Professional Documents

Culture Documents

Ice Lab

Uploaded by

Iqra AngelsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ice Lab

Uploaded by

Iqra AngelsCopyright:

Available Formats

Internal Combustion Engine Lab

VVT-I , IVTEC and VVTL-I TECHNOLOGIES LUBRICATING OILS AND TRANSMISSION OILS TORSION BAR, SUSPENSION SYSTEM IN QINGQI NOISE CONTROL IN 2-STROKE ENGINE

SUBMITTED TO :

SIR USMAN

SUBMITTED BY:

Iqra Younas

2008-ME-105

2/28/2012

Iqra Younas

2008-ME-105

ICE lab

What's VVT-i and VVTL-i???

VVT-i is Variable Valve Timing - with intelligence and VVTL-i is Variable Valve Timing & Lift with intelligence. So we got that out of the way what do they both do to my motor??? VVT-i is in the Toyota Celica GT's first. Variable Valve Timing with intelligence is quite remarkable in it operation and what it does. Most cars run on valve timing that is set and cannot be changed unless you buy a set of aftermarket cam gears. Which this method is quite pricey but can give you better performance usually at the cost of fuel economy and usually makes your lowend power suffer to make the top end of your power band better. This sometimes hurts drivability. So you can see for buying adjustable cam gears it can do well at the track but you might have a hard time driving around at 30 miles per hour. VVT-i, varies the timing of the intake valves by adjusting the relationship between the camshaft drive (belt, scissor-gear or chain) and intake camshaft. Engine oil pressure is applied to an actuator to adjust the camshaft position. Adjustments in the overlap time between the exhaust valve closing and intake valve opening result in improved engine efficiency.

VVTL-i

The new 180hp Celica GT-S (USA/CAN) now features the amazing VVTL-i engine developed by Toyota and Yamaha. Based on the standard 140hp 1.8 VVT-i, the VVTL-i has both Variable Valve Timing and Variable Valve Lift. The latter is achieved by an extra cam lobe that is brought into play by the engine electronics via a hydraulic actuator.

Iqra Younas

2008-ME-105

ICE lab

Interestingly, Toyota have set up the system so that the extra power kicks in a little over 6000 rpm. The torque curve of a VVTL-i is almost exactly the same as a VVT-i up to that point and then suddenly, where the VVT-i begins to run out of steam and revs, the new engine develops a new lease of life producing the extra 49 bhp right through to its rpm redline. The disappointing thing is that even with the new close ratio gearbox, the engine drops out of its optimum rev range when changing down. It seems very strange to us that the extra horsepower doesn't kick in just below 6000 rpm so that the engine can be kept in its sweet spot - this would almost certainly knock over a second off the already impressive 0-60 time of the Celica, putting it into another class altogether. Perhaps Toyota are saving this extra power for a later date. We expect to see after market chips that vary the valve lift at a lower engine speed, though as yet, none have appeared. The diagram below shows the two cams which are both always turning, and the hydraulic actuator that moves the 'Rocker Arm Pin' into place at a preset engine speed.

I-VTEC with Variable Cylinder Management (VCM)

In 2003, Honda introduced an i-VTEC V6 (an update of the J-series) that includes Honda's cylinder deactivation technology which closes the valves on one bank of (3) cylinders during light load and low speed (below 80 km/h (50 mph)) operation. According to Honda, "VCM technology works on the principle that a vehicle only requires a fraction of its power output at cruising speeds. The system electronically deactivates cylinders to reduce fuel consumption. The engine is able to run on 3, 4, or all 6 cylinders based on the power requirement. Essentially getting the best of both worlds.V6 power when accelerating or climbing, as well as the efficiency of a smaller engine when cruising." The technology was originally introduced to the US on the 2005 minivan, and can now be found on the Honda Accord Hybrid, the 2006 Honda Pilot, and the 2008 Honda Accord. Example: EPA estimates for the 2011 (271 hp SOHC 3.5L) V6 Accord are 24 mpg combined vs. 27 in the two 4cylinder-equipped models. i-VTEC VCM was also used in 1.3L 4-cylinder engines used in Honda Civic Hybrid. It is a version of i-VTEC with direct injection.

Iqra Younas

2008-ME-105

ICE lab

Lubricating and transmission oil

Selected fractions of refined petroleum or other oils (with or without additives) used to lessen friction between moving surfaces. Also known as lube oil. Motor oil and transmission oil or fluid are needed for basic car maintenance. There are several differences between the two, and each is designed to serve a particular purpose for the car.

Function

Although both motor oil and transmission fluid (oil) are designated to cool and lubricate, only transmission fluid must be constantly under pressure. Furthermore, motor oil also cleans and protects the engine, while transmission fluid provides shift control.

