Professional Documents

Culture Documents

Basic Heat Treatment of Metals

Uploaded by

calliepearsonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Heat Treatment of Metals

Uploaded by

calliepearsonCopyright:

Available Formats

BASIC HEAT TREATMENT OF METALS

************************************* BASIC HEAT TREATMENT OF METALS As Steelworkers, we are interested in the heat treatment of metals, because we have to know what effects the heat produced by welding or cutting has on metal. We also need to know the methods used to restore metal to its original condition. The process of heat treating is the method by which metals are heated and cooled in a series of specific operations that never allow the metal to reach the molten state. The purpose of heat treating is to make a metal more useful by changing or restoring its mechanical properties. Through heat treating, we can make a metal harder, stronger, and more resistant to impact. Also, heat treating can make a metal softer and more ductile. The one disadvantage is that no heat-treating procedure can produce all of these characteristics in one operation. Some properties are improved at the expense of others; for example, hardening a metal may make it brittle. HEAT-TREATING THEORY The various types of heat-treating processes are similar because they all involve the heating and cooling of metals; they differ in the heating temperatures and the cooling rates used and the final results. The usual methods of heat-treating ferrous metals (metals with iron) are annealing, normalizing, hardening, and tempering. Most nonferrous metals can be annealed, but never tempered, normalized, or case-hardened. Successful heat treatment requires close control over all factors affecting the heating and cooling of a metal. This control is possible only when the proper equipment is available. The furnace must be of the proper size and type and controlled, so the temperatures are kept within the prescribed limits for each operation. Even the furnace atmosphere affects the condition of the metal being heat-treated.

The furnace atmosphere consists of the gases that circulate throughout the heating chamber and surround the metal, as it is being heated. In an electric furnace, the atmosphere is either air or a controlled mixture of gases. In a fuel-fired furnace, the atmosphere is the mixture of gases that comes from the combination of the air and the gases released by the fuel during combustion. These gases contain various proportions of carbon monoxide, carbon dioxide, hydrogen, nitrogen, oxygen, water vapor, and other various hydrocarbons. Fuel-fired furnaces can provide three distinct atmospheres when you vary the proportions of air and fuel. They are called oxidizing, reducing, and neutral. STAGES OF HEAT TREATMENT Heat treating is accomplished in three major stages: Stage l-Heating the metal slowly to ensure a uniform temperature Stage 2-Soaking (holding) the metal at a given temperature for a given time and cooling the metal to room temperature Stage 3-Cooling the metal to room temperature HEATING STAGE The primary objective in the heating stage is to maintain uniform temperatures. If uneven heating occurs, one section of a part can expand faster than another and result in distortion or cracking. Uniform temperatures are attained by slow heating. The heating rate of a part depends on several factors. One important factor is the heat conductivity of the metal. A metal with a high-heat conductivity heats at a faster rate than one with a low conductivity. Also, the condition of the metal determines the rate at which it may be heated. The heating rate for hardened tools and parts should be slower than unstressed or untreated metals. Finally, size and cross section figure into the heating rate. Parts with a large cross section require slower heating rates to allow the interior temperature to remain close to the surface temperature that prevents warping or cracking. Parts with uneven cross sections

experience uneven heating; however, such parts are less apt to be cracked or excessively warped when the heating rate is kept slow. SOAKING STAGE After the metal is heated to the proper temperature, it is held at that temperature until the desired internal structural changes take place. This process is called SOAKING. The length of time held at the proper temperature is called the SOAKING PERIOD. The is used for metals that require a rapid cooling rate, and soaking period depends on the chemical analysis of the oil mixtures are more suitable for metals that need a metal and the mass of the part. When steel parts are slower rate of cooling. Generally, carbon steels are uneven in cross section, the soaking period is deter- waterhardened and alloy steels are oil-hardened. Nonmined by the largest section. Ferrous metals are normally quenched in water. During the soaking stage, the temperature of the metal is rarely brought from room temperature to the final temperature in one operation; instead, the steel is slowly heated to a temperature just below the point at which the change takes place and then it is held at that temperature until the heat is equalized throughout the metal. We call this process PREHEATING. Following preheat, the metal is quickly heated to the final required temperature. When apart has an intricate design, it may have to be preheated at more than one temperature to prevent cracking and excessive warping. For example, assume an intricate part needs to be heated to 1500F for hardening. This part could be slowly heated to 600F, soaked at this temperature, then heated slowly to 1200F, and then soaked at that temperature. Following the final preheat, the part should then be heated quickly to the hardening temperature of 1500F. NOTE: Nonferrous metals are seldom preheated, because they usually do not require it, and preheating can cause an increase in the grain size in these metals.

