Professional Documents

Culture Documents

Eco-Friendly Green Inhibitor To Improve The Strength of Concrete Contaminated by Chloride and Sulphate

Uploaded by

Dharmaraaj RajalinggamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eco-Friendly Green Inhibitor To Improve The Strength of Concrete Contaminated by Chloride and Sulphate

Uploaded by

Dharmaraaj RajalinggamCopyright:

Available Formats

IJRRAS 9 (3) December 2011

www.arpapress.com/Volumes/Vol9Issue3/IJRRAS_9_3_03.pdf

ECO-FRIENDLY GREEN INHIBITOR TO IMPROVE THE STRENGTH OF CONCRETE CONTAMINATED BY CHLORIDE AND SULPHATE

Abdulrahman A. S1 & Mohammad Ismail2 Faculty of Civil Engineering, Universiti Teknologi Malaysia, 81310 UTM, Johor Bahru, Johor, Malaysia Email: 1asipita2@gmail.com ; 2mohammad@utm.my

ABSTRACT In recent years the use of inhibitors in producing high performance concrete has increased significantly as a result of chloride and sulphate attacks. The present inhibitors in market are toxic to the environment. Hence, the objective of the present investigation was to study a novel, eco-friendly and hydrophobic green plant extracts inhibitor (Bambusa Arundinacea) and compares its effectiveness with calcium nitrite and ethanolamine inhibitors. Concrete mix was designed to 30MPa with 0.45 W/C ratios and tested at 7, 28 and 90 days. 1.5% and 4.5% weight of cement content of chloride and sulphate were added as an analytical grade of magnesium chloride and magnesium sulphate. Inhibitors additions were 2% and 4%. The results of the inhibitors studied showed that Bambusa Arundinacea exhibited superior compressive strength compared to calcium nitrite and ethanolamine. Bambusa Arundinacea may be considered a better substitute for nitrite and amine- based corrosion inhibiting admixtures for durable concrete structures due its geometric pore blocking effects. Keywords: Concrete, Chloride attack, Green plant extracts, Inhibitors, Sulphate attack. 1. INTRODUCTION Most common attacks to concrete integrity are sulphate and corrosion products as a result of chloride contamination. Many synthetic compounds were developed to combats this endemic problem, but most of them are highly toxic to both human beings and environment (Satapathy 2009). These inhibitors may cause temporary or permanent damage to human organ such as kidney or liver (Raja and Sethuraman 2008). The known hazardous effects of most synthetic organic inhibitors and restrictive environmental regulations have now made researchers to focus on the need to develop cheap, non-toxic and environmental friendly natural products as inhibitors. Environmental concerns worldwide are increasing and are likely to influence the choice of inhibitors in the future. Uhlig, 2004 reported that there was a growing demand for corrosion inhibitors that are less toxic and biodegradable compared to current formulations. Green inhibitors displaying substantially improved environmental properties as compared to the existing inhibitors whose toxic level is above 50%. Inhibitors toxicity according to (Uhlig 2004) is measured as LD50 and LC50. LD50 is the lethal dose of a chemical at which 50% of a group of animals are killed for 24h exposure time, whilst LC50 is lethal concentration in air or water which kills 50% of test population. Inhibitor biodegradation, or biological oxygen demand (BOD), should at least be 60%. The BOD is a measure of how long the inhibitor will persist in the environment. Recent research (Raja and Sethuraman 2008; Abdulrahman 2011; Mohammad Ismail 2011) has shown that green inhibitors are more environmental benign than organic and inorganic inhibitors. The alternative way to minimize the risk of organic and inorganic inhibitors is the adoption of green inhibitor to reduce the environmental hazard. This approach gets to the root causes of the problem and is based on the principle of what you dont have cant harm you. So investigating the use of natural green organic inhibitors (Bambusa Arundinacea) which is expected to be hydrophobic in nature, non-toxic and eco-friendly to improve the strength and prevent sulphate attack and chloride ingress to concrete is most apt and desirable. 2. EXPERIMENTAL

2.1 Materials used Ordinary Portland Cement (OPC) was used in this research. Chemical compositions accompanied by some important physical and mechanical properties of the cement are given in Table 1.

