T1 t1), and t2 = t1 + R(T1 t1) Note that for steam heaters, R = 0, = 1 exp(-NTU), and t2 = t1 + (TS t1) (c) There is one drawback to calculating terminal temperatures in this way to prevent circular references in the algorithm, the hot and cold stream flow rates are required as input data. In the case of process streams this is generally not a problem, as they are known from the material balance. In the case of utility streams, however, eg. cooling water, this algorithm does not accurately represent the way the process is operated. Normally, for utilities, the objective is to minimize the flowrate required to achieve a particular terminal temperature for the process stream being heated or cooled, and that is how the control loop is set up. Therefore, instead of specifying utility stream flow, we should specify the EMAT for each exchanger. We then need to go through an iterative trial and error procedure to ensure that the specified EMAT values result in terminal temperatures and heat transfer duties consistent with the HX size and the expected U values at the new (off-design) operating conditions. The iteration stops when the required U and available U agree within the specified tolerance limits. (d) Flow rates for the heating and cooling utilities are calculated from the heat balance. The simulation models tell us that if we change the set points of the HX control loops to achieve the indicated terminal temperatures and duties, then the energy cost of operating the HEN will drop from $332/h to $238/h, a saving of 28% in utility costs in Case A and a saving of 26.5% in Case B. The control logic for the steam heaters should be as shown in Exhibit 3-3. The recommended control logic for the trim cooler is presented in Exhibit 5-3. Exhibit 5-3: Recommended Control Strategy for Trim Cooler

Page 37 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

5.2

Complex HENs

The spreadsheet-based simulation approach illustrated in section 5.1 can be extended to much more complex networks, and has in fact been successfully applied to several process units in oil refining CDU, NHT, CCR, Isomerization, etc. as well as gas processing plants. Exhibit 5-4: Simplified Flowsheet of NHT Plant

The spreadsheet simulation model for the NHT process (as designed) is shown in Exhibit 5-5. Observe that the actual (operating) U values, even for the base case scenario, are significantly lower than the expected clean U values, almost by an order of magnitude. Why such a huge discrepancy? The reason is that most EPC contractors tend to use overly conservative fouling factors, which result in excessive heat transfer area. The fact that actual U values are so low indicates that both shell and tube side the velocities are extremely low, under which conditions rapid fouling is much more likely. Therefore the exchangers will have to be cleaned more frequently, defeating the purpose of choosing a high fouling allowance to begin with. What we need to do is check the shell and tube side velocities for each application, and determine where the HX operation falls on the fouling threshold chart (see Exhibit 2-11). Normally the velocities should be in the range of 3-10 ft /sec.

Page 38 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 5-5: Simulation Model of HEN for NHT Process (Design Case)

Page 39 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

A detailed HX simulation (as opposed to HEN simulation) should also be done for each HX, as illustrated in Exhibits 5-6a and 5-6b. From this analysis, it is possible to determine what mechanical modifications, e.g. adding another tube-side pass, adding a longitudinal shell-side baffle (conversion from E-shell to F-shell configuration), etc, would be most practical to achieve the desired performance. Exhibit 5-6a: Simulation Model for Shell & Tube Heat Exchanger

Page 40 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

To assess maximum heat transfer capacity of the HX, adjust the duty until the available fouling factor is approx 0.0005 (generally between 0.0003 and 0.001). To goal of making such mechanical modifications is to get additional heat transfer capacity from the HX, and thereby to achieve better overall heat recovery in the HEN. Exhibit 5-6b: Overall Temperature Profile for Simulated HX Operation

HX Temp Profile 160 150 140 130 Temp, F 120 110 100 90 80 70 0 5 10 15 20 25 30 35 Q, MMBtu/h Hot Stream Cold Stream

Although all the HEN simulation models of Saudi Aramco plants have thus far been developed internally from scratch, it is possible to purchase commercial software programs that automate much of the work. One is Persimmon , that provides a convenient ready-made Excel interface for general HEN simulation as well as some advanced features such as a module for determining optimum HX cleaning schedules. This software has been extensively used in the oil refining and petrochemical industries, and is available from Veritech Energy, Virginia, USA. Also, a suite of inter-related programs that include Integrity and Express, are available from ESDU International plc, London, UK. [Note: Software names have been mentioned here for the readers convenience only, and should not be construed as a commercial endorsement.] A very useful tool for assessing whether the pinch HX is in the network is the Driving Force Plot, as in Exhibit 5-7. If the actual temp profile of the HX is far from the ideal driving force profile, the HX is wasting temperature gradient. If the available temperature gradient within the HX is significantly less than the ideal, then that HX is the one limiting the heat transfer capability of the HEN. To get improved performance from the HEN, some corrective action in terms of piping modifications or addition of more surface area will be required. Another useful tool is the Exchanger Response (or Sensitivity) Plot, illustrated in Exhibit 5-8.

Page 41 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 5-7: Sample Driving Force Plot from Integrity

Poor Alignment

Good Alignment

Source: G. T. Polley (gtpolley@aol.com), personal communication (2006)

Exhibit 5-8: Sample Exchanger Response Plot from Express

Source: G. T. Polley (gtpolley@aol.com), personal communication (2006)

Page 42 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Unfortunately, the problem of optimum operation of existing HENs has received very little attention from research scholars, and there is a dearth of published material on the subject. Only four relevant papers were found after conducting an exhaustive literature search: K. Li and B. Niemeyer, Optimal Operation of HENs Under Uncertainty, Int J of Heat Exchrs, vol V (2004), pp 79-94. B. Glemmestad, S. Skogestad and T. Gundersen, Optimal Operation of HENs, Computers & Chem Eng, vol 23 (1999) pp 509-522. N. G. Brancaccio, G. T. Polley and B. L Pretty, Spreadsheet Modeling of HENs using Effectiveness-NTU Method, NPRA Computer Conference, Atlanta, GA (Nov 11-13, 1996). R. Ratnam and V. S. Patwardhan, Sensitivity Analysis of HENs, Chem Eng Sci, vol 46, no 2 (1991), pp 451-458. The general consensus seems to be that a two-step approach is best: (a) (b) Set up the model to determine the optimum temperature set-points for HEN control, with the objective of minimizing total utility cost. Run the model periodically with updated process flow and inlet temperature data, say every 4-8 hours, and adjust the set points accordingly.

5.3

HEN Operability Considerations and Constraints

HEN operability depends not only on the design structure (ie. if the matches make effective use of the available heat and temperature gradients), but also on parametric changes that are unavoidable in practice. In all cases, the problem can be thought of as due to a mismatch between process requirement and equipment capability/performance. A HX may be improperly sized for its duty either because it was incorrectly designed for the specified service to begin with, or because the actual operating conditions (flow rates, temperatures, heat transfer coefficients) have deviated from expected design conditions. The consequences of undersized HX are generally well known, but the pitfalls of over-sized HX are often not recognized. Consider the simple system shown in Exhibit 5-9. Exchanger E-1 requires 1622 ft2 in order to achieve the necessary duty. However, it has been oversized by 10% and 1785 ft2 have been installed. Similarly exchanger E-2, which requires 5155 ft2, has also been oversized by 10% with 5671 ft2. Detailed simulation results are summarized in Exhibit 5-10. The result of over-sizing E-1 means that it performs better than expected. So, the cold stream leaves the unit at 280F rather than the targeted value of 277F. Since, this does not have a detrimental effect upon the process downstream of the unit this over-performance would not normally draw attention.

Page 43 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 5-9: Network Performance with Over-sized HX

Note: Blue font = specified data, black font = calculated values 10% excess area for E-1 and E-2, no excess area for steam heater H.

Exhibit 5-10: Simulation Results for HEN of Exhibit 5-9

However, the hot stream leaves the unit at a temperature of 253F rather than the expected value of 259F. This reduces the available temperature driving force in E-2 to below that used for design, and results in less heat recovery than expected for this unit. The cold stream now leaves the E-2 at 210F rather than the expected 212F. The shortfall in performance occurs despite the exchanger actually being over-sized by 10%, and has two negative consequences (a) energy penalty of 0.4 MMBtu/h, and (b) failure to meet the target cold stream temperature of 300F. One could argue that the target temperature could be achieved by adding more surface area to the heater as well, but that is additional investment for no energy benefit. A possible solution to avoiding the energy penalty is to add 690 ft2 more surface area to E-2. We now have traded off a capital cost penalty for an energy penalty. Observe that we would have to add 690 ft2 more area over and above the 10% over-size already built into the design, for a total of 1205 ft2 extra (ie. 23% over-sized). This is more than 7 sq ft extra in E-2 for each sq ft of excess area in E-1.

Page 44 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

The proper solution to this problem is to recognise that E-1 is over-performing, and operate a bypass around it in order to restore the temperature driving force on E-2. These insights cannot be obtained without a thorough analysis, as illustrated above. This example further demonstrates that in order to employ effective Heat Load Management, the control system must be designed properly as well, and adequate instrumentation must be provided. An important principle for understanding the performance of HENs is the propagation of disturbances. Recall that the increase in area of E-1 resulted in a disturbance to temperatures at which both hot and cold streams left the exchanger, and in turn affecting the performance of E-2 located downstream. Reduced heat transfer in E-2 caused the temperature of the cold stream leaving it to fall, thereby increasing the required duty on the heater positioned downstream of E-2. Note that both disturbances only affected equipment that was located downstream along the paths defined by the individual streams and the heat recovery exchangers (Exhibit 5-11a). Now consider what would have happened if the temperature at which the cold stream entered E-2 had been disturbed (see Exhibit 11b). This disturbance affects the temperature at which the cold stream leaves E-2 and enters the heater positioned downstream. It also affects the temperature at which the hot stream involved in the match leaves the exchanger. Given the network structure, it cannot possibly affect the temperature of the hot stream entering E-2. In short, the disturbance cannot move upstream. The principle is simple, but general: disturbances can only propagate downstream. Exhibits 5-11a and b: Propagation of Disturbances along Downstream Paths

The concept of downstream paths though simple is very powerful. For instance, if one process stream is known to be subject to large disturbances and another stream needs to have a closely controlled temperature, the designer can prevent control problems by simply ensuring that the sensitive stream is not on a path downstream of the variable stream. If it is known that one particular exchanger is the subject of severe fouling but some others in the system are not, then the effects of that fouling on the overall system can be compensated for

Page 45 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

by installing extra area to clean exchangers that are on the same path as the dirty one. The exchanger that is subject to fouling can then be designed with the objective of minimizing the fouling within it rather than adding extra area to the unit (with resultant lower velocity and higher fouling), which is the normal practice. The concept of downstream paths is particularly relevant for Load Management in HENs. The opportunities for exploiting changes in operating conditions of a given HX only exist along thermal paths downstream of that location. The real parameters of significance for developing an optimum HEN load management strategy are not the unique target temperatures for streams, but the maximum and minimum allowable temperatures. The target temperatures are useful the plant design; the allowable bounds are useful for heat load management. During plant operation it is normal to find that the actual process temperature differs from the original target (design) temperature. It is the relationship between actual temperature and the bounds that is important. For instance, in the HEN of Exhibit 5-8, rather than simply compensate for the over-performance of E-1 relative to the design target, the operator can exploit the flexibility inherent in the HEN by operating a bypass around E-1 such that both the outlet temperatures are close to their optimum values, and result in minimum steam use.

Page 46 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

6.0

Boilers

Almost all industrial plants use steam as the principal energy source for process heating. However, boilers should not be seen as islands, but merely as one of the components of the overall utility system, also known as the Combined Heat and Power (CHP) system for the facility. Normally, a plant CHP system has multiple boilers, which may or may not be of equal capacity and operating pressure, and may or may not use the same fuel or operate at the same efficiencies. Furthermore, some of the process steam may be generated in Waste Heat Boilers (unfired heat exchangers), while some might be generated in Heat Recovery Steam Generators (HRSGs) associated with a gas turbine. Also HRSGs can be either supplementary fired or unfired. Both HRSGs and WHBs are part of the plant CHP system. Although their mechanical designs are radically different, functionally they are both identical to boilers. This manual is focused on the predominant type of boilers used in Saudi Aramco plants, viz. natural-circulation oil- and gas-fired water-tube industrial boilers. Operating pressures of modern boilers can range from 150 to 1800 psig, with 150 psig and 600 psig being the most common within the company. However, most of the load management principles described and recommendations made in this manual will apply to other types of boilers as well, including smaller fire-tube boilers used in lower pressure applications such as HVAC.

6.1

Boiler Sparing Philosophy for Optimum Reliability

Most industrial plants have multiple boilers, for two reasons. One is that the plant may have a steam demand that is larger than the maximum practical size of an industrial boiler, which is around 1,000 Klb/h. Many Saudi Aramco gas plants use much more than this amount. The other reason is to ensure improved reliability of steam supply. Thus even in plants where the total steam demand could be comfortably supplied by one boiler (eg. the refineries), it is common practice to operate multiple boilers, on the basis that if one of them trips the other(s) can instantaneously pick up the slack and the main process continues to operate at full rate. The policy of running more boilers than needed is expressed as N+, where N is the minimum number of boilers required to supply the peak process steam demand, and is the number of extra boilers that are kept in operation to provide instantaneous spare capacity in the event one of the boilers trips. Some Saudi Aramco plants operate with an N+1 policy, while others follow an N+2 policy; but there is a cost. When excess numbers of boilers are operated, the average steam generation rate for each boiler will be significantly less than design, and the energy efficiency will be lower, as shown in Exhibit 6-2. The fact is that improved reliability can be achieved in a number of different ways, most of which do not incur such a high energy cost penalty. An understanding of the factors that govern reliability of steam supply to the process is therefore critical to the question of optimum load management policies. The crucial issue is not how many boilers to operate as running spares, but whether adequate steam reserve is available at all times to accommodate shortterm process load swings.

Page 47 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 6-1: Typical Design of Field-erected Water-tube Boiler Fired with Clean Fuels

Source: Singer, ed, Combustion: Fossil Power Systems, 3rd ed, Combustion Engg Inc, Windsor, CT (1981), p8-25

Page 48 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

Exhibit 6-2: Comparison of Boiler Sparing Policies

Basis: Fuel cost = $1.25/MMBtu, Operating rate = 8760 h/yr

The Reliability of a boiler is usually measured in terms of an Availability Factor, defined as

Availability Factor = (Available On-stream hours) / (Total hours in the Period)

Another measure of reliability is also important:

Forced Outage Rate (FOR) =

Forced Outage Hours Service Hours + Forced Outage Hours

One of the ways to reduce the required steam reserve is to minimize process variability (cf. section 2.4). Another is to develop a load-shedding program during upsets, when non-critical steam users (such as storage tank coils, or even the de-aerator) can be temporarily shut off. A third might be to increase the amount of steam generated in the process WHBs. A fourth option would be to keep the spare boiler on hot standby, rather than full operation; this will enable rapid startup (within 20-30 min at most) to full rate in case one of the boiler trips, during which time the plant can resort to load shedding or one of the other tactics. In the worst case, production rate might have to be slowed down somewhat for a few minutes, which can be easily made up as soon as the spare boiler is up and running; hardly a disaster. In Exhibit 6-2, notice the available steam reserve for the N+0 operating policy. It is equivalent to more than 2 full boilers. This is the type of analysis that should be done when determining the optimum boiler load management policy. The example cited assumes equal sized boilers at the same pressure and with the same energy efficiency profiles. In such cases, a CHP model such as that described in section 6.4 can be a more effective analytical tool.

Page 49 of 75

Document Responsibility: Energy Systems Unit, CSD Issue Date: 5 July 2006 Next Planned Update: 5 July 2009

SABP-A-008 Load Management for Energy Efficiency: Heat Transfer Equipment

6.2

Load Allocation among Multiple Parallel Boilers

A common practice in many facilities is to distribute the steam load among the boilers equally on a prorated basis. This practice is not optimal, and should be discontinued. Best Practice depends upon the amount of reliable data available, and the sophistication of the control system. One is load allocation by efficiency; the other is by least operating cost. 6.2.1 Load Allocation by Efficiency