Professional Documents

Culture Documents

Sample Report - Greeked Text

Uploaded by

Joshua RaincloudCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample Report - Greeked Text

Uploaded by

Joshua RaincloudCopyright:

Available Formats

Sample report.

Some items of text have been obscured

The Queen's University of Belfast Mechanical & Manufacturing Engineering Stage 2 - Gearbox Design Project 2010/2011

David Thornhill

Summary Ooxx oxxooo oxxxoxoxx oox xoxxx o oxxxxo xoooxxo ooxo xxx oox xxooxxo oo oox xoxxx o oxxxxo xooxox xoxoxo. Xo oox xoxoo oo oox oxxo xo xooxoxoxxo oxxxxo xxxxxoxxxoxoo xxx xoooxoxo ooxo oxooxoxo xxooooxxoxx oxxxxoxxxoox ooo x oxo xoxxx xxxooox. Xxoxxoxoxxox xxox xoxoxxxo oo oxoxoxxox xxo oxxxxo xxoxxxoxox xoo xxoxxo xoxooxoo xoxxooxooxo x xoxo oo oox xxoxxoxoxxox xx xoxoxoxo xo ooxx oxxooo. Xxoo xxo xxoxxxoxox xoo xoxxooxoox xxoxxoxo oox oxxo oo oox xxxooox xxx oxoxoxo xxxox Xooxoxooxx oo xoooxxx x ox xooxo xooxo. Xoo xxxxxox oo oox oxxxxo xxxxxoxxxoxoo xxox xxoxxoxxo xoo x ox xooxo xxx xoooxxxo ooxo xoxoo xooox xoxxoxxoxox ooxxxoxx oo ox xxoxoxoxo ooo xxoxoxxoxox. Ooox oox xooxo xooxo x xxxxox ooxxxox xxx xoooxxxo oo oox xxxoxxxx.

Contents

Page No.

1 Design overview ..................................................................................................................... 1 1.1 Introduction ...................................................................................................................... 2 1.2 Xoxxo xoxoo .................................................................................................................... 3 1.3 Xxoxoxoo ......................................................................................................................... 5 1.4 Oxoxxo xoxoo .................................................................................................................. 5 1.5 Xooxoxooxo oxoxxox ..................................................................................................... 6 1.6 Solid modelling ................................................................................................................ 7 1.7 Conclusions ..................................................................................................................... 7 Appendix 1 - Design specification ............................................................................................ 8 Appendix 2 - Design spreadsheets ........................................................................................ 10 A2.1 Gear stress analysis - Stage 1 ................................................................................. 11 A2.2 Gear stress analysis - Stage 2 ................................................................................. 13 A2.3 Gear forces ................................................................................................................. 15 A2.4 Shaft and key size selection ..................................................................................... 16 A2.5 Input shaft loads and bearing selection .................................................................. 17 A2.6 Midshaft loads and bearing selection...................................................................... 18 A2.7 Output shaft loads and bearing selection ............................................................... 19 A2.8 Midshaft and output shaft gearwheel press fits ..................................................... 20 Appendix 3 - Marking ............................................................................................................... 21

List of figures Figure 1: Figure 2: Figure 3: Figure 4: Figure 5: Figure 6: Xxxoxoo oxxx oo xxxooox ....................................................................................... 2 Xoxxo xoxoo .............................................................................................................. 3 Xxoxoxoo ................................................................................................................... 4 Oxoxxo xoxoo ........................................................................................................... 5 Xxxooox oxoxxo ........................................................................................................ 6 Xxooxxo xxxoxoo oo xxxo xxxx ooooxxo xxoxx xoo ooxxo xxo oooxx ............ 7

1 Design overview

Page 1 of 23

1.1 Introduction Oxxxxoxo oo ooxoxxxo oo xxoo xoxxo xxoo xo xoxxo xoxoo xxxxo oo oxox oxooxxo oox xxxooox oxx x oxoxxoxoo oxoxo oo oxo. Oox ooxxxox ooo oox xxxooox xx xxox oo xxxo xoxxxoxxx xoooo ooo oxxoo xxxxoo xoxox oox xoxoox xoo xxxox xox oo xxxx oxooxoxo xoxxo ooo xxxxxxx oxxoxoxox oxox xoo oxoxxoxoxoo. Oox oxxxxo xoxxoxo xx xooxo xo xxxoxoo xo Figure 1.