COOLING STAGE After a metal has been soaked, it must be returned to room temperature to complete the heat-treating process. To cool the metal, you can place it in direct contact with a COOLING MEDIUM composed of a gas, liquid, solid, or combination of these. The rate at which the metal is cooled depends on the metal and the properties desired. The rate of cooling depends on the medium; therefore, the choice of a cooling medium has an important influence on the properties desired. Quenching is the procedure used for cooling metal rapidly in oil, water, brine, or some other medium. Because most metals are cooled rapidly during the hardening process, quenching is usually associated with hardening; however, quenching does not always result in an increase in hardness; for example, to anneal copper, you usually quench it in water. Other metals, such as air-hardened steels, are cooled at a relatively slow rate for hardening. Some metals crack easily or warp during quenching, and others suffer no ill effects; therefore, the quenching medium must be chosen to fit the metal. HEAT COLORS FOR STEEL You are probably familiar with the term red-hot as applied to steel. Actually, steel takes on several colors and shades from the time it turns a dull red until it reaches a white heat. These colors and the corresponding temperatures are listed in table 2-1. During hardening, normalizing, and annealing, steel is heated to various temperatures that produce color changes. By observing these changes, you can determine the temperature of the steel. As an example, assume that you must harden a steel part at 1500F. Heat the part slowly and evenly while watching it closely for any change in color. Once the steel begins to turn red, carefully note each change in shade. Continue the even heating until the steel is bright red; then quench the part. The success of a heat-treating operation depends largely on your judgment and the accuracy with which you identify each color with its corresponding temperature. From a study of table 2-1, you can see that close observation is necessary. You must be able to tell the

difference between faint red and blood red and between dark cherry and medium cherry. To add to the difficulty, your conception of medium cherry may differ from that of the person who prepared the table. For an actual heat-treating operation, you should get a chart showing the actual colors of steel at various temperatures. TYPES OF HEAT TREATMENT Four basic types of heat treatment are used today. They are annealing, normalizing, hardening, and tempering. The techniques used in each process and how they relate to Steelworkers are given in the following paragraphs. ANNEALING In general, annealing is the opposite of hardening, You anneal metals to relieve internal stresses, soften them, make them more ductile, and refine their grain structures. Annealing consists of heating a metal to a specific temperature, holding it at that temperature for a set length of time, and then cooling the metal to room temperature. The cooling method depends on the metal and the properties desired. Some metals are Ferrous Metal furnace-cooled, and others are cooled by burying them To produce the maximum softness in steel, you heat in ashes, lime, or other insulating materials. the metal to its proper temperature, soak it, and then let Welding produces areas that have molten metal next it cool very slowly. The cooling is done by burying the to other areas that are at room temperature. As the weld hot part in an insulating material or by shutting off the cools, internal stresses occur along with hard spots and furnace and allowing the furnace and the part to cool brittleness. Welding can actually weaken the metal. together. The soaking period depends on both the mass of the part and the type of metal. The approximate Annealing is just one of the methods for correcting these soaking periods for annealing steel are given in tablc problems. 2-2

You might also like

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Technical Manual For Plasma NitridingDocument4 pagesTechnical Manual For Plasma NitridingStojanova NikolinaNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Orbital ForgingDocument4 pagesOrbital ForgingMrLanternNo ratings yet

