Professional Documents

Culture Documents

Table of Contents

Uploaded by

Syikin FauziOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table of Contents

Uploaded by

Syikin FauziCopyright:

Available Formats

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

TABLE OF CONTENTS No. ITEMS Page

1. INTRODUCTION 1.1 Objective 1.2 Equipment 1.3 Theory / Examples 2. PROCEDURE

3.0 RESULTS & ANALYSIS 4.0 DISCUSSION

5.0 CONCLUSION

REFERENCES & APPENDICES

SCL

Font ARIAL ( 12 ) Spacing 1.5

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

1. INTRODUCTION 1.1 Objective Introduction Pumps provide energy to the fluids, and for their correct application need to understand the operational characteristics following the curves of each pump. It is also needed to know how these pumps are used in order to satisfy the needs of the total head (H) and the flow rate (Q).

Objective: 1. Understand the operational characteristics of the centrifugal pumps. 2. Obtain the characteristic curves of the centrifugal pump. 3. Prove the operational characteristics of two pumps that are working in series or parallel. 4. Obtain conclusions and make recommendations about the behavior of the pumps operating at different velocities, this is, construct the curves for the different velocities. 5. Design and conduct the experiment, by analyzing the experimental information. 6. Determine the variables that are needed to measure in order to predict the performance of the equipment.

1.2 Equipment

Apparatus/Equipment:Pump Test Rig

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

1.3 Theory / Examples

In the centrifugal pumps the fluid enters axially through the eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. The fluid gains both velocity and pressure when it goes through the impeller. One part of the casing (the doughnut shaped diffuser, or scroll) opposes the acceleration of the fluid increasing more the pressure. The impeller blades are usually backward curved, but there are also radial and forward curved blade designs, which slightly change the output pressure. The blades may be open or closed. The diffuser may be vaneless or fitted with fixed vanes to help guide the flow toward the exit.

The operational characteristics of the pump can be obtain by drawing the curves of the head (H), power (P) and efficiency of the pump taking as an independent variable the flow rate (Q); for a number of constant velocities N. It is important to notice that the efficiency takes a maximum value and then suffers a reduction; the ideal condition of the operation is achieved when the total head (H) and flow rate (Q) have the same value as the maximum efficiency. This point is known as the operating point.

An example of a centrifugal pump and its operational characteristics is shown in the next figure:

Example of a centrifugal pump and its operational characteristics

When we are working with centrifugal pumps sometimes we can need a bigger total head (H) or flow rate (Q) than the one that we can achieved by using only one pump. In consequence, the pumps can be connected in series to obtain an increment in the total head

Page: /

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

(H) or they can be connected in parallel to increase the flow rate (Q).

When two pumps work in series, the total head is calculated by adding the total head (H) of each pump working by itself with the same flow rate (Q). If the pumps are connected in parallel the curve H vs. Q can be obtain by adding the flow rates (Q) of each pump operating itself with the same total head (H).

Example of two pumps connected in series and parallel

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

2.0 PROCEDURE

3.0 RESULTS & ANLYSIS

Procedure: Series 1) The control valve is been opened : V1,V3,V4 2) The control valve will be closed:V2,V5 3) The control valve will be opened fully : V6 4) The main switch will be powered on. 5) Pump of 1 & 2 will be switch on both the operation pump switch. 6) The pump rotation will be adjusted until rotation speed reach 1700 rpm. 7) Let the pumps run for while,et the water flow circulate in the pipeline system.Until all the bubbles have dispersed 8) Wait and monitor the flowrate and pressure reading are stable,then only start record the experiment reading

Parallel 1) The control valve is been opened : V1,V2,V4,V5 2) The control valve will be closed:V3 3) The control valve will be opened fully : V6 4) The main switch will be powered on. 5) Pump of 1 & 2 will be switch on both the operation pump switch. 6) The pump rotation will be adjusted until rotation speed reach 1700 rpm. 7) Let the pumps run for while,et the water flow circulate in the pipeline system.Until all the bubbles have dispersed 8) Wait and monitor the flowrate and pressure reading are stable,then only start record the experiment reading

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

4.DISSCUSSION 5. CONCLUSION

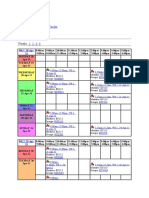

Result Series flowrate LPM M3/S Inverter/rpm BHP/watt P1 P2 h P(pa)

