Professional Documents

Culture Documents

AGR Comparison

Uploaded by

Pardeep Kumar JainOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGR Comparison

Uploaded by

Pardeep Kumar JainCopyright:

Available Formats

INFLUENCE OF SULFUR REMOVAL ON IGCC PERFORMANCE AND COST Richard A.

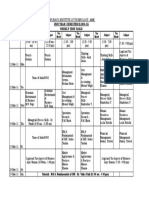

Newby SAIC February 2005 Rough estimates have been made of the impact of the level of sulfur removal on the plant performance and cost of IGCC power generation. The results relate to the use of Eastern bituminous coal having relatively high sulfur content (2-4 wt%). Several IGCC process studies and technology assessments provide information relating to this influence of the IGCC sulfur removal on the plant performance and cost, although a definitive evaluation of this has not been reported. References used here are listed. The current commercial, coal-based IGCC plants use primarily MDEA acid gas removal (AGR) technology, with COS hydrolysis, to meet moderate levels of sulfur removal (about 98% removal) with the clean fuel gas sulfur content being greater than 100 ppmv. Other gasification plants for refinery coke applications and for fuels /chemicals production apply other technologies (Selexol, Rectisol, Sulfinol) to meet more stringent gas desulfurization requirements. Selexol is proposed for use in several, future coal-based IGCC plants. It appears that the limits of practical use of the AGR technologies might be: MDEA (with COS hydrolysis): 99% sulfur removal, about 100 ppmv total sulfur in gas, Selexol (with COS hydrolysis): 99.9% sulfur removal, about 10 ppmv total sulfur in gas, Rectisol: 99.98% sulfur removal, about 2 ppmv total sulfur in gas. The results presented depend on several factors that have additional influences: gas pressure, coal properties, plant application (hydrogen production, F-T liquids production, CO2 removal and sequestration). It is important to note that the gas cleaning system in IGCC represents a relatively small portion of the total power plant capital investment, 10-15%, combined with the influence of increased sulfur removal on increased power plant heat rate increased sulfur removal efficiency results in a moderate increase in the power plant total investment, and a lower power plant thermal efficiency leading to an overall significant increase in the $/kW power plant investment and cost-of-electricity. The quantitative results from two evaluations put in terms of relative performance and cost factors are listed below. These results have been plotted and scaled to give rough correlations for the impact of sulfur removal on performance and costs in the attached figures. AGR Technology Used Fluor Selexol Selexol SWPC MDEA with COS hydrolysis 99.98 Rectisol * Ill #6 coal cost $1/MMBtu Study Sulfur removal (%) 89.0 99.8 99.1 Sulfur content of clean gas (ppmv) 1,463 25 128 2.8 Relative Plant Heat Rate 1 1.037 1 1.035 Relative Capital Investment 1 1.091 1 1.076 Relative Cost of Electricity* 1 1.076 1 1.042

Selexol 1.07 1.06 1.05 1.04 1.03 1.02 1.01 1 0.99 0 1000 2000

MDEA

Rectisol

Relative Plant Heat Rate

3000

4000

5000

6000

1 / ( 1 - Removal eff )

Selexol Relative Capital Investment 1.16 1.14 1.12 1.1 1.08 1.06 1.04 1.02 1 0.98 0 1000 2000

MDEA

Rectisol

3000

4000

5000

6000

1 / ( 1 - Removal eff )

Selexol Relative Cost of Electricity 1.12 1.1 1.08 1.06 1.04 1.02 1 0.98 0 1000 2000

MDEA

Rectisol

3000

4000

5000

6000

1 / ( 1 - Removal eff )

References Feerrar, S. et al, Effects of Sulfur Emission Controls on the Cost of Gasification Combined Cycle Power Systems, report prepared by Fluor Engineering for EPRI, EPRI Report AF-916, October 1978. Lorton, G. A., Assessment of Sulfur Removal Processes for Advanced Fuel Cell Systems, report prepared by C. F. Braun & Co. for EPRI, EPRI Report EM-1333, January 1980. Biasca, F. E., et al, Process Screening Study of Alternative Gas Treating and Sulfur Removal Systems for IGCC Power Plant Applications, report prepared by SFA Pacific, Inc. for EPRI, EPRI Report AP-5505, December 1987. Korens, N., D. R. Simbeck, and D. J. Wilhelm, Process Screening Analysis of Alternative Gas Treating and Sulfur Removal for Gasification, report prepared by SFA Pacific, Inc. for DOE/NETL, December 2002 (report available on the NETL website, Gasification Technologies page). Newby, R. A., et al, Filter-Reactor Novel Gas Cleaning Process Conceptual Evaluation, Optional Program Draft Report, prepared by Siemens Westinghouse Power Corporation, under contract No. DE-AC26-99FT40674, October 2004.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 21.12.07 Jawaban PT SejahteraDocument76 pages21.12.07 Jawaban PT Sejahtera202010415109 ADITYA FIRNANDO100% (1)