355

IJRRAS 9 (3) December 2011

Abdulrahman & Ismail Eco-Friendly Green Inhibitor

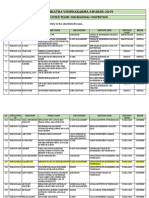

Table 1. Chemical composition, physical and mechanical properties of the cement Chemical Composition Silica (SiO2) Alumina (Al2O3) Ferric oxide (Fe2O3) Calcium oxide (CaO) Sulphur trioxide (SO3) Magnesium oxide (MgO) Insoluble residue Loss on ignition Lime saturated factor Physical/Mechanical Property Surface area (Blaine) (m2/kg) Specific gravity Initial setting time (min) Final setting time (min) Compressive strength at 1 day Compressive strength at 3 days Compressive strength at 7 days Compressive strength at 28 days Soundness (mm)

Value (%) 20.2 4.9 3 62.5 1.8 2.6 1.9 2.7 0.85

Magnitude 314 3.28 105 190 13.5MPa 20.5MPa 28.5MPa 35.6MPa 8.7

The chloride and sulphate were admixed into the concrete as magnesium chloride and magnesium sulphate of analytical reagent grade. The concentrations of Magnesium chloride used were 1.5% and 4.5% by mass of cement and the corresponding chloride concentrations were 0.94% and 2.82% respectively. Coarse aggregates of size 20 mm and 10 mm of quartzite origin were used in the ratio of 1.78:1 to satisfy the overall grading requirement of coarse aggregate (Pradhan and Bhattacharjee 2009). Land quarried sand passing through ASTM sieve No. (4.57mm) conforming to zone II classification of British standard was used as fine aggregate. The sand has a fineness modulus of 2.5. Tap water was used for the preparation of specimens. All the concrete mixes were designed for similar workability with slump of 3060 mm. The water content was kept constant to 230 kg/m3 for the desired slump in all the mixes to have similar workability. The watercement ratio (w/c) used was 0.45. The fresh density of concrete was then obtained as per guidelines specified by British method of mix selection (DOE) to be 2380Kg/m3. Mix design is as shown in Table 2. Table 2 Concrete mix proportions Cement content Fine aggregate (Kg/m3) Content (Kg/m3) 511 623

Water-cement Ratio (w/c) 0.45

Water content (Kg/m3) 230

Coarse aggregate content (Kg/m3) 1016

2.2 Preparation of plant extracts Fresh leaves of Bambusa Arundinacea (Indian Bamboo) was washed under running water, shade dried and ground into powder. The powdered leaves were extracted using 95% ethanol. 5g each of powdered leaves was soaked in 200ml in ethanol as in previous work (Sethuraman 2005) for 14 days and thereafter filtered. In order to leave the sample free of ethanol, the filtrate was subjected to evaporation using a rotary evaporator (Fig 1).

Fig.1. Rotary evaporator 2.3 Preparation of concrete specimens for compressive strength test 100 100 100mm concrete cubes were prepared using 1:1.2:2 mixes designed with a W/C ratio of 0.45. Inhibitor admixtures, namely Calcium nitrite, Ethanolamine and Green Bambusa arundinacea were added on the basis of weight of cement. The concrete cubes were demoulded after 24 h of casting and subjected to water curing. The