- Diamond Chemical Vapor Deposition: Nucleation and Early Growth StagesFrom EverandDiamond Chemical Vapor Deposition: Nucleation and Early Growth StagesNo ratings yet

- 1 s2.0 S0143974X21002212 MainDocument14 pages1 s2.0 S0143974X21002212 MainRavi PadmanabhanNo ratings yet

- (PN) Plasma Nitriding of Titanium AlloysDocument41 pages(PN) Plasma Nitriding of Titanium AlloysNgọc Minh LêNo ratings yet

- A Seminar Report ON Grinding: Submitted by Rajshree B. Tech (Mechanical Engineering) Third Year Roll No: 160180104039Document21 pagesA Seminar Report ON Grinding: Submitted by Rajshree B. Tech (Mechanical Engineering) Third Year Roll No: 160180104039Raj ShreeNo ratings yet

- Metric Tap Chart with Thread Sizes and Drill SizesDocument1 pageMetric Tap Chart with Thread Sizes and Drill SizessonytechoNo ratings yet

- 87 Computer Simulation of Microstructure Evolution during Hot Forging of Waspaloy and Nickel Alloy 718 ریزساختار 718 فورج داغ PDFDocument10 pages87 Computer Simulation of Microstructure Evolution during Hot Forging of Waspaloy and Nickel Alloy 718 ریزساختار 718 فورج داغ PDFAmir JoonNo ratings yet

- Ballpeenhammer FDocument15 pagesBallpeenhammer FnickoleNo ratings yet

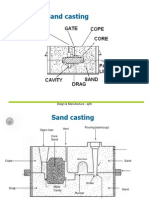

- Recent Advances in Sand CastingDocument25 pagesRecent Advances in Sand Casting9591007896No ratings yet

- AFRICAN OX-CART DESIGNDocument62 pagesAFRICAN OX-CART DESIGNreissmachinistNo ratings yet

- Report Gundriling AAMAstakhovDocument27 pagesReport Gundriling AAMAstakhovGyörgy Murvai100% (1)

- Metal Casting ProcessesDocument173 pagesMetal Casting Processesvishal shindeNo ratings yet

- Hot Working & Cold WorkingDocument34 pagesHot Working & Cold Workingavutu_kunduruNo ratings yet

- Heat Treatment Definition and ObjectivesDocument56 pagesHeat Treatment Definition and ObjectivesAakarsh RastogiNo ratings yet

- About Hot Plate Welding PDFDocument5 pagesAbout Hot Plate Welding PDFmehdi7891No ratings yet

- AbrasivesDocument49 pagesAbrasivesfockewulNo ratings yet

- Shaping Machine Operations GuideDocument25 pagesShaping Machine Operations Guidekatakamharish100% (1)

- Report On Heat Treatment of Plain Carbon Steel Kuet MeDocument11 pagesReport On Heat Treatment of Plain Carbon Steel Kuet MeAhmed JishanNo ratings yet

- Upset Forging of ValvesDocument10 pagesUpset Forging of ValvesSankar KumarNo ratings yet

- Materi PPT Secondary EngDocument5 pagesMateri PPT Secondary EngFanya arifantiNo ratings yet

- Gear and Gear TrainDocument21 pagesGear and Gear Trainm_er100No ratings yet

- Some Interesting Projects in FoundryDocument59 pagesSome Interesting Projects in FoundrySneha KritiNo ratings yet

- Shot Blasting Is A Rapid, Environment Friendly, CostDocument10 pagesShot Blasting Is A Rapid, Environment Friendly, CostSulfikar SalimNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument20 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Uts Material SuperplastisDocument10 pagesUts Material SuperplastisHandrizaHanifAsyrafiNo ratings yet

- ZG AmerikaneriDocument5 pagesZG AmerikaneriTom Whybother100% (1)

- Mechanism of RollingDocument4 pagesMechanism of RollingGanesh Kotipalli100% (1)

- Stress relieving steel at 650°C for 1 hour removes 90% internal stressesDocument4 pagesStress relieving steel at 650°C for 1 hour removes 90% internal stressesAshish BoraNo ratings yet

