Professional Documents

Culture Documents

Exp 1 Microstructures Hardness

Uploaded by

Muhammad KhuzairiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp 1 Microstructures Hardness

Uploaded by

Muhammad KhuzairiCopyright:

Available Formats

E1-MAB 2023

EXPERIMENT 1 HEAT TREATMENT OF METALS Objectives: To understand the basic principle of hardness measurement To be able to perform the hardness testing. To be able to analyze the results obtained. To recognize and identify each micro constituent present in the microstructure of metals To use phase diagram or TTT diagram to relate the microstructure developed with the effects of composition, impurities and heat treatment - To deduce the materials properties based on microscopic examination.

Introduction for Hardness Measurement: Hardness is a measure of a materials resistance to localized plastic deformation (e.g., a small dent or a scratch). Hardness tests are performed more frequently than any other mechanical test for several reasons: 1. They are simple and inexpensiveordinarily no special specimen need be prepared, and the testing apparatus is relatively inexpensive. 2. The test is nondestructivethe specimen is neither fractured nor excessively deformed; a small indentation is the only deformation. 3. Other mechanical properties often may be estimated from hardness data, such as tensile strength. There are the most common hardness test methods used in today`s technology: 1. Rockwell hardness test 2. Brinell hardness 3. Vickers hardness 4. Knoop hardness 5. Shore hardness

.

Steels are based on the Fe-C system and exhibit both diffusional and diffusionless transformation. Martensite is the name given to the diffusionless shear-type transformation that occurs when the high-temperature austenitic phase is rapidly cooled or quenched at such a rate as to avoid decomposition by a diffusional mechanism. The rapid cooling retains carbon in super-saturated solid solution to produce a body-centered tetragonal crystal structure. As-quenched martensite is very hard, brittle and in a state of stress. In order to change it to a more useful form it needs stress relieving and tempering to restore ductility and toughness. Tempering involves reheating it to a temperature below the eutectoid temperature. During tempering, the carbon trapped in solution is able to diffuse, relaxing the BCT to a BCC structure, and iron carbides precipitates begin to form; the precise nature of the carbide phase depends on the composition of the steel and tempering temperature and duration. Generally, the iron carbides will not be detected by light microscopy at any but the highest (~650 0C) tempering temperatures; they are finely dispersed at lower tempering temperatures and indeed can contribute to strength. Thus, tempered martensite can deliver excellent combinations of strength and toughness superior to diffusionally formed microstructures. Consequently, it is the preferred structure for a number of engineering applications. This experiment is designed to compare the heat treatment response of a plain carbon steel BS 970/080M40 (En8) with that of a low alloy steel BS 970/817M40 (En24) containing similar concentrations of carbon.

1/3

E1-MAB 2023

Introduction for Microstructures:

Microstructure is subject to direct microscopic observation, using optical or electron microscopes. In metal alloys, microstructure is characterized by the number of phases present, their proportions, and the manner in which they are distributed or arranged. The microstructure of an alloy depends on such variables as the alloying elements present, their concentrations, and the heat treatment of the alloy (i.e., the temperature, the heating time at temperature, and the rate of cooling to room temperature). The term phase equilibrium, often used in the context of this discussion, refers to equilibrium as it applies to systems in which more than one phase may exist. Phase equilibrium is reflected by constancy with time in the phase characteristics of a system. Equilibrium phase diagrams represent the relationships between temperature and the compositions and the quantities of phases at equilibrium. For a binary system of known composition and temperature that is at equilibrium, at least three kinds of information are available: (1) the phases that are present, (2) the compositions of these phases, and (3) the percentages or fractions of the phases. The procedures for making these determinations will be presented in this experiment.

