Professional Documents

Culture Documents

Transformers

Uploaded by

Yenny TigaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transformers

Uploaded by

Yenny TigaCopyright:

Available Formats

TRANSFORMERS A transformer is a device in which an input alternating current produces an output alternating current of different voltage.

A step-up transformer results in an increased voltage. A step-down transformer results in a decreased voltage. The transformer itself consists of two separate coils, a primary and a secondary, usually wound around a soft iron core, to intensify the magnetic field in the primary. The transformer works on the principle of mutual induction. An alternating current flows in the primary, thus creating changing magnetic fields that thread through the secondary. Thus, there is a changing magnetic flux in the secondary coil, which produces a current in that coil. Since the magnetic field is changing at a given frequency, the current induced in the secondary coil is also an alternating one. If the secondary coil contains more turns of wire than the primary, the transformer will be a step-up one. If the secondary coil contains less turns of wire than the primary, the transformer will be a step-down one. A step-up transformer is shown below.

Mathematically:

where VP = primary voltage, VS = secondary voltage, NP = number of turns of wire in primary coil and NS = number of turns of wire in secondary coil.

In an ideal transformer no energy is lost and so the energy input is the same as the energy output per unit time. We can write this as: Power in = Power out VP IP = VS IS

From which we have:

This formula implies that in a step-up transformer, although the output voltage is higher than the input voltage, the output current is lower than the input current. This is a direct consequence of the conservation of energy law. Clearly, if the output current did not decrease compared to the input current, VS IS would be greater than VP IP and energy would have been created from nothing. Similarly for step-down transformers, the output voltage is lower than the input voltage but the output current is higher than the input current. From a practical point of view, transformers need to be designed carefully. There are many sources of potential energy losses in transformers, heat losses in the coils, heat losses in the core due to eddy currents and possible magnetic leakage. The eddy currents in the core are induced by the changing magnetic fields threading through the transformer. To reduce the effect of eddy currents, the core is made of layers called laminations separated by thin insulating layers, rather than being one solid block of metal. Modern transformers operate with around 99% efficiency and have many practical applications. Perhaps the most important application is in the transfer of electrical energy from a power station to its point of use. Energy losses in power transmission lines can be shown to be proportional to I2R. Clearly, the lower the current, the lower the energy loss in the line. For this reason, the 240 V power produced by the generators at a power station is stepped up by transformers to very high voltages (220 kV to 500 kV) before being transmitted from the power station. In this way the current flowing in the transmission lines is very low and energy loss in the lines is minimised. (Also, lower currents mean that smaller diameter transmission lines can be used, which leads to savings in materials and construction costs.) In order to be used by the various consumers, the voltage needs to be stepped down to the required value. This happens at electricity sub-stations, where transformers step the high voltage down to 240 V for domestic use or other particular values for industry and public transport (e.g. electric trains). Transformers are also used in certain electrical appliances in the home that are connected to the mains domestic power supply. For example, transformers in the 1 to 100 watt power level are often used as step-down transformers to couple electronic circuits to loudspeakers in radios, television sets, and Hi-Fi equipment. In many electronic devices a number of different voltages are required for normal operation. Transformers are used to convert the 240 V mains supply voltage to the required voltage. This can be achieved by having several secondary coils wrapped around the primary or by having one secondary coil and tapping into it after the appropriate number of turns of wire.

You might also like

- Reference List of Drawings: Pwo NoDocument45 pagesReference List of Drawings: Pwo Nowaveengg.coNo ratings yet

- Samsung CL29K3W Chassis KS3ADocument92 pagesSamsung CL29K3W Chassis KS3AHernan Ortiz EnamoradoNo ratings yet

- Working of Tesla CoilDocument3 pagesWorking of Tesla CoilSagar Sikchi100% (1)

- Revision Checklist For O Level Physics 5054 FINALDocument24 pagesRevision Checklist For O Level Physics 5054 FINALYenny Tiga100% (3)

- Wires and Connections Component Circuit Symbol Function of ComponentDocument8 pagesWires and Connections Component Circuit Symbol Function of ComponentHanim HusaifNo ratings yet