- Metal Cutting (F) SDocument62 pagesMetal Cutting (F) SBrijesh VermaNo ratings yet

- Size Reduction by Grinding Methods Technical ReportDocument12 pagesSize Reduction by Grinding Methods Technical ReportkrishnaNo ratings yet

- MCP 101 Product Realization Lab ManualDocument75 pagesMCP 101 Product Realization Lab ManualjasvindersinghsagguNo ratings yet

- Design Sand Casting Class IDocument23 pagesDesign Sand Casting Class Iiamajith123No ratings yet

- GrindingDocument52 pagesGrindingRavi Arjun KumarNo ratings yet

- Metal Casting 3Document23 pagesMetal Casting 3bhushan wandreNo ratings yet

- DrillingDocument36 pagesDrillingMax LuxNo ratings yet

- Welding Technology English (Cont.)Document143 pagesWelding Technology English (Cont.)Long Beautéophile100% (1)

- Sheet Metal Forming Methods and Classification GuideDocument103 pagesSheet Metal Forming Methods and Classification Guidegosaye desalegnNo ratings yet

- Is The Lost Foam Process The Future of Metal CastingDocument7 pagesIs The Lost Foam Process The Future of Metal Castingjmtindia100% (2)

- Forging of MetalsDocument31 pagesForging of MetalsSaiful IslamNo ratings yet

- Case Hardening SteelsDocument52 pagesCase Hardening SteelsGururaja TantryNo ratings yet

- Fe Co ElectroformingDocument8 pagesFe Co ElectroformingIsman KhaziNo ratings yet

- Production Process.II (CBCGS) Module.1 Metal CuttingDocument24 pagesProduction Process.II (CBCGS) Module.1 Metal CuttingOmkar BedadeNo ratings yet

- U1Metal Cutting & Tool DesignDocument62 pagesU1Metal Cutting & Tool DesignVansh puriNo ratings yet

- Unit 2 Broaching: StructureDocument8 pagesUnit 2 Broaching: Structurempraga93No ratings yet

- TB Grinding EnglishDocument20 pagesTB Grinding EnglishVk PrabakranNo ratings yet

- MFG Tooling - 09 Progressive Dies PDFDocument16 pagesMFG Tooling - 09 Progressive Dies PDFNhan LeNo ratings yet

- Chapter 4 - Casting ProcessesDocument40 pagesChapter 4 - Casting ProcessesErnawati ZailiNo ratings yet

- Nitriding 2Document9 pagesNitriding 2Haziq MansorNo ratings yet

- Ch17 Metal FormingDocument37 pagesCh17 Metal FormingSaman BrookhimNo ratings yet

- Mill Keyways On LatheDocument1 pageMill Keyways On LatheJim100% (3)

- Jay Holland DetailedDocument5 pagesJay Holland DetailedJay NovaNo ratings yet

- Research and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalDocument12 pagesResearch and Innovations For Continuous Miner's Cutting Head, For Efficient Cutting Process of Rock/CoalKarthii Aju100% (1)

- Introduction To Work HoldingDocument29 pagesIntroduction To Work HoldingAndres Fitria FarrelNo ratings yet

- Cartridge Type Boring BarDocument4 pagesCartridge Type Boring BarvishalNo ratings yet

- Ballpeen HammerDocument3 pagesBallpeen HammerTimberlyNo ratings yet

- CastingDocument56 pagesCastingTushar Prakash ChaudhariNo ratings yet

- Changing The Properties of SteelsDocument21 pagesChanging The Properties of SteelsBHARANINo ratings yet

- Forensic Kuala KetilDocument10 pagesForensic Kuala KetilcalliepearsonNo ratings yet

- Use of Rubber Particles From Recycled TiresDocument11 pagesUse of Rubber Particles From Recycled TirescalliepearsonNo ratings yet

- Chapter 1.1 - Introduction To RCDocument17 pagesChapter 1.1 - Introduction To RCcalliepearsonNo ratings yet

- Project ManagementDocument1 pageProject ManagementcalliepearsonNo ratings yet

- Universiti Tun Hussein Onn Malaysia: ConfidentialDocument8 pagesUniversiti Tun Hussein Onn Malaysia: ConfidentialcalliepearsonNo ratings yet

- Hypothesis TestingDocument1 pageHypothesis TestingcalliepearsonNo ratings yet

- Assignment 1Document2 pagesAssignment 1datonizamNo ratings yet

- Pair Assignment Wk1 To Wk3Document2 pagesPair Assignment Wk1 To Wk3calliepearsonNo ratings yet

- AASHTO Design ExampleDocument10 pagesAASHTO Design ExampleWhy MerahNo ratings yet

- Climatic Change and The Socioeconomic Sustainability of The Paddy Farmers in MalaysiaDocument1 pageClimatic Change and The Socioeconomic Sustainability of The Paddy Farmers in MalaysiacalliepearsonNo ratings yet

- Pair Assignment Wk1 To Wk3Document2 pagesPair Assignment Wk1 To Wk3calliepearsonNo ratings yet

- Introduction To EcDocument15 pagesIntroduction To EceyuyazmiNo ratings yet

- INSTRUCTION: Answer FOUR (4) From SIX (6) Questions. ARAHAN: Sila Jawab EMPAT (4) Dari ENAM (6) SoalanDocument14 pagesINSTRUCTION: Answer FOUR (4) From SIX (6) Questions. ARAHAN: Sila Jawab EMPAT (4) Dari ENAM (6) SoalancalliepearsonNo ratings yet

- Environment Pollution and ControlDocument16 pagesEnvironment Pollution and ControlcalliepearsonNo ratings yet

- B5001Document12 pagesB5001calliepearsonNo ratings yet

- Bs Mini ProjectDocument16 pagesBs Mini ProjectcalliepearsonNo ratings yet

- TW Assignments 2015Document7 pagesTW Assignments 2015calliepearsonNo ratings yet

- Soalan 1: ARAHAN: Sila Jawab EMPAT (4) Dari ENAM (6) Soalan. INSTRUCTION: Answer FOUR (4) From SIX (6) QuestionDocument14 pagesSoalan 1: ARAHAN: Sila Jawab EMPAT (4) Dari ENAM (6) Soalan. INSTRUCTION: Answer FOUR (4) From SIX (6) QuestioncalliepearsonNo ratings yet

- TW Trip Report TemplateDocument2 pagesTW Trip Report TemplatecalliepearsonNo ratings yet

- Assignment 1 RCDocument2 pagesAssignment 1 RCcalliepearsonNo ratings yet

- Inverse HyperbolicDocument3 pagesInverse HyperboliccalliepearsonNo ratings yet

- Movie OstDocument2 pagesMovie OstcalliepearsonNo ratings yet

- Eng Math 1 12/13 BFC 13903Document6 pagesEng Math 1 12/13 BFC 13903calliepearsonNo ratings yet

- UNIT1Document39 pagesUNIT1Mohammad MubarakNo ratings yet

- Further Differentiation and IntegrationDocument11 pagesFurther Differentiation and IntegrationcalliepearsonNo ratings yet

- Natural Gas Brochure 1Document2 pagesNatural Gas Brochure 1calliepearsonNo ratings yet

- UTHM BWM 10103 TEST 1 SOLUTIONSDocument6 pagesUTHM BWM 10103 TEST 1 SOLUTIONScalliepearsonNo ratings yet

- If U F (X) and Can Be Differentiate, Then The Following Formula Can Be Used. 1 SinDocument3 pagesIf U F (X) and Can Be Differentiate, Then The Following Formula Can Be Used. 1 SincalliepearsonNo ratings yet

- Lesson 1Document4 pagesLesson 1calliepearsonNo ratings yet

- Energy and KidsDocument4 pagesEnergy and Kidsapi-270337822No ratings yet

- Onan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750Document92 pagesOnan Service Manual MDJA MDJB MDJC MDJE MDJF Marine Diesel Genset Engines 974-0750GreenMountainGenerators80% (10)