100

27.78

1490

253

1.406

13,789.514

120

33.33

2011

501

12

4.217

41,368.542

140

38.88

2462

833

19

6.676

65500.19

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

Parallel flowrate LPM M3/S Inverter/rpm BHP/watt P1 P2 h P(pa)

100

27.78

1285

169

0.712

6894.757

120

33.33

1795

316

10

4.568

44815.92

140

38.88

2207

510

10

16

9.136

89631.84

Discussion From the experiment we already plotting a graph for graph 1:head loss we already know plotting curve for series directly proportional of limit while for parallel we already get the plotting inversely propotional. this is happen because the value of head loss is different. Compare to the series,the value of power parallel is more high from series. Pump can be combined in series to obtain an increase in head at the same flowrate as the single pump.For parallel pump,when two-pump having similar head flowrate characteristic are operated in parallel the combined pump-head-flowrate curve is obtained by adding flowrates of the singles pumps at the same head.

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

Conclusion from the experiment we can conclude that pump of parallel which have high value of head loss compare to the series,which it have a low efficiency.In other aspect we can obtain that the value for BHP(watt),series obtain higher than series,which it consume of high using of power, in environmental condition that is not good to practice in life.

6.0 REFERENCES & APPENDICES

References

1) Fluid mechanics and hydraulics(laboratory manual),Norashikin Ahmad Kamal, Hamidon Ahmad,Wardah Tahir, University Publication Centre,2011. 2) Fluid mechanics and hydraulics,third edition, Ranald V. Giles, Jack B. Evett, Cheng Liu Mc Graw Hill,1994 3) 1000 solved problems in fluid mechanics (includes hydraulic machines), K. Subramanya, Tata McGraw-Hill Education,2005. 4) http://staff.fit.ac.cy/eng.fm/classes/amee202/Fluids%20Lab%20Friction%20losses.pd

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

APPENDIX 1)PREESURE READING

2)EXPERIMENT DURING PROCESS

3)PUMP IS RUNNING ON

4)TAKING FLOWRATE READING AND SPEED

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

STUDENT CENTERED LEARNING ACTIVITIES

briefly explain the differences between series and parallel pump and the purposes for each pump and the purposes for each pump in real engineering application PUMP (SERIES) PUMP (PARALLEL)

Pumps in Serial - Heads Added

Pumps in Parallel - Flow Rate Added

When two (or more) pumps are arranged in serial, their resulting pump performance curve is obtained by adding their heads at same flow rate as indicated in the figure below. Centrifugal pump in series are used to overcome larger system head loss than one pump can handle alone. For two identical pumps in series the head will be twice the head of a single pump at the same flow rate. With constant flowrate the combined head moves from 1 to 2. In practice the combined head and flow rated moved along the system curve to 3. If one of the pumps stops, the operation point moves allong the

When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding their flowrates at the same head as indicated in the figure below.

Centrifugal pumps in parallel are used to overcome larger volume flows than one pump can handle alone. For two identical pumps in parallel the flowrate will double (moving from 1 to 2) compared to a single pump if head is kept constant. In practice the combined head and volume flow moves along the system curve as indicated from 1 to 3. If one of the pumps in parallel or series stops, the operation point moves along the system resistance curve from point 3

Page: /

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

system resistance curve from point 1 to point 2 - head and flow rate are decreased. Series operation of single stage pumps is seldom encountered more often multistage centrifugal pumps are use. Uses PART WASHER is a piece of equipment used to remove contaminants or debris, such as dirt, grime, carbon, oil, grease, metal chips, cutting fluids, mold release agents, ink, paint, and corrosion from workpieces.] Parts washers are one of the last steps in the parts manufacturing process; they are designed to clean, degrease and dry bulk loads of small or large parts in preparation for surface treatment, packaging and distribution. Newly machined, molded and fabricated products are coated in oils, chemicals, burrs, abrasive dust, paint and other residue left over from the fabrication process of metal, plastic and rubber components, and finishing coatings are not effective if they are applied on a dirty surface. Parts cleaners may be as simple as a stand-alone basket immersion washer, or they may be as complex

to point 1 - the head and flow rate are decreased.

Uses MULTISTAGE CENTRIFUGAL PUMP centrifugal pump containing two or more impellers is called a multistage centrifugal pump. The impellers may be mounted on the same shaft or on different shafts. If we need higher pressure at the outlet we can connect impellers in series. If we need a higher flow output we can connect impellers in parallel. All energy added to the fluid comes from the power of the electric or other motor force driving the impeller.