356

IJRRAS 9 (3) December 2011

Abdulrahman & Ismail Eco-Friendly Green Inhibitor

specimens were removed after 7, 28, 90 days of curing and subjected to compressive strength testing (as per British Standard BS1881: Part 116: 1983) using 2000KN capacity compression testing machine. Triplicate specimens were tested and average values were reported. 3. RESULTS and DISCUSSIONS 3.1 Effects of MgCl2 additions on concrete strength MgCl2 was chosen for this work base on the literature and its negative and deteriorating effects. It was considered more detrimental to concrete than CaCl2 and NaCl (Poursaee A. 2010). Bambusa Arundinacea inhibitor was also chosen as a candidate green inhibitor to be compared with Calcium nitrite (Ca(NO2)2) and Ethanol amine (C2H7NO) for this work as a result of its high inhibition efficiency and good adsorption characteristics as reported by (Abdulrahman 2011). The compressive strength values of the specimens that have been cured for 7, 28 and 90 days are given in Table 3, for 1.5% and 4.5% MgCl2 additions. The compressive strength for the specimens increased with time to 90 days regardless of type of corrosion inhibitors. But Ca(NO 2)2 inhibitor standout for increase in early strength and decrease in long term strength for 2% additions to the mix (Figs. 2 and 3). This finding is similar to what were reported by (De Schutter and Luo 2004; Ann Ki Yong 2006; Ashassi-Sorkhabi, Aliyev et al. 2007). Ca(NO2)2 inhibitor addition to concrete influences the hydration process of cement paste. It accelerate and stabilize the formation of crystal phase of Ca(OH)2 which lead to increase in the micropores diameter in the hardened cement paste and thus increase the permeability of concrete (Kondratova 2003). Conversely, Bambusa arundinacea inhibitor increased the strength of chloride sample by 20% as showed in Table 3. The 90 days strength of Bambusa arundinacea inhibitor when compared with Ca(NO2)2 and C2H7NO inhibitors, showed superior strength (Fig. 3) this is as a result of its permeability reduction property (Nmai 2004). Meanwhile, additions of MgCl2 salt have no detrimental effects on the compressive strength of concrete at early age of hydration, rather it increases the strength. This is as a result of formation of calcium chloro-aluminate due to chloride that was chemically bonded by reactions with C3A compound of the Portland cement. Table 3 Effect of chloride contamination on the compressive strength (MPa) for 0.45 W/C ratio System 1.5% MgCl2 additions 7 days 28 days Control without MgCl2 Control with MgCl2 2% Calcium Nitrite Inhibitor 30.83 39.34 47.89 43.27 48.22 60.70 54.87 51.90 38.87 30.83 37.04 31.51 43.27 43.74 28.74 54.87 58.20 49.30 90 days 7 days 4.5% MgCl2 additions 28 days 90 days

4% Calcium Nitrite Inhibitor 2% Ethanolamine inhibitor 4% Ethanolamine inhibitor 2% Green Bambusa arundinecea inhibitor 4% Green Bambusa arundinecea inhibitor

47.86 45.65 42.30 47.29

58.69 49.58 52.79 41.91

70.63 70.98 70.21 68.40

40.41 44.00 40.75 29.20

55.94 62.09 56.31 41.31

61.60 45.10 47.20 61.90

39.31

45.98

54.36

34.80

41.81

56.67

357

IJRRAS 9 (3) December 2011

Abdulrahman & Ismail Eco-Friendly Green Inhibitor

80

Compressive Strength, MPa

70

60 50 40

30 20 10 0 0 20 40 60 80 100

Control

Control with salt

2% Ca(NO2)2 4% Ca(NO2)2 2% C2H7NO 4% C2H7NO

2% Bamboo

4% Bamboo

Age (Days)

Fig.2. 1.5% MgCl2 addition to 0.45W/C concrete

70

Compressive Strength, MPa

60 50 40 30 20 10 0 Control

Control with salt

2% Ca(NO2)2 4% Ca(NO2)2 2% C2H7NO 4% C2H7NO 2% Bamboo

20

40

60

80

100

4% Bamboo

Age (Days)

Fig. 3. 4.5% MgCl2 addition to 0.45W/C concrete

3.2 Effects of MgSO4 additions on concrete strength The results of the compressive strength test indicated that the additions of Bambusa Arundinacea, Calcium nitrite and Ethanolamine inhibitors increased the compressive strength of concrete when compared to the control concrete. Meanwhile, 90 days compressive strength of Bambusa arundinacea is higher than the other two inhibitors (Calcium nitrite and Ethanolamine) as in Table 4 and elaborately depicted in Figs 4 and 5. This can be attributed to the presence of electronegative functional groups and -electrons in their structures. It formed conjugated double bonds that prevent water permeability into the concrete to initiate sulphate attack. This bonds formed are hydrophobic as a result of heteroatom of quaternary nitrogen atom and aromatic ring which blocks concrete pores (Ali 2008; Raja and Sethuraman 2008; Abiola 2009). The water in contact with a porous hydrophilic concrete, penetrates the it by means of capillary forces following the Washburn equation, p = (2 /r c) cos , where represents the liquid surface tension, rc is the capillary pore radius, and is the contact angle. A water droplet, on a hydrophilic concrete, wets the surface by spreading itself and by absorption through the solid porosity. The contact angle becomes less than 90, p becomes positive and the liquid fills the pore spontaneously (Tittarelli F 2008). However, in this case the molecular attraction between water and the concrete pore walls was lowered by Bambusa arundinacea hydrophobic agents. Where the contact angle becomes higher than 90, the water droplet keeps it spherical, and an external pressure p (in this case negative) is necessary to allow the liquid to penetrate the solid porosity. Bambusa arundinacea hinder liquid water to penetrate the structure when pressure is not excessively high. This is as a result of the pores containing high level of potassium and calcium from the inhibitor which combined with hydroxide to maintain the pH of between 12 and 13. This high level of alkalinity passivates the steel, forming a dense gamma ferric oxide that is self-maintaining and prevent rapid corrosion. 358

