Professional Documents

Culture Documents

PLS20120301

Uploaded by

bmacavanzaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PLS20120301

Uploaded by

bmacavanzaCopyright:

Available Formats

Wrench

Time

by

Design

Plant upgrades are opportunities to

bring engineering and maintenance

departments together

WWW.PLANTSERVICES.COM

M

A

R

C

H

2

0

1

2

Sustainability at Volkswagen / p.11

Take Your Lube Practices to a Higher Level / p.21

Does Your CMMS Suffer From TMI? / p.37

U.S. Army Battles Waste and Emissions / p.50

www.automationdirect.com/pneumatic-parts

www.automationdirect.com

1-800-633-0405

Go online or call to get complete information,

request your free catalog, or place an order.

Also Available

Tubing and Hose

Pneumatic

Air Cylinders

Pneumatic

Solenoid Valves

and Manifolds

Air Preparation

Fittings and

Air Couplings

Parts you use every day,

at everyday great prIces

Weve got the pneumatic parts you need, and they

ship the same day* New are quick-disconnect hose

couplings, which allow easy changing of tools or

hose connections. Brass fittings work with water,

oil and many compressed gases. Aluminum

manifolds give you flexibility in designing a system.

And everyone needs a blow gun in their tool kit!

See everything at:

Quick-disconnect Air Couplings

llus ano couplcts |ot 1/+ ano 1/s incb bosc sizcs

ualc ano |cualc Nl1 tbtcaoco

Coupatiblc witb tbtcc o| tbc uost populat

conncction stylcs

Brass Threaded Fittings

1o oi||ctcnt stylcs, incluoin 1cc ano clbow

ualc ano |cualc conncctots in 1/s to 1/z incb sizcs

wotk witb watct, oil, ait ano otbct ascs

uaxiuuu ptcssutc soo psi

Aluminum Manifolds

ouno uani|olos witb 1/s incb Nl1 input, ano two ot

tbtcc 1/+ incb Nl1 outputs

cctanulat uoocls witb 1/z incb Nl1 inputs on citbct

cno, ano tbtcc ot |ivc 1/+ incb Nl1 outputs

Pneumatic Blow Guns

lalu typc witb sa|cty tip, pistol tips, pockct stylc, ano

plastic tip witb |lcxiblc nozzlcs in vatious lcnbs

>tatt at.

$6.75

>tatt at.

$4.00

(s-packl

>tatt at.

$5.00

>tatt at.

$4.25

PS1203_FPA.indd 2 2/29/12 11:01 AM

Covered by one or more of the following U.S. Patents: 6,244,821; 6,589,016; 6,817,835; 6,939,108; 7,252,478; 7,284,960; D587,799; D607,988; 7,654,798 and other patents pending.

2011 Delta T Corporation dba the Big Ass Fan Company. All rights reserved.

WWW.BIGASSFANS.COM | (877) BIG FANS

The Problem: Gas bills were going through the roof at Federated Co-ops 300,000 sq ft

distribution center in Saskatoon, Canada.

The Solution: Five PowerfoilX Big Ass Fans were installed to put the heat where the people

are on the floor reducing gas bills by $19,800 in one winter alone.

Want to know your payback number? Call now to

discuss your savings with an applications engineer!

TWO YEAR PAYBACK TWO YEAR PAYBACK

WE EXPERIENCED A SIGNIFICANT DECREASE IN

NATURAL GAS CONSUMPTION. BIG ASS FANS

IMMEDIATELY PROVIDED A COMFORTABLE WORKING

ENVIRONMENT WHILE REDUCING OUR COSTS.

Trevor Carlson

Environmental and Technical Services Manager

Federated Co-operative Ltd.

The patent-pending SmartSense365 fan

controller is an automated system with three

user modes: winter, summer and manual. Its

engineered to modulate fan speed according

to ceiling- and oor-level temperature readings,

maximizing year-round energy savings and

comfort with just the push of a button.

FROM WINTER OPERATION!

PS1203_FPA.indd 3 2/29/12 11:15 AM

Eric Rieger, President of WEBIT Services, had a major server

room emergency after three off-the-shelf A/C units quit. Now

he has a MovinCool Offce Pro 12. And greater peace of mind.

800-264-9573 | MovinCool.com

Whatever your

heat problem is...

Weve got you covered.

For computer servers to operate properly, they've got to be kept

cool. Which was Eric Rieger's intention when he purchased three

retail A/C units from a local big box store. Rieger, President of

WEBT Services, a managed technology services provider in the

Chicago area, thought he had found an ideal solution. But all

three subsequently failed. The last one on Christmas Day. After

quickly contacting his local distributor, Rieger chose a MovinCool

Offce Pro 12. ts performance and reliability are impressive, he

reports. And the peace of mind it delivers is priceless.

The self-contained MovinCool Offce Pro 12 pumps out 12,000

Btu/hr, works on standard 115v power and requires no costly

installation. Just roll it in. Plug it in. Turn it on. And its programmable

digital controller easily integrates into offce automation systems.

even recommend MovinCool to clients, concludes Rieger.

From mission critical cooling applications to computers and

manufacturing processes and people, MovinCool is the solution.

2012 DENSO Sales California, nc. MovinCool, SpotCool and Offce Pro are registered trademarks of DENSO Corporation. QR Code is a registered trademark of DENSO Wave.

ts performance and

reliability are impressive,

and the peace of mind it

delivers is priceless.

To read more about Erics application

story, visit: MovinCool.com/Webit

Scan to see the top 50 reasons

why MovinCool products are the

highest quality in the industry.

MovinCool.com/50Reasons

PS1203_FPA.indd 4 2/29/12 11:15 AM

WWW.PLANTSERVICES.COM MARCH 2012 5

22 / COVER STORY

Wrench Time by Design

Plant upgrades are

opportunities to bring

engineering and maintenance

departments together

30 / COMPRESSED AIR SYSTEMS

Central or Departmental

Air System?

Size and congure air piping

for the right t

37 / ASSET MANAGEMENT

SOFTWARE

Too Much Information

Part II

Work breakdown structure in

CMMS can streamline project

cost tracking

41 / MOTORS AND DRIVES

More Torque, Less Money

Fewer components give worm-

gear reducers a single-stage

advantage

44 / PRODUCT ROUNDUP

Thermal Technologies

Resources support HVAC and

combustion processes

FEATURES

SPECIALISTS

COLUMNS AND DEPARTMENTS

9 / MR. SUSTAINABILITY

Stale Fixed Costs

Can Spoil Prots

How long ago were energy

costs baked into your

overhead?

15 / HUMAN CAPITAL

Step Up to The Plate

Rethink reliability in terms

of your equipments on-base

percentage

17 / ASSET MANAGER

Conguration Without

Customization

Modify software with no

expense or risk

21 / TECHNOLOGY TOOLBOX

Well-Oiled Testing

and Training

Formulations are just part of

lubrication improvements

50 / ENERGY EXPERT

Wage War on

Energy Impact

The U.S. Army recognizes the

value of net-zero waste, water,

and emissions

7 / FROM THE EDITOR

Call Me Rockheaded

Should I be worried that the

Cloud can read my mind?

11 / WHAT WORKS

00

2

cleaning system

reduces environmental

impact and reject rates

48 / CLASSIFIEDS / AD INDEX

TABLE OF CONTENTS

MAR0H 20T2 / \0L. 32, N0. 3

PLANT SER\I0ES (ISSN 0T99-80T3) s pubshed monLhy by PuLman Meda, Inc., 555 wesL Perce Road,

SuLe 30T, ILasca, IL 60T43. Phone (630) 467-T300, Fax (847) 29T-48T6. Perodcas PosLage pad aL ILasca,

IL and addLona mang offces. 0anada PosL InLernaLona PubcaLons Ma ProducL Saes AgreemenL No.