Page:

LAB REPORT

CEW421 FLUIDS AND HYDRAULICS LABORATORY EC221 UNIVERSITI TEKNOLOGI MARA PULAU PINANG

as a five-step deburring, aqueous tumbling, rinsing, drying and paint coating machine. Parts washers are essential in maintenance, repair and remanufacturing operations as well, from cleaning fasteners, nuts, bolts and screws to engine parts and automotive assemblies.

Page:

You might also like

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Fluid Mechanics-II Lab Manual: University College of Engineering and TechnologyDocument27 pagesFluid Mechanics-II Lab Manual: University College of Engineering and Technologyzia malikNo ratings yet

- Lab 1 Series Parallel PumpsDocument16 pagesLab 1 Series Parallel PumpsSasys Rgl100% (11)

- Pumps in Series and ParallelDocument6 pagesPumps in Series and ParallelSuhadahafiza Shafiee0% (1)

- Centrifugal Pump Performance CharacteristicsDocument15 pagesCentrifugal Pump Performance CharacteristicsEiyra Nadia33% (3)

- PUMP-PALANGGA MO SAPATH NA, NO PRESSUREDocument6 pagesPUMP-PALANGGA MO SAPATH NA, NO PRESSUREDianne Kaye AndradeNo ratings yet

- Centrifugal Pump Characteristics CurvesDocument10 pagesCentrifugal Pump Characteristics CurvesJackSparrow86No ratings yet

- Series & Parallel Pump TestDocument22 pagesSeries & Parallel Pump TestIkhwan Z.100% (23)

- PumpsDocument5 pagesPumpsMonicaa BautistaNo ratings yet

- Circuits - CourseDocument93 pagesCircuits - Coursehasan bish100% (1)

- Handout Water PumpDocument7 pagesHandout Water PumpGarrett KnappNo ratings yet

- NG2S242 - CW Brief - Centrifugal Pumps - 2023-24Document9 pagesNG2S242 - CW Brief - Centrifugal Pumps - 2023-24Mirazul IslamNo ratings yet

- Experiment 9 4 Hydraulics Lab 21Document8 pagesExperiment 9 4 Hydraulics Lab 21MousaNo ratings yet

- Pumps in Parallel PDFDocument10 pagesPumps in Parallel PDFZezo HassanNo ratings yet

- Centrifugal Pump Performance Characteristics For DDocument6 pagesCentrifugal Pump Performance Characteristics For DPinaki SankarNo ratings yet

- 20 - Pumps PDFDocument6 pages20 - Pumps PDFEmmanuel EvangelistaNo ratings yet

- Fluid Pump Report 2013Document33 pagesFluid Pump Report 2013M Shahrul Izuan100% (1)

- Understanding Centrifugal PumpDocument7 pagesUnderstanding Centrifugal PumpjokishNo ratings yet

- Pump FinalDocument14 pagesPump FinalMansoob BukhariNo ratings yet

- Pump Performance - Double PumpsDocument8 pagesPump Performance - Double PumpsAshNo ratings yet

- Centrifugal Pump Performance CurvesDocument15 pagesCentrifugal Pump Performance CurvesVeshal Purshothama SeelanNo ratings yet

- Activity 7Document5 pagesActivity 7Katy PerryNo ratings yet

- Discussion (Meant by Pump Characteristic)Document5 pagesDiscussion (Meant by Pump Characteristic)Akmal ShaariNo ratings yet

- Lab 3-Pumps in Series and ParallelDocument5 pagesLab 3-Pumps in Series and ParallelnidhalsaadaNo ratings yet

- Centrifugal pump lab experimentDocument17 pagesCentrifugal pump lab experimentKarla PerezNo ratings yet

- Level 0 - Pump EfficiencyDocument6 pagesLevel 0 - Pump EfficiencySAYA HENSEMNo ratings yet

- Open Ended LabDocument6 pagesOpen Ended LabVishal DhimanNo ratings yet

- Experiment No 7+8+9Document32 pagesExperiment No 7+8+9Muhammad kamran AmjadNo ratings yet

- Performance Test On Single Stage Axial Flow FanDocument3 pagesPerformance Test On Single Stage Axial Flow FanAkhil Jaiswal100% (1)

- Fluid Mechanics Lab Pump CurvesDocument7 pagesFluid Mechanics Lab Pump Curvesuzair akramNo ratings yet

- 1.0 TITLE Centrifugal PumpDocument11 pages1.0 TITLE Centrifugal PumpnorsiahNo ratings yet