Oxooxo

Ooxxo Xoxx

Figure 1: Xxxoxoo oxxx oo xxxooox Page 2 of 23

Oox oxxxxo xx oxoxoxoxoo xoooxooxooxo xxoo oo xxxxxxo oxxoxoxx ooo xooxoxo xo xoxxx o oxxxxo oxxoxoxx. Oox oooxx xoxoox xox xxxxoooxo oo oxxxxo ooooxo oxxoxoxx xxoo x xxooxxx oxox oo oxo oooxxxoo ooxox. Oox xxxox ooxxxxooxx oxox x oxxxxoxo oxox oo oxxooo oxox oooxxxoo ooxox. Oxooxxxoxoo ooo oox oxxoxoxx xoo xxxox xx xoooxoxo oo xxoxxo oxooxxxoxoo. X oxooxo xoxx xoo ooxxo xoxx xox xoooxoxo oo xooox oxo oo ox ooxxxo xx xooxoo ooxxoxo. Ooxxx xox xooxo xo Oxxxox o.

Oxxoxox Xooxxox Xooxxox o

Xxoxxo

Oxxo oo ooo xxxo

Xxooo

Oxoxxxo xoxoo

Figure 2: Xoxxo xoxoo 1.2 Xoxxo xoxoo Oxxxox oxooxx x xxxoxoo ooooxxo oox xoxxo xoxoo. Oox xoxoo xx xxoooxo xo oooo xoox oo oxxxoxoxox xxxxoxox xoxxoxxoo oo oox xoxoo xoxo xo xx ooxoxoxooxo oxoxxxo xxxoxoxx: oxoox, xooxoooxxxo xoxooxo, xxxo ooooxo. Xooxoxxox xox xoooxoxo xo oox xoxoo, oxxo oo xooxoo oxxxxoxox, xoxox oox xoxoo xoxoxxx oxxxxoxo. Ooxx xoxoxoox ooxooxox oo oox xoooxox oo oox xoxooxox xoxxo, xo xoooxxoxoo, xxxxox xo xxxxxo oo xoooxxx xxooxxooo xooxoooxxxo oxxxxoxox oo oox xoxoo. Oox oxxoo oxoo oxxoxox xx oxoxxo ooxo oox oxoo xx xo oxx oo xxooxoxoo xxxxo ooxox xxoxoxoxo oo oox oxoxxxo xxxox xoo oox xxxxo xoxxooxoo xxoxoxoxo oo oox oxoxxo ooxo xxoxox oo oox oxoo oxxoxox. Oo xoxxox oox xoxoo xx xooxxooo xxxxoooxo xxxxooo oo oox oxxoxoxx, xooxooxox xox xoooxoxo oo oox xoxoo ooxo xoxo xxxxoxo oox xooxo oxxxxxox oo oox oxo oxxoxoxx. Oxx oo oox oxxxxoxo oo oox xoxoo xoo xxoxoo oxxoo xo xx oxxxxxxoo ooo oox oxxoo oo ox xxo ooooxxo oox oxoo oxoo oxxoxoxx xoxoxxoo xooxooxo. Oox oxxxxoxo oo oox xoxoo xx oxoxxxo oo oox oxxoo oo oox xxoxoo xo ooxo oox xxxo ooo xxo xxo oox xxoxoo oxxoo xxoooxo oxoxox oo xxo xooo oox xoxoo oxoooo oox xxooo oo oox xxoxoo. Oox oxxxxoxo oo oox xoxoo xx xoxoxxxxo xxxxo oxxo oo oox oxxoxox oo xoooxox xo xoxxxxox xoxoxxoo oxxxxoxo. Page 3 of 23

Oo xoxxox oox oxxxo ooooxo oxxoxoxx xox xooxxooo xooxxoxo xo ooxo ooxox xx oo oxoxxo xoxxoxoxx x oxxx xoxxxo oxxoxox xooxxoxo xx xxxoxxo oo oox oxxoo oxoo oxxoxox. Xox xoxxoxoo xx xooxoxo oo x xxo xxoxx xooxxoxoox ooox oox oxoxxox oo oox xxxoxxxx. Oox xooxxoxo xx oxxoxo xo ooxo xo ooxx ooo oxo oo oox xooxo oxxxxxo oo oox oxxoxox. Oo xoxoxoo oxo xxxxxxox ooox oox xxxoxxxx x oxoxxo oxx xxxo xx xxxoxxo oo oox xoxxo xoxoo oxxo oo oox oxoo oxoo oxxoxox. Xooooxxo ooo xooxo oo oox xooxo, oox xoxoo oxxxxoxo xx o.1xx oxxx xoxox oox xxxo oxxoxoxx ooxo xoxox oox oxxoxox xx xo xoxxx. Ooxx xx xo oox xxxo xxooxxx xx ooo xxxooxo xoxo oox oxxoxox, xoxxo xx x oxxoo xooxooxoxoxx oxo, xx xxxoxo oooo oox xoxoo. Xo ooxo oox xxxo ooxx ooo xxo oxxxxxo oxoxox xxxxxooo x xoxooox oxxo oo oxxxo xx xooxo oo oox xoxoo. X xxxxoxo oxxo oo xx xoooxoxo ooo oox xxxo xo oox xxxoxxxx oo xxo xox xxxxxooo. Xo xxxooxoxxoxoo xxoxo xxoxxo xx ooxxoxo xo oox xoxoo oo ooxoxxxo oooxxx ooox x ooxox oxo oo oox xxxooox. X xxxoo xooxooxo xx xoxxoxoox oo oox xoxoo oxxo oo oox xxoxxo oo xxxx xxox ooxo xoxo oox ooxox oxo xx ooxxoxo oo oox xoxoo xo xxoooo xoxx xooo xoooxxo xxoo oox xxxoxxxx. Oox xoxoo oo oox oxoo oo oox xxoxxo xx oxoxxxo xo oxxxxoxo xoo xx oooxxoxo oo xooox oox ooxox oxo oo ox oxoo xo xoxxx.

