Professional Documents

Culture Documents

Stamping Dies

Uploaded by

tangantulisOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stamping Dies

Uploaded by

tangantulisCopyright:

Available Formats

Sheet Metal Stamping Dies & Processes

Training Objectives After watching the video and reviewing this printed material, the viewer will gain knowledge and understanding of the stamping process and the die systems used to form sheet metal. the terms ductility and formability are explained the essential components of the stamping process are detailed basic stamping terms are defined progressive and transfer die technology is illustrated die lubrication is addressed circle grid analysis is explained

Sheet Metal Stamping Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. These parts achieve their shape through the effects of the die tooling. Production stamping is generally performed on materials .020 to .080 thick, but the process also can be applied to foils as thin as .001 or to plate stock with thickness' approaching 1.000. Formability is the primary attribute of sheet metal material. Formability is further defined as the materials ability to be: bent stretched drawn

The metallurgical term for these qualities is ductility. Ductility is the materials ability to deform and elongate without fracture. The extent to which a stamping is subjected to such deformation is directly related to the parts overall shape and geometry. Other factors also influence the materials formability. They include: the die design the press the press speed lubrication sheet metal feeding mechanisms monitoring and control systems

The word die is a generic term used to describe the tooling used to produce stamped parts. A die set assembly consisting of a male and female component is the actual tool that produces the shaped stamping. The male and female components work in opposition to both form and punch holes in the stock. The upper half of the die set, which may be either the male or female, is mounted on the press ram and delivers the stroke action. The lower half is attached to an intermediate bolster plate which in turn is secured to the press bed. Guide pins are used to insure alignment between the upper and lower halves of the die set.

Fundamental Manufacturing Processes Video Series Study Guide

- 1 -

Sheet Metal Stamping Dies & Processes

The most common types of dies perform cutting and forming. Cutting dies are used to shear sheet material into what is called a blank. These blanks are then exposed to blanking dies which cut the entire perimeter of the part, or to forming dies where the blank is stamped into a part. Punching is another function of cutting dies. Punching is the cutting of a slug from the sheet metal stock to produce a hole or slot. Cutting dies are also used to trim excess metal from around a formed part. Hole punching and other cutting operations require specific and carefully maintained clearances between the punch (male component) and the die (female component). The setting of the required clearances is determined by both the stock thickness and temper. In general, die clearances increase as the stock thickness increases. The depth of punch penetration into the sheet metal stock will also increase as softer stock is used. Forming is a general term used to describe a stamped part whose shape and contour is reproduced directly from the shape and contour of a die set. The main forming operations accomplished with press mounted dies are: drawing bending flanging hemming

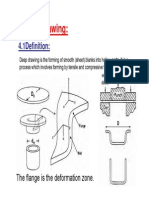

Drawing, or draw forming, involves forcing a blank deeply into a die cavity and shaping it into the shape and contour of the punch face and sides. Without sufficient formability qualities, drawn blanks are subject to wrinkling, thinning, and fracturing. Draw forming requires an addition to the die set called a blankholder. The function of the blankholder, usually a ring through which the punch and ram pass, is to control the metal flow as it is forced into the die cavity. In practice, the blankholder must exert less pressure against the blank than the punch, so metal can flow into the die; yet it must exert enough pressure to prevent the material from wrinkling. Bending is a relatively simple forming operation which provides rigidity and shape to sheet metal parts. Similar to bending is flanging. However a flange is significantly smaller in dimension than the rest of the part. The functions of a flange include: giving a more finished appearance rigidity edge strengthening providing a fastening or attachment surface

Hemming is the folding over of a short flange upon itself to form a smooth, rounded edge and to facilitate the attachment of mating parts. Multiple stamping operations may be performed within a single die, or at a number of die stations within a die set and with a single stroke of the press. Single station dies can be either compound dies or combinations dies. A compound die performs basic cutting operations such as blanking and hole punching to produce parts. Combination dies combine shaping and forming functions with cutting operation to manufacture parts.

Fundamental Manufacturing Processes Video Series Study Guide

- 2 -

Sheet Metal Stamping Dies & Processes

Multiple station dies are arranged so that a series of sequential operations are accomplished with each press stroke. Two die types are used; progressive and transfer. With progressive dies, coil stock is fed into the press. Individual stampings are connected with a carrier strip as they progress through the various die operations and are ultimately separated and then discharged from the press. In transfer die operations individual stock blanks are mechanically moved from die station to die station within a single die set. Large stampings are done with tandem press lines where the stock is moved from press to press in which specific operations, such as drawing or trimming, are performed. The resistance of the sheet metal stock to the forces exerted by the moving dies creates friction. For this reason, lubrication is vital for successful sheet metal forming. A lubrication's function is to minimize contact between the tooling and the work piece. This results in reduced tonnage requirements, longer tooling life, and improved product quality. Lubricants range from light mineral oils to high viscosity drawing compounds. They may be oil base, water soluble, or synthetic materials. These lubricants may be applied in a variety of ways, including: manually by roller or brush drip machine roller spraying flooding