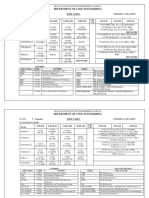

Procedure: Samples: Specimen No.: 1. 2. 3. 4. 5. Normalized - EN8/EN24 Water quench with agitation - EN8/EN24 Oil quench with mild agitation - EN8/EN24 Copper Copper after annealing

The Hardness Measurements: 1. Remove any oxidation scale from 2 opposite faces by grinding on SiC paper and measure the Rockwell Hardness on C scale (only for EN8/EN24 samples) and Rockwell Hardness on F scale (for copper samples) or any appropriate scale. 3 consistent readings should be obtained from each sample. Spurious readings, usually associated with quench-cracks, should be discarded. Submit your raw data in table format at the end of the experiment. 2. Remove the oxidation scale completely and polish smoothly for the micro-hardness test on vickers scale (HV). Perform the micro-hardness test using THREE (3) different COUNTER LOADS, 100gm, 200gm, and 300gm. Take and record TEN (10) readings on each counter load. Analyze the results obtained statistically and write your comments. The microstructure determination: Examine the specimens using optical microscope with appropriate magnification and field of view. The microscope is linked to a computer which could display and store the microstructure images. In the computer, launch the microstructure software and capture the photomicrographs to save in JPEG file format. Using table below, hand-sketch all the photomicrographs of the specimens using the most appropriate magnification (usually >100x). Indicate the field of view and carefully annotate your drawings with the corresponding micro-constituents identity. Record all the relevant microscopic observation in your results.

2/3

E1-MAB 2023

Discussion Write-up: Draw a line graph showing the hardness response for all specimen no.1 to no.5. Comment on the differences. Also, by using line graph, show the effects of (a) tempering time and (b) tempering temperature on the hardness response of tempered martensite; results for the two types steels must be shown on the same graphs. For micro-hardness testing (i.e microvickers) comment on the possible errors encounter during the testing. Propose the best counter load used in order to give accurate and consistent results. Justify your reasons. Explain what are the typical products or components that are suitable for this kind of hardness measurement. In your formal report, include the properly hand drawn microstructures alongside with the photomicrograph. The figures should complete with annotation and brief explanation notes. Recognise the phases present for each specimen and include in your discussion in each case how the microstructures developed in terms of heat treatment, cooling rate, carbon content, impurities content etc. Iron-iron carbide phase diagram in Fig.E8.1should be used extensively in order to determine the phases present in each specimen. Also, identify the distinguishable materials properties based on its microstructure and name some of the applications for each specimen. Note : Etching is used in order to make the specimen visible under the inspection of microscope. Etching involves chemical reaction which reacts with binary/multi-phase alloys differently and produces different texture for each phase.

References: 1. William D. Callister, Jr., Materials Science and Engineering, An Introduction, 2008, John Wiley. 2. http://www.calce.umd.edu. 3. J. F. Shackelford, Introduction to Materials Science for Engineers,2007, Practice Hall. 4. R.W.K. Honeycombe & H.K.D.H Bhadeshia, Steels: Microstructure and Properties,1995, Edward Arnold.

3/3

You might also like

- Ceramics Science and Technology, Volume 1: StructuresFrom EverandCeramics Science and Technology, Volume 1: StructuresRalf RiedelNo ratings yet

- Modeling The Heat Treatment Response of P/M Components: Research TeamDocument7 pagesModeling The Heat Treatment Response of P/M Components: Research Teamsakthistory1922No ratings yet

- Characterization and Modeling of Molding Compound Properties During CureDocument4 pagesCharacterization and Modeling of Molding Compound Properties During CureebenananamacNo ratings yet

- Thermal FatigueDocument39 pagesThermal FatigueDaniel MilosevskiNo ratings yet

- SteelMicrostructuresLab (4) (1)Document7 pagesSteelMicrostructuresLab (4) (1)muhammad.amir14333No ratings yet

- Zhu 2024 J. Phys. Conf. Ser. 2680 012034Document7 pagesZhu 2024 J. Phys. Conf. Ser. 2680 012034765257795No ratings yet

- Properties of X46Cr13 SteelDocument4 pagesProperties of X46Cr13 SteelEmir AvcıoğluNo ratings yet

- A Finite Element Model For TBC Damage Detection and Lifetime PredictionDocument12 pagesA Finite Element Model For TBC Damage Detection and Lifetime Predictionklomps_jrNo ratings yet

- Le Rapport de Heat TreatmentDocument11 pagesLe Rapport de Heat TreatmentGedeon ApeneneNo ratings yet

- Tensile and Fracture Properties of X80 Steel Microstructures Relevant To The HazDocument9 pagesTensile and Fracture Properties of X80 Steel Microstructures Relevant To The HazMarcelo Varejão CasarinNo ratings yet