4002866T. 0anadan Ma DsLrbuLor InformaLon. FronLer/BwI,P0 Box T05T, ForL Ere, 0nLaro, 0anada, L2A

5N8. PrnLed n U.S.A. P0STMASTER. Send address changes Lo PLANT SER\I0ES, PuLman Meda, Inc., P0

Box 3435, NorLhbrook, IL 60065-3435. SUBS0RIPTI0NS. 0uafed reader subscrpLons are accepLed from

PLANT SER\I0ES managers, supervsors and engneers n manufacLurng panLs n Lhe U.S. and 0anada. To

apply for qualied-reader subscriptions, please go to www.plantservices.com. To non-qualied subscribers in

Lhe U.S., subscrpLons are $96 per year. Snge copes are $T5. SubscrpLon Lo 0anada and oLher nLernaLona

are accepLed aL $200 (Arma ony) 20T2 by PuLman Meda, Inc. A rghLs reserved. The conLenLs of Lhs

publication may not be reproduced in whole or in part without consent of the copyright owner. In an effort to

more closely align with our business partners in a manner that provides the most value to our readers, content

pubshed n PLANT SER\I0ES magazne appears on Lhe pubc doman of PLANT SER\I0ES` websLe, and may

aso appear on websLes LhaL appy Lo our growng markeLpace. PuLman Meda, Inc. aso pubshes 0HEMI0AL

PR00ESSIN0, 00NTR0L, 00NTR0L DESI0N, F00D PR00ESSIN0, INDUSTRIAL NETw0RKIN0, THE

J0URNAL, PHARMA0EUTI0AL MANUFA0TURIN0 and wELLNESS F00DS. PLANT SER\I0ES assumes no

responsibility for validity of claims in items published.

Economy in Conict: Sustainability Vs. Consumerism

Is the economy suffering from the effects of a contradiction?

http://community.plantservices.com/content/economy-conict-

sustainability-vs-consumerism

Supplies at Work: Automating a Lead and Zinc Processing

Plant and More

In Lhs nsLamenL. Emerson Lo auLomaLe ead and znc panL,

Honeywell to deliver control and safety system for Australia

Pacfc LN0 Pro|ecL, and ABB awarded mne hosL order.

http://community.plantservices.com/content/supplies-work-auto-

mating-lead-and-zinc-processing-plant-and-more

You Know Dust Collectors, but Do You Know TCO?

These three steps will help you calculate total cost of ownership.

http://www.plantservices.com/wp_downloads/Camll-Farr-dust-

collector-lter.html

Plant Maintenance and Reliability Strategies Webinar

Join Plant Services editors and industry experts as we engage

in lively discussions about hot topics challenging todays

manufacturing plant.

http://webcast.streamlogics.com/audience/index.

asp?eventid=53496950

PS1203_XX_TOC.indd 5 2/29/12 11:19 AM

Put alidonenergy waste

Copyright 2011 Atlas Copco Compressors LLC. All rights reserved.

Hi, I'm Bob, Senior Marketing Support Specialist at Atlas Copco Compressors. For the last 38 years,

I've been part of the team taking care of our valued customers in the United States. Today, let me tell

you how Variable Speed Drive technology represents a great value proposition for your production.

All across the globe, customers are compressing air that just goes to waste. Energy can represent

over 80% of a compressors lifecycle cost and generating compressed air can account for more than

40% of a plants total electricity bill. Most production environments have a fluctuating air demand

depending on the time of day, week or even month. So put a lid on those energy costs with Atlas

Copcos VSD technology that mirrors air usage, automatically adjusting the motor speed depending

on the demand, making major energy costs savings a reality while helping to protect the environment

for future generations.

Our mission is to continue to bring sustainable productivity through safer, cleaner, more energy-

efficient, and cost-effective compressed air technology. Simply log onto www.atlascopco.us/bobusa

or call 866-688-9611 to learn more about us, our products, and how we have earned and will continue

to earn our reputation.

PS1203_FPA.indd 6 2/29/12 11:23 AM

FROM THE EDITOR

MIKE BACIDORE, EDITOR IN CHIEF

WWW.PLANTSERVICES.COM MARCH 2012 7

CALL ME ROCKHEADED

Should I be worried that the Cloud can read my mind?

As we leave February in the rearview

mirror and speed headlong into March,

lets check the GPS, or, better yet, ask Siri

where were headed. Siri is an application

that works on Apples iOS. But it is so

much more than just another app.

Siri is the automated intelligent per-

sonal assistant whose help is there for

the asking. It understands your natural

speech and will even ask you for more

information, if necessary. Youve seen

and heard the ads on TV From now

on, Ill call you Rock God, OK?

When you receive information from

Siri, you also share information with Siri,

just like you would a real personal assis-

tant. Siri knows all. And, because Siri ex-

ists in the Cloud, it grows smarter by the

second, pooling and analyzing data from

all users and giving it an almost Borg-

like collective intelligence. Resistance is

futile. You will be assimilated.

Te information superhighway is

paved with technology and driven by

data, but ideas on where were going are

far from road-tested. My favorite place

to kick the tires on informed specula-

tion and bankable prediction is at the

ARC World Industry Forum. Almost

700 individuals from 21 countries at-

tended. Andy Chatha, president and

CEO of ARC Advisory Group (www.

arcweb.com), began the conference with

his annual assessment of whats impor-

tant. Tis year, he identifed the top four

transformational technologies social

media, analytics, the mobile Internet,

and cloud architecture.

Tese are no longer consumer

technologies, he explained. Tey have

matured to the point where you can use

them across the enterprise.

Social media means being always con-

nected with faster response and immedi-

ate access to experts. Analytics are now

much easier to use. Tey can now run in

seconds, instead of days. And the strug-

gle or challenge with the mobile Internet

is in managing all of the devices. Tere

are now more mobile devices than there

are people on this planet, said Chatha.

His cloud architecture is a bit less

ambitious than that of the Borg, but for

good reason. Industrial manufacturers

are interested in production ef cien-

cies. Te architecture would include, for

example, an E&D applications platform

and an operations applications platform

within an enterprise applications plat-

form, explained Chatha.

John Berra, former chairman of

Emerson Process Management (www.

emersonprocess.com), shared a real-

world application of the concept, when

he explained how one company reduced

its total maintenance costs by 30% from

using the predictive intelligence it had

collected from 27 plants in its own pri-

vate cloud.

Road-tested? Yes. Driven by data? Ab-

solutely. Transformational? You betcha.

Te path to manufacturing proftabil-

ity is a winding road that is best seen and

understood from the birds-eye view. Te

more information were able to analyze,

the smarter our maintenance strategies

become. Surrender your data.

Resistance is futile.

THERE ARE NOW MORE

MOBILE DEVICES THAN

PEOPLE ON THIS PLANET.

PUTMAN MEDIA, INC.

555 W. Pierce Rd., Suite 301,

Itasca, IL 60143

(630) 467-1300 Fax: (630) 467-1120

MIKE BRENNER

Group Publisher

mbrenner@putman.net

EDITORIAL STAFF

MIKE BACIDORE

Editor in Chief

mbacidore@putman.net

RUSSELL L. KRATOWICZ, P.E., CMRP

Executive Editor

russk@putman.net

ALEXIS GAJEWSKI

Associate Editor, Digital Media

agajewski@putman.net

STEPHEN C. HERNER

V.P., Creative Services

sherner@putman.net

ANGELA LABATE

Associate Art Director

alabate@putman.net

DAVID BERGER, P.ENG.

Contributing Editor

PETER GARFORTH

Contributing Editor

SHEILA KENNEDY

Contributing Editor

TOM MORIARTY, P.E., CMRP

Contributing Editor

PUBLICATION SERVICES

CARMELA KAPPEL

Assistant to the Publisher

ckappel@putman.net

JERRY CLARK

V.P., Circulation

jclark@putman.net

JACK JONES

Circulation Director

jjones@putman.net

RITA FITZGERALD

Production Manager

rtzgerald@putman.net

JILL KALETHA

Reprints Marketing Manager

Foster Reprints

(866) 879-9144 ext.168

jillk@fosterprinting.com

EXECUTIVE STAFF

JOHN M. CAPPELLETTI

President/CEO

JULIE CAPPELLETTI-LANGE

Vice President

KEITH LARSON

V.P., Content

ROSE SOUTHARD

V.P., Technology

Mike Bacidore, Editor in Chief

mbacidore@putman.net, (630) 467-1300 x444

PS1203_XX_EV.indd 7 2/29/12 11:25 AM

PS1203_FPA.indd 8 2/29/12 11:27 AM

STALE FIXED COSTS CAN SPOIL PROFITS

How long ago were energy costs baked into your overhead?