- UNIT FOUR: Fundamentals of Marketing Mix: - Learning ObjectivesDocument49 pagesUNIT FOUR: Fundamentals of Marketing Mix: - Learning ObjectivesShaji ViswambharanNo ratings yet

- Contact and Profile of Anam ShahidDocument1 pageContact and Profile of Anam ShahidSchengen Travel & TourismNo ratings yet

- Service and Maintenance Manual: Models 600A 600AJDocument342 pagesService and Maintenance Manual: Models 600A 600AJHari Hara SuthanNo ratings yet

- Electronics Ecommerce Website: 1) Background/ Problem StatementDocument7 pagesElectronics Ecommerce Website: 1) Background/ Problem StatementdesalegnNo ratings yet

- April 26, 2019 Strathmore TimesDocument16 pagesApril 26, 2019 Strathmore TimesStrathmore Times100% (1)

- 2nd Pornhub Awards - WikipediaaDocument13 pages2nd Pornhub Awards - WikipediaaParam SinghNo ratings yet

- ServiceDocument47 pagesServiceMarko KoširNo ratings yet

- Katie Tiller ResumeDocument4 pagesKatie Tiller Resumeapi-439032471No ratings yet

- Forensic Science From The Crime Scene To The Crime Lab 2nd Edition Richard Saferstein Test BankDocument36 pagesForensic Science From The Crime Scene To The Crime Lab 2nd Edition Richard Saferstein Test Bankhilaryazariaqtoec4100% (25)

- QueriesDocument50 pagesQueriesBajji RajinishNo ratings yet

- Iq TestDocument9 pagesIq TestAbu-Abdullah SameerNo ratings yet

- Kami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Document3 pagesKami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Anna HattenNo ratings yet

- Accomplishment Report 2021-2022Document45 pagesAccomplishment Report 2021-2022Emmanuel Ivan GarganeraNo ratings yet

- HCW22 PDFDocument4 pagesHCW22 PDFJerryPNo ratings yet

- Steam Turbine Theory and Practice by Kearton PDF 35Document4 pagesSteam Turbine Theory and Practice by Kearton PDF 35KKDhNo ratings yet

- Traffic LightDocument19 pagesTraffic LightDianne ParNo ratings yet

- Books of AccountsDocument18 pagesBooks of AccountsFrances Marie TemporalNo ratings yet

- Electronics Project Automatic Bike Controller Using Infrared RaysDocument16 pagesElectronics Project Automatic Bike Controller Using Infrared RaysragajeevaNo ratings yet

- DLL - The Firm and Its EnvironmentDocument5 pagesDLL - The Firm and Its Environmentfrances_peña_7100% (2)

- Annamalai International Journal of Business Studies and Research AijbsrDocument2 pagesAnnamalai International Journal of Business Studies and Research AijbsrNisha NishaNo ratings yet

- Mercedes BenzDocument56 pagesMercedes BenzRoland Joldis100% (1)

- Krok2 - Medicine - 2010Document27 pagesKrok2 - Medicine - 2010Badriya YussufNo ratings yet

- Lankeda 3d Printer Filament Catalogue 2019.02 WGDocument7 pagesLankeda 3d Printer Filament Catalogue 2019.02 WGSamuelNo ratings yet

- Algorithms For Image Processing and Computer Vision: J.R. ParkerDocument8 pagesAlgorithms For Image Processing and Computer Vision: J.R. ParkerJiaqian NingNo ratings yet

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDocument35 pagesMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićNo ratings yet

- SEG Newsletter 65 2006 AprilDocument48 pagesSEG Newsletter 65 2006 AprilMilton Agustin GonzagaNo ratings yet

- CR Vs MarubeniDocument15 pagesCR Vs MarubeniSudan TambiacNo ratings yet

- Coffee Table Book Design With Community ParticipationDocument12 pagesCoffee Table Book Design With Community ParticipationAJHSSR JournalNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)