- HCIA-Data Center Facility V1.0 Mock ExamDocument3 pagesHCIA-Data Center Facility V1.0 Mock ExamaguilaspyNo ratings yet

- EM - 2010 - M - Power - Factor PDFDocument7 pagesEM - 2010 - M - Power - Factor PDFagustantoNo ratings yet

- Sag-Electrical Installation and Maintenance NciiDocument3 pagesSag-Electrical Installation and Maintenance NciiCris Licsi Mantes75% (4)

- PQ Unit-1Document25 pagesPQ Unit-1HariNarayanNo ratings yet

- Maths Igcse Scheme of Work 0580 - 2010Document6 pagesMaths Igcse Scheme of Work 0580 - 2010Yenny Tiga100% (2)

- Power Electronics AssignmentsDocument5 pagesPower Electronics AssignmentsDavidz GanNo ratings yet

- Maths Igcse Scheme of Work 0580 - 2011Document6 pagesMaths Igcse Scheme of Work 0580 - 2011Yenny TigaNo ratings yet

- Examiner Tips For O Level Physics 5054Document10 pagesExaminer Tips For O Level Physics 5054muzaahNo ratings yet

- GEN. Back Up PROTECTIONDocument33 pagesGEN. Back Up PROTECTIONsabeerNo ratings yet

- Maths IGCSE Scheme of Work 0580 - 2012Document3 pagesMaths IGCSE Scheme of Work 0580 - 2012Yenny TigaNo ratings yet

- Y R R Y B N: Motor Blower Trip IndDocument3 pagesY R R Y B N: Motor Blower Trip IndZunnur ZamzamNo ratings yet

- ReportDocument21 pagesReporthrishikesh anvekarNo ratings yet

- Step Recovery DIODEDocument9 pagesStep Recovery DIODEwoyaoxiaxiaNo ratings yet

- 0102 - Forever Flasher PDFDocument3 pages0102 - Forever Flasher PDFMuhammadAsifNo ratings yet

- Switching Over Voltages in Air-Insulated Substation c4 - 301Document8 pagesSwitching Over Voltages in Air-Insulated Substation c4 - 301rdcatano4267No ratings yet

- Manual Portable Aircond MideaDocument18 pagesManual Portable Aircond Mideamalaikat maut100% (1)

- ECS 11-0003 Testing and Commissioning Guidance NotesDocument48 pagesECS 11-0003 Testing and Commissioning Guidance NotesEzeldeen AgoryNo ratings yet

- Type of Lasers-Nd:Yag and Nd:GlassDocument2 pagesType of Lasers-Nd:Yag and Nd:GlasstonikNo ratings yet

- BETA-2 Pancake Geiger TubeDocument4 pagesBETA-2 Pancake Geiger TubeqqazertyNo ratings yet

- Plasma Device and TechnologyDocument27 pagesPlasma Device and Technologymahmoud EissaNo ratings yet

- Satellite Antenna System With Arduino by Umesh Ghodke K6VUG (FARS)Document17 pagesSatellite Antenna System With Arduino by Umesh Ghodke K6VUG (FARS)Pradeep KumarNo ratings yet

- Driver Lamparas Fluorescentes 12 VoltsDocument7 pagesDriver Lamparas Fluorescentes 12 VoltsDiego García MedinaNo ratings yet

- Maths Igcse Scheme of Work 0580 - 2012Document3 pagesMaths Igcse Scheme of Work 0580 - 2012Yenny TigaNo ratings yet

- Voltage Sag NotesDocument53 pagesVoltage Sag NotesHariNarayanNo ratings yet

- Maths Introduction Igcse Extended 3 YrsDocument9 pagesMaths Introduction Igcse Extended 3 YrsYenny TigaNo ratings yet

- Maths Introduction Igcse Extended 3 YrsDocument9 pagesMaths Introduction Igcse Extended 3 YrsYenny TigaNo ratings yet

- Noark On-Grid Inverter Catalogue 2023 V1.0Document32 pagesNoark On-Grid Inverter Catalogue 2023 V1.0Mary Dunlap100% (1)