Die making is as much of an art as a science. When all the dynamics of stamping are taken into account, the resulting part may not meet all expectations. To help fine tune the stamping process and finalize die design, die makers use an analytical tool called Circle Grid Analysis, or CGA. The application of CGA involves the etching of a pattern of small circles on the surface of the blank. This pattern deforms along with the blank as it is formed, providing point-topoint calculations of the deformation that occurred. Analyzing this stamped grid pattern suggests the location and type of rework that must be performed on the dies to produce easily manufactured parts. The CGA process is repeated on the die until an acceptable part is produced.

Fundamental Manufacturing Processes Video Series Study Guide

- 3 -

Sheet Metal Stamping Dies & Processes

Review Questions 1. Most sheet a. .020 to b. .050 to c. .001 to d. .010 to metal stamping uses materials: .080 thick .125 thick 1.000 thick .100 thick

2. Ductility refers to a materials ability to: a. resist penetration b. resist corrosion c. bend over upon itself d. deform and elongate 3. A compound die is a die that performs: a. hemming and flanging b. blanking and hole punching c. bending only d. hole punching only 4.. a. b. c. d. The device(s) used to insure die component alignment are called: roller bearings ways guide pins "v" grooves

5. The terms drawing, flanging, and hemming are examples of: a. forming b. punching c. slitting d. extruding 6. A carrier strip is used with: a. transfer dies b. progressive dies c. tandem presses d. combination dies 7. The principle function of a lubricant in press stamping is to: a. cool the dies b. enable easy stack removal c. prevent wrinkling d. minimize tool contact to the work 8. Circle Grid Analysis, or CGA, is used to: a. calculate tonnage exerted on the work b. predict deformation distances c. finalize die design d. determine optimum press speed

Fundamental Manufacturing Processes Video Series Study Guide

- 4 -

Sheet Metal Stamping Dies & Processes

Answer Key 1. 2. 3. 4. 5. 6. 7. 8. a d b c a b d c

Fundamental Manufacturing Processes Video Series Study Guide

- 5 -

You might also like

- Chapter 4 Tool and Die DesignDocument70 pagesChapter 4 Tool and Die Designdawit solomonNo ratings yet

- Punch and DieDocument16 pagesPunch and DieNani DatrikaNo ratings yet

- 3 Die CuttingDocument41 pages3 Die CuttingNarendrareddy RamireddyNo ratings yet

- Die Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingDocument30 pagesDie Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingAmitNo ratings yet

- Deep Drawing Process GuideDocument4 pagesDeep Drawing Process GuideBalvinder PrajapatiNo ratings yet

- Types of DiesDocument17 pagesTypes of DiesJayditya KumarNo ratings yet

- Lecture-14 Sheet Metal Forming ProcessesDocument34 pagesLecture-14 Sheet Metal Forming ProcessesDida KhalingNo ratings yet

- CH03. Sheet Metal ProcessesDocument73 pagesCH03. Sheet Metal ProcesseshizanorhudaNo ratings yet

- 04 Cutting ClearanceDocument18 pages04 Cutting Clearancegaurav deshmukhNo ratings yet

- Module2: Design and Calculations of Piercing & Blanking DieDocument89 pagesModule2: Design and Calculations of Piercing & Blanking DieVipul MetaNo ratings yet

- Press Tools ProjectDocument19 pagesPress Tools ProjectKanahaiya100% (1)

- PRESSTOOL MASTER 1st SemDocument111 pagesPRESSTOOL MASTER 1st Semmathapatikumar56No ratings yet

- Selection of Material and Hardware Used in Press ToolDocument22 pagesSelection of Material and Hardware Used in Press ToolVipul MetaNo ratings yet

- Computing Die Thickness and MarginsDocument3 pagesComputing Die Thickness and MarginsAnand PrajapatiNo ratings yet

- DiesDocument4 pagesDiesjohan pambudiNo ratings yet

- 03 Cutting ForceDocument3 pages03 Cutting ForceAhmad Mustaghfiri Asrar100% (1)

- Shearing Process GuideDocument29 pagesShearing Process GuideSriram MuruganNo ratings yet

- MP SheetMetal PDFDocument48 pagesMP SheetMetal PDFNhan LeNo ratings yet

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDocument17 pages15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- T&D - Core 4 Tool & DieDocument44 pagesT&D - Core 4 Tool & Dietisha revillaNo ratings yet

- Tool Design - Chapter 4 (Part 4)Document22 pagesTool Design - Chapter 4 (Part 4)Fiq IFTNo ratings yet