I had lunch again the other day with a childhood friend,

a tool and diemaker whos worked his way up and is now

quoting jobs for his multinational metalworking company.

He said the poor economy has driven smaller, specialized

mom-and-pop shops out of business, and hes bidding on

quite a few exotic new jobs. Hes seeing more requests for

quotes on familiar kinds of work as demand is picking up.

With plants here and in Mexico and China, he has options

for how and where to plan the work. Along with stellar qual-

ity and service, he expects to have the lowest cost, but hes

surprised by reality. Some competitors are beating us on

price, he told me. I dont know how they can do it.

We talked about how and why some companies might

take a job at a loss. And we acknowledged that any company

can have a costing structure that misleads them about the

margin on a specifc part, causing them to think theyre

making money on it when theyre not. Ten, I asked him

how well his company is paying attention to overhead items

such as insurance and energy. He knew theyd done some

work on the air compressors, but overhead isnt really in his

area of responsibility.

His facility might have a better handle on its fxed costs,

but its still not uncommon for even successful perhaps

especially the most successful facilities to be complacent

about overhead. If those successful companies have been

in business a long time, theyre likely to have energy costs

baked into that overhead, where theyre easy to ignore.

Some plants ignore energy costs until its too late. As Bill

Holmes, owner of Holmes Energy (www.holmesenergy.com)

observed, its a bad idea to wait until your plant is on the

chopping block before you go afer energy opportunities.

For example, participating in demand response gives

electric power users an opportunity to save cash with little

or no investment. But only about 20% of the market for load

shedding signed up.

Time-of-use rates are cited as an advantage of smart grid,

so I asked Gregg Dixon, senior vice president, EnerNOC

(www.enernoc.com), if broader acceptance of automated load

shedding is waiting for a consensus on smart grid standards.

Not at all, Dixon told me. Today, we can put in a site

server an industrial PC with UPS and a wireless broad-

band modem and connect it to the building management

system or plant SCADA with a dry contact or Ethernet, said

Dixon. Te site server is connected to our energy network

operations center (EnerNOC), and the sofware automati-

cally curtails the load, for example, by raising the HVAC set-

point, turning of lights, or shutting of non-critical loads.

Te operations center monitors the curtailment to see that

it performs according to the commitment and then bills the

power company. Its not rocket science, said Dixon.

Tat sounds OK for a college campus or a shopping mall,

but what about industrial facilities, I asked, where the main

loads are critical for production? EnerNOC has a number of

clients, including a steel mill that can turn of arc furnaces.

If you schedule it properly, its just like scheduling produc-

tion, with two-hour notifcation or whatever is needed to not

compromise safety or productivity, said Dixon.

EnerNOC employs process experts, including refnery and

chemical engineers, wastewater, and refrigeration techni-

cians. We know their operational sensitivities, said Dixon.

We know what to look for. We sit down with plant person-

nel and talk about the options, and we almost always fnd

loads that can be curtailed.

Along the way, they ofen fnd energy efciency and peak

load trimming opportunities plants can exploit 24/7, not just

during a demand response event. We call demand response

the skeleton key to energy efciency, said Dixon.

EnerNOCs consulting and system installation are done

at no charge to the industrial facility.

Dixon said that, so far, demand response penetration is

only about 20% of the opportunity. We estimate theres

about 80,000 MW available, and about 16,000 MW has been

done, he said.

Say 20% of companies are spending less for electricity.

Tat means, all else being equal, one plant in fve can quote

a lower price and still get their margin on a new job.

Email Paul Studebaker, editor in chief of Sustainable Plant

(www.sustainable plant.com), at pstudebaker@putman.net.

WWW.PLANTSERVICES.COM MARCH 2012 9

PAUL STUDEBAKER, CMRP

MR. SUSTAINABILITY

ITS STILL NOT UNCOMMON FOR EVEN

SUCCESSFUL PERHAPS ESPECIALLY

THE MOST SUCCESSFUL FACILITIES

TO BE COMPLACENT ABOUT OVERHEAD.

PS1203_09_MRSUSTAIN.indd 9 2/29/12 11:32 AM

COMPRESSORS

Beware of small

expenses. A small leak

will sink a large ship.

Your compressed air system may cost you more

than you think.

It takes more than good equipment to make an efcient air

system. Thats why our air system specialists are here for you.

We look beyond the basics to nd savings in the whole system

and determine what you need to run at peak performance.

Kaesers compressed air energy audits stand out in the

industry for completeness and accuracy. Our Air Demand

Analysis (ADA) will identify and help you eliminate

inefciencies related to controls, leaks, articial demand,

inadequate piping, and storage as well as reduce waste

and scrap caused by inconsistent pressure in production

equipment. It will also help you cut maintenance costs by

optimizing run time and reducing excess cycling. ADA docu-

mentation will even help you apply for electric utility rebates.

Add in superior products plus our reputation for strong

customer service, and its no wonder Kaeser delivers the best

value. Let us to put our expertise to work for you.

)LUQHTPU-YHURSPU

kaasar 6omprassors, Inr. B007777B78 kaasar.romlkk

Built for a lifetime is a trademark of Kaeser Compressors, Inc. 2011 Kaeser Compressors, Inc.

Only 59% of compressed air is

actually put to productive use.

Scan this code for more info.

k

a

e

s

e

r

.

c

o

m

PS1203_FPA.indd 10 2/29/12 11:33 AM

Less is more. Volkswagen Plastics Technology in Braun-

schweig, Germany, started using a single-layer painting

system for an interior component. Te process reduces the

consumption of resources and emissions. However, the

painting system demands an absolutely clean, residue-free

surface. Tis has been achieved with a dry CO

2

snow jet

cleaning technique designed to be gentle on materials.

CLEANLINESS

Every day, Plastics Technology processes approximately 45

tons of material to manufacture injection-molded parts.

About 450 interior components of diferent colors are

produced and installed into various passenger vehicles

around the world. Some of the injection-molded parts have

a high-gloss fnish and can be installed without needing to

be coated. One of the latest vehicle models is ftted with a

high-gloss panel made from acrylonitrile-butadiene-styrene,

polycarbonate (ABS-PC) blend, which is subsequently paint-

ed with a semi-transparent high-gloss metallic paint. Tis

paint is applied to the component as a single layer without

an undercoat, so the surface has to be fawless, explains

Uwe Strauss, painting systems/plastics technology planning

at the Braunschweig plant. Te tiniest dust particle or water

mark would cause rejects. Terefore, we needed a cleaning

solution that is efcient, is gentle on materials, and guaran-

tees consistent results.

CO

2

SNOW

Te classic alternative wet-chemical cleaning with

a powerwash system was rejected for reasons of cost-

efectiveness and sustainability. Due to its high space

requirements, it would have been impossible to install such

a cleaning system upstream of the paint shop. In tests with

conventional dry-ice cleaning systems, the coarse ice pellets

damaged the sensitive surface of components. Te CO

2

snow

jet process from Advanced Clean Production (ACP, www.

acp-micron.com) gave Volkswagen an alternative. We told

one of the companys employees about what we needed,

recalls Strauss. It wasnt long before we were sent a pro-

posal and tests confrmed that we could achieve optimum

cleaning results with the process. With the CO

2

snow jet

technique, liquid carbon dioxide is used instead of dry-ice

pellets. Carbon dioxide gas is a by-product from a variety

of manufacturing processes in the chemical industry; it is

environmentally neutral and gentle on resources.

RESIDUE-FREE

Te modularly constructed CO

2

snow jet system achieves

its cleaning power via the supersonic two-component ring

nozzle integrated into the compact cleaning head. Liquid

carbon dioxide is guided through the nozzle and expands

on exit to form a mixture of snow and gas. Oil-free com-

pressed air accelerates the non-toxic, non-combustible CO

2

snow crystals to supersonic speed. When the jet impacts

on a surface, the snow crystals liquefy and sublimate. Te

sublimation impulse causes any particulate contamination

present to detach and be carried away. In the liquid phase,

carbon dioxide acts as a solvent that removes organic con-

tamination. At the same time, the low degree of hardness of

the snow crystals ensures gentle and reproducible cleaning

results on the high-gloss surface. We carried out test series

with other components made of diferent materials, reports

WWW.PLANTSERVICES.COM MARCH 2012 11

WHAT WORKS

CARRIED-AWAY CONTAMINATION

CO

2

cleaning system reduces environmental impact and reject rates

CARBON DIOXIDE IS A BY-PRODUCT

FROM A VARIETY OF MANUFACTURING

PROCESSES IN THE CHEMICAL

INDUSTRY; IT IS ENVIRONMENTALLY

NEUTRAL AND GENTLE ON RESOURCES.

The CO

2

snow jet system has been integrated into a large paint

booth measuring 5.5 x 4 x 3 m together with a turning station.

(Source: Volkswagen Plastics Technology)

PS1203_11_12_WHATWORKS1.indd 11 2/29/12 11:55 AM

WHAT WORKS

Strauss. Tis proved that the CO

2

cleaning process can be

implemented for our entire range of workpieces.

PAINTING INTEGRATION

ACP designed a robotic cleaning system with a nozzle array

containing seven cleaning heads. Te component-specifc

programs fled in the robots controls ensure that each

workpiece is cleaned fully and automatically, according to

its geometry. Oil-free compressed air and liquid carbon

dioxide stored in tanks are fed to the array via a hose system.

Te robot is integrated into a booth measuring about 5.5

by 4 by 3 m. Te cleaning cell located at the rear wall has a

continuous extraction unit. Tis prevents cleaned parts from

becoming recontaminated by dirt as its removed. A turning

station, which can be switched on separately, is located in

the booth downstream of the cleaning process, allowing

suspension gear to be rotated by 180. ACP provided us

with ideal support both during the test phase and afer-

ward, when we started implementing the cleaning system,

enabling us to integrate it into the painting process within

the space of just three months, says Strauss.

SERIES OPERATION

Te CO

2

snow jet system has been running in three-shif

series operation at the Volkswagen plant since August

2010. Several thousand plastic parts are cleaned every day.

Te workpieces are suspended on special painting

racks at the injection-molding plant, explains Strauss. If

high-gloss parts are handled, workers wear gloves. Te

racks are mounted on trolleys, transported to the painting

line, and fed into the painting chain. Te frst station in the

line is the cleaning unit. To prevent dust from sediment-

ing on the workpieces afer cleaning, theyre fed through

two ionizing rods. Afer being transported along a short

stretch designed as a cleanroom, paint is then applied to

the components by two robots in the painting booth. On

leaving the evaporation zone, the parts are then dried at

around 80 C.

With the CO

2

snow jet system, weve not only found

a cost-efective and reliable cleaning solution, weve suc-

ceeded in reducing the workload on our staf, decreasing

environmental pollution, and also lowering our reject rate

by another 3%, summarizes Strauss.

OWN YOUR ENVIRONMENT.

HAZARDOUS LOCATION PANELBOARDS

TYPE 4X STAINLESS STEEL PANELBOARDS

216.267.9000

WWW.ADALET.COM

&/(9(/$1'2++2867217;

FACTORY SEALED / DIVISION 2

EXPLOSIONPROOF / DIVISION 1

TYPE 4X STAINLESS STEEL

PS1203_11_12_WHATWORKS1.indd 12 2/29/12 11:56 AM

GIVE

YOURSELF

THE

ADVANTAGE.

WIRING DEVICES

POWER DISTRIBUTION

PORTABLE LIGHTING

TOOL SUPPORT

REELS & GRIPS

ADVANTAGE: WOODHEAD.

T HE WOODHEAD ADV ANT AGE

You owe it to yourself. By choosing

Woodhead, youll be giving yourself the

advantage on each and every job. The

advantage that comes with using the

industrys premier electrical products.

Superior quality, selection, safety, reliability

and performanceeven in harsh-duty envi-

ronments. They all add up to the advantage

that only comes with Woodhead.

www. woodhead.com/ps

PS1203_FPA.indd 13 2/29/12 11:34 AM

PS1203_FPA.indd 14 2/29/12 11:35 AM

STEP UP TO THE PLATE

Rethink reliability in terms of your equipments on-base percentage

As I removed my laptop to get some work done on a

three-and-a-half-hour fight home the other night, the fight

attendant announced what the in-fight movie was going to

be. Im probably among the last people to have seen the movie,

Moneyball. It might be that Im too cheap to buy an $8.50

movie ticket, $5 bag of popcorn, and $4 Coke (Diet Coke, no

less). I wanted to see the movie because it involved baseball

and a view of things from a diferent perspective.

So, while the laptop remained on the tray table, it was

benched for the fight.

Te story was about Major League Baseballs Oakland Ath-

letics, a small-market team that couldnt compete economi-

cally with larger-market teams. Te As had good coaches

and developed some great players. However, they didnt have

the money to induce top talent to stay or to come over to the

team. Tis meant that they would forever be handicapped

in their quest of a World Series title. Tis isnt unlike many

industrial plants its hard to fnd good talent to replace the

aging workforce, and its even tougher to keep them as com-

petitors ofer a little more.

Tere were a number of interesting lessons from the story

of Billy Beane, the general manager, and his unassuming

sidekick a young, Yale-trained, economics major named

Peter Brand, who had no baseball experience, but could boil

baseball success down to one thing getting on base repeat-

edly. Veteran scouts looked for attributes they believed would

do two things draw in fans and give the team a reasonable

chance to win. Tey used an old formula that everyone else

used, but one with which the As couldnt compete.

Te two main characters, Beane and Brand, developed

a strategy that involved fnding players with high on-base

percentages who werent high-salary guys; it didnt matter

whether they were hits or walks. Te old guard Manager

Art Howe, the veteran players, and the scouts didnt like

the new strategy because it took them out of their comfort

zone. Te old guard knew better than some college kid, or

so they thought. Te strategy foundered as the manager

circumvented the plan, a key player had to learn a new posi-

tion, and an aging veteran player wasnt brought in to relieve

another player.

Te manager resisted the plan as Beane tried to reason

with him. Eventually, Beane took decisive and controversial

action trading two of the teams best players. Tis kept

Howe from reverting to the old management style. Beane

also showed confdence in the player who had to learn a

new position and stuck with him. Te aging veteran, David

Justice, had a key role to play, and Beane appealed to him to

be the veteran leader.

Beane faced decisions at a couple of key moments in the

movie, each of which had serious consequences for his ca-

reer. Because his vision and strategy were so unorthodox,

he most certainly would have been on the unemployment

line if it didnt work.

Manager Howe needed much more than an explanation

of Beanes vision and strategy. Pivotal actions taken clearly

could have led to Howes walking of the job.

It was a risk Beane took because the manager had to get

in line or be gone. Combined with trading two young, star

prospects in the middle of the season, Beanes actions were

akin to the old adage of landing the troops and burning the

boats there was no turning back. It was bold and made

people aware of his deep commitment to the strategy. Beane

also showed commitment by sticking with the player who

had to learn the new position acknowledging shortcom-

ings, but staying the course as the player learned new skills

to ft into the overall plan. In dealing with David Justice,

Beane showed respect for the experienced player but asked

him to step up and be a leader among his peers.

As with plant reliability, the practice of quickly fxing

equipment and rewarding that practice is an out-of-date

strategy. Getting on base, or avoiding outs in the frst place,

is like having reliable equipment. Te strategy in how to get

to the vision of high on-base percentages or high equipment

reliability needs to be enacted by people, through focused

and consistent leadership.

Beane was open to new thinking. But he also was ultimately

accountable for the results. Its why he made the big bucks.

Tom Moriarty, P.E., CMRP, is president of Alidade MER. Contact

him at tjmpe@alidade-mer.com and (321) 773-3356.

WWW.PLANTSERVICES.COM MARCH 2012 15

HUMAN CAPITAL

TOM MORIARTY, P.E., CMRP

AS WITH PLANT RELIABILITY,

THE PRACTICE OF QUICKLY FIXING

EQUIPMENT AND REWARDING THAT

PRACTICE IS AN OUT-OF-DATE STRATEGY.

PS1203_15_HUMANCAPITAL.indd 15 2/29/12 12:00 PM

EASE YOUR PAIN.

IS YOUR ERP

A PAIN IN

THE ASSET?

Most ERP software does a poor job at enterprise asset management (EAM) tasks like mainte-

nance and asset lifecycle management. Only IFS Applications offers class-leading EAM as part

of an agile, fully integrated enterprise resources planning (ERP) suite. So you can implement

EAM with components of ERP, an entire ERP package or even integrate EAM seamlessly with

your legacy ERP system. So your business can be as agile as your thinking.

www.youragileassets.com

IFSFOR AGILE BUSINESS

PS1203_FPA.indd 16 2/29/12 11:38 AM

CONFIGURATION WITHOUT CUSTOMIZATION

Modify software with no expense or risk

There are many factors to consider when selecting a

CMMS, including an ability to meet your technical specifca-

tions, vendor track record, and pricing. In this dynamic world,

plants need sofware that can mold to the constant changes

customers, employees, management, and regulatory bodies

precipitate. CMMS vendors and their solutions must be fex-

ible, agile, and confgurable to meet the changing demands.

In earlier years, sofware packages were customized to

close the gap between user requirements and the applications

capability. Typical areas of customization were industry- or

company-specifc anomalies, interfaces to other applications,

and more complex requirements for data entry, reporting,

and business logic (error-checking algorithms and workfow).

Custom changes required considerable time and money to

implement, and there was no guarantee that future releases

of the base package would be compatible with the customized

source code. Moreover, as business grows and needs evolve,

the custom code no longer fts with current business realities.

Modern CMMS sofware can be confgured to meet the

needs of today and tomorrow without the expense and risk

associated with customization. Confguration doesnt require

changes to the source code. Usually, all thats required to con-

fgure the sofware is a one-time setup, for example, ticking a

box on a master fle, selecting a menu option, or dragging and

dropping an object on a particular screen. Tis typically can

be done by a system administrator or super-user, as opposed to

the vendor. Lets highlight some advanced features and func-

tions that help you stay relevant as your business needs change.

USER CONFIGURABILITY

One of the most visible diferences between modern CMMS

packages and older, less fexible applications is the ability to

tailor the sofware to a given user or user group, such as plan-

ners. Examples of screen confguration options are:

- the language used for screens, reports, and forms

- security level access that includes which features, func-

tions, and data felds are visible to the user

- menu items, tabs, and icons that the user can see

- feld labels, positions, and the space they occupy on screen.

Sophisticated CMMS packages also will allow the addition

of user-defnable felds on a given menu, tab, or screen. In

some cases, this includes whatever algorithm or Boolean logic

that might be necessary to generate a value, such as generating

a default value.

NAVIGATION AIDS

Another popular feature that ensures greater agility is the

ability for users to navigate throughout the system to get at

information quickly and easily. For example, the better CMMS

packages not only have drill-down capability to reveal greater

and greater levels of detail, but they allow users to drill around

to fnd related information. For example, when viewing a pur-

chase order line item on screen, a user might wish to jump to

the relevant items master information, then do a where used

query, and then drill into one of the assets that use the item.

A powerful navigation aid is the MS Explorer-style lookup

capability for equipment, parts, projects, and many other data

hierarchies. Te more sophisticated CMMS packages allow

users to drag and drop elements of the hierarchy, for example,

moving a serialized component from one asset to another,

including carrying its full history. Other high-end features are:

- a favorites" menu, where users can store frequently used

links to screens within the CMMS

- a navigation bar showing where you are in the system

- a history" tab to show where you have been within

a user-defned period of time

- a search engine to locate a given screen or feld.

WORKFLOW ENGINE

A workfow engine is the backbone on which a CMMS is built,

carrying the business rules and sequencing of virtually every

process the sofware governs. For example, companies need

to be able to adjust approval limits and signatories, as well as

conditions (budget remaining) or contingencies (approver on

vacation). Te workfow engine can launch notifcations or

alarms when certain conditions are met, such as when a criti-

cal PM is signifcantly past due or when a budget is exceeded.

Some CMMS vendors have a graphical workfow engine,

where activities, arrows, and decision boxes within the fow

can be dragged and dropped to allow users to build or adjust

the workfow logic easily. For some packages, the procedural

help (how to initiate a work order) can be linked to the graphi-

cal workfow. Users can toggle back and forth between the

WWW.PLANTSERVICES.COM MARCH 2012 17

YOU NEED THE FLEXIBILITY TO ADD

FIELDS THAT ARE RELEVANT TO A

GIVEN ASSET CLASS OR TYPE.

ASSET MANAGER

DAVID BERGER, P.ENG.

PS1203_17_ASSET.indd 17 2/29/12 12:07 PM

ASSET MANAGER

process fow and the appropriate help screens.

USER-DEFINABLE SPECIFICATION TEMPLATE

Diferent businesses describe their assets diferently. Computer

screens are sized in inches by referring to the diagonal distance

across the screen. A motor has horsepower, voltage, speed, and

torque. You need the fexibility to add felds that are relevant

to an asset class or type such as computer monitors, motors,

doors, and sewers. Tis is accomplished with user-defnable

templates for entering and reporting on tombstone data.

FORMS AND REPORT GENERATORS

Tere are three major activities for which your CMMS

provides tremendous support data entry, data analysis,

and reporting. Te forms generator gives users the ability to

confgure data input forms (work request, purchase request,

timesheet) to maximize efciency and reduce the chance of

error. Modern features include:

- spreadsheet mode, not a tabular mode, for data entry

- ability to hide, add, and format felds and labels

- ability to associate Boolean logic (<, >) and formulae to a

given data entry feld for the purpose of error checking

- copy feature for entering repetitive data

- extensive default values based on optional algorithms

(most frequent, last used, fxed value, formula based).

Data reporting must be easily modifed, including:

- ability to hide, add, and format felds and labels

- ability to apply simple math, Boolean logic, or more ad-

vanced math to any feld or grouping of data

- sort and flter capability for reports, listings, and queries,

including use of Boolean logic, simple math, and formulae

- drill-down capability on any feld

- extensive graphics capability for displaying data or a subset

thereof, including a user-defnable dashboard.

DOCUMENT MANAGEMENT

Another feature that brings tremendous fexibility is sophis-

ticated document management capability. Relevant external

documents such as equipment manuals, drawings, safety

sheets, and contracts abound. Documents arrive in multiple

formats, from handwritten notes scribbled on a scrap of paper

to 3-D CAD drawings or training videos. It should be easy to

attach these documents to the CMMS master fle (drawings on

the asset registry) or to objects such as work orders or purchase

orders. More sophisticated features to look for are version

control (management of change), application launch option,

and the ability to edit, index, and redline.

Email Contributing Editor David Berger, P.Eng., partner, Western

Management Consultants, at david@wmc.on.ca.

Sustainable industrial production means

long-term, holistic thinking. Key examples

include minimal unplanned downtime, less

friction and reduced lubricant consumption.

The effect: lower energy consumption,

less CO

2

emission, longer maintenance

intervals and longer component lifetime.

To keep up with your sustainability

goals, we are continually improving

our environmentally-friendly lubricants.

Klber Lubrication: Innovation for

ecologically and economically

efcient solutions.

Klber Lubrication North America L.P.

info@us.kluber.com

www.klubersolutions.com/sustainability1

your global specialist

Specialty lubricants

for sustainable

efciency

PS1203_17_ASSET.indd 18 3/1/12 11:42 AM

PS1203_FPA.indd 19 2/29/12 11:38 AM

Buy it your way from

Allied Electronics.

1.800.433.5700

Allied Electronics, Inc 2012. Allied Electronics and the Allied Electronics logo are trademarks of Allied Electronics, Inc. An Electrocomponents Company.

THINK ALLIED

SM

The Allied Catalog features

thousands of products from

300+ world-class suppliers.

Choose from more than

two million product solutions

at alliedelec.com.

We are ready to assist you.

Call your local sales rep. at

1.800.433.5700.

Online Local Service Catalog

We Do Business Your Way

PS1203_FPA.indd 20 2/29/12 12:26 PM

TECHNOLOGY TOOLBOX

SHEILA KENNEDY

WELL-OILED TESTING AND TRAINING

Formulations are just part of lubrication improvements

Choosing the right blend of lubrication training, testing,

business processes, and formulations can help keep your

machines and components healthy and running smoothly.

Te training and development of lubrication skills is the

hottest thing out there right now, and I believe it will be with

us for a long time in the future, says Bill Lyons, mainte-

nance optimization manager at Holcim U.S., a cement and

component manufacturer in Waltham, Massachusetts.