- Study On Time Dependent Dielectric BreakdownDocument4 pagesStudy On Time Dependent Dielectric Breakdown전종욱No ratings yet

- 50 9 CR SteelsDocument14 pages50 9 CR SteelsLTE002No ratings yet

- Microstructure, Tensile Deformation, and Fracture in Aged Ti 10V-2Fe-3AIDocument15 pagesMicrostructure, Tensile Deformation, and Fracture in Aged Ti 10V-2Fe-3AIsatyanarayana chvvNo ratings yet

- Fracture Mechanics Evaluations of Neutron Irradiated Type 321 Austenitk SteelDocument16 pagesFracture Mechanics Evaluations of Neutron Irradiated Type 321 Austenitk SteelSayiram GNo ratings yet

- Macroscopic Analysis of Time Dependent Plasticity in TiDocument6 pagesMacroscopic Analysis of Time Dependent Plasticity in TiAamir RazaNo ratings yet

- Sample 1Document2 pagesSample 1Will KurlinkusNo ratings yet

- Ceramics 03 00033Document12 pagesCeramics 03 00033Kristanto WahyudiNo ratings yet

- Sirine 3Document10 pagesSirine 3Syrine BOUDEFNo ratings yet

- Meier Experiment 3Document7 pagesMeier Experiment 3sekarnanoNo ratings yet

- Solidification of SteelDocument7 pagesSolidification of SteelDan Pascu100% (1)

- Matecconf Bcee32018 04006Document8 pagesMatecconf Bcee32018 04006abdiseptiaputraNo ratings yet

- Computer Simulation of Microstructure Transformation in Heat Treatment ProcessesDocument8 pagesComputer Simulation of Microstructure Transformation in Heat Treatment Processessakthistory1922No ratings yet

- Evaluation of Heat Treatments For Additively Manufactured 316L Simpson PDFDocument7 pagesEvaluation of Heat Treatments For Additively Manufactured 316L Simpson PDFOlivier DubetNo ratings yet

- Heat Treatment & Phase Transformations: Laboratory Manual Cum Observation BookDocument45 pagesHeat Treatment & Phase Transformations: Laboratory Manual Cum Observation Book035K Ayush ChoudharyNo ratings yet

- Theoretical and Applied Fracture Mechanics: R. Branco, J.D. Costa, F.V. AntunesDocument7 pagesTheoretical and Applied Fracture Mechanics: R. Branco, J.D. Costa, F.V. AntunesShubhom PaulNo ratings yet

- Constantinescu 2004Document15 pagesConstantinescu 2004ram shyamNo ratings yet

- International Journal of Fatigue Vo53!33!39Document7 pagesInternational Journal of Fatigue Vo53!33!39Rga NtaNo ratings yet

- Bainítico - Ferry2002Document8 pagesBainítico - Ferry2002Douglas RodriguesNo ratings yet

- Pb-Sn Phase Diagram AnalysisDocument8 pagesPb-Sn Phase Diagram AnalysisSarbajitNo ratings yet

- Numerical Study of Residual Thermal Stresses in MMCDocument12 pagesNumerical Study of Residual Thermal Stresses in MMCKamel FedaouiNo ratings yet

- Sif02 PDFDocument436 pagesSif02 PDFprajjwal patidarNo ratings yet

- Nominal moment capacity of box RC beams exposed to fireDocument14 pagesNominal moment capacity of box RC beams exposed to fireReivax50No ratings yet

- Cardone 2019Document9 pagesCardone 2019Constanza CornejoNo ratings yet

- Article Exe2Document7 pagesArticle Exe2PUI DE GAMINGNo ratings yet

- Hardness Test PracticalDocument7 pagesHardness Test PracticalTandoh Achiever TenengNo ratings yet

- ENS167 Sample FinalDocument1 pageENS167 Sample FinalFatima Zaynab AbdulzamadNo ratings yet

- Studying The Effect of Various Parameters On Dry Sliding Wear Behavior of Tc21 Titanium Alloy Using Taguchi Experimental DesignDocument13 pagesStudying The Effect of Various Parameters On Dry Sliding Wear Behavior of Tc21 Titanium Alloy Using Taguchi Experimental Designiaset123No ratings yet

- Anales de Mecánica de La Fractura (Vol. 33)Document6 pagesAnales de Mecánica de La Fractura (Vol. 33)ElíGomaraGilNo ratings yet

- Predicting Effect of Temperature Field On Sensitization of Alloy 690 WeldmentsDocument8 pagesPredicting Effect of Temperature Field On Sensitization of Alloy 690 WeldmentsRobert SimmonsNo ratings yet

- Lab 7 Fracture Ductile To Brittle TransitionDocument4 pagesLab 7 Fracture Ductile To Brittle TransitionTommy MilesNo ratings yet

- Metal Big Area Additive Manufacturing Process Modeling and ValidationDocument17 pagesMetal Big Area Additive Manufacturing Process Modeling and ValidationTiago Camargo AlvesNo ratings yet

- Statics and DynamicsDocument5 pagesStatics and DynamicsShahrul AzeerieNo ratings yet

- Shear and Compression Behaviour of Sheet Moulding CompoundsDocument7 pagesShear and Compression Behaviour of Sheet Moulding Compoundspstedile1234No ratings yet

- Quench Sensitivity Al AlloysDocument31 pagesQuench Sensitivity Al AlloysCatalin Marian Vartosu-TomaNo ratings yet

- 1 s2.0 S0921509397004917 MainDocument5 pages1 s2.0 S0921509397004917 MainMehtap KuzuNo ratings yet

- Creep and Creep Modelling of A Multimodal Nickel-Base SuperalloyDocument10 pagesCreep and Creep Modelling of A Multimodal Nickel-Base Superalloyhassan ghorbaniNo ratings yet

- Crack Detection Methods For Lead-Free Solder Joints: Milos Dusek & Christopher HuntDocument26 pagesCrack Detection Methods For Lead-Free Solder Joints: Milos Dusek & Christopher HuntpastelquenteNo ratings yet

- Bratina 2005Document19 pagesBratina 2005Malek GolNo ratings yet

- Heat Treatment Effects on Carbon Steel Microstructure & HardnessDocument7 pagesHeat Treatment Effects on Carbon Steel Microstructure & Hardnessputri nur shahidaNo ratings yet

- SS 1672Document13 pagesSS 1672dbaNo ratings yet

- TMT Effect on Hardness, Impact Toughness of Low Alloy SteelsDocument6 pagesTMT Effect on Hardness, Impact Toughness of Low Alloy SteelsAdo1999No ratings yet

- Review On Thermomechanical Anlysis of Nano Composites: Y.Sowjany A, V.Jayaprasa D, K.Dileep Kuma R, N.Mohanra oDocument6 pagesReview On Thermomechanical Anlysis of Nano Composites: Y.Sowjany A, V.Jayaprasa D, K.Dileep Kuma R, N.Mohanra olydiaNo ratings yet

- Creep Behaviour and Failure Modelling of Modified 9Cr1Mo SteelDocument13 pagesCreep Behaviour and Failure Modelling of Modified 9Cr1Mo SteelJackfusionNo ratings yet

- Ijmet 08 01 005 PDFDocument9 pagesIjmet 08 01 005 PDFIAEME PublicationNo ratings yet

- Evaluation of The Austenite Recrystallization by Multideformation and DoubleDocument10 pagesEvaluation of The Austenite Recrystallization by Multideformation and DoubleJoselo HRNo ratings yet

- Numerical Analysis of Quenching and Cooling ProcesDocument7 pagesNumerical Analysis of Quenching and Cooling ProcestalalNo ratings yet

- Modeling and Finite Element Analysis For A Casting Defect in Thin-Wall StructuresDocument6 pagesModeling and Finite Element Analysis For A Casting Defect in Thin-Wall StructuresSeethaNo ratings yet

- 2023 - Z. Zhang - JMRT - Temperature-Dependent Deformation and Fracture Properties of Low-Carbon Martensitic Steel in Different Stress StatesDocument13 pages2023 - Z. Zhang - JMRT - Temperature-Dependent Deformation and Fracture Properties of Low-Carbon Martensitic Steel in Different Stress StatesFuhui ShenNo ratings yet

- AMP CAT 2 QP Key Final PDFDocument83 pagesAMP CAT 2 QP Key Final PDFthandialNo ratings yet

- 3BSE079234 - en 800xa 6.0 ReleasedDocument7 pages3BSE079234 - en 800xa 6.0 ReleasedFormat_CNo ratings yet

- Physical parameters shaping of Farwa Lagoon - LibyaDocument7 pagesPhysical parameters shaping of Farwa Lagoon - LibyaAsadeg ZaidNo ratings yet

- Dynamic model of manipulatorsDocument20 pagesDynamic model of manipulatorsbalkyderNo ratings yet

- Alc10 DatasheetDocument7 pagesAlc10 Datasheetd4l170No ratings yet

- Handout 06 - Geothermometry PDFDocument7 pagesHandout 06 - Geothermometry PDFOg LocabaNo ratings yet

- Eurotech IoT Gateway Reliagate 10 12 ManualDocument88 pagesEurotech IoT Gateway Reliagate 10 12 Manualfelix olguinNo ratings yet

- Training Matrix For TM IDocument14 pagesTraining Matrix For TM IApril NavaretteNo ratings yet

- Ibrahim Zeid: RsrecialDocument96 pagesIbrahim Zeid: RsrecialengrodeNo ratings yet

- Crystal Chem Crystallography: - Chemistry Behind Minerals and How They Are AssembledDocument33 pagesCrystal Chem Crystallography: - Chemistry Behind Minerals and How They Are AssembledArkodip MandalNo ratings yet

- Database Classification TypesDocument10 pagesDatabase Classification TypesBhiea Mische MatilacNo ratings yet

- F (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )Document9 pagesF (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )muhammad abrarNo ratings yet

- A Guide To The Preparation of Civil Engineering Drawing PDFDocument186 pagesA Guide To The Preparation of Civil Engineering Drawing PDFEraj100% (3)

- Power Theft Identification Using GSM TechnologyDocument3 pagesPower Theft Identification Using GSM TechnologyIJORAT100% (1)

- 997-3 CIP Safety Adapter: Single Point Lesson (SPL) - Configure CIP Safety Adapter and A-B PLCDocument18 pages997-3 CIP Safety Adapter: Single Point Lesson (SPL) - Configure CIP Safety Adapter and A-B PLCTensaigaNo ratings yet

- Sem 2Document128 pagesSem 2Agustin A.No ratings yet

- EET422 EMC Intro-Banana Skins 2011-2012 MSWDocument6 pagesEET422 EMC Intro-Banana Skins 2011-2012 MSWVeeradasan PerumalNo ratings yet

- Python Programming Lecture#2 - Functions, Lists, Packages & Formatting I/ODocument69 pagesPython Programming Lecture#2 - Functions, Lists, Packages & Formatting I/OHamsa VeniNo ratings yet

- 1.11 CHEM FINAL Chapter 11 Sulfuric AcidDocument21 pages1.11 CHEM FINAL Chapter 11 Sulfuric AcidSudhanshuNo ratings yet

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDocument16 pagesGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelNo ratings yet

- Tunnel DamperDocument8 pagesTunnel DamperIvanNo ratings yet

- Data Warehousing: Modern Database ManagementDocument49 pagesData Warehousing: Modern Database ManagementNgọc TrâmNo ratings yet

- Self Report QuestionnaireDocument6 pagesSelf Report QuestionnaireMustafa AL ShlashNo ratings yet

- Dynamic Modeling of GE 1.5 andDocument31 pagesDynamic Modeling of GE 1.5 andErtuğrul ÇamNo ratings yet

- Time TableDocument7 pagesTime TableChethan .H.GNo ratings yet

- Operational Guidelines For VlsfoDocument2 pagesOperational Guidelines For VlsfoИгорьNo ratings yet

- Displaymax JR 1500 SpecsDocument1 pageDisplaymax JR 1500 SpecsFRANCISCONo ratings yet

- Steps For Charm ConfigurationDocument7 pagesSteps For Charm ConfigurationpoornasapNo ratings yet

- User Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPDocument6 pagesUser Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPCariza DollienteNo ratings yet

- AutoCAD Mechanical 2015 Overview Brochure - A4Document4 pagesAutoCAD Mechanical 2015 Overview Brochure - A4Raul ReynosoNo ratings yet

- Sixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFDocument19 pagesSixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFSunil100% (1)