Professional Documents

Culture Documents

Posible Exam Questions

Uploaded by

hemant_ghugeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Posible Exam Questions

Uploaded by

hemant_ghugeCopyright:

Available Formats

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20.

Characteristics of Batch process. How it is different from Continuous process with examples. Is Batch process more complex and if yes, why? Hierarchy of S88 model Why do we have to have S88 model What are the constituents of Recipe with examples? S95 Concept of Shared resources with examples What is Arbitration Complexity matrix for Batch process automation What is the lowest level element in the Batch model.give example? Seven layers of Control Activity model Control Activity model Vs. Batch model What is FDA, What is Validation, Why is Validation so important in Bio-Pharma? GAMP project life cycleV model Documentation requirements in FDA validated projects..Documentation terms like URS, FDS, Scope of Batch Control System Interlocks, Exception Handling, Analog Variables Monitoring and Control, Sequence, Operations, Recipes etc. What is interlock and what is permissive. Explain the difference with example. What is fail safe position concept in case of any device? Explain with example. What are the different regulatory controls Feedback, Feed Forward, Ratio, Cascade etc. and do they exist in batch control systems? What are the challenges for Regulatory control in Batch processes?

21. Describe key differences which distinguish a batch process from a continuous process. Explain various classifications for batch processes. 22. Develop complete Physical and Procedural control S88 model for following Paint process. Assign components of following process to S88 elements appropriately.

23. Describe in detail various levels of Control Activity Model. Provide appropriate examples for each level from typical Pharmaceutical Batch process.

24. Discuss FDA Validation in detail on following points: a. What is Validation? b. Why is it necessary for Pharmaceutical manufacturers? c. What is GAMP and what is GAMP-4 Project life cycle? d. What are the key documents suggested in GAMP-4 project life cycle? e. What is 21 CFR Part 11? 25. Describe various challenges faced for Regulatory control in Batch processes. Discuss these challenges specifically for following: a. Reset Windup b. Cascade Control c. Set-point ramping 26. Discuss Control Activity inter-relationship model and various functions of Batch Management. 27. Define Recipe. Describe various components of Recipe. Develop Control Recipe with all essential components for following sequence: a. Initialize b. Charge A c. When enough A has been charged, turn on the agitator, start charging B. Ratio B to A so that they complete charging at the same time. d. Charge preset amount of catalyst D. e. Raise temperature to 100 degC as rapidly as possible while minimizing overshoot. f. When reactor is at 100 degC, start E feed. Feed E at the maximum possible feed rate to minimize cycle time as long as pressure and temperature do not exceed their respective set points. Raise temperature to 200 degC based on % of total E fed. g. Sample to lab and start cooling to 100 degC. h. Hold for 30 minutes. i. When lab analysis is OK and temperature is 100 degC, pump to storage. 28. Discuss project life cycle for a typical FDA validated Batch project. Describe various documentation requirements during each stage of this life cycle.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- History of Photography Timeline Assignment 1Document14 pagesHistory of Photography Timeline Assignment 1api-357703158No ratings yet

- Epoxidation of Vegetable Oils - A ReviewDocument8 pagesEpoxidation of Vegetable Oils - A ReviewNorberto SchischoffNo ratings yet

- Sleeperwall 1Document6 pagesSleeperwall 1John SmithNo ratings yet

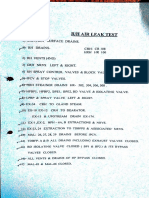

- Air Leak Test PDFDocument1 pageAir Leak Test PDFhemant_ghugeNo ratings yet

- ATM Block Ticket No.Document1 pageATM Block Ticket No.hemant_ghugeNo ratings yet

- NomenclatureDocument1 pageNomenclaturehemant_ghugeNo ratings yet

- Overflow: PWM ControllerDocument1 pageOverflow: PWM Controllerhemant_ghugeNo ratings yet

- Assignment 4Document3 pagesAssignment 4hemant_ghugeNo ratings yet

- ElectivesDocument1 pageElectiveshemant_ghugeNo ratings yet

- P&ID of System Prepair List of Equipment RequiredDocument1 pageP&ID of System Prepair List of Equipment Requiredhemant_ghugeNo ratings yet