During the past few years, many lubrication improvement

projects were launched in most of Holcims 12 manufactur-

ing plants, from storage and handling to regreasing bearings

using ultrasonic measuring tools, explains Lyons. I see our

plants moving further with in-house oil analysis, helping to

move us to a more proactive approach to better understand-

ing the lubrication condition, he says.

Lyons believes that increasing skill levels and using new

technology has a great efect on costs. I looked at our bear-

ing spend fve years ago, and the amount seemed very high

to me, he says. Recently, I ran the same report, and I now

see our bearing spend has dropped more than 50% since the

previous report.

Organizations such as the International Council for Ma-

chinery Lubrication ofer certifcation programs for lubrica-

tion technicians and oil analysts.

Lab testing approaches: Independent oil analysis labs must

adapt to evolving customer requirements and technology

continually. Insight Services keeps its technicians abreast of

changing base stocks and additive packages, and its improv-

ing its testing and reporting capabilities.

Were currently working on two changes to oil analysis

testing in our laboratory varnish analysis and flter debris

analysis, says David Kirkwood, business development man-

ager for Insight Services. Varnish analysis improvements

include changes that will allow us to categorize the type of

varnish, the make-up of the sof contaminant, and ultimate-

ly pinpoint the origin of the problem. Also, Insight will be

able to use flter debris analysis to capture the organics that

make up the varnish for closer examination.

Reliability-focused practices: Lubrication process im-

provement providers use existing products to get better

results. Manufacturers are becoming wise to the value that

machine lube processes can deliver, says Mike Johnson,

principal consultant for Advanced Machine Reliability Re-

sources. Johnson developed an analysis tool called

LubeCoach, a grease interval and volume calculator. It aids

in selecting or correcting lube types, application volume,

and frequency, and in solving process problems such as

overfeed and underfeed. LubeCoach, available in multiple

bearing application formats, is presently spreadsheet-based

but will soon be ofered in a Web-based format.

Advanced ester chemistry: Polyol ester (POE) fuid de-

velopments resulted in new industrial lubricant products.

POEs are fantastic long-range solutions for air compressor

lubrication. With fuid analysis, a customer can realize more

than 8,000 hours of fuid life with POEs in air compressors,

says Jim Girard, vice president and chief marketing ofcer

at Lubriplate Lubricants. Because fuid life is extended, less

used oil requires disposal. POE-based fuids also minimize

harmful air compressor deposits.

Targeted applications: Lubricant formulations ofen are

designed to meet specifc industrial conditions. Summits

SumTech FGCO calcium oleate grease was designed specif-

cally for the food service, beverage, and food processing in-

dustries. Among its properties are excellent water washout,

higher weld load, and lower wear scar.

Te Hydroguard hybrid breather from Des-Case increases

lubricant reliability in low-fow applications by preventing

contamination. Suitable for multiple industries, the product

uses check valves and an expansion chamber to prevent

moisture ingress. It breathes when pressured, and the air

is cleaned and dried before it enters the system.

Email Contributing Editor Sheila Kennedy, managing director

of Additive Communications, at sheila@addcomm.com.

WWW.PLANTSERVICES.COM MARCH 2012 21

www.holcim.us

www.lubecouncil.org

www.testoil.com

www.precisionlubrication.com

www.lubriplate.com

www.klsummit.com

www.descase.com

REFERENCE WEB SITES:

INDEPENDENT OIL ANALYSIS LABS MUST

ADAPT TO EVOLVING CUSTOMER

REQUIREMENTS AND TECHNOLOGY

CONTINUALLY.

PS1203_XX_TECHTOOL.indd 21 2/29/12 4:19 PM

Plant upgrades and overhauls mean involving the

engineering department and having the foresight to not only

change what is lacking, but plan for future needs, as well.

Tree plants took advantage of facility modifcations and

parlayed them into better maintenance and reliability.

In the frst example, the addition of secondary wastewater

treatment necessitated an upgrade in emergency standby

power, which meant installing a new system that matched

the existing one. Te improvement allowed the treatment

plant to meet EPA standards and gave it the backup power it

required in the event of an outage.

Equipment stress protection made a diference in the

second example, in which a frearm manufacturer increased

reliability and productivity by implementing functional

interface stress hardening. Engineering, operations, and

maintenance personnels ability to work and plan together

allowed the facility to mitigate equipment downtime.

Finally, when a food production plant had expanded to

the point where it was unequipped to handle the breadth

and volume of its products, a complete facility overhaul al-

lowed for more ef cient operations and the plant moved to a

predictive maintenance strategy.

STAND BY YOUR POWER

Built in the late 1990s, the South Bay International Waste-

water Treatment plant is a joint efort between Mexico and

the United States to treat sewage from Tijuana, Mexico, and

eliminate environmental concerns in the Tijuana River Val-

ley just south of San Diego. Te plant is located on a 75-acre

site in the United States. Te International Border and Water

Commission (IBWC, www.ibwc.gov), the plants operator,

needed to add secondary treatment to improve the quality of

the discharge water because it was found not to meet current

environmental standards set by the EPA.

Te South Bay wastewater treatment plant has a capac-

ity of 25 million gal/day. Its original design consisted of

advanced primary treatment, which involved the addition of

chemicals to the infuent to promote removal of solids and

dissolved organic compounds through settling. Te treated

water was then discharged via a 4.5-mile pipe extended out

into the Pacifc Ocean near the Mexico-California border.

Secondary treatment involves bacteria-activated sludge

combined with aeration and additional settling. Encouraged

by the large supply of oxygen bubbled through the sewage,

aerobic bacteria consume the remaining organic compounds

in the ef uent. Te sludge is then removed by additional

settling and then recycled to reuse the bacteria. Afer

secondary treatment, the water quality is much improved

and meets EPA standards. Adding secondary treatment

has greatly increased the plants electrical load. Te large

aeration pumps and activated sludge system necessitated the

addition of another 2,000 kW of emergency standby power,

so the plant turned to MTU Onsite Energy (www.mtuonsi-

teenergy.com).

22 MARCH 2012 WWW.PLANTSERVICES.COM

ENGINEERING / PLANT MAINTENANCE

By Mike Bacidore, Editor in Chief

Wrench

Time

by

Design

Plant upgrades are opportunities to

bring engineering and maintenance

departments together

PS1203_XX_XX_COVERSTORY.indd 22 2/29/12 5:05 PM

WWW.PLANTSERVICES.COM MARCH 2012 23

Te plant hasnt been expanded in terms of overall ca-

pacity, says Steve Smullen, area operations manager, IBWC.

It was originally designed for both advanced primary treat-

ment and secondary treatment, but the secondary facilities

were not immediately funded. Recently, we got the funding,

and now weve added a biological system, aeration and set-

tling facilities to meet our EPA permit requirements. As a

consequence of completing the secondary treatment, we also

added quite a bit of additional electrical load to the plant to

operate three 700 hp aeration blowers and related equip-

ment. In case of a utility outage, we needed the additional

standby generation to handle those larger loads.

Te plant wanted the new power system installation to

physically match that of an existing 2,000 kW generator that

was installed during the original construction in the late

90s, says Tim Oergel of W.W. Williams, the local distributor

for MTU Onsite Energy. Getting the two generators to ft

into identical packages was a challenge, he says.

One design issue was that the MTU Onsite Energy unit

was 16 years newer than its companion, which was from a

diferent manufacturer. Te new unit operates at 12.47 kV

housed in a specially designed ISO container. Tis newer

generator set is EPA-certifed to meet Tier 2 emissions regu-

lations, whereas the existing generator set was manufactured

at the beginning of Tier requirements and was compliant

with, but not EPA certifed to, Tier 1 standards.

In addition to not having modern emissions control

hardware, the existing generator drive engine set did not

have an electronic governor or other electronic controls to

help it synchronize with the new generator drive engine. To

get the two generators to communicate with each other, the

existing generators governor was replaced, along with many

other controls. Te overhaul also included new paralleling

switchgear, automatic transfer switches, and various com-

munications interfaces.

While the MTU Onsite

Energy EPA-certifed Tier 2

generator set is more fuel ef-

fcient and has signifcantly

cleaner exhaust, it also has

higher heat rejection that

requires a specialized radiator, says Oergel. Because we

had to match the size of the original 40-f ISO container, we

had to be creative in designing a radiator with higher heat

rejection to ft in the same-sized package as the original

generator set. Te solution was a specially designed radiator

from R.F. Partridge & IEA Radiator that was direct-driven

through a planetary gear of the engines crank shaf. With

a larger surface area and greater airfow, the special radia-

tor was able to ft inside the container and still provide the

necessary cooling.

Te physical installation of the containers is unique, as

well. Each containerized generator set is mounted on a con-

crete pad outside of the plants main building. Because the

plant is located in earthquake country, both generator-set

containers are supported by a seismically reinforced mezza-

nine structure consisting of I-beams connected in crisscross

patterns (Figure 1). Tese structures support the weight of

the containers and are bolted to the concrete pad to prevent

damage to the generators in the event of an earthquake.

Installation, fnal commissioning, and load-bank testing

were completed in the summer of 2010 to make sure that

both units could carry the full plants load while operating

in parallel. Getting the diferent units to operate together

was a challenge, says Oergel. Tere were many sequence-

of-operation changes that were needed to make sure both

units functioned properly and could carry the load.

TEACH A MAINTENANCE ENGINEER TO FISH

Sturm Ruger (www.ruger.com) manufactures American-

made frearms for the commercial sporting market, ofering

more than 400 variations on more than 70 products across

25 product lines. Its main rife and pistol components

manufacturing plant in Newport, New Hampshire, is more

ef cient and proftable today than it was in 2007 because of

a proactive maintenance department and a vice president of

operations who understands the value and the necessity of

reliable equipment.

In 2007, with unscheduled downtime on the automa-

tion and manufacturing controls and CNC machine tools,

David Ford, the hydraulic maintenance specialist, requested

a portable oil fltration system to cut down on hydraulic oil

contamination, save some money on oil costs, and, hope-

fully, boost machine uptime.

Tom Sullivan, vice president of operations at the Newport

plant, thought it was a good idea, but not all oil flter systems

are equal. He asked Howard Cooper at Amemco (www.

amemco.net) to prepare a plant-wide equipment survey and

conduct an orientation semi-

nar on functional interface

stress hardening (FISHing).

Tese meetings brought the

maintenance and manu-

facturing engineers, plant

management, and maintenance specialists together to hear

Cooper explain how to replace preventive maintenance with

condition-based maintenance (CBM) and how to maximize

uptime and equipment reliability by going FISHing.

Coopers facility and equipment survey revealed one

root-cause stress to be frequent power surges and voltage

transients that were afecting CNCs, PLCs, computer and

electronic controls, and drive systems. Te survey identifed

and prioritized other root-cause stresses and resulted in a

machine-by-machine stress protection solutions report. Tis

document served as a stress-hardening protection recom-

mendation and installation guide.

AT LEAST ONCE OR TWICE A WEEK, YOUD

HEAR FROM A CNC OPERATOR THAT THE

MACHINE HAD JUST STOPPED.

PS1203_XX_XX_COVERSTORY.indd 23 2/29/12 5:04 PM

ENGINEERING / PLANT MAINTENANCE

Kim White, Sturms maintenance manager, authorized

Bill Ross, Sturms maintenance electrician, to test the pro-

posed solutions in the report. Te initial testing involved

installing high-speed clamping/fltering transient voltage

surge suppression (TVSS) units from Total Protection Solu-

tions (www.tpssurge.com) and air-to-air heat exchangers on

two Portland reamers in the gun forge molding department.

Historically, Sturm Ruger was replacing at least one of

these motion axis drives every other month and experienc-

ing the loss of production. Since the replacement, there have

been no costly axis drive replacements needed and no scrap

being generated from marginal and failing axis drives.

Summer heat also was afecting the companys Tech-

nidrills and Extrom Carlson CNCs in the woodworking

department. Frequently the cabinet doors were lef open

to keep the controls from malfunctioning or failing. Te

report included the size and type of control coolers to use,

the proper connection points, and mounting details for the

TVSS devices. Te woodshop hasnt experienced downtime

or quirky malfunction problems since making the changes.

Based on these pilot-test results, Sturm Ruger began

implementing the FISH report suggestions across the manu-

facturing facility. From the time I started with Sturm Ruger

back in 2003, says Ross, at least once or twice a week,

youd hear from a CNC operator that the machine had just

stopped or wouldnt start up correctly. Wed have to shut of

the main power switch feeding the machine tool and turn

it back on again to reset or reboot it. Tat seemed to fx the

problem until the next occurrence. Since completing this

equipment stress protection project, Ive not heard of that

happening again.

Te overall efect was like installing a large UPS on every

machine tool, but the real savings came from increased reli-

ability, productivity, and uninterrupted profts.

Shortly afer restructuring maintenance, the concepts and

methods of the original project were expanded to include

additional machining and process control areas, as well as

TPS suppressors to protect Sturms low-voltage lighting.

FOOD PRODUCTION OVERHAUL

Minnesota-based Faribault Foods (www.faribaultfoods.

com) is no stranger to the importance of sustainability in

food production. As a producer of many foods including a

wide variety of beans, chili, organic soup, juices, and canned

pasta, Faribault Foods is a member of the Sustainability

Initiative Team (SIT), a part of the Foundation for Strategic

Sourcing. Te group is comprised of executives from major

consumer packaged goods, contract manufacturing, and

More green cleaning solutions

PS1203_22_28_COVERSTORY.indd 24 3/1/12 11:40 AM

packaging supplier companies that work together to develop

industry standards to promote sustainability.

While business drivers might have progressed in recent

years, the bean production process hasnt changed much in

the companys 115-year history. Beans come to the primary

production facility from all over the Midwest. Teyre placed

into a soaking and rehydration system, and then blanched

and transferred to a canning line, where broth, sauce, or

brine is added for favor. Te cans are sealed and sent to the

cooking system, where theyre held at a particular tempera-

ture to make them a commercially sterile product. Finally,

the cans are cooled, packed on pallets, and shipped to thou-

sands of retail locations across the country.

Te Faribault bean plant was designed as a seasonal

vegetable canning facility, explains Phil Hines, director of

engineering, Faribault Foods. When I joined the company

in 2005, it was being operated year-round as a rehydrated

bean canning facility. We needed to modernize our produc-

tion infrastructure to meet long-term business goals and

deliver the high-quality, sustainable products our customers

have come to expect.

With several hundred varieties of product going through

the facility each year, it simply wasnt designed to keep pace

with the companys growing business. In addition to pro-

ducing several of its own brands, the company also produces

private-label brands for many large grocery retailers and

provides copacking, or contract manufacturing services as

well. We needed to demonstrate and document reliable,

repeatable production practices to our customers particu-

larly to those working with us on copack products, explains

SEISMIC REINFORCEMENT

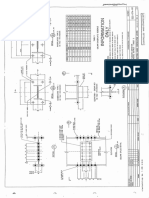

Figure 1. The South Bay wastewater treatment plant is located in

earthquake country, so the generator-set containers are supported

by a seismically reinforced mezzanine structure consisting of

I-beams connected in crisscross patterns.

than anyone on planet earth.

ECOFLE`, |E ||||S|+S VOS

FLE`|b|E, EO|O|A| A||

EO|OV|A| S||bbE| E||O|O+

VO|E LEE|EbOV ||||S||A| F|OO|

CLEA||| E|||VE| |A| A|+

O|E| VA||FA||E|

If you havent yet realized the cost and resource savings of sustainable

cleaning, its time to go green. And with the most complete line of durable and

dependable green oor cleaning machines in the industry, Advance is the

perfect partner. Advance sweepers, scrubbers and combination equipment

help facility managers earn LEED certication, help contractors ensure

customer satisfaction, take advantage of LEED credit incentives and comply

with emerging health and safety standards. We can show you how reducing

your environmental impact can also have a positive impact on your bottom

line. Its true. To learn more, go to advance-us.com/greencleaning for our

green cleaning white papers.

2011 Nilsk-Advance

800-850-5559 www.advance-us.com A Nilsk-Advance Brand

PS1203_22_28_COVERSTORY.indd 25 3/1/12 11:41 AM

and steam (WAGES) resource consumption (Figure 2).