- Cutting ClearanceDocument2 pagesCutting ClearancevinodNo ratings yet

- DieDocument6 pagesDieAditya GoelNo ratings yet

- Deep Drawing UhuyyyyDocument20 pagesDeep Drawing UhuyyyyeltonNo ratings yet

- Deep Drawing Process GuideDocument26 pagesDeep Drawing Process Guidemck_medo100% (1)

- Press Tool CalculationDocument76 pagesPress Tool CalculationPrashant AmbadekarNo ratings yet

- 5 Deep DrawingDocument8 pages5 Deep DrawingSiva PraneethNo ratings yet

- Types of Press Tools Classified and ExplainedDocument24 pagesTypes of Press Tools Classified and ExplainedAvula VinayNo ratings yet

- 3-Classification of CUTTING DIESDocument5 pages3-Classification of CUTTING DIESGurdeepNo ratings yet

- Metal Stamping Dies GuideDocument7 pagesMetal Stamping Dies GuideedpsousaNo ratings yet

- Sheet MetalDocument21 pagesSheet MetalRam Janm Singh100% (2)

- Unit I - Theory of Metal CuttingDocument111 pagesUnit I - Theory of Metal CuttingSaravana KumarNo ratings yet

- Material Removal Process (Metal Machining Process) : Theory of Metal CuttingDocument129 pagesMaterial Removal Process (Metal Machining Process) : Theory of Metal CuttingIjanSahrudinNo ratings yet

- Press Working Operation NOTESDocument6 pagesPress Working Operation NOTESZakyNo ratings yet

- 01 Introduction To Press ToolsDocument31 pages01 Introduction To Press ToolsNiranjan HalgarNo ratings yet

- Sheetmetal IntroductionDocument9 pagesSheetmetal IntroductionVinay BalineniNo ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- Presstool MasterDocument111 pagesPresstool MasterRajesh Kumar100% (2)

- 878-TOOL DESIGN AND DRAWING PART -ADocument17 pages878-TOOL DESIGN AND DRAWING PART -AsandhuNo ratings yet

- Tool Design - Chapter 4 (Part 3)Document59 pagesTool Design - Chapter 4 (Part 3)Fiq IFTNo ratings yet

- Course Material TwoDay Workshop Sheetemetal DHIO GTTCDocument132 pagesCourse Material TwoDay Workshop Sheetemetal DHIO GTTChsvjvv100% (1)

- Theory of Metal Cutting FundamentalsDocument24 pagesTheory of Metal Cutting FundamentalsSreehari ViswanathanNo ratings yet

- Sheet Forming Processes: Shearing & BendingDocument50 pagesSheet Forming Processes: Shearing & Bendingsudharsans88No ratings yet

- Deep Drawing and Super-Plastic Forming Processes ComparedDocument83 pagesDeep Drawing and Super-Plastic Forming Processes ComparedYasir HussainNo ratings yet

- Metal Forming LabDocument57 pagesMetal Forming LabRohitGuptaNo ratings yet

- LO 03 - BendingDocument61 pagesLO 03 - Bendingladyinred90No ratings yet

- Module 3: Cutting Tool Materials and FluidsDocument88 pagesModule 3: Cutting Tool Materials and FluidssushilNo ratings yet

- Design of Jigs and FixturesDocument3 pagesDesign of Jigs and FixturesRajueswarNo ratings yet

- Production Process.II (CBCGS) Module.1 Metal CuttingDocument24 pagesProduction Process.II (CBCGS) Module.1 Metal CuttingOmkar BedadeNo ratings yet

- Press Tool Theory - 1Document144 pagesPress Tool Theory - 1Abhishek AbhiNo ratings yet

- Unit-III - Theory On The Metal Cutting OperationDocument217 pagesUnit-III - Theory On The Metal Cutting OperationKansath KamalNo ratings yet

- MLD TheoryDocument96 pagesMLD TheorySheik Abdullah100% (1)

- METAL CUTTING TOOL DESIGN COURSEDocument3 pagesMETAL CUTTING TOOL DESIGN COURSEHemanth YadaNo ratings yet

- Progressive Die Design Course 3D ModelingDocument1 pageProgressive Die Design Course 3D ModelingRodrigo Iyomasa0% (1)

- Sheet Metal Stamping GuideDocument5 pagesSheet Metal Stamping Guider_saniosNo ratings yet

- DV11PUB9 Study Guide PDFDocument5 pagesDV11PUB9 Study Guide PDFEnriqueGDNo ratings yet

- Sheet Metal OperationsDocument27 pagesSheet Metal OperationsbmvinayNo ratings yet

- Chapter 4 Die DesignDocument102 pagesChapter 4 Die DesignTamirat Nemomsa100% (3)