- Mini Tesla Coil ProjectDocument7 pagesMini Tesla Coil ProjectabinashNo ratings yet

- Topic6 TransfomerDocument40 pagesTopic6 TransfomerLucas GabrielNo ratings yet

- Tutorial Exercises On Transformer: Introduction To Electrical Machine (Course Code-Emeg2261)Document2 pagesTutorial Exercises On Transformer: Introduction To Electrical Machine (Course Code-Emeg2261)Hanan Shayibo100% (1)

- SodiumDocument4 pagesSodiumGopal VenkayyaNo ratings yet

- Katalog RKS LAST 12 02 2019 ONEPAGE PDFDocument18 pagesKatalog RKS LAST 12 02 2019 ONEPAGE PDFivicaNo ratings yet

- Buzzer SpeakerDocument4 pagesBuzzer SpeakerEla100% (1)

- PLama Arc SpeakerDocument6 pagesPLama Arc SpeakerRomina GuadagniniNo ratings yet

- Mini Tesla Coil Project PDFDocument11 pagesMini Tesla Coil Project PDFDrishti Uppal100% (1)

- MS Research Proposal 1stDocument14 pagesMS Research Proposal 1stabeer fatimaNo ratings yet

- Project Proposal Plasma SpeakerDocument3 pagesProject Proposal Plasma Speakerapi-283530338No ratings yet

- Permit To Work Self Assesment ChecklistDocument3 pagesPermit To Work Self Assesment Checklistஹரிஹரசுதன்No ratings yet

- HVI Products PresentationDocument33 pagesHVI Products PresentationAhmad HidayatNo ratings yet

- Mini Tesla Coil Project PDFDocument11 pagesMini Tesla Coil Project PDFDrishti UppalNo ratings yet

- The History of Gas-Insulated SubstationsDocument7 pagesThe History of Gas-Insulated SubstationsMaharajaNo ratings yet

- Tesla CoilDocument6 pagesTesla CoilKim AffandiNo ratings yet

- DRSSTC Current TransformersDocument5 pagesDRSSTC Current TransformerseqwqweNo ratings yet

- Trafoindo Catalogue Oil Immersed TransformersDocument2 pagesTrafoindo Catalogue Oil Immersed TransformersOcktafriandi HendraNo ratings yet

- Wireless ElectricityDocument26 pagesWireless ElectricityJames jill100% (1)

- Design and Implementation of A Bidirectional DC-DC Converter For Stand-Alone Photovoltaic SystemsDocument12 pagesDesign and Implementation of A Bidirectional DC-DC Converter For Stand-Alone Photovoltaic SystemsIfan Seven SeasNo ratings yet

- 1000W 1500W 2000W Big Formart CW Fiber Laser Cleaning Machines PDFDocument5 pages1000W 1500W 2000W Big Formart CW Fiber Laser Cleaning Machines PDFVisi ArtNo ratings yet

- How To Make 250 To 5000 Watts PWM DC AC 220V Power InverterDocument22 pagesHow To Make 250 To 5000 Watts PWM DC AC 220V Power Invertermaster chibuking100% (1)

- Ee8261 - Engineering Practices Laboratory: Syllabus Group B (Electrical & Electronics) A.Electrical Engineering PracticeDocument24 pagesEe8261 - Engineering Practices Laboratory: Syllabus Group B (Electrical & Electronics) A.Electrical Engineering PracticeSenthil IlangovanNo ratings yet

- Control of A DC Motor DriveDocument25 pagesControl of A DC Motor DrivePoliConDrive0% (1)

- Voltage Sag DistributionDocument7 pagesVoltage Sag DistributionSravan KumarNo ratings yet

- Superconducting Fault Current LimitersDocument47 pagesSuperconducting Fault Current LimitersSanthosh GuduruNo ratings yet

- Class 12 Physics ProjectDocument14 pagesClass 12 Physics ProjectSRIJAN MANI TRIPATHINo ratings yet

- Spin Valve TransistorDocument22 pagesSpin Valve Transistorbvenugopal_2No ratings yet

- Cocu 1 - Three Phase DrawingDocument11 pagesCocu 1 - Three Phase DrawingHardiySarawakNo ratings yet

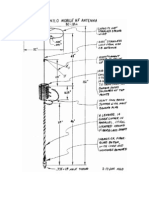

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- Vacuum InterrupterDocument2 pagesVacuum InterrupterpattarawatNo ratings yet

- 32e 06 PDFDocument5 pages32e 06 PDFAnnisa Fikri SNo ratings yet

- Automatic Load SharingDocument41 pagesAutomatic Load SharingSaravanan ViswakarmaNo ratings yet

- Salzer Catelouge1 PDFDocument32 pagesSalzer Catelouge1 PDFnitin hadkeNo ratings yet

- Cascade Arrangements of TransformersDocument3 pagesCascade Arrangements of TransformerstutorrituNo ratings yet

- How To Make A Joule ThiefDocument1 pageHow To Make A Joule ThiefRestorEleCisco100% (1)

- Wave Let TransformDocument6 pagesWave Let Transformnirmal_inboxNo ratings yet

- CommaxDocument24 pagesCommaxEduard PopescuNo ratings yet

- ElbaDocument17 pagesElbacathytingNo ratings yet

- Lab Sheet Teknologi Elektrik No 1-Rev1Document11 pagesLab Sheet Teknologi Elektrik No 1-Rev1semi2542No ratings yet

- GEDP & DDF PresentationDocument20 pagesGEDP & DDF Presentationmohsinaliqureshi02No ratings yet

- Load Characteristics: M. Afnan HabibiDocument32 pagesLoad Characteristics: M. Afnan HabibiAnesia AlferdoNo ratings yet

- Lab 5 Diode As Rectifier BBN 10205 (Done)Document10 pagesLab 5 Diode As Rectifier BBN 10205 (Done)Zhamir ZhakwanNo ratings yet

- Exercise: Use The Table Above As A Guide To Answer The Following QuestionsDocument1 pageExercise: Use The Table Above As A Guide To Answer The Following QuestionsYenny TigaNo ratings yet

- Physics Presentation - Haadi & AqilDocument11 pagesPhysics Presentation - Haadi & AqilYenny Tiga100% (1)

- Electrostatic NotesDocument9 pagesElectrostatic NotesYenny TigaNo ratings yet

- Notes - Radiation Related TermsDocument7 pagesNotes - Radiation Related TermsYenny TigaNo ratings yet

- 2011 ThermometerDocument1 page2011 ThermometerYenny TigaNo ratings yet

- Decay EquationsDocument1 pageDecay EquationsYenny TigaNo ratings yet

- Pressure ExerciseDocument2 pagesPressure ExerciseYenny TigaNo ratings yet

- Cie o Level Physics Syllabus For Year 2012Document46 pagesCie o Level Physics Syllabus For Year 2012Sakib Ex-rccNo ratings yet

- Kinematics, VectorDocument1 pageKinematics, VectorYenny TigaNo ratings yet

- Maths Introduction CoverDocument1 pageMaths Introduction CoverYenny TigaNo ratings yet

- A Guide To Additional Results Reporting June 20101Document4 pagesA Guide To Additional Results Reporting June 20101Mohsin SadiqNo ratings yet

- Work Energy Cartoon DiscussionDocument2 pagesWork Energy Cartoon DiscussionYenny TigaNo ratings yet

- Energy Conversion and ConservationDocument4 pagesEnergy Conversion and ConservationYenny TigaNo ratings yet

- Physics Resistance ExDocument1 pagePhysics Resistance ExYenny TigaNo ratings yet

- Chapter: Work, Energy & Power Work: Case Description Work Done? ExplanationDocument1 pageChapter: Work, Energy & Power Work: Case Description Work Done? ExplanationYenny TigaNo ratings yet

- Index of Refraction& Snells WorksheetDocument1 pageIndex of Refraction& Snells WorksheetYenny Tiga0% (1)

- Uses of RadioactivityDocument2 pagesUses of RadioactivityYenny TigaNo ratings yet

- TransformerDocument3 pagesTransformerYenny TigaNo ratings yet

- Travel and Tourism SOW - Front Page (Word 97-2003)Document38 pagesTravel and Tourism SOW - Front Page (Word 97-2003)Yenny Tiga100% (3)

- ResistanceDocument1 pageResistanceYenny TigaNo ratings yet

- Transformer 1Document1 pageTransformer 1Yenny TigaNo ratings yet

- Sumo Robot PCB AssemblyDocument15 pagesSumo Robot PCB AssemblyBayu Kresna WiratamaNo ratings yet

- New Microsoft Word DocumentDocument6 pagesNew Microsoft Word DocumentSanket KareNo ratings yet

- Relay For Controlling Level of Conductive Liquids en / End: Operating Principle TypesDocument4 pagesRelay For Controlling Level of Conductive Liquids en / End: Operating Principle TypesJemerald MagtanongNo ratings yet

- Speed Fax SiemensDocument92 pagesSpeed Fax SiemensbethonetNo ratings yet

- Paneles de Distribucion GeDocument89 pagesPaneles de Distribucion GeLuis D UrciaNo ratings yet

- Chapter 8: DC Machine Fundamentals: e (V X B) LDocument29 pagesChapter 8: DC Machine Fundamentals: e (V X B) LMuhammad R ShihadehNo ratings yet

- Full Wave Rectifier Single Phase ReportDocument10 pagesFull Wave Rectifier Single Phase ReportAmer Al-khorasaniNo ratings yet

- Transient Voltage Suppressor (TVS) DiodesDocument24 pagesTransient Voltage Suppressor (TVS) DiodesGiovanni GonzalezNo ratings yet

- Solutions Week6 PracticeProblems ArpinDocument5 pagesSolutions Week6 PracticeProblems ArpinTalha SadiqNo ratings yet

- Lec 1 Introduction 19 Series EEE 2205Document22 pagesLec 1 Introduction 19 Series EEE 2205Nasif TahmidNo ratings yet

- Bushing CatalogueDocument5 pagesBushing CatalogueNiaz Hussain PanhwarNo ratings yet

- Symbols: Name of Electrical/Electronic Symbol Schematic SymbolDocument10 pagesSymbols: Name of Electrical/Electronic Symbol Schematic SymbolRamesh ParmarNo ratings yet

- Accuspin 1R 120V 230VDocument70 pagesAccuspin 1R 120V 230VAndrew Holmes100% (1)

- Asic Library DesignDocument12 pagesAsic Library DesignS RAVINo ratings yet

- Diode Rectifier TutorialDocument6 pagesDiode Rectifier TutorialCephas Mpandika KalemboNo ratings yet

- Pathway Separation Between Telecommunication Cables and Power CablesDocument4 pagesPathway Separation Between Telecommunication Cables and Power CablesVíctor CasadoNo ratings yet

- DC MotorsDocument6 pagesDC MotorsLord8 MatiraNo ratings yet

- Earthing System Design Criteria and Calculation: ProjectDocument9 pagesEarthing System Design Criteria and Calculation: Projectcherif yahyaouiNo ratings yet

- MMA WELDING PRODUCT REPAIR PROCESS OF GYSMI 160P 1 - 16. Auteur - Alexis Gillet Date - 30 - 06 - 2016.Document16 pagesMMA WELDING PRODUCT REPAIR PROCESS OF GYSMI 160P 1 - 16. Auteur - Alexis Gillet Date - 30 - 06 - 2016.jakalae5263No ratings yet

- CheckFire Suppression SC-N ManualDocument43 pagesCheckFire Suppression SC-N ManualFrancisco RojasNo ratings yet

- Lot (1) - RFQ-Drawing - Bayt As-Sultan H.CDocument20 pagesLot (1) - RFQ-Drawing - Bayt As-Sultan H.CMOHAMMED. HAKAMINo ratings yet

- Ina 125Document18 pagesIna 125Prasad SasidharanNo ratings yet

- Codigos de Error LG InverterDocument2 pagesCodigos de Error LG InvertercipaarzuNo ratings yet

- 100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDocument7 pages100 VOLT 30 AMP H-Bridge PWM Motor Driver/Amplifier: M.S.Kennedy CorpDaniel SanchezNo ratings yet