Once the company decided to invest in a complete facility

overhaul, Hines and his team designed a comprehensive

plan to identify opportunities for improvement, documenta-

tion requirements, and an ongoing timeline for implementa-

tion. We knew this wasnt going to be a one-time efort,

explains Hines, who, along with his team, selected a process

solution based on the Rockwell Automation Integrated

Architecture system, featuring eight Allen-Bradley Control-

Logix programmable automation controllers (PACs). Each

PAC communicates via a ControlNet network to intelligent

feld devices and 12 human-machine interface (HMI) sta-

tions comprised of Allen-Bradley PanelView Plus termi-

nals and industrial computers running FactoryTalk View

SE sofware. Te control system monitors the production

infrastructure in real-time, including WAGES consumption

information. Faribault Foods implemented instrumenta-

tion from Endress+Hauser for seamless integration. When

we started this project, we were in the beginning stages

of automating of our production system, explains Hines.

As a result, this project represented a substantial technol-

ogy change for the maintenance department. Te biggest

challenge was training. Every maintenance person needs

to understand the functionality of the new sensing and

controls devices in order to troubleshoot the operation and

TIGHT CONTROL

Figure 2. The control system monitors the entire production

infrastructure in real-time, including WAGES consumption

information, allowing the Faribault Foods team to identify

opportunities for improvement.

WHERE I DEAS MEET I NDUSTRY

Since1948, SPX has set the global standard for energy efcient compressed air treatment

solutions. The tradition continues with the introduction of the HES Series high capacity

refrigerated air dryer, ows 3750 to 12500 scfm (6371-21238 nm

3

/h).

THE I NNOVATI ON EDGE

Utilizing the latest technological advancements, the HES Series offers a new way of

thinking and fresh approach to efciently treat compressed air.

724.745.1555

LOOKING FOR A NEW WAY TO EFFICIENTLY

TREAT COMPRESSED AIR?

Featuring:

t Power consumption in direct proportion to real-time demand.

t Redundancy in critical components offering fault- tolerant operation.

t Modular construction promotes ease of movement and installation versatility.

t ISO Quality Class performance for particulate removal, pressure dew point & remaining oil.

www.spx.com

ENGINEERING / PLANT MAINTENANCE

PS1203_22_28_COVERSTORY.indd 26 2/29/12 5:13 PM

By simply attaching his Bluetooth

adapter

to an Agilent handheld DMM, and pairing it to

his Android device running a freeAgilentapp.

Agilent lets you turn your Android smartphone

or tablet into a remote measurement, control,

and reporting device.Accelerate your work

by connecting with Agilent.

Heres how.

How about you?

How did Dan receive automatic email alerts triggered by

suspect voltage drops at an industrial jobsite while he

was 3 miles away at a different site?

Dan Cole, Scranton, PA

How?

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Scan the QR

code or visit

http://goo.gl/uVLdq

to see a video demo

800-463-9275

www.newark.com/agilent

Agilent and our

Distributor Network

Right Instrument.

Right Expertise.

Delivered Right Now.

Download wireless remote connectivity app note

Watch the video to see HOW it works

www.newark.com/Agilent_HHDMM

Agilent Technologies 2012 Bluetooth and the Bluetooth logo are registered trademarks owned by Bluetooth SIG, Inc., U.S.A. and licensed to Agilent Technologies, Inc.

PS1203_FPA.indd 27 3/1/12 10:11 AM

28 MARCH 2012 WWW.PLANTSERVICES.COM

ENGINEERING / PLANT MAINTENANCE

to be able to diferentiate between

control system issues and mechanical

issues. We implemented a training

program for all maintenance staf and

specialty training for a selected group

who would focus on maintaining and

updating the new control systems.

As part of the project, Faribault

standardized many of the devices, says

Hines. For example, we use the same

VFD model throughout the facility,

he explains. We also included elec-

tronic documentation of the location,

description, and function of each

device and the ability to allow outside

vendors to access our system through

a VPN connection for data collection

and troubleshooting.

To ensure a smooth transition,

Hines wanted to train his staf on the

new technology as soon as the system

was online. Previously, one or two

staf members possessed 90% of the

control system knowledge, he says.

With the new system, we wanted to

make sure everyone understood how

it worked.

Te companys heat-and-energy-re-

covery system reuses 100% of the heat

from the can cooling process to warm

city water for the soaking, blanching,

and cooking operations. Te result is

a 38.2% decrease in natural gas usage,

which won the company Xcel Energys

2009 award for the largest natural gas

reduction among industrial customers

in the state of Minnesota. In addi-

tion, the system reuses cooled water to

reduce the temperature of the cans in

the cooking process, which cuts down

on the companys overall water usage

by more than 100 million gal/year.

Tighter control of the process also

allows for reduced waste in the manu-

facturing process. To accommodate

the cooking process, the company

leaves head space in each can es-

sentially an air pocket between the

can lid and the beans. Previously, at

the end of the manufacturing line, the

head space would be pushed out along

with a few ounces of canning fuid,

which would be fushed down the

drain. Now, thanks to the increased

process accuracy and reliability, the

plant-foor team can fll to exact levels,

ensuring that no fuid is wasted when

the head space is forced out of the can.

As Faribault Foods moves to a

predictive maintenance strategy, the

asset management and training sup-

port also are proving useful. Faribault

Foods is now producing the same

amount of product in fve days that

previously required seven.

When Hines frst started the

upgrade process, the plant typically

was running at 75% of its maximum

throughput. Now, the facility runs at

90%, and it has better product quality,

as well.

Summit offers high performance synthetic lubricants for a

wide range of gear and bearing applications. Formulated

using the latest technology, these lubricants have excellent

oxidation and thermal stability, which significantly reduces

thermal degradaon and deposit formaon when compared

to conventional lubricants. Syngear synthetic lubricants

offer extended drain intervals while providing increased

wear protection, longer life, less downtime, and higher

productivity.

1. Syngear SH 1000 Series - For use in all types of

heavily loaded low speed enclosed gears, as well as

plain and roller bearings.

2. Syngera SH 7000 Series - For use in high speed

enclosed gears and plain or rolling element bearings

operating in severe temperature conditions.

Recommended for use in applications where the

corrosion of yellow metals is a concern.

3. Syngear FG Series - For gear systems operating in

the food service and packaging industries. NSF H-1

and ISO 21469 Certified.

4. Varnasolv - For use as a lubricant additive to remove/

suspend varnish and carbon deposits while the gearbox

is in operation.

For information on our complete line of industrial gear

lubricants or for technical assistance in choosing the

correct gear oil for your applicationContact Summit

at 800.749.5823 or info@klsummit.com.

ISO 9001:2008

Summit Industrial Products

P.O. Box 131359 Tyler, TX 75713

Ph. 800.749.5823 www.klsummit.com

ISO 21469

Certified

PS1203_22_28_COVERSTORY.indd 28 2/29/12 5:13 PM

2 0 1 2 X C E L E N E R G Y I N C .

IF YOUR BUILDING

IS YOUR BABY, WE

HAVE THE FORMULA

FOR COOLING IT

MORE EFFICIENTLY.

If your cooling equipment is more than 15 years old, you could

be paying way too much when you use it. New cooling systems

are at least 20 percent more energy efficient than older models.

And Xcel Energy rebates are currently available for up to

60 percent of your installation cost. Very cool.

Visit ResponsibleByNature.com/Business

today for details.

PS1203_FPA.indd 29 3/1/12 8:56 AM

Which is better a classical centralized air system or a

departmental compressed air system? Reports suggest that

neither system is better. Quite ofen, the right choice is a

combination or variation of both. Heres why.

A central air system satisfes total plant air demand. Air

from one or more compressors is distributed from a central

point to areas requiring service. Tese compressors are in-

stalled in a powerhouse with other utilities. In a departmen-

tal air system, several compressors are located at principal

points of use throughout the plant. Tis approach can be

used instead of, or in combination with, the central type.

VARIATION CAN PAY

Each has its advantages and disadvantages. In deciding

which is best, weigh the benefts gained against the draw-

backs for the choice. Te case for one system over the other

isnt always clear cut. Te judicious plant engineer, afer

weighing the facts and fgures, might arrive at a combination,

or even a variation. Heres a hypothetical example.

A 50,000-cfm centralized air system has several compres-