- Six Weeks Industrial Training ReportDocument27 pagesSix Weeks Industrial Training ReportGagan Deep100% (2)

- Grant Prideco USA OCTG Tubular ProductsDocument2 pagesGrant Prideco USA OCTG Tubular ProductsMas Bagaz NoviantoNo ratings yet

- Poster Corrosion Well Logging 9Document1 pagePoster Corrosion Well Logging 9Moh Abd Ben100% (1)

- PMBOK Chapter 7 - QualityDocument30 pagesPMBOK Chapter 7 - QualitylatehoursNo ratings yet

- E020 Series Sealed Snap-acting Momentary Pushbutton SwitchesDocument9 pagesE020 Series Sealed Snap-acting Momentary Pushbutton SwitchesabcNo ratings yet

- APICS Certified in Production and Inventory Management (CPIMDocument29 pagesAPICS Certified in Production and Inventory Management (CPIMPulokesh GhoshNo ratings yet

- Glenium 51 TDSDocument2 pagesGlenium 51 TDSTooma DavidNo ratings yet

- Adhesion Testing MethodDocument3 pagesAdhesion Testing MethodMohd Effiezool YaserNo ratings yet

- Transport and Main Roads Specifications MRTS24 Manufacture of Precast Concrete CulvertsDocument28 pagesTransport and Main Roads Specifications MRTS24 Manufacture of Precast Concrete CulvertsrenandNo ratings yet

- Parr - Stress Crack Corrosion Corrosion of Stainless Steel by Hot Caustic Corrosion Info PDFDocument2 pagesParr - Stress Crack Corrosion Corrosion of Stainless Steel by Hot Caustic Corrosion Info PDFsurawutwijarnNo ratings yet

- Auto Parts Inventory SystemDocument4 pagesAuto Parts Inventory SystemVince Ryan L. ArboledaNo ratings yet

- Study Notes On Financial Management of Sick UnitsDocument20 pagesStudy Notes On Financial Management of Sick UnitsShashi ShekharNo ratings yet

- BHEL Haridwar Block 2 Heavy Fabrication, Training ReportDocument53 pagesBHEL Haridwar Block 2 Heavy Fabrication, Training ReportUdit Soni100% (5)

- Inventory Management, JIT, and Backflush Costing Key ConceptsDocument57 pagesInventory Management, JIT, and Backflush Costing Key ConceptsnikkaaaNo ratings yet

- Int McKesson CaseStudyDocument4 pagesInt McKesson CaseStudyIntelligratedNo ratings yet

- Glafltlok: Cable Ties & Wire Accessories /2007Document41 pagesGlafltlok: Cable Ties & Wire Accessories /2007Manpreet SinghNo ratings yet

- Catalyst TubeDocument8 pagesCatalyst TubePradeep SinghNo ratings yet

- C595Document7 pagesC595JoSueMeJiaNo ratings yet

- 2005 PSS Road MeshDocument4 pages2005 PSS Road MeshJim Arturo Rivera VidalNo ratings yet

- Nature and Scope of Operations ManagementDocument2 pagesNature and Scope of Operations ManagementSathya GaneshNo ratings yet

- Spcification - VolzDocument2 pagesSpcification - Volzmdalt9180No ratings yet

- ZARA PresentationDocument17 pagesZARA PresentationMuhammad NaveedNo ratings yet

- Reguler - Kelompok 1 SoalDocument4 pagesReguler - Kelompok 1 SoalKezia BatubaraNo ratings yet

- Part Iii Material Handling and Identification TechnologiesDocument50 pagesPart Iii Material Handling and Identification TechnologiesNaval GuptaNo ratings yet

- Management Practices and Financial Reporting in The Sri Lankan Apparel SectorDocument26 pagesManagement Practices and Financial Reporting in The Sri Lankan Apparel SectorBhupendra RaiNo ratings yet

- BMT WeldingGuide 1017 2Document8 pagesBMT WeldingGuide 1017 2kcarmachNo ratings yet

- Mechanical Properties - Bolt, Nut, FastenersDocument4 pagesMechanical Properties - Bolt, Nut, FastenersmegatornadoNo ratings yet

- Formwork:: Requirements of A Good Formwork SystemDocument8 pagesFormwork:: Requirements of A Good Formwork SystemJonah ScottNo ratings yet

- Qap KLMDocument200 pagesQap KLMSachin JadhavNo ratings yet

- Amity Business School, Noida Uttar Pradesh-201313: Supply Chain Management (POM702)Document13 pagesAmity Business School, Noida Uttar Pradesh-201313: Supply Chain Management (POM702)N Uday AshishNo ratings yet

- GMP Guild For Cosmetic IngredientDocument48 pagesGMP Guild For Cosmetic IngredientLennon Tan Qin JiNo ratings yet