- Sugar PlantDocument2 pagesSugar Planthemant_ghugeNo ratings yet

- Weirs 2Document3 pagesWeirs 2hemant_ghugeNo ratings yet

- IB Physics Answers ThemeADocument15 pagesIB Physics Answers ThemeANicole El-hazhaliNo ratings yet

- ZondST2D Eng PDFDocument148 pagesZondST2D Eng PDFLilyOhhNo ratings yet

- Separation Science - Chromatography Unit Thomas Wenzel Department of Chemistry Bates College, Lewiston ME 04240 Twenzel@bates - EduDocument69 pagesSeparation Science - Chromatography Unit Thomas Wenzel Department of Chemistry Bates College, Lewiston ME 04240 Twenzel@bates - EduthecriticNo ratings yet

- 207.OTN 260SCX2 and 130SCX10 Cards V1 04 11feb16Document24 pages207.OTN 260SCX2 and 130SCX10 Cards V1 04 11feb16Ronald N Meza C100% (1)

- Modelling of Li-Ion Batteries Using Equivalent Circuit DiagramsDocument5 pagesModelling of Li-Ion Batteries Using Equivalent Circuit DiagramsCarlos Morales ZamoraNo ratings yet

- Leica Reflectors DSDocument1 pageLeica Reflectors DSpleyvazeNo ratings yet

- Hydraulic and Pneumatic Basics - 1Document14 pagesHydraulic and Pneumatic Basics - 1Ally Yap100% (1)

- Charge Induced On Two Styrofoam BallsDocument15 pagesCharge Induced On Two Styrofoam Ballsmrvedant660No ratings yet

- The Inclined Plane (George Ricarrson - 2501987261)Document12 pagesThe Inclined Plane (George Ricarrson - 2501987261)George RYNo ratings yet

- Testing of Transformer Oil and Winding Temperature IndicatorsDocument6 pagesTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyNo ratings yet

- Apendice B - Transport Phenomena - Bird 2edDocument9 pagesApendice B - Transport Phenomena - Bird 2edarur007No ratings yet

- LMI Series G Metering Pump Datasheet PDFDocument6 pagesLMI Series G Metering Pump Datasheet PDFVkita MolinaNo ratings yet

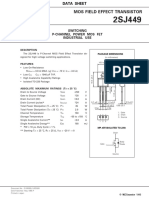

- 2SJ 449 - NecDocument9 pages2SJ 449 - NecStevenNo ratings yet

- D6937 4047 PDFDocument2 pagesD6937 4047 PDFEmily MurilloNo ratings yet

- How To Carry Out Tack WeldingDocument2 pagesHow To Carry Out Tack WeldingwentropremNo ratings yet

- Metal FormingDocument13 pagesMetal Formingabdsu75No ratings yet

- Adaptive Control by LandauDocument6 pagesAdaptive Control by LandauSabit RashidNo ratings yet

- Hot Rolled Bulb Flats PDFDocument4 pagesHot Rolled Bulb Flats PDFLaurentiu GavrilaNo ratings yet

- Cows and ChickensDocument9 pagesCows and Chickensapi-298565250No ratings yet

- Worksheet 1 131 2021W2 HydrostaticsDocument8 pagesWorksheet 1 131 2021W2 HydrostaticseNo ratings yet

- 69kV and Above Oil Immersed Transformer Instruction ManualDocument30 pages69kV and Above Oil Immersed Transformer Instruction ManualYaser MajeedNo ratings yet

- Vectors DPPDocument13 pagesVectors DPPAchyuth DaggumatiNo ratings yet

- IIT-JEE - 2020 - 2021: BY Referral CodeDocument31 pagesIIT-JEE - 2020 - 2021: BY Referral CodeBishwadeep RoyNo ratings yet

- (Main) : Computer Based Test (CBT)Document12 pages(Main) : Computer Based Test (CBT)Resonance Eduventures100% (1)

- Chapter 24 - How Lenses Are Edged - 2007 - System For Ophthalmic DispensingDocument16 pagesChapter 24 - How Lenses Are Edged - 2007 - System For Ophthalmic DispensingsNo ratings yet

- PIA CAE SolidworksDocument15 pagesPIA CAE SolidworksCchh UuyyNo ratings yet

- CS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaDocument3 pagesCS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaZhichaoWangNo ratings yet