Significance

Motor oil is designed to lubricate the moving parts inside of an engine to prevent metal to metal contact. Additionally, it is intended to keep engine parts cool and clean the engine of waxes, carbon deposits and tar naturally found in oil. Transmission fluid also lubricates and cools moving parts; however, it is a thicker fluid that delivers power from the engine to the transmission.

Benefits

In motor oil, additives such as detergents, buffers and solvents are added to keep the engine clean from deposits. Although transmission fluid is similar to motor oil, it is intended to be used in the hydraulic system of a vehicle. Corrosion inhibitors, polyalphaolefins (PAO) and esters are some additives included in transmission fluid to make it last a long time.

Differences

Transmission fluid is a hydraulic fluid and motor oil is a lubricant. While transmission fluid does have some lubricating properties, it is not enough to sustain an engine. Motor oil is an excellent lubricant, but not such a good hydraulic fluid so it cannot be used in a transmission. Transmission fluid can also be used in power steering systems without harm since that is a hydraulic system, but not motor oil.

Iqra Younas

2008-ME-105

ICE lab

Transmission oil has detergents in it that have been used in the past to clean engines, but today's 10w30 and other weight motor oils have detergents in them as well. There is no reason to run transmission oil through a motor. Transmission oil can cause serious problems if run through a motor for extended periods of time.

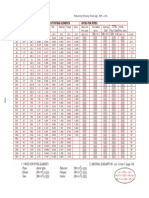

Motor oil

Motor oil or engine oil is an oil used for lubrication of various internal combustion engines. The main function is to lubricate moving parts; it also cleans, inhibits corrosion, improves sealing, and cools the engine by carrying heat away from moving parts. An example is lubricating oil for 4-stroke or 4-cycle internal combustion engines such as those used in portable electricity generators and "walk behind" lawn mowers. Another example is 2-stroke oil for lubrication of 2-stroke or 2-cycle internal combustion engines found in snow blowers, chain saws, model airplanes, gasoline powered gardening equipment like hedge trimmers, leaf blowers and soil cultivators. Often, these motors are not exposed to as wide service temperature ranges as in vehicles, so these oils may be single viscosity oils.

Transmission oil

Automatic transmission fluid (ATF) is the fluid used in vehicles with self shifting or automatic transmissions. It is typically colored red or green to distinguish it from motor oil and other fluids in the vehicle. On most vehicles its level is checked by a dipstick while the engine is running.The fluid is a highly specialized oil optimized for the special requirements of a transmission, such as valve operation, brake band friction and the torque converter as well as gear lubrication.

Iqra Younas

2008-ME-105

ICE lab

ATF is also used as a hydraulic fluid in some power assisted steering systems, as a lubricant in some 4WD transfer cases, and in some modern manual transmissions.

Torsion bar

A torsion bar is a flexible spring that can be moved about its axis via twisting. Torsion bars are designed and based on the amount of torque used in the twisting of the spring, the angle of the twist, the overall dimensions of the torsion bar and what materials the torsion bar is made from. The most common place to find a torsion bar is in the suspension of a car or truck, in machines used for production or in other precision devices. The flexibility of the spring is the main reason that a torsion bar is used. If a more rigid structure were used such as a steel rod were used too much load bearing pressure would be placed on the both the wheels and the under body of the vehicle.

How a Torsion Bar Works???

A torsion bar works by resisting the torque placed on it. When one end of the torsion bar is affixed to an object that cannot be moved, the other end of the bar is twisted, thus causing torque to build up. When this happens, the torsion bar is resistant to the torque and will quickly go back to its starting position once the torque is removed. In general, the object that cannot be moved is usually a frame. If there is not any force applied to the torsion bar, it will stay at the same position until force is applied.

Suspension system

The job of a car suspension is to maximize the friction between the tires and the road surface, to provide steering stability with good handling and to ensure the comfort of the passengers. In this article, we'll explore how car suspensions work, how they've evolved over the years and where

Iqra Younas

2008-ME-105

ICE lab

the design of suspensions is headed in the future. If a road were perfectly flat, with no irregularities, suspensions wouldn't be necessary. But roads are far from flat. Even freshly paved highways have subtle imperfections that can interact with the wheels of a car. It's these imperfections that apply forces to the wheels. According to Newton's laws of motion, all forces have both magnitude and direction. A bump in the road causes the wheel to move up and down perpendicular to the road surface. The magnitude, of course, depends on whether the wheel is striking a giant bump or a tiny speck. Either way, the car wheel experiences a vertical acceleration as it passes over an imperfection. In QINGQI , there is no torsion bar and the suspension system. The driven body is attached with the motorcylce front wheel by chain mechanism. The differential gears are there to maintain its motion.

How noise can be controlled in 2- stroke engine ??