- Lab 7 LatestDocument14 pagesLab 7 LatestImran KaiNo ratings yet

- 08 2Document17 pages08 2Rustic70No ratings yet

- Centrifugal PumpDocument14 pagesCentrifugal PumpVivek Blueblood KannaNo ratings yet

- Study of The Centrifugal Pump Efficiency at Throttling and Speed ControlDocument4 pagesStudy of The Centrifugal Pump Efficiency at Throttling and Speed ControlHassan SouleymanNo ratings yet

- Experiment No. 7 Pump Performance - Single Pump: MEHB221 Fluids Mechanics Lab 2016Document6 pagesExperiment No. 7 Pump Performance - Single Pump: MEHB221 Fluids Mechanics Lab 2016Syahmi ShahimanNo ratings yet

- 1.course Plan-text-ME 3111Document4 pages1.course Plan-text-ME 3111mama dullaNo ratings yet

- Some Aspects of Numerical Simulation of Control Valves For Steam TurbinesDocument1 pageSome Aspects of Numerical Simulation of Control Valves For Steam TurbinesSharat ChandraNo ratings yet

- Cavitation Analysis CFDDocument4 pagesCavitation Analysis CFDshdjjfNo ratings yet

- Centrifugal Pump FullDocument25 pagesCentrifugal Pump FullMohamad FaizNo ratings yet

- M 389 ContentDocument52 pagesM 389 ContentokahertaberNo ratings yet

- LAB SHEET For Centrifugal Pump (I)Document2 pagesLAB SHEET For Centrifugal Pump (I)Mohd FazliNo ratings yet

- Experiment 3Document9 pagesExperiment 3Abigail RadubanNo ratings yet

- Fluid Mechanics Lab Characteristics CurvesDocument7 pagesFluid Mechanics Lab Characteristics Curvesuzair akramNo ratings yet

- Fluid Mechanics Lab Characteristics CurvesDocument7 pagesFluid Mechanics Lab Characteristics Curvesuzair akramNo ratings yet

- Serial and Parallel Pump Operations-Variable Speed Pump DriveDocument10 pagesSerial and Parallel Pump Operations-Variable Speed Pump DriveAyberk ArdıçNo ratings yet

- Energy Regeneration Hydraulic System Via A Relief ValveDocument15 pagesEnergy Regeneration Hydraulic System Via A Relief ValvenqnghiNo ratings yet

- Pump Lab Report: Parallel vs Series ConfigurationsDocument7 pagesPump Lab Report: Parallel vs Series ConfigurationsElyse Kymberly TeohNo ratings yet

- 40 Years of Experience With Liquid-Liquid Extraction Equipment in The Nuclear IndustryDocument7 pages40 Years of Experience With Liquid-Liquid Extraction Equipment in The Nuclear Industryshrishapaik737No ratings yet

- Universal Pump Test R: Analyzing Centrifugal Pump PerformanceDocument9 pagesUniversal Pump Test R: Analyzing Centrifugal Pump PerformanceOsama RaheelNo ratings yet

- Fluid Machine LAB OKDocument57 pagesFluid Machine LAB OKRicardo ChilizaNo ratings yet

- Basic HydraulicsDocument22 pagesBasic HydraulicsGorge SoroNo ratings yet

- Series and Parallel PumpDocument15 pagesSeries and Parallel PumpbandarNo ratings yet

- Centrifugal pump characteristicsDocument23 pagesCentrifugal pump characteristicsmubara marafaNo ratings yet

- Series & Parallel PumpDocument14 pagesSeries & Parallel PumpDivaan Raj Karunakaran100% (3)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- 1 s2.0 S2095756415200165 MainDocument7 pages1 s2.0 S2095756415200165 MainSyikin FauziNo ratings yet

- 10 DeterminationOfComfortableSafeWidthInAnExclusiveMotorcycleLane PDFDocument14 pages10 DeterminationOfComfortableSafeWidthInAnExclusiveMotorcycleLane PDFSyikin FauziNo ratings yet

- Final Manual For Specification StandardsDocument192 pagesFinal Manual For Specification Standardsbhargavraparti100% (1)

- Assessment of Heavy Metals in A Municipal Solid Waste Dump.Document7 pagesAssessment of Heavy Metals in A Municipal Solid Waste Dump.Syikin FauziNo ratings yet

- Construction Waste Management Malaysian PerspectiveDocument11 pagesConstruction Waste Management Malaysian PerspectiveSyikin FauziNo ratings yet

- Jadual Exam 2011Document2 pagesJadual Exam 2011Syikin FauziNo ratings yet

- Hydrogen storage methods for a sustainable futureDocument9 pagesHydrogen storage methods for a sustainable futureCevdet AyazNo ratings yet

- 00051181applying Technical Limit Methodology ForDocument7 pages00051181applying Technical Limit Methodology Fordrilling moneytreeNo ratings yet

- A01 097Document55 pagesA01 097mouse1201No ratings yet

- Utilev Ut15we Ssheet en Rev00Document4 pagesUtilev Ut15we Ssheet en Rev00Marco ChablaNo ratings yet

- Developing Low Sour GasDocument12 pagesDeveloping Low Sour GasOilfieldJimNo ratings yet

- Palm Acid OilDocument4 pagesPalm Acid OilWeizhan LeeNo ratings yet

- Teknik Permesinan Kapal II (Minggu - 2) : Jurusan Teknik Sistem Perkapalan ITS SurabayaDocument11 pagesTeknik Permesinan Kapal II (Minggu - 2) : Jurusan Teknik Sistem Perkapalan ITS SurabayaRazaq PayapoNo ratings yet

- Science 20 Unit ADocument133 pagesScience 20 Unit Aapi-2079572300% (1)

- Azeri Light 2005 06Document18 pagesAzeri Light 2005 06Robby KurniawanNo ratings yet

- Daihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformanceDocument8 pagesDaihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformancePrince ChaudharyNo ratings yet

- Coskovic Branimir Etfos 2017 Zavrs SveucDocument2 pagesCoskovic Branimir Etfos 2017 Zavrs SveucsffvghjNo ratings yet

- Shop Manual U-341FDocument115 pagesShop Manual U-341FDavid100% (3)

- Full Text 01Document56 pagesFull Text 01juanky079No ratings yet

- Master Ceramico OX - English - Rev-DDocument2 pagesMaster Ceramico OX - English - Rev-DfaniaaaNo ratings yet

- Practice Set SSC-CGL Tier IDocument17 pagesPractice Set SSC-CGL Tier IdragonbourneNo ratings yet

- Volkswagen Touareg 2003 Workshop Manual PDFDocument165 pagesVolkswagen Touareg 2003 Workshop Manual PDFdaniel0% (1)

- Waste Plastic Conversion Into Hydrocarbo PDFDocument7 pagesWaste Plastic Conversion Into Hydrocarbo PDFLotfi BrahimNo ratings yet

- Oil Gas Sampling SystemsDocument8 pagesOil Gas Sampling SystemsCarlos JuárezNo ratings yet

- Fiat 127 1049 CM: Opis Části Servisního ManuáluDocument34 pagesFiat 127 1049 CM: Opis Části Servisního ManuáluhaithamNo ratings yet

- Procedure (Filtration)Document2 pagesProcedure (Filtration)Jerome MagnoNo ratings yet

- Gas Turbine Manual PDFDocument721 pagesGas Turbine Manual PDFZakki Afifi100% (2)

- DIN en ISO 14175-2008-06 - Welding Consumables, Gases and Gas Mixtures For Fusion Welding and Allied ProcessesDocument13 pagesDIN en ISO 14175-2008-06 - Welding Consumables, Gases and Gas Mixtures For Fusion Welding and Allied ProcessesEduardo Javier Granados SanchezNo ratings yet

- Lecture - 1 For Process Industries OneDocument37 pagesLecture - 1 For Process Industries OneteweleNo ratings yet

- Foam PumpDocument18 pagesFoam PumpPanagiotis MouzenidisNo ratings yet

- Complete Dummy's Guide to a Diffusion Pumped Vacuum SystemDocument4 pagesComplete Dummy's Guide to a Diffusion Pumped Vacuum Systemjokerbuddy01No ratings yet

- Convert Gasoline Engine To Run On Alcohol 2008Document4 pagesConvert Gasoline Engine To Run On Alcohol 2008david2325100% (1)

- (P&id1) PDFDocument1 page(P&id1) PDFHatem FaroukNo ratings yet

- 1.classification of Reciprocating PumpsDocument8 pages1.classification of Reciprocating Pumpsgonri lynnNo ratings yet

- D6560 Determination of Asphaltenes (Heptane Insolubles)Document5 pagesD6560 Determination of Asphaltenes (Heptane Insolubles)dodofan2000100% (1)