Figure 3: Xxoxoxoo

Page 4 of 23

1.3 Xxoxoxoo Oox xxoxoxoo, xooxo xo Oxxxox o, xoxoxoxx oox xxxooo xoxxx xxoxoo xoxxo xx xxoxoxxoxoxo xooxxoxooo xxoo oox xoxoo xoo oox oxoxo xoxxx xxxoxoxxo xoxxo xx xxoxoxxoxoxo xxxxoxoxoo oxo xx ooxxxo oo oox xoxoo xxxox xo xooxooxoxoxx oxo. Oox oxxoo oxoo oxxoxox xoxox oxoxxo xxoo x xooxooxo oo oox xoxoo oxo oox oxoo oxoo oxxoxox xoxox xxoo oox oxo oo oox xxxoxoxxo. Xo oooxo oxxxxxox oox xoxoo xoxoxoxx xxxxoxo oxoxxox oo oox xoxxo xoxoo.

Xxxoxooxoxo Oxo xxxoxo Oxoxxo oxx OXooox

Oxxo oo ooo OOxxo oo ooo oxoxxo Xxxo Figure 4: Oxoxxo xoxoo 1.4 Oxoxxo xoxoo Oox oxoxxo xoxoo, Oxxxox o, xxxx x oxxx-oo-oxxx oxxoxox xooxoxxxxoo xoo xoxxoxoxx xooxxoxxoo ooo oox oxxxo ooooxo oxxoxoxx xx xoooxoxo oo x xxxoxooxoxo oxo xoo oxo xxxoxo xooxxxoo oo oox oxxoo-oxoo oxxoxox. Oox xxxoxoxxo xx xo xooxooxoxoxx oxo oo oox xoxoo xoo xx xxxxooo ooxxoxo oo x xooxooxo oo oox oxooxoxo xoo oo oox xoxoo. Oo xoxoxoo oxxxxxx oo oxo x oxoxxo oxx xxxo oxox oo x xoooxo ooxo xx ooxxoxo oo oox xoxoo oxxo oo oox xxxoxooxoxo oxo. Oox xoooxo xoooxoxx xo xoxoxxxxo xoxoxxoo oxxxxoxo ooo xoo ooxox oxo xoxooxo oo oox xoo oo oox xoxoo. Ooo oox xxoxoxxx oo oxxxxxxxooo oox xoooxo xx x xoxoxox oxo oo oox xoxoo xo oox xxoxxx oo oxo xxxo ooxx oxo xx xoxoxooxo oo xo O-oxox. Xo oxxx xxooxo, oox xoooxo oxx x xoxooox oxxo oo xo xxxo xoo oo xooox xox xxxxxooo, xxooxo xxo xooxoo, xxoooxo oxxxxxox oox oxoxxo oxx xxxo. Oox xoo oo oox xoooxo xooooxoxx oxoooo oox xoo oo xox xxxxoooxox oxxxxoxo oo Page 5 of 23

Xxxxo

oox xoxoo xo ooxo xo xxoo ox xoxxxxo xo xoxxx xxxxooo xoxo x ooxox oxo xx xxxxoxo oo oox xoxoo. X xxoxxo xx xoooxoxo oo xoxxxxox xxox oo ooxoxxxo oox oooxxx oo oox ooxox oxo xoxxo xxo ox xxxxoxo xo xoxxx oo xo xooxooxo oooxxo xo oox xoxoo. Xx oox oxoxxo oxx xxxo xx oo xxxooxo oxxxxoxo ooxo oox oxxxo ooooxo oxxoxoxx xo xx xoxooxo xo x ooxxxox xoxxo xx xooxxoooxxxooo xoxxoxo xxoo oox xoxoo oo x xxxxoo xoxxo xx x xoxxxxxoo oxo xo x xoooo xoxooxo oooxo oxxxxoxo xo oox xxxo xxxx oxxo oo oox oxooxoxo oxxoxox.

Xxxxo

Oxoxx o

Xoxooxox oxox

Oxoxx xxo Figure 5: Xxxooox oxoxxo 1.5 Xooxoxooxo oxoxxox Oxxxox x xooxx oox oxoxxo xoxx oo oox xxxooox. Xxoooxooxox oox oxoxxo xoxoo xx x xoxooxox oxox ooxo xoooxx oox xxxooox oo ox ooooxo oo oooxo xxxoxox xoxxooxoox oo xox xxx xxoxx ooxxxx. Oo oxxxoxoxox xooxxoooxx xoxxoxxoo oo oox xxxooox oox xoxooxox oxox xoxooxooxoxx x xxxxoo ooxo xx xxxxoxoxoo xoxxoxo xxoo oox oxxoxox oooxx. Xxoxxooxxxoxo oo oox oxoxxo xoxoox xxxx oox xoxooxox oxox xoooxoxx x ooxo xxooxxx oo xoxoo oo. Oo xoxoxoo xoxxoxox xxoo xoxooxo xoxxooxoox, oo oooxo oxxoxox oo oox xxxooox xooooxoxx xooox ooxx xxooxxx oxoxxox oo oox xoxooxox oxox. Oxxo oxoxxox oo oox oxooxox oo oox xoxooxox oxox xox oxo oxoxx xxox. Ooxo xox oxxxxoxo ooo xxoxoxxoxoxox xxoxoxxx xoo xxoox oo oooxo oxoxoxooxo xxoxoxx. Page 6 of 23

Xoxxxooxxo xxx-

Ooxxo xxo

Figure 6: Xxooxxo xxxoxoo oo xxxo xxxx ooooxxo xxoxx xoo ooxxo xxo oooxx Oox oxo oxooxx oo oox xxxo xxxx xox xxxxoxo ooxxooxo xxxox oxo 65xx ooox X8 xoxxxooxxo xxx-xxoxxx. Oo xoxxox oox oxo xxxxx xox xoxxxxxoo xoxxoxo xxoo xxxo oooxo, oxo ooxxo xxox xox xoxoxxxo oxooxo oo xxxxoxoxoo xxxoxoxo oooxx; oox xo oox oox oo oox xxxx xoo oox xo oox ooooox. Oxxxox x xooxx x xxooxxo xxxoxoo ooooxxo oox xxxxo ooxxo xxo ooox xoo xooxxxoo xxoxx ooox; xo xxoo ox oooxo ooxo ooxox xx xoxxoxoxx xo oox xoo oo oox ooxxo xxo ooox xo oox oxxooxoxo xxxx xo ooxo oox ooxxo xxo xxo oxoxo xoxoxoo oox oxo xxxxx ooox oxxox xxoxxxo oxoxoo ooxxooxo. Oox xxxo oxoxxxo oox oxo xxxxx xxoo ox xxoxxoxo xxxox oxxxxo xxxxxo.

1.6 Solid modelling To the best of my knowledge there were no features of the design that I was unable to achieve because of the limitations of the solid modelling software. 1.7 Conclusions Xoo xxxxxox oo oox oxxxxo xxxxxoxxxoxoo xxox xxoxxoxxo xoo x oo xooxo xxx xoooxxxo ooxo xoxoo xooox xoxxoxxoxox ooxxxoxx oo ox xxoxoxoxo ooo xxoxoxxoxox. X xoxo oo oox oxxxxo xxxxxoxxxoxoo xx xoxoxoxo xo Xxxxooxx o xoo xoxxxx oo oxxxxo xxoxxoxoxxox xox xoxoxoxo xo Xxxxooxx o. Ooox oox xooxo xooxo x xxxxox ooxxxox xxx xoooxxxo oo oox xxxoxxxx xoo ooxx xx xoxoxoxo oooxx xxoo ooxx oxxooo.

Page 7 of 23

Appendix 1 - Design specification

Page 8 of 23

Gearbox design specification

Senior Designer and Project Engineer: David Thornhill Introduction: Although a specific application for the gearbox has yet to be determined it is likely to find application in the aerospace industry. As such, it is important that the design is optimised to provide the required power capacity at the minimum weight. It may be assumed that the installed attitude of the gearbox will remain constant.

Specification: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Gearbox to use two gear stages Speed ratio between input and output shafts: 12:1 Speed of input shaft: 3000 rev/min Power capacity (at input shaft): 14 kW The input shaft and the intermediate shaft are to be vertically above the output shaft. The output shaft is to allow drive to be taken from either side of the gearbox. Direction of input shaft rotation viewed on end is clockwise. Lubrication is to be by oil splash. Gears to have a minimum life of 20000 hrs Minimum gear stress safety factor: 1.2 Gears to be of helical form ( 20 - 30 helix angle) to minimise noise, vibration and harshness (NVH) Gears are to be sufficiently wide that the helix causes at least one tooth to be in full mesh at all times on each gear pair. Individual gear pair ratios to make use of hunting teeth. Bearings should have a life of 10000 hrs with 90% reliability. If, however, it can be proven that the bearings become unacceptably large a reduced service life may be specified that will allow smaller bearings to be utilised. The input shaft will be subject to a maximum radial load (N) of 10 x the input torque (Nm). This will act vertically downwards on the shaft at a distance of 25 mm from the outermost surface of the gearbox case. The output shaft is not subjected to any external radial loading. The gearbox is to provide adequate mounting feet to support itself and any reactions due to the torque and forces acting on the input and output shafts. The input and output shafts are to be equipped with keyways of proportions adequate to transmit the required torque.

15.

16. 17. 18.

Page 9 of 23

Appendix 2 - Design spreadsheets

The following spreadsheets have been revised from their originally submitted and marked form to reflect changes to the design that were necessary during the solid modelling stage of the project.

Page 10 of 23

A2.1 Gear stress analysis - Stage 1

Senior designer Geometry Module (mm) Facewidth (mm) Helix angle (deg) No of teeth Gear ratio Centre distance (mm) Reference diameter (mm) Pitch diameter (mm) Tip diameter (mm) Root diameter (mm) Quality Grade (1-12) Surface finish - Flank (micro m Ra) Surface finish - Root (micro m Ra) Material Material Quality (A, B or C) UTS (MN/m^2) UTS Core (MN/m^2) Surface hardness (HV) Surface hardening Case depth (mm) Post hardening operation Operation Gear speed (rev/min) Required life (hours) Application factor, KA Kinematic viscosity of lubricant at 40 C (mm^2/s) Power (kW)

Notes: 1. Typically the module size of the second stage will be the next size up from the first stage. Generally, if the permitted stress levels are much higher than the actual stress levels the module size should be reduced. 2. If the gear face widths are too small the module size should be reduced. Try to keep in the range 20 30. 3. Face width must be greater than: m/tan( ) , where m is the module and is the helix angle.

David Thornhill Comment 1.50 20.00 20.00 84 4.42 82.21 30.33 134.09 30.33 134.09 33.33 137.09 26.58 130.34 Comment 5 0.80 3.20 5 0.80 3.20 19

Steel Steel B B 2300 2300 1000 1000 700 700 Case hardened 0.30 0.30 Very light grind

3000.0 678.6 25000 1 115 14

Page 11 of 23

Contact stress Speed and lubrication factor, ZL*Zv Roughness factor, ZR Material quality factor, ZM Work hardening factor, ZW Size Factor, ZX Life factor, ZN Minimum demand safety factor Casedepth factor, Zc Disc/gear correction factor, ZG Endurance limit for contact stress for discs (MN/m^2) Endurance limit for contact stress for gears (MN/m^2) Permissible contact stress (MN/m^2) Zone factor, ZH Elasticity factor, ZE Contact ratio factor, Z epsilon Dynamic factor, Kv Transverse load factor, KH alpha Face load factor, KH beta Nominal tangential force acting on teeth at ref circle (N) Actual calculated contact stress (MN/m^2) Root bending stress Life factor, YN Surface condition factor, YR Size factor, YX Material quality factor, YM Sensitivity factor, Y delta Minimum demand safety factor Residual stress due to post heat treatment finish (MN/m^2) Basic endurance limit of polished specimen under a reversing bending load (MN/m^2) Permissible bending stress (MN/m^2) Tooth form factor, YF Stress correction factor, YS Helix angle factor, Y beta Transverse load factor, KF alpha Face load factor, KF beta Actual bending stress (MN/m^2) Sub surface bending stress Residual stress due to post heat treatment finish (MN/m^2) Permissible bending stress (MN/m^2) Actual bending stress (MN/m^2) 240 380 120.376 240 380 102.9011 1.0 0.905 1.0 0.9 1.027 1.2 -400 560 750.8 1.544 1.837 0.833 1.150 1.350 368.6187 362.2568 1.0 0.905 1.0 0.9 1.033 1.2 -400 560 755.7 1.320 2.112 0.931 0.945

Comment

0.900 1.000

0.900 1.000

1.000 1.000 1.000 1.2 1.2 1.000 1.000 0.838 0.899 2130 2130 1783.993 1915.021 1177.68 1264.176 2.371 189 0.804 1.025 1.150 1.433 2939 1141.739 1141.739 Comment

Comment Over Eng

Over Eng

Page 12 of 23

A2.2 Gear stress analysis - Stage 2

Senior designer Geometry Module (mm) Facewidth (mm) Helix angle (deg) No of teeth Gear ratio Centre distance (mm) Reference diameter (mm) Pitch diameter (mm) Tip diameter (mm) Root diameter (mm) Quality Grade (1-12) Surface finish - Flank (micro m Ra) Surface finish - Root (micro m Ra) Material Material Quality (A, B or C) UTS (MN/m^2) UTS Core (MN/m^2) Surface hardness (HV) Surface hardening Case depth (mm) Post hardening operation Operation Gear speed (rev/min) Required life (hours) Application factor, KA Kinematic viscosity of lubricant at 40 C (mm^2/s) Power (kW)

Notes: 1. Typically the module size of the second stage will be the next size up from the first stage. Generally, if the permitted stress levels are much higher than the actual stress levels the module size should be reduced. 2. If the gear face widths are too small the module size should be reduced. Try to keep in the range 20 30. 3. Face width must be greater than: m/tan( ) , where m is the module and is the helix angle.

David Thornhill Comment 2.50 24.00 20.00 57 2.71 103.76 55.87 151.65 55.87 151.65 60.87 156.65 49.62 145.40 Comment 5 0.80 3.20 5 0.80 3.20 21

Steel Steel B B 2300 2300 1000 1000 700 700 Case hardened 0.40 0.40 Very light grind

678.6 250.0 25000 1 115 14

Page 13 of 23

Contact stress Speed and lubrication factor, ZL*Zv Roughness factor, ZR Material quality factor, ZM Work hardening factor, ZW Size Factor, ZX Life factor, ZN Minimum demand safety factor Casedepth factor, Zc Disc/gear correction factor, ZG Endurance limit for contact stress for discs (MN/m^2) Endurance limit for contact stress for gears (MN/m^2) Permissible contact stress (MN/m^2) Zone factor, ZH Elasticity factor, ZE Contact ratio factor, Z epsilon Dynamic factor, Kv Transverse load factor, KH alpha Face load factor, KH beta Nominal tangential force acting on teeth at ref circle (N) Actual calculated contact stress (MN/m^2) Root bending stress Life factor, YN Surface condition factor, YR Size factor, YX Material quality factor, YM Sensitivity factor, Y delta Minimum demand safety factor Residual stress due to post heat treatment finish (MN/m^2) Basic endurance limit of polished specimen under a reversing bending load (MN/m^2) Permissible bending stress (MN/m^2) Tooth form factor, YF Stress correction factor, YS Helix angle factor, Y beta Transverse load factor, KF alpha Face load factor, KF beta Actual bending stress (MN/m^2) Sub surface bending stress Residual stress due to post heat treatment finish (MN/m^2) Permissible bending stress (MN/m^2) Actual bending stress (MN/m^2) 240 380 138.9686 240 380 123.6383 1.0 0.905 1.0 0.9 1.027 1.2 -400 560 751.2 1.523 1.855 1.0 0.905 1.0 0.9 1.032 1.2 -400 560 754.6 1.355 2.046 0.904 0.945

Comment

0.900 1.000

1.000

0.900 1.000

1.000 1.2 1.000 0.871 2130 1854.393 1188.587

1.000 1.2 1.000 0.902 2130 1920.23 1230.785

2.371 189 0.807 1.008 1.150 1.240 7053 1164.107 1164.107 Comment

0.833 1.150 1.182

379.1003

371.9306 Comment Over Eng

Page 14 of 23

A2.3 Gear forces

Senior designer

Specification Gear ratio Input speed (rev/min) Power (kW) Gears Gear 1 2 3 4 12 3000 14

Dr D. Thornhill

Module 1.50 1.50 2.50 2.50

Helix Angle 20.00 20.00 20.00 20.00

Number of teeth 19 84 21 57

Ref Dia mm 30.33 134.09 55.87 151.65

Speed rev/min 3000.00 678.57 678.57 250.00

Torque N.m 44.56 197.02 197.02 534.76

Gears tooth forces Gear Tangential N 1 2938.7 2 2938.7 3 7052.8 4 7052.8

Separating N 1138.2 1138.2 2731.7 2731.7

Axial N 1069.6 1069.6 2567.0 2567.0

Acting to L or R R L R L

Page 15 of 23

A2.4 Shaft and key size selection

Shaft and key size

Input shaft size Torque (N.m) Shaft allowable shear stress, a ( N / mm 2 ) Shaft diameter under key, d uk (mm) Key width, b (mm) Key height, h (mm) Key depth in shaft, t 1 (mm) Shaft outside diameter at keyway, d (mm) Input shaft key size Key allowable shear stress, a ( N / mm 2 ) Key allowable compressive stress, a ( N / mm 2 ) Shaft outside diameter, d (mm) Key width, b (mm) Key height, h (mm) Minimum key length by shear, l s (mm) Minimum key length by compression, l c (mm) Standard key length (mm) 44.56 205.00 10.35 6.00 6.00 3.50 18.00

137.00 275.00 18.00 6.00 6.00 6.02 6.00 18.00

Output shaft size Torque (N.m) Shaft allowable shear stress, a ( N / mm 2 ) Shaft diameter under key, d uk (mm) Key width, b (mm) Key height, h (mm) Key depth in shaft, t 1 (mm) Shaft outside diameter at keyway, d (mm) Output shaft key size Key allowable shear stress, a ( N / mm 2 ) Key allowable compressive stress, a ( N / mm 2 ) Shaft outside diameter, d (mm) Key width, b (mm) Key height, h (mm) Minimum key length by shear, l s (mm) Minimum key length by compression, l c (mm) Standard key length (mm)

534.76 205.00 23.68 10.00 8.00 5.00 34.00

137.00 275.00 34.00 10.00 8.00 22.96 28.60 32.00

Midshaft size, d (mm)

26

117 Fill in the cells highlighted in beige with your own values or values from tables, as appropriate, and enter appropriate formulas into the remaining cells to determine the shaft sizes and key lenths.

Page 16 of 23

A2.5 Input shaft loads and bearing selection

Input shaft loads and bearing selection

10xT I

R 1v a c

r1

Fa1 Fs1 b

R 2v

R 1h a c Ft1 b

R 2h

Variables a b c Reactions

19 74.25 51

mm mm mm

Gear width Left gap Right gap

24 3 40

Vertical Horizontal Combined Bearings Part No. C a T e Y

R1 (N) 123.2 2186.7 2190.1

R2 (N) -815.8 752.0 1109.5

Fill in the cells highlighted in beige with your own values and enter appropriate formulas into the remaining cells to determine the bearing reactions and bearing lives

Left (A) Right (B) 32005X 32205B 27000 35800 11 16 15 19.25 0.43 0.57 1.4 1.05

Fr/Y Test Ax Force Fa/Fr P L10 ( 10 6 ) Hours % New C ?

1564.4 1056.7 -253.9 782.2 1851.8 0.357 1.669 2190.1 2388.2 4328.1 8306.0 24045.2 46144.4 240.5 461.4 20752 22628

117

Page 17 of 23

A2.6 Midshaft loads and bearing selection

Midshaft loads and bearing selection

Fs2 Fa2 r2 Ft2

R 3v

Fa3 Fs3 b c

r3

R 4v

R 3h Ft3 b c

R 4h

Variables a b c Reactions

19.25 45.25 70.5

mm mm mm

Gear width Pinion width Left gap Right gap

20 32 3 3

Vertical Horizontal Combined Bearings Part No. C a T e Y Fr/Y Test Ax Force Fa/Fr P L10 ( 10 6 ) Hours % New C ?

R3 (N) 1883.3 -4662.3 5028.3

R4 Rightward (N) (N) -3476.8 -5329.2 1497.4179 6363.1

Left (A) Right (B) 32206 32206 50100 50100 15 15 21.25 21.25 0.37 0.37 1.6 1.6 3142.7 3976.9 417.1 1571.3 3068.8 0.313 0.482 5028.3 7455.2 2128.4 572.7 52277.6 14066.1 522.8 140.7 30503 45226

Fill in the cells highlighted in beige with your own values and enter appropriate formulas into the remaining cells to determine the bearing reactions and bearing lives

117

Page 18 of 23

A2.7 Output shaft loads and bearing selection

Output shaft loads and bearing selection

Fs4 Ft4

Fa4

r4

R 5v b

R 6v

R 5h b

R 6h

Variables a b

19 58.0

mm mm

Gear width Gap Bearing gap

24 0 20

Reactions R5 (N) 6982.4 9363.2 11680.0 R6 (N) -4250.7 -2310.4 4838.0 Fill in the cells highlighted in beige with your own values and enter appropriate formulas into the remaining cells to determine the bearing reactions and bearing lives

Vertical Horizontal Combined Bearings Part No. C a T e Y Fr/Y Test Ax Force Fa/Fr P L10 ( 10 6 ) Hours % New C ?

Left (B) Right (A) 33109 33109 84200.00 84200.00 19.00 19.00 26.00 26.00 0.37 0.37 1.60 1.60 7300.0 -2138.1 3650.0 0.313 11680.0 723.7 48246.7 482.5 52514 3023.8 6217.0 1.285 11882.4 683.4 45561.5 455.6 53424

117

Page 19 of 23

A2.8 Midshaft and output shaft gearwheel press fits

Midshaft and output shaft gear wheel press fits

Midshaft Gear tooth root diameter, D (mm) Shaft nominal diameter at press fit, d (mm) Length of press fit, l (mm) Young' modulus for gear ( kN / mm 2 ) Allowable shear stress for gear ( N / mm 2 ) Contact pressure based on shear stress ( N / mm 2) Hoop stress, h ( N / mm 2 ) Radial stress, r ( N / mm 2) Maximum interference on diameter, MAX (mm) Hole in gearwheel Shaft diameter Upper limit of size (mm) Lower limit of size (mm) Upper limit of size (mm) Lower limit of size (mm) 31.025 31.000 31.060 31.044 0.019 59.27 894.7 4.54 130.34 31.00 20.00 205.00 200.00 188.69 211.31 -188.69 0.060

Minimum interference on diameter, MIN (mm) Contact pressure based on min interference ( N / mm 2) Torque capacity of joint (N.m) Safety factor

Output Shaft Gear tooth root diameter, D (mm) Shaft nominal diameter at press fit, d (mm) Length of press fit, l (mm) Young' modulus for gear ( kN / mm 2 ) Allowable shear stress for gear ( N / mm 2 ) Contact pressure based on shear stress ( N / mm 2) Hoop stress, h ( N / mm 2 ) Radial stress, r ( N / mm 2) Maximum interference on diameter, MAX (mm) Hole in gearwheel Shaft diameter Upper limit of size (mm) Lower limit of size (mm) Upper limit of size (mm) Lower limit of size (mm) 46.025 46.000 46.090 46.074

145.40 46.00 24.00 205.00 200.00 179.98 220.02 -179.98 0.090

Minimum interference on diameter, MIN (mm) Contact pressure based on min interference ( N / mm 2) Torque capacity of joint (N.m) Safety factor

0.049 98.26 3919.03 7.328566

117

Page 20 of 23

Appendix 3 - Marking

Page 21 of 23

Report (10%)

Poor 0 - 39

Adequate 40 - 49

Good 50 - 59

V. Good 60 - 69

Excellent 70 - 84

Exceptional 85 - 100

Overall Presentation Quality of Figures Quality of Discussion TOTAL

Gearcase Drawing (15%) Are all views correct and relevant (0 - 3%) Datums properly defined (0 - 4%) Geometric tolerances (0 - 2%) Dims to correct datums (0 2%) All dimensions available (0 2%) Are notes free from errors (0 2%) TOTAL

Mark

Comment

Penalty marks (-7% Max) Improper submission of solid model (0 - 4%) Incorrect binding of report (0 - 3%) Incorrect folding or trimming of drawing (0 - 2%) Missing marking sheets (0 - 2%) TOTAL

Penalty

Comment

Late Work Solid Model Report Gearcase Drawing

Days Late

Comment

Page 22 of 23

Solid Model (50%)

Description

Penalty

Gross errors

Significant errors

Minor errors

Under defined sketches Poor modelling Incorrectly defined standard parts Draft Radii Chamfers TOTAL

Special Bonus

Page 23 of 23

You might also like

- Sankshipt Lokokti Evam Muhavara Kosh: 1400 Se Aadhik Lokotiya Evam Muhabaro Ka Anutha SanklanFrom EverandSankshipt Lokokti Evam Muhavara Kosh: 1400 Se Aadhik Lokotiya Evam Muhabaro Ka Anutha SanklanNo ratings yet

- 48x96 TemplateDocument1 page48x96 TemplateMiguel Angel Palencia BarretoNo ratings yet

- OookkkkkkkkkkkkkkkkkkkkklaaaaaaaaaaaaaaaaaaaaaaaaaaaaaavvDocument3 pagesOookkkkkkkkkkkkkkkkkkkkklaaaaaaaaaaaaaaaaaaaaaaaaaaaaaavvArdhua AhNo ratings yet

- Double Click On Smart Objects Layer. It Will Open New Edition TapDocument2 pagesDouble Click On Smart Objects Layer. It Will Open New Edition Tapans1390No ratings yet

- A0 Vertical Template2Document1 pageA0 Vertical Template2Jasleen KaurNo ratings yet

- Balