Professional Documents

Culture Documents

Organic Rankine Cycle

Uploaded by

moh1234bukOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Organic Rankine Cycle

Uploaded by

moh1234bukCopyright:

Available Formats

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

The Organic Rankine Cycle

Power Production from Low Temperature Heat

Hartmut Spliethoff, Andreas Schuster

Institute for Energy Systems Technische Universitt Mnchen

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Contents

Introduction

History Recapitulation Clausius Rankine Cycle

State of the Art Applications

Biomass Combustion Geothermal Power Plants

Innovative Applications

Solar Desalination with Organic Rankine Cycle Waste-heat recovery from biomass digestion plants

Conclusion and Outlook

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Who was the Rankine - cycles father ?

William John Macquorn Rankine * 5th July 1820 24th December 1872 Scottish physicist and engineer one of the founders of thermodynamics important contributions to the theory of steam engine

WJM Rankine

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

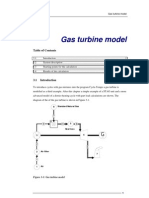

Assembly of a steam power station

Boiler House

(steam generator)

Turbine House

(steam turbine, condenser, generator)

Cooling Towers

Boiler

Steam Turbine

G

Generator

Coal Stockyard

Condenser

Flue Gas Cleaning

(dust removal, nitric oxide M removal, desulphurization)

Jrgen Karl

Feed Pump

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Power range and efficiency of common power machines for external combustion

1000

Steam Power Plants

power range [MW] 100 10 1 0,1 0,01 0 20 40 efficiency [%]

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006 5

Organic Rankine Cycle Steam Engine Stirling Engine

Jrgen Karl, Dezentrale Energiesysteme

60

80

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

The Organic Rankine Cycle an application for small power range

The ORC uses organic substances instead of water as working fluid Silicone Oils Hydrocarbons Fluorocarbons

water organic fluids

Organic fluids lead to higher turbine efficiencies due to the higher mass flow (leakage ) low maintenance operation good part load behavior

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006 6

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

The Organic Rankine Cycle an application for small power range and external heat source

Turbine

temperature [C] temperature [ C]

200 500

400 150

100 bar

44

Heat 4 Exchanger

Boiler

biomass boiler geothermal heat waste heat

2 3 4 3 Steam 2

Generator

300

100 200 50 100

22 1 1

2 2

25 bar

33 44

5 6

3 5

10 bar

Turbine

5 G

Generator

10 bar

5 bar

x=0 x= ,2 0,2

5

Condenser

0 0

00

0,0 1,0

1 1

0,4 0 ,4

,6 0 ,6

0,8

00

1 bar

8 0,8

p=1 bar p=0,05 bar

55

6 1 0 0

District Heating Network Cooling Tower Condenser

2,0 4,0 6,0 8,0 1,2 1,4 1,6 1,8 10,0 2,0 spezific entropy [kJ/kgK] spezific entropy [kJ/kgK]

1

Feed Pump Pump Feed

M

(dust removal, nitric oxide M removal, desulphurization)

Availaible in a power range up to 1500 kW MW

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

ORC with recuperator without recuperator

temperature [C]

200

150

25 bar

3

10 bar

100

1

x= 0 ,2

0, 4

0,6

5 bar

5 5 6

50

5

0

p=1 bar

1,0

1,2 1,4 1,6 1,8 spezific entropy [kJ/kgK]

0,8

2,0

Expansion does end in the area of superheated steam 5 Sensible Heat of steam ( 5 - 6 ) can be used for preheating the liquid working fluid

8

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

State of the Art Applications

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

ORC Unit from Turboden, Brescia Italy

Units from 500 kW up to 1500 kW available Standardized Product

Rekuperator Condenser

Evaporator

Turbine Generator Feed Pump

Units are delivered completely assembled to installation site

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

10

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Biomass Combustion

Thermo oil loop

G

Sauerlach 700 kWel

Toblach 1500 kWel

Organic Rankine Cycle

Fuach 1100 kWel

11

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Insertion

dependency of electric efficiency of exhaust gas losses of biomass boiler flow temperature / return temperature thermo oil 270 C / 220 C

Electric Efficiency 1012 % Manufacturer information of 1618 % dont include the furnace

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

12

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Geothermal Power Plants

ORC System

15-110 m/h 21C, 120-395 m/h

Return Cooler

28C

Water processing

Well

www.geothermie.de

Altheim 1000 kWel

www.geothermie.de

Neustadt-Glewe 210 kWel

98C

Bore Hole

Injection Bore Hole

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

13

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Innovative applications

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

14

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Innovative stand-alone solar desalination system with an Organic Rankine Cycle

Collector Loop

Organic Rankine Cycle

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Osmosis Process

15

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Design Criteria for ORC with solar heat

Scroll expander for mechanical power in the range of 10 kW Scroll expander is a positve displacement expansion machine Different working fluids offer nearly the same efficieny Fluid with efficiency maximum at the lowest posssible temperature fits best

5,6 R227 R245fa 5,4 5,2 R236fa 5,0 4,8 R134a 4,6 4,4 4,2 4,0 50 75 100 125 150 live steam temperature [ C]

cycle efficiency [%]

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

16

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Status of the project

The project is succesfully finished The expander efficiency is between 60 and 70 % over a wide operation range The cycle efficiency is around 4 % The fresh water production is approximately 320 l/h with a thermal input of 35 kW

The research was done in the framework of the project RO-Solar-Rankine (COOPCT-2003-507997) funded by the European Comission. Therefore the TU Mnchen is much obliged.

17

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

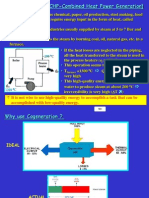

Waste-heat recovery from biomass digestion recovery with low temperature ORC plants

Organic Waste Energy Crops

Gainful use of the excess heat of the IC engine is important for the economic and energetic efficiency Only 2025 % of the waste heat of the engine is needed for heating the digester The characteristics of heat demand and the location of the digestion plants is hindering for the use of waste heat in district heating networks enhanced electricity production by the application of ORC

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

Manure

Desulphurization Biogas IC engine

Grid

Fermenter

Biogas tank

ORC System

18

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Case Study for biomass digestion plant

Thermo oil loop Test Rig at TUM

IC engine

Organic Rankine Cycle

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006 19

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Case Study for biomass digestion plant

Combustion Engine 555 kW Deutz TCG 2016 V12 Electrical Power 537 kWel Exhaust gas temperature of ~ 490 C Additional Power production of 35 kWel equivalent to an efficiency gain of 2.6 % With an interest rate of 5 % and 7.500 full load hours electricity production cost of 5.65 Ct/kWh can be reached

5 Ct

O.R.

6C

t

t 7C

8C t

9C

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

20

Lehrstuhl

Energie Systeme

Prof. Dr.-Ing. H. Spliethoff

Conclusions:

Organic Rankine Cycles are a modification of the well known Clausius Rankine Cycle The use of organic fluids offer various advantages The ORC technology for electricity production from biomass and geothermal heat is state of the art ORCs are also suitable for waste-heat recovery and power production from solarthermal heat these applications are subject of further research ORC linked with Reverse Osmosis is a promising possibility for seawater desalination

Electricity generation, combined heat and power Strasbourg, 14 -16 September 2006

21

You might also like

- Stavanger Tourist SpotDocument96 pagesStavanger Tourist Spotregupathi6413No ratings yet

- Citric Acid Passivation of Stainless SteelDocument41 pagesCitric Acid Passivation of Stainless Steelnqh2009100% (2)

- Ebsilon Basis ABB Indialearn About Power Plant Modeling Using EBSILONDocument81 pagesEbsilon Basis ABB Indialearn About Power Plant Modeling Using EBSILONPAdmanaban1967No ratings yet

- Power Tube Biasing Operation Manual 15-01-08Document2 pagesPower Tube Biasing Operation Manual 15-01-08MitchNo ratings yet

- Latest Technologies Supercritical & Igcc: Presented byDocument61 pagesLatest Technologies Supercritical & Igcc: Presented bymvpngpNo ratings yet

- Trouble Shooting and Problems of A CFBC Unit PDFDocument72 pagesTrouble Shooting and Problems of A CFBC Unit PDFgangaraoNo ratings yet

- Optimization of Startups - RTPDocument11 pagesOptimization of Startups - RTPmoh1234buk100% (1)

- GEOELEC - Binary-Plant Pisa BombardaDocument41 pagesGEOELEC - Binary-Plant Pisa BombardajparmarNo ratings yet

- 1000 MW Thermal Power PlantDocument31 pages1000 MW Thermal Power PlantJ Murugadasan100% (3)

- Chapter-8 Turbine and Governor TestingDocument10 pagesChapter-8 Turbine and Governor Testingafru2000No ratings yet

- Small Scale Organic Rankine Cycle (ORC) A Techno-Economic ReviewDocument26 pagesSmall Scale Organic Rankine Cycle (ORC) A Techno-Economic ReviewJoao MinhoNo ratings yet

- PepsicoDocument18 pagesPepsicorahil virani0% (1)

- Coal Blending With Fly Ash-An ApproachDocument28 pagesCoal Blending With Fly Ash-An ApproachcaptainrajneeshNo ratings yet

- Energyauditofboiler 161207011009Document38 pagesEnergyauditofboiler 161207011009Randy PrandykaNo ratings yet

- BR GT GasturbineDocument9 pagesBR GT GasturbineVioleta Patriche100% (1)

- Gas Engine FundamentalsDocument13 pagesGas Engine Fundamentalsherdin56No ratings yet

- Reference LAC50 DMDocument41 pagesReference LAC50 DMVivek Singh100% (1)

- Organic Rankine Cycles (Henrik Xhman)Document40 pagesOrganic Rankine Cycles (Henrik Xhman)Kazim Raza100% (1)

- 2 ERG 401 2015 Energy Performance Analysis of BOILERDocument57 pages2 ERG 401 2015 Energy Performance Analysis of BOILERnaveenNo ratings yet

- Combined CycleDocument34 pagesCombined Cycleatulsemilo100% (2)

- List of Power Stations in India Power SectorDocument16 pagesList of Power Stations in India Power SectorkprsannaNo ratings yet

- ORC Waste Heat-HoldmannDocument27 pagesORC Waste Heat-Holdmannbart.amaral3771100% (2)

- Chapter RankineDocument32 pagesChapter RankineZack ZukhairiNo ratings yet

- Use in Air Conditioning: Air Conditioning Air Handling Units Sensible Heat Latent HeatDocument7 pagesUse in Air Conditioning: Air Conditioning Air Handling Units Sensible Heat Latent Heatprasha_patNo ratings yet

- ReportDocument19 pagesReportMainak Vk ChatterjeeNo ratings yet

- Ultrasupercritical Technology in Thermal Power PlantDocument12 pagesUltrasupercritical Technology in Thermal Power PlantChintan Patel100% (1)

- Ash ReinjectionDocument22 pagesAsh Reinjectiongaol_bird009No ratings yet

- Coal Fired Power PlantDocument56 pagesCoal Fired Power PlantAugustine Owo Ukpong100% (1)

- Turboden ORC BrochureDocument13 pagesTurboden ORC BrochureSandeep Trichal100% (1)

- Energy Audit & Efficiency Improvement of Operating Power PlantsDocument56 pagesEnergy Audit & Efficiency Improvement of Operating Power Plantsmhdsoleh100% (1)

- Versant ModifiedDocument57 pagesVersant ModifiedAryan Kharadkar100% (3)

- Feasibility Study Report (1) ESPDocument32 pagesFeasibility Study Report (1) ESPrajanarsuNo ratings yet

- Extending the Range of Single-Shaft Combined Cycle Power PlantsDocument12 pagesExtending the Range of Single-Shaft Combined Cycle Power PlantsSrinivasa Rao PallelaNo ratings yet

- Organic Rankine CycleDocument22 pagesOrganic Rankine Cyclebondut100% (2)

- SST700Document4 pagesSST700Davichín Morató FernandezNo ratings yet

- Qoaider CSP EnerMENA PresentationDocument24 pagesQoaider CSP EnerMENA PresentationDr alla talal yassinNo ratings yet

- Thermodynamic and Economic Analysis of A Binary Geothermal Power Plant Feasibility Study4Document24 pagesThermodynamic and Economic Analysis of A Binary Geothermal Power Plant Feasibility Study4Angela Paul PeterNo ratings yet

- 2015-Dynamic Simulation and Experimental Validation of AnOrganic Rankine Cycle ModelDocument284 pages2015-Dynamic Simulation and Experimental Validation of AnOrganic Rankine Cycle ModelSsheshan PugazhendhiNo ratings yet

- Organic Rankine CycleDocument6 pagesOrganic Rankine CycleAdrian RajendraNo ratings yet

- Rankine Cycle SumDocument76 pagesRankine Cycle Sumمحمد تانزيم ابراهيم100% (1)

- Thermal Power Plant: Prepared by Mr.M.Boominathan, Maintenance Engineer, Mrungtamines LTD, OdishaDocument22 pagesThermal Power Plant: Prepared by Mr.M.Boominathan, Maintenance Engineer, Mrungtamines LTD, OdishaAnonymous JgPHsDNo ratings yet

- National Mission on Advanced Ultra-Supercritical TechnologyDocument3 pagesNational Mission on Advanced Ultra-Supercritical TechnologyAnuragNo ratings yet

- Rankine Cycles Modeling and Control. Ylva TeleDocument55 pagesRankine Cycles Modeling and Control. Ylva TeleSyed Anas SohailNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat Exchangerdieuhien0210No ratings yet

- TTPS Overview ReportDocument9 pagesTTPS Overview ReportJabin Joe50% (2)

- Thesis - Exergy - A Useful ConceptDocument377 pagesThesis - Exergy - A Useful Conceptdanpopescu4u100% (1)

- Thermodynamic Cycles OverviewDocument29 pagesThermodynamic Cycles Overviewcr anamNo ratings yet

- Pnacj953 PDFDocument395 pagesPnacj953 PDFSwaroop KumarNo ratings yet

- Minimum Load/Ramp Test Procedure For Coal Based Thermal Power Plants (TPPS)Document36 pagesMinimum Load/Ramp Test Procedure For Coal Based Thermal Power Plants (TPPS)Honcho Abhi SinhaNo ratings yet

- Thermo Flow Brochure 2002Document14 pagesThermo Flow Brochure 2002marco_a_salasNo ratings yet

- Boiler Warburton 1981Document197 pagesBoiler Warburton 1981Sai AravindNo ratings yet

- Gas Turbine Cycle TempoDocument3 pagesGas Turbine Cycle TempoReza TeflissiNo ratings yet

- Design and Analysis of Fire Tube Boiler With Heat Flow AnalysisDocument3 pagesDesign and Analysis of Fire Tube Boiler With Heat Flow Analysisbez100% (1)

- Report On Jamshoro Thermal Power PlantDocument24 pagesReport On Jamshoro Thermal Power PlantSuresh Kumar100% (2)

- Coal-Fired Power Plant Heat Rate Improvement Options, Part 1 - PowermagDocument12 pagesCoal-Fired Power Plant Heat Rate Improvement Options, Part 1 - PowermagRavi Satyapal100% (1)

- Once Through and Drum Type Boiler Designs ComparedDocument3 pagesOnce Through and Drum Type Boiler Designs ComparedagusfaizinNo ratings yet

- Types of Thermal Energy StorageDocument4 pagesTypes of Thermal Energy StorageVinayak MuleyNo ratings yet

- Gas Turbine PPT SeminarDocument17 pagesGas Turbine PPT SeminarPrabhat GuptaNo ratings yet

- Steinmueller Broschuere 1Document46 pagesSteinmueller Broschuere 1andri.motoGNo ratings yet

- Thesis Jose EstevezDocument108 pagesThesis Jose EstevezSeptian Khairul MasdiNo ratings yet

- Handout 1 - EES TutorialDocument7 pagesHandout 1 - EES TutorialLindi NewmanNo ratings yet

- Heat Exchangers: Types, Design Parameters, and Analysis MethodsDocument52 pagesHeat Exchangers: Types, Design Parameters, and Analysis MethodsSyazwan WanNo ratings yet

- The Concept of Exergy and Energy Quality - Truls GundersenDocument26 pagesThe Concept of Exergy and Energy Quality - Truls Gundersenuser_account100% (1)

- Simple ORC Model SQ110918Document9 pagesSimple ORC Model SQ110918radanpetricaNo ratings yet

- Indonesia IPP AnnexDocument41 pagesIndonesia IPP AnnexUranika L WireksoNo ratings yet

- Analysis and Perspective On Heat Pump For IndustriDocument27 pagesAnalysis and Perspective On Heat Pump For IndustriJianping TangNo ratings yet

- C9 Part3 V2Document33 pagesC9 Part3 V2Emin ÇelikNo ratings yet

- PHD Thesis On Thermal Power PlantDocument6 pagesPHD Thesis On Thermal Power Plantafkneafpz100% (1)

- Production of R-134a: BackgroundDocument12 pagesProduction of R-134a: Backgroundmoh1234bukNo ratings yet

- Absorption Chiller ApplicationDocument2 pagesAbsorption Chiller Applicationmoh1234bukNo ratings yet

- UPSC IFS Botany Syllabus: Paper - IDocument3 pagesUPSC IFS Botany Syllabus: Paper - IVikram Singh ChauhanNo ratings yet

- EVOLUTION Class Notes PPT-1-10Document10 pagesEVOLUTION Class Notes PPT-1-10ballb1ritikasharmaNo ratings yet

- CSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineDocument48 pagesCSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineKislan MislaNo ratings yet

- Product:: Electronic, 2 C #18 STR TC, PE Ins, OS, PVC JKT, CMDocument2 pagesProduct:: Electronic, 2 C #18 STR TC, PE Ins, OS, PVC JKT, CMAnonymous XYAPaxjbYNo ratings yet

- Advanced Composite Materials Design EngineeringDocument19 pagesAdvanced Composite Materials Design EngineeringpanyamnrNo ratings yet

- Overlord - Volume 01 - The Undead KingDocument223 pagesOverlord - Volume 01 - The Undead KingPaulo FordheinzNo ratings yet

- Unit 4.2Document45 pagesUnit 4.2Gundrathi Narendra GoudNo ratings yet

- Chapter 4 Cost MinimizationDocument6 pagesChapter 4 Cost MinimizationXavier Hetsel Ortega BarraganNo ratings yet

- Meningitis & EncephalitisDocument7 pagesMeningitis & EncephalitisABAKADANo ratings yet

- IotDocument88 pagesIotLalithyaNo ratings yet

- Qand ADocument5 pagesQand AJoshua PascasioNo ratings yet

- Ch3 XII SolutionsDocument12 pagesCh3 XII SolutionsSaish NaikNo ratings yet

- Arta Fridei Kahlo A Fost Intotdeauna o ReactieDocument13 pagesArta Fridei Kahlo A Fost Intotdeauna o ReactieAlta DaianNo ratings yet

- The Relevance of Vivekananda S Thought IDocument16 pagesThe Relevance of Vivekananda S Thought IJaiyansh VatsNo ratings yet

- Fund. of EnterpreneurshipDocument31 pagesFund. of EnterpreneurshipVarun LalwaniNo ratings yet

- Shaw-Box Hoist - 700 Series Electric Wire Rope 10 To 25 Ton Manual PDFDocument68 pagesShaw-Box Hoist - 700 Series Electric Wire Rope 10 To 25 Ton Manual PDFMbalekelwa MpembeNo ratings yet

- CE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingDocument36 pagesCE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingCelil OrakNo ratings yet

- Edexcel A-Level Biology Experimental Design Marks Scheme (1) (Full Permission)Document16 pagesEdexcel A-Level Biology Experimental Design Marks Scheme (1) (Full Permission)FardeenKhanNo ratings yet

- SC Earthquake GuideDocument8 pagesSC Earthquake GuideNevin SmithNo ratings yet

- Surface Hardening enDocument20 pagesSurface Hardening engtm1207No ratings yet

- Specs Mantilla UV BT8800 Oct 2014Document2 pagesSpecs Mantilla UV BT8800 Oct 2014Julio MendezNo ratings yet

- Nitocote WP DDocument4 pagesNitocote WP DdaragNo ratings yet

- Lab Manual Cape Bio Unit 1 2023Document37 pagesLab Manual Cape Bio Unit 1 2023drug123addict25No ratings yet

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDocument31 pagesAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcNo ratings yet