IJRRAS 9 (3) December 2011

Abdulrahman & Ismail Eco-Friendly Green Inhibitor

Table 4 Effect of sulphate attack on the compressive strength (MPa) for 0.45 W/C ratio

System 1.5% MgSO4 additions 7 days Control without MgCl2 Control with MgCl2 2% Calcium Nitrite Inhibitor 30.83 31.60 40.80 28 days 43.27 43.28 68.30 90 days 54.87 54.20 58.55 4.5% MgSO4 additions 7 days 30.83 26.98 30.09 28 days 43.27 41.44 51.51 90 days 54.87 47.00 52.73

4% Calcium Nitrite Inhibitor 2% Ethanolamine inhibitor 4% Ethanolamine inhibitor 2% Green Bambusa arundinecea inhibitor 4% Green Bambusa arundinecea inhibitor

47.82 42.91 38.53 35.52

52.51 56.69 51.04 48.36

49.85 56.80 54.90 58.92

23.01 24.96 33.52 36.94

53.59 33.42 45.60 48.53

51.25 45.90 52.07 59.20

33.71

45.58

58.43

21.65

34.25

60.80

Table 5 Compressive strength test (MPa) for 0.45 W/C ratios of 1.5% MgSO 4 additions

System Control without MgSO4 7 days 30.83 28 days 43.27 90 days 54.87

Control with MgSO4 2% Calcium Nitrite Inhibitor 4% Calcium Nitrite Inhibitor 2% Ethanolamine inhibitor 4% Ethanolamine inhibitor 2% Green Bambusa arundinacea inhibitor 4% Green Bambusa arundinacea inhibitor

31.60 40.80 47.82 42.91 38.53 35.52 33.71

43.28 68.30 52.51 56.69 51.04 48.36 45.58

54.20 58.55 49.85 56.80 54.90 58.92 58.43

Fig.4. 1.5% MgSO4 addition to 0.45W/C concrete

359

IJRRAS 9 (3) December 2011

Abdulrahman & Ismail Eco-Friendly Green Inhibitor

Fig.5. 4.5% MgSO4 addition to 0.45W/C concrete

CONCLUSION

The following conclusions can be drawn from the results: 1. Inhibitors additions to chloride contaminate concrete have no harmful effects to the compressive strength, rather all the inhibitors increase the strength tremendously. But 2% inhibitors additions to high chloride contaminate concrete (4.5%) is strongly recommended as Bambusa Arundinacea inhibitor showed superior strength over and above Ethanol amine and Calcium nitrite inhibitors by 27% and 20% respectively. 2. Bambusa Arundinacea did not contain heavy metals (Abdulrahman 2011), which eliminate the fear of possible formation of dioxin from chlorine-containing water. Dioxin is persistent and accumulates in fatty tissue which is highly toxic to humans.

ACKNOWLEDGEMENTS

This work was financially supported by the Construction Technology Management Centre (CTMC), Universiti Teknologi Malaysia (UTM) and Federal University of Technology, Minna, Nigeria. We are immensely grateful to all the technicians at the Structure and Materials laboratory, Faculty of Civil Engineering and Staff of Chemical Engineering pilot plant (CEPP), UTM, for their support.