The Small engines are found in many applications, from yard tools such as chainsaws and trimmers, right up to those powering dirt bikes and snowmobiles. Many of these engines are two-stroke varieties known for producing a lot of noise. Aside from possible hearing damage, there may be legal restrictions on small engine decibel levels in your state. Depending on the type of small engine involved, there are a number of different aftermarket options that can muffle its noise.

Reactive Mufflers Absorptive Silencers Reactive/Absorptive Mufflers Tail Pipe Design Tuned Resonators

With these some important measures, the noise can be greatly reduced. If the exhaust pipe is missing the bike can never run prperly at all.

You might also like

- VJ-KPK-Project Tracking Log-TemplateDocument1 pageVJ-KPK-Project Tracking Log-TemplateIqra AngelsNo ratings yet

- Plier 700 Nose Plier 550: Sr. No. Tool Name Qty Reqd. Price PKR Stock StatusDocument1 pagePlier 700 Nose Plier 550: Sr. No. Tool Name Qty Reqd. Price PKR Stock StatusIqra AngelsNo ratings yet

- Service Form - VJDocument1 pageService Form - VJIqra AngelsNo ratings yet

- New Codes-10-4-19 - FA Details, Add To List and Queries 16.04.19 NYADocument488 pagesNew Codes-10-4-19 - FA Details, Add To List and Queries 16.04.19 NYAIqra AngelsNo ratings yet

- Arab Republic of Egypt Republique Arabe d'Egypte لوخد ةريشأت ىلع لوصحلا بلط Entry Visa Application Form Demande De Visa D'EntréeDocument2 pagesArab Republic of Egypt Republique Arabe d'Egypte لوخد ةريشأت ىلع لوصحلا بلط Entry Visa Application Form Demande De Visa D'EntréeIqra AngelsNo ratings yet

- 2007 EdsDocument2 pages2007 EdsIqra AngelsNo ratings yet

- Energy Crisis in PakistanDocument5 pagesEnergy Crisis in PakistanIqra AngelsNo ratings yet

- KPK-SOP-01-Procedure For Service Report WritingDocument6 pagesKPK-SOP-01-Procedure For Service Report WritingIqra AngelsNo ratings yet

- Detail of Dish Ends Sent to VendorsDocument4 pagesDetail of Dish Ends Sent to VendorsIqra AngelsNo ratings yet

- CCI 18-Feb-22Document1 pageCCI 18-Feb-22Iqra AngelsNo ratings yet

- 2007 EdsDocument2 pages2007 EdsIqra AngelsNo ratings yet

- Comparative Study of ReligionsDocument4 pagesComparative Study of ReligionsAmir SultanNo ratings yet

- 9th Computer Science Assessment Scheme 2Document1 page9th Computer Science Assessment Scheme 2Iqra AngelsNo ratings yet

- 07 Execution PhaseDocument14 pages07 Execution PhaseNinthu Ninthoo100% (1)

- Alternative Energy MixerDocument8 pagesAlternative Energy MixerIqra AngelsNo ratings yet

- LPG Global Technology Conference2006 PresentationDocument10 pagesLPG Global Technology Conference2006 PresentationIqra AngelsNo ratings yet

- LPG Storage Tanks LPG Tank 100 M Ton Qty LPG Tank 100 M Ton QtyDocument69 pagesLPG Storage Tanks LPG Tank 100 M Ton Qty LPG Tank 100 M Ton QtyIqra AngelsNo ratings yet

- PPT ch2 3Document81 pagesPPT ch2 3Iqra AngelsNo ratings yet

- Epilux 200 Polyamide Cured Coaltar EpoxyDocument3 pagesEpilux 200 Polyamide Cured Coaltar EpoxyIqra AngelsNo ratings yet

- Evidence of Research On NTDocument5 pagesEvidence of Research On NTIqra AngelsNo ratings yet

- Dounuts RecipeDocument2 pagesDounuts RecipeIqra AngelsNo ratings yet

- MDS Foam AFFDocument2 pagesMDS Foam AFFIqra AngelsNo ratings yet

- Dimensions & Section Properties of Structural Shapes No Sheet DescriptionDocument71 pagesDimensions & Section Properties of Structural Shapes No Sheet DescriptionMohd Sherwani Abu BakarNo ratings yet

- Dispensing Units Bos 1-2Document1 pageDispensing Units Bos 1-2Iqra AngelsNo ratings yet

- Camouflage Matt EnamelsDocument3 pagesCamouflage Matt EnamelsIqra AngelsNo ratings yet

- Inoperative Invoice PlanDocument165 pagesInoperative Invoice PlanIqra AngelsNo ratings yet

- Epilux-78 HB PrimerDocument3 pagesEpilux-78 HB PrimerIqra AngelsNo ratings yet

- Excel Critical Path TrackerDocument176 pagesExcel Critical Path Trackerislouma2No ratings yet