- B.ST XI Subhash Dey All Chapters PPTs (Teaching Made Easier)Document1,627 pagesB.ST XI Subhash Dey All Chapters PPTs (Teaching Made Easier)AH tronix61% (18)

- BD All Automotive ContactsDocument39 pagesBD All Automotive ContactsScribdTranslationsNo ratings yet

- Constro 2023 BrochureDocument8 pagesConstro 2023 BrochureRita BawejaNo ratings yet

- Boiler - Self Certification SchemeDocument2 pagesBoiler - Self Certification SchemeSIL PROJECTSNo ratings yet

- Prasath Resume For Industrail & Process EngineerDocument3 pagesPrasath Resume For Industrail & Process EngineerPrasathNo ratings yet

- BSM1501 Podcast Chapter 2Document2 pagesBSM1501 Podcast Chapter 2Babalwa MpongosheNo ratings yet

- Channel Marketing Budget TemplateDocument16 pagesChannel Marketing Budget TemplateIvanNo ratings yet

- Export and Import Management 1Document32 pagesExport and Import Management 1Sri Ganesh ComputersNo ratings yet

- Challenges Faced by Tata Motors: Tata Ace Challenge: Targeting The Bottom of PyramidDocument1 pageChallenges Faced by Tata Motors: Tata Ace Challenge: Targeting The Bottom of PyramidLijo MathewNo ratings yet

- Agricultural CrisisDocument18 pagesAgricultural CrisisAnneSitjar100% (1)

- EContent 11 2023 02 02 12 16 55 ProductionAnalysisppt 2023 01 05 11 27 11Document43 pagesEContent 11 2023 02 02 12 16 55 ProductionAnalysisppt 2023 01 05 11 27 11Priyanka RajputNo ratings yet

- 5 Dunning's OLI and Porter's Diamond, Global Sourcing and ProductionDocument9 pages5 Dunning's OLI and Porter's Diamond, Global Sourcing and ProductionOlga LiNo ratings yet

- China Agricultural ReformsDocument233 pagesChina Agricultural ReformsNitinSinghNo ratings yet

- A Simple Solution For Starting A Profitable Cannabis BusinessDocument18 pagesA Simple Solution For Starting A Profitable Cannabis BusinessMartin TrifonovNo ratings yet

- Application Summary FormDocument2 pagesApplication Summary FormJaeKimNo ratings yet

- An Economic History of The USSR, 1917-91 by Alec NoveDocument482 pagesAn Economic History of The USSR, 1917-91 by Alec NoveMaks imilijanNo ratings yet

- Print - Udyam Registration CertificateDocument1 pagePrint - Udyam Registration CertificateDebiprasad DashNo ratings yet

- OrganicDocument5 pagesOrganicTempNo ratings yet

- HARDOX400 - 10mm Plate - MTCDocument2 pagesHARDOX400 - 10mm Plate - MTCMohammad Adil100% (1)

- Food Waste Reduction in Supply Chains Through Innovations: A ReviewDocument18 pagesFood Waste Reduction in Supply Chains Through Innovations: A ReviewLejandra MNo ratings yet

- Week 12Document1 pageWeek 12Rathi54No ratings yet

- Current Affairs Q&A PDF - 1&2 January 2021: Join @bhawna - Weekly - Quiz - PdfsDocument45 pagesCurrent Affairs Q&A PDF - 1&2 January 2021: Join @bhawna - Weekly - Quiz - PdfsHIRENo ratings yet

- Economics A04Document13 pagesEconomics A04Peter&GaryNo ratings yet

- Key Partners Key Activities Value Proposition Customer Relationships Customer SegmentsDocument1 pageKey Partners Key Activities Value Proposition Customer Relationships Customer SegmentsMichelle BerlianmastanNo ratings yet

- V Guard Anupama PDFDocument105 pagesV Guard Anupama PDFAnupama ThomasNo ratings yet

- Document 10Document24 pagesDocument 10Yufi Alwie PRatama RNo ratings yet

- Sales Leads ForeverDocument17 pagesSales Leads ForeverAnkita ShrivastavaNo ratings yet

- Tally - Erp9: Free Online Computer Classes OnDocument14 pagesTally - Erp9: Free Online Computer Classes OnAditya VermaNo ratings yet

- DusaA Etall2015rcuaplicatiiinstatisticaDocument253 pagesDusaA Etall2015rcuaplicatiiinstatisticaAdriana PadureNo ratings yet