REFERENCES

[1]. [2]. [3]. Abdulrahman, A.S. Mohammad Ismail, Mohammad Sakhawat Hussain (2011). "Inhibition of Corrosion of Mild Steel in Hydrochloric Acid by Bambusa Arundinacea." International Review of Mechanical Engineering 5(No.1). Abiola, O. K. O., James O. E. (2009). "The effects of Phyllanthus amarus extract on corrosion and kinetics of corrosion process of aluminum in alkaline solution." Corrosion Science 51(11): 2790-2793. Ali, S. A. Al-Muallem, H. A. Saeed, M. T. Rahman, S. U. (2008). "Hydrophobic-tailed bicycloisoxazolidines: A comparative study of the newly synthesized compounds on the inhibition of mild steel corrosion in hydrochloric and sulfuric acid media." Corrosion Science 50(3): 664-675. Ann Ki Yong, J. H. S., Kim H. S., Kim S. S., Moon H. Y (2006). "Effect of Calcium nitrite-based corrosion inhibitor in preventing corrosion of embedded steel in concrete." Cement Concrete Research 36: 530-535. Ashassi-Sorkhabi, H., T. A. Aliyev, et al. (2007). "Inhibiting effects of some synthesized organic compound on the corrosion of St-3 in 0.1N H2SO4 solution." Electrochimica Acta 52(16): 5238-5241. De Schutter, G. and L. Luo (2004). "Effect of corrosion inhibiting admixtures on concrete properties." Construction and Building Materials 18(7): 483-489. Kondratova, I. L. M., P.Bremner, T. W. (2003). "Natural marine exposure results for reinforced concrete slabs with corrosion inhibitors." Cement and Concrete Composites 25(4-5): 483-490. Mohammad Ismail, Abdulrahman, A. S., Mohammad Sakhawat Hussain (2011). "Solid Waste as Environmental Benign Corrosion Inhibitors in Acid Medium." International Journal of Engineering Science and Technology (IJEST) 3(2): 1742-1748. Nmai, C. K. (2004). "Multi-functional organic corrosion inhibitor." Cement and Concrete Composites 26(3): 199-207. Poursaee A., L. A., Hansson C. M. (2010). "Corrosion of steel bars in OPC mortar exposed to NaCl, MgCl 2 and CaCl2: Macro- and micro-cell corrosion perspective." Cement and Concrete Research 40: 426430. Pradhan, B. and B. Bhattacharjee (2009). "Performance evaluation of rebar in chloride contaminated concrete by corrosion rate." Construction and Building Materials 23(6): 2346-2356. Raja, P. B. and M. G. Sethuraman (2008). "Natural products as corrosion inhibitor for metals in corrosive media -- A review." Materials Letters 62(1): 113-116. Satapathy, A. K. G., G. Sahoo, S. C. Amit, Kumar Rodrigues, P. V. (2009). "Corrosion inhibition by Justicia gendarussa plant extract in hydrochloric acid solution." Corrosion Science 51(12): 2848-2856. Sethuraman, M. G, Raja P. B. (2005). "Corrosion inhibition of mild steel by Datura metel in acidic medium." Pigment & Resin Technology Volume 34 ( 6 ): 327331. Tittarelli F, M. G. (2008). "The effect of silane-based hydrophobic admixture on corrosion of reinforcing steel in concrete." Cement and Concrete Research 38: 13541357. Uhlig, H. (2004). Corrosion and Control, George Harrap and Co. Ltd.

[4]. [5]. [6]. [7]. [8]. [9]. [10]. [11]. [12]. [13]. [14]. [15]. [16].

360

You might also like

- Write A Short Note On SymmetryDocument1 pageWrite A Short Note On SymmetryDharmaraaj RajalinggamNo ratings yet

- CE 8004 URBAN PLANNING TOPICS AND PRINCIPLESDocument8 pagesCE 8004 URBAN PLANNING TOPICS AND PRINCIPLESDharmaraaj RajalinggamNo ratings yet

- Anna University:: Chennai: Rollno - Iiii - I - IiDocument2 pagesAnna University:: Chennai: Rollno - Iiii - I - IiDharmaraaj RajalinggamNo ratings yet

- Energy Efficiency in Buildings PDFDocument120 pagesEnergy Efficiency in Buildings PDFvndeshmukh100% (1)

- 1349 - Activity 4 - Entrepreneurship QuizDocument1 page1349 - Activity 4 - Entrepreneurship QuizDharmaraaj RajalinggamNo ratings yet

- C E 482 ArchitectureDocument2 pagesC E 482 ArchitectureDharmaraaj RajalinggamNo ratings yet