- Bitumen 10/20 Data SheetDocument1 pageBitumen 10/20 Data SheetIqra Angels100% (1)

- Pipe Fittings Surface Area PDFDocument1 pagePipe Fittings Surface Area PDFIqra Angels83% (6)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Vehicle Pre-trip Inspection GuideDocument16 pagesVehicle Pre-trip Inspection GuideBudi KurniawanNo ratings yet

- Global Electric Power Steering (EPS) Market Analysis and ForecastDocument19 pagesGlobal Electric Power Steering (EPS) Market Analysis and ForecastSanjay MatthewsNo ratings yet

- Deferral Approval MailDocument3 pagesDeferral Approval MailSameera AnjumNo ratings yet

- The Harley-Davidson Source BookDocument293 pagesThe Harley-Davidson Source Bookt.pentzekNo ratings yet

- Mitsubishi L 200Document32 pagesMitsubishi L 200Alex Raduță100% (2)

- RT700 PartsDocument250 pagesRT700 PartsbogdanmichaelNo ratings yet

- Partquip-mountings-catalogues-030827.Engine Mounting & Rubber Catalogue 2022 - AprilDocument410 pagesPartquip-mountings-catalogues-030827.Engine Mounting & Rubber Catalogue 2022 - AprilMutorua KaveraNo ratings yet

- Bajaj CableDocument5 pagesBajaj Cablekiran lingam100% (2)

- Replace oil, fuel & air filters for Audi, VW, Skoda & Seat carsDocument18 pagesReplace oil, fuel & air filters for Audi, VW, Skoda & Seat carsicfcfciNo ratings yet

- 移动式破碎机S ZR450JC规格说明书 PDFDocument1 page移动式破碎机S ZR450JC规格说明书 PDFwalk111No ratings yet

- B Class w247 November 2022Document2 pagesB Class w247 November 2022Dimitris EfstathiouNo ratings yet

- Assembly-Power Distribution Center C5: Connector DetailsDocument4 pagesAssembly-Power Distribution Center C5: Connector DetailsEnrique Arevalo LeyvaNo ratings yet

- Camión Minero 777-797Document1 pageCamión Minero 777-797Joel RodríguezNo ratings yet

- MMW Automotive EngineeringDocument7 pagesMMW Automotive EngineeringNiño Jay BadangNo ratings yet

- Nissan Car Fault Codes DTCDocument1,060 pagesNissan Car Fault Codes DTCnanteza florenceNo ratings yet

- JCB 550-80 Specs SheetDocument2 pagesJCB 550-80 Specs SheetErk AKDEMIRNo ratings yet

- AiO.02.19.001 CompressedDocument24 pagesAiO.02.19.001 CompressedhugoDiaz1981No ratings yet

- Honda Amaze BrochureDocument11 pagesHonda Amaze Brochurekatoyev852No ratings yet

- Spicer TE30 Hydrodynamic Transmission: 225 To 300 KW (300 To 400 HP) For Reach Stackers and Heavy Forklift TrucksDocument2 pagesSpicer TE30 Hydrodynamic Transmission: 225 To 300 KW (300 To 400 HP) For Reach Stackers and Heavy Forklift TrucksRam SinghNo ratings yet

- E 8 10n en (Efb)Document4 pagesE 8 10n en (Efb)Tomy Abad AbadNo ratings yet

- Porsche Type G SerialsDocument6 pagesPorsche Type G Serialsmanu75010No ratings yet

- RCLRPT 23V144 1487Document3 pagesRCLRPT 23V144 1487Joey KlenderNo ratings yet

- 51 - 0217 Glazing 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06Document130 pages51 - 0217 Glazing 4641147 3611 5' E12 Saloon 518 ECE L M 1976/06George ZormpasNo ratings yet

- Suspension CalculatorDocument89 pagesSuspension CalculatorMichael Serra100% (1)

- A Case Study Ford Motor CompanyDocument5 pagesA Case Study Ford Motor Companysaleem razaNo ratings yet

- Bentley - Int ContinentalGTC - 2007 PDFDocument17 pagesBentley - Int ContinentalGTC - 2007 PDFAyush MehtaNo ratings yet

- BAB III Gearbox AvanzaDocument11 pagesBAB III Gearbox AvanzaCandra BudiNo ratings yet

- ERF EC8 EC 8.28 (6X4/8X4) : Normal ModerateDocument4 pagesERF EC8 EC 8.28 (6X4/8X4) : Normal Moderateعبدالغني القباطيNo ratings yet

- Namu Per Final AaDocument24 pagesNamu Per Final AaBabasaheb vetalNo ratings yet

- International Vs CumminsDocument4 pagesInternational Vs Cumminsoal2010No ratings yet