Professional Documents

Culture Documents

Structural Steel Construction

Uploaded by

Nik ZalaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Steel Construction

Uploaded by

Nik ZalaniCopyright:

Available Formats

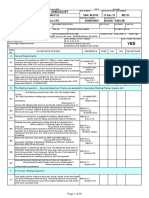

MAHASALAM SDN BHD

MSSB/MTS/CON/SSW

Construction Method Statements Manual

1.0 OBJECTIVE

Structural Steel Works

Page : 1/3

To outline the method statements by which structural steel works are carried out.

2.0 SCOPE This method statements shall apply for structural steel works on building and civil engineering projects.

3.0 REFERENCES MS ISO 9001 Clause 7.5.1 Process Reference P4.2 Receiving Inspection and Testing Inspection and Test Plan Project Filing Index Receiving Inspection Checklist Request for Inspection Form Structural Steel Works Inspection Checklist Construction Drawings Project Specifications

- MSSB/PRO/CON/03 - MSSB/ITP - MSSB/PFI - MSSB/RIC - MSSB/RFI - MSSB/SSTIC

4.0 DEFINITIONS NIL

5.0 RESPONSIBILITIES Site Engineer Site Supervisor

Revision : 0

Effective Date:01-11-2006

MAHASALAM SDN BHD

MSSB/MTS/CON/SSW

Construction Method Statements Manual

6.0 MATERIALS

Structural Steel Works

Page : 2/3

Structural members, bolts, nuts etc

7.0 HANDLING AND STORAGE OF MATERIALS Handling : Transportation shall be carried out by lorries or other suitable machinery. Storage : As per temporary building and site facilities layout plan.

8.0 PLANT, MACHINERY AND EQUIPMENT Welding machine, Tourque wrench, Mobile crane etc.

9.0 PREPARATORY WORKS 9.1 Obtain relevant approved construction drawings from the client / clients representative. Arrange for preparation of shop drawings, if required. Submit the shop drawings to client / clients representative for approval, where necessary. Set out the locations, positions and levels for structural members with reference lines. Carry out receiving inspection of necessary materials using Receiving Inspection Procedure. File completed Receiving Inspection Checklist as per Project Filing Index.

9.2 9.3

9.4

9.5

9.6

Revision : 0

Effective Date : 01-11-2006

MAHASALAM SDN BHD

MSSB/MTS/CON/SSW

Construction Method Statements Manual

Structural Steel Works

Page : 3/3

10.0 WORK METHODOLOGY 10.1 Carry out marking for structural members as per drawings and cut to the required sixes. 10.2 The structural steel works shall then be erected, adjusted and completed in the required position to the lines and levels as specified in the drawings with appropriate allowances for permanent deformations during fabrication and erection. 10.3 Carry out necessary connections between structural members using bolting or welding methods as specified. 10.4 Check the member / components of rolled and built up sections for compliance within tolerances for deviations etc as defined in the Project specification. 10.5 Check the required torque for bolted connections using torque wrench in accordance with Project Specifications. 10.6 Carry out the required checks for welding etc in accordance with Inspection and Test Plan. 10.7 Clean the structural members of all dirt, grease, scale and rust by controlled high pressure jets or abrasive blast cleaning. 10.8 Carry out the necessary paint system / metallic coating as per Inspection and Test Plan. 10.9 Submit Request for Inspection Form for joint inspection and joint measurement with client / clients representative using Structural Steel Works Inspection Checklists. 10.10 On completion of joint inspection, request client / clients representative to sign on the Request for Inspection Form and file as per Project Filing Index.

Revision : 0

Effective Date : 01-11-2006

You might also like

- 02 SpecificationsDocument194 pages02 SpecificationsNabeel Adeeb Alshare100% (1)

- Guidesteelworkssupervision PDFDocument78 pagesGuidesteelworkssupervision PDFPhạm Văn ĐảngNo ratings yet

- MIP6-CV-0013-008 - METHOD STATEMENT FOR STRUCTURAL STEEL ERECTION - Rev.A4...Document30 pagesMIP6-CV-0013-008 - METHOD STATEMENT FOR STRUCTURAL STEEL ERECTION - Rev.A4...Kepweng ManggagamotNo ratings yet

- National Structural Concrete Specification For Building ConstructionDocument0 pagesNational Structural Concrete Specification For Building Constructionmajkil1988100% (1)

- BS National Structural Concrete Specification For Building ConstructionDocument132 pagesBS National Structural Concrete Specification For Building ConstructionAmie D MalobagoNo ratings yet

- Fabrication Inspection of Structural Steel Final 1.28.15Document12 pagesFabrication Inspection of Structural Steel Final 1.28.15Vinod Kumar Verma100% (1)

- MGB-MS-003-ST-003 Formwork InstallationDocument8 pagesMGB-MS-003-ST-003 Formwork InstallationImho Tep100% (1)

- Ontario Precast Concrete SpecificationDocument23 pagesOntario Precast Concrete Specificationumerfr2No ratings yet

- Structural steelwork specificationDocument161 pagesStructural steelwork specificationYadunath RavikumarNo ratings yet

- Structural Steelwork Method StatementDocument6 pagesStructural Steelwork Method StatementAdib SalahNo ratings yet

- Structural Steel Fabrication and Erection SpecificationDocument21 pagesStructural Steel Fabrication and Erection SpecificationFarid RezaeianNo ratings yet

- STRUCTURAL STEEL Rev.1Document11 pagesSTRUCTURAL STEEL Rev.1mohdNo ratings yet

- 05 12 00 Structural Steel FramingDocument35 pages05 12 00 Structural Steel FramingfoxeyladyNo ratings yet

- Station Scaffolding and Formwork Erection and DismantlingDocument14 pagesStation Scaffolding and Formwork Erection and Dismantlingsunil tyagiNo ratings yet

- 277 SpecDocument86 pages277 Specmanil_5No ratings yet

- Final ReportDocument74 pagesFinal ReportDrew FerrerNo ratings yet

- Opss-Prov 906 - 2020 - Construction Specification For Structural Steel For BridgesDocument16 pagesOpss-Prov 906 - 2020 - Construction Specification For Structural Steel For BridgesPubcrawlNo ratings yet

- Pre-Fabricated Bridge - MSTDocument12 pagesPre-Fabricated Bridge - MSTwafikmh4No ratings yet

- AESS - Steel StructureDocument56 pagesAESS - Steel Structurevirginia_aureliaNo ratings yet

- NKWASHI CONCRETE BOX CULVERT SPECIFICATIONSDocument137 pagesNKWASHI CONCRETE BOX CULVERT SPECIFICATIONSjohn bandaNo ratings yet

- Blinding Concrete Works Contents Revised 19-04-16RDocument3 pagesBlinding Concrete Works Contents Revised 19-04-16RJoel Alcantara100% (1)

- SECTION 08 63 00 Metal-Framed SkylightsDocument14 pagesSECTION 08 63 00 Metal-Framed SkylightsJuanPaoloYbañezNo ratings yet

- MARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaDocument10 pagesMARJAN INCREMENT PROGRAM Installation of Steel Support and Gratings For TR AreaFaraaz MohammedNo ratings yet

- Micropile SpecDocument14 pagesMicropile SpecVijaya BhaskarNo ratings yet

- Steel Fabrication Method StatementDocument23 pagesSteel Fabrication Method StatementvivekNo ratings yet

- SteelDocument16 pagesSteelAmjad PervazNo ratings yet

- CON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)Document22 pagesCON 311 V00 (Method Statement For Structural Steel and Pipe Support Fabrication)mnmsingam100% (1)

- TTO-ST-0-SPC-05100 - Structural Steel SpecificationDocument18 pagesTTO-ST-0-SPC-05100 - Structural Steel Specificationsara saravananNo ratings yet

- NPQS C3-70 Prestressed ConcreteDocument30 pagesNPQS C3-70 Prestressed ConcreteGuobin SimNo ratings yet

- Elastomeric BearingsDocument10 pagesElastomeric Bearingsprincebh3No ratings yet

- Section 13 4200 - Pre-Fabricated Precast Concrete Structures Part 1 - GeneralDocument13 pagesSection 13 4200 - Pre-Fabricated Precast Concrete Structures Part 1 - GeneralRavindra MRNo ratings yet

- Engineering Services: Steel Structures Technical ProcedureDocument7 pagesEngineering Services: Steel Structures Technical Procedurekevin_au18No ratings yet

- MS - For Steel Struc. Triple Beam To Be Lift.Document13 pagesMS - For Steel Struc. Triple Beam To Be Lift.Elezer BatchoNo ratings yet

- Opss-Prov 906 - 2004 - Construction Specification For Structural Steel For BridgesDocument29 pagesOpss-Prov 906 - 2004 - Construction Specification For Structural Steel For BridgesPubcrawlNo ratings yet

- Structural Steel FramingDocument21 pagesStructural Steel FramingAlejandro MorelNo ratings yet

- 05 - 12 - 00 - 00 (05120) - Steel FramingDocument12 pages05 - 12 - 00 - 00 (05120) - Steel FramingMatthew Ho Choon LimNo ratings yet

- Method of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Document17 pagesMethod of Statment For Welding of Carbon Steel Pipes Dks-mst-c11-001 Rev 1Sherief Abd El Baky83% (12)

- NPQS C5-10 Structural SteelworkDocument0 pagesNPQS C5-10 Structural SteelworkCasimir Ghee Heng LimNo ratings yet

- Method of Statements (Rolling Rolling Procedure)Document12 pagesMethod of Statements (Rolling Rolling Procedure)Ravi TyagiNo ratings yet

- OPSS 1351 Apr10Document12 pagesOPSS 1351 Apr10irratrixNo ratings yet

- Ontario Bridge Steel Construction SpecificationDocument20 pagesOntario Bridge Steel Construction Specificationumerfr2No ratings yet

- Structural Steel Specifications.Document17 pagesStructural Steel Specifications.maodcb5No ratings yet

- Bs130 CSPG Guidelines 24062021 PDFDocument38 pagesBs130 CSPG Guidelines 24062021 PDFRamesh GuptaNo ratings yet

- MOS-CVL-14Formwork MOSDocument3 pagesMOS-CVL-14Formwork MOSWaqar Ahmad MalikNo ratings yet

- Section 05120 Structural SteelDocument9 pagesSection 05120 Structural SteelMØhãmmed ØwięsNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- FL - Aluminum Widows - Arcadia IncDocument25 pagesFL - Aluminum Widows - Arcadia IncDeepakDeepuNo ratings yet

- Udlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)Document120 pagesUdlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)mtcengineering100% (2)

- WELDING PROCESSES GUIDEDocument52 pagesWELDING PROCESSES GUIDEIka Puspita NurainiNo ratings yet

- EPMA Introduction To PM HIP Technology English PDFDocument32 pagesEPMA Introduction To PM HIP Technology English PDFFlávia CostaNo ratings yet

- Astm A 888 2013 PDFDocument58 pagesAstm A 888 2013 PDFjoao carlos protzNo ratings yet

- Floor Finish: Estimated Unit Rate Amount Quantity (UAE DHS) (UAE DHS) Item Description UnitDocument10 pagesFloor Finish: Estimated Unit Rate Amount Quantity (UAE DHS) (UAE DHS) Item Description UnitThanuja WijesingheNo ratings yet

- Propiedades Mecanicas - FastenerDocument4 pagesPropiedades Mecanicas - FastenerEHT pipe100% (1)

- Structure Diagram STST WeldmetalDocument1 pageStructure Diagram STST WeldmetalwenigmaNo ratings yet

- Mos Lab Manul by Abhidhesh YadavDocument45 pagesMos Lab Manul by Abhidhesh YadavabhiNo ratings yet

- Analyze A Sample of Brass QualitativelyDocument4 pagesAnalyze A Sample of Brass QualitativelyMEGHNA MATHURNo ratings yet

- Ecoreco E-Waste Recovery-By Mr. T R Rao 2Document10 pagesEcoreco E-Waste Recovery-By Mr. T R Rao 2bksoni100% (1)

- 2009 Dual Man - CNC FleetDocument1 page2009 Dual Man - CNC FleetGeorge KeithNo ratings yet

- Check ValvesDocument44 pagesCheck ValvesOlawale John AdeotiNo ratings yet

- The Complete Line of Hydraulic Shears Press Brakes Iron WorkersDocument22 pagesThe Complete Line of Hydraulic Shears Press Brakes Iron WorkersJim ConneryNo ratings yet

- Series FBV-3C-SS, FBVS-3C-SS Specification SheetDocument2 pagesSeries FBV-3C-SS, FBVS-3C-SS Specification SheetWattsNo ratings yet

- Heat Resistant Alloy HN Data SheetDocument2 pagesHeat Resistant Alloy HN Data SheetAzize RazamNo ratings yet

- Broom Manufacture Machine: StartDocument62 pagesBroom Manufacture Machine: StartHaziq PazliNo ratings yet

- PEB Steel Alliance Ltd. Offers State-of-the-Art Steel Building SolutionsDocument26 pagesPEB Steel Alliance Ltd. Offers State-of-the-Art Steel Building SolutionsAbdul MaminNo ratings yet

- English For Technical StudentsDocument138 pagesEnglish For Technical StudentshappinesNo ratings yet

- Crosby ShacklesDocument1 pageCrosby Shacklesroy sihalohoNo ratings yet

- B 93 - B 93M - 15Document4 pagesB 93 - B 93M - 15phaindikaNo ratings yet

- Aluminium Dross - A Case Study-FinalDocument20 pagesAluminium Dross - A Case Study-FinalRoberto Nasi100% (2)

- 100 AC-DC: FeaturesDocument3 pages100 AC-DC: FeaturesLee Chong EeNo ratings yet

- Quality Function Deployment: Presented by Angela Presberry Mercena JohnsonDocument87 pagesQuality Function Deployment: Presented by Angela Presberry Mercena JohnsonsenthilmhNo ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceDocument12 pages1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- WES Hygienic Design Handbook - Jan 01Document54 pagesWES Hygienic Design Handbook - Jan 01Alfonso FuentesNo ratings yet

- MSDS Steel Sheet Safety DataDocument4 pagesMSDS Steel Sheet Safety Datachinck83No ratings yet

- Asme Ix QW MTDocument57 pagesAsme Ix QW MTharabiNo ratings yet

- Peka SC Year 3Document11 pagesPeka SC Year 3joepcw1578No ratings yet