- B.E. (FULL TIME) DEGREE EXAM END SEMESTER ARCHITECTURE EXAMDocument2 pagesB.E. (FULL TIME) DEGREE EXAM END SEMESTER ARCHITECTURE EXAMDharmaraaj RajalinggamNo ratings yet

- Energía MundoDocument85 pagesEnergía MundoJesusAlonsoCandenasNo ratings yet

- C E 9406 Architecture and Town PlanningDocument2 pagesC E 9406 Architecture and Town PlanningDharmaraaj RajalinggamNo ratings yet

- 1.9875 Zero Emissions Buildings Framework ReportDocument118 pages1.9875 Zero Emissions Buildings Framework ReportDharmaraaj RajalinggamNo ratings yet

- 40 HouseDocument130 pages40 HouseAaron SteeleNo ratings yet

- The 2020 Global Status Report For Buildings and ConstructionDocument80 pagesThe 2020 Global Status Report For Buildings and ConstructionComunicarSe-ArchivoNo ratings yet

- 1544024358starting Online Business Short Course AssessmentDocument1 page1544024358starting Online Business Short Course AssessmentTaha OjisanNo ratings yet

- Unit 2 QBDocument15 pagesUnit 2 QBDharmaraaj RajalinggamNo ratings yet

- Quiz: How Entrepreneurial Are You?: Yes (1 PT.) No (0 PT.)Document3 pagesQuiz: How Entrepreneurial Are You?: Yes (1 PT.) No (0 PT.)Dharmaraaj RajalinggamNo ratings yet

- IDocument73 pagesIDharmaraaj RajalinggamNo ratings yet

- Construction of Residential Building Estimate ReportDocument4 pagesConstruction of Residential Building Estimate ReportDharmaraaj RajalinggamNo ratings yet

- Unit 3 QBDocument8 pagesUnit 3 QBDharmaraaj RajalinggamNo ratings yet

- Evm and The Project Management ProcessDocument2 pagesEvm and The Project Management ProcessDharmaraaj RajalinggamNo ratings yet

- Fibers: Investigation On The Mechanical Properties and Post-Cracking Behavior of Polyolefin Fiber Reinforced ConcreteDocument8 pagesFibers: Investigation On The Mechanical Properties and Post-Cracking Behavior of Polyolefin Fiber Reinforced ConcreteDharmaraaj RajalinggamNo ratings yet

- Repair and Rehabilitation of StructuresDocument76 pagesRepair and Rehabilitation of StructuresDharmaraaj RajalinggamNo ratings yet

- Unit 1 QBDocument17 pagesUnit 1 QBDharmaraaj RajalinggamNo ratings yet

- You Are Advised To Apply For PAN and GSTIN Immediately and Update The Same On This Website by 31.03.2021, To Avoid Suspension of Udyam RegistrationDocument1 pageYou Are Advised To Apply For PAN and GSTIN Immediately and Update The Same On This Website by 31.03.2021, To Avoid Suspension of Udyam RegistrationDharmaraaj RajalinggamNo ratings yet

- Nijotech Vol 33 No 2 PP 1 PDFDocument8 pagesNijotech Vol 33 No 2 PP 1 PDFDharmaraaj RajalinggamNo ratings yet

- Effect of Green Inhibitor On The Corrosion Behaviour of Reinforced Carbon Steel in ConcreteDocument8 pagesEffect of Green Inhibitor On The Corrosion Behaviour of Reinforced Carbon Steel in ConcreteDharmaraaj RajalinggamNo ratings yet

- Transport LabDocument15 pagesTransport LabDharmaraaj RajalinggamNo ratings yet

- April Content - 2016Document5 pagesApril Content - 2016Dharmaraaj RajalinggamNo ratings yet

- Strength of Material ManualDocument28 pagesStrength of Material Manualapi-3869476No ratings yet

- Shortlisted Teams After Evaluation of Video Clips-PPTsDocument2 pagesShortlisted Teams After Evaluation of Video Clips-PPTsDharmaraaj RajalinggamNo ratings yet

- Francis Xavier Engineering CollegeDocument11 pagesFrancis Xavier Engineering CollegeDharmaraaj RajalinggamNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SDS-Sodium Nitrite Solution 40 CHE-2021SDocument9 pagesSDS-Sodium Nitrite Solution 40 CHE-2021SpibemauNo ratings yet

- SDS-C11 HCA179 Chartek 1709 Part A - EngDocument11 pagesSDS-C11 HCA179 Chartek 1709 Part A - EngMinha Mubarok Ibn MasduqiNo ratings yet

- Dose Response RelationshipDocument24 pagesDose Response RelationshipPoonam RaiNo ratings yet

- MSDS - MolykoteDocument18 pagesMSDS - MolykotesatheeshNo ratings yet

- Material Safety Data Sheet: Ingredient Name Cas No. % WT Exposure LimitsDocument8 pagesMaterial Safety Data Sheet: Ingredient Name Cas No. % WT Exposure LimitsaggibudimanNo ratings yet

- Isopropanol: Bio-Strategy Pty LTDDocument9 pagesIsopropanol: Bio-Strategy Pty LTDArpit PatelNo ratings yet

- Alwa-Mould D Component 2Document8 pagesAlwa-Mould D Component 2amiller1987No ratings yet

- Jasmine Essential Oil MSDSDocument5 pagesJasmine Essential Oil MSDSSri RengaNo ratings yet

- Mr-68-c en Sds AerosolDocument10 pagesMr-68-c en Sds AerosolBala KrishnanNo ratings yet

- HA OralDocument10 pagesHA Orallina yohanesNo ratings yet

- Urea CFL MsdsDocument8 pagesUrea CFL MsdsNawaitsuk IcuzNo ratings yet

- Msds - Radix Al (Handrub) - 1Document14 pagesMsds - Radix Al (Handrub) - 1Jyoti GambhirNo ratings yet

- Fao Specifications and Evaluations For Agricultural PesticidesDocument55 pagesFao Specifications and Evaluations For Agricultural PesticidesNO AZNo ratings yet

- BergaCare SmartLipids Retinol SDSDocument6 pagesBergaCare SmartLipids Retinol SDSJessik CerónNo ratings yet

- 16Document14 pages16dervin.d.lopezNo ratings yet

- WHO PropoxurDocument37 pagesWHO Propoxurgilang kusumasariNo ratings yet

- Antong 75 Sp-Acephate75 Msds-1Document5 pagesAntong 75 Sp-Acephate75 Msds-1Mash HudaNo ratings yet

- Laudis MsdsDocument10 pagesLaudis Msdsyanri cahyoNo ratings yet

- Grease - e - SiliconeDocument24 pagesGrease - e - Siliconeucb51525354100% (1)

- Setting Cleaning Validation Limits for Topical FormulationsDocument8 pagesSetting Cleaning Validation Limits for Topical Formulationsvijayns_250355172No ratings yet

- Foster 60-25 Safety Data SheetDocument7 pagesFoster 60-25 Safety Data SheetMinh BảoNo ratings yet

- Safety Data Sheet: According To GB/T 16483-2008Document8 pagesSafety Data Sheet: According To GB/T 16483-2008DoubleANo ratings yet

- OECD SIDS Review of Hexylene GlycolDocument136 pagesOECD SIDS Review of Hexylene GlycolPankil DhariaNo ratings yet

- Sun Cobalt Octoate 8% Material Safety Data SheetDocument3 pagesSun Cobalt Octoate 8% Material Safety Data SheetkunalNo ratings yet

- Clariant SDS Sanodal Orange 3LW Liq India EnglishDocument14 pagesClariant SDS Sanodal Orange 3LW Liq India EnglishRamesh KumarNo ratings yet

- Dichtol WFT SD - 1532 - EN - 2Document8 pagesDichtol WFT SD - 1532 - EN - 2gersomNo ratings yet

- 48alloy771 - Kester SDS GHS Un - English (Us)Document13 pages48alloy771 - Kester SDS GHS Un - English (Us)Joze MartinezNo ratings yet

- Material Safety Data Sheet: 1-IdentificationDocument3 pagesMaterial Safety Data Sheet: 1-IdentificationKhaled Anwar100% (1)

- 3 ThreeBond 1227 ENGLISH-convertido (1Document8 pages3 ThreeBond 1227 ENGLISH-convertido (1Alfonso De La RosaNo ratings yet

- Cuda Canada 100Z: Safety Data Sheet A014EXX-CUD100Document8 pagesCuda Canada 100Z: Safety Data Sheet A014EXX-CUD100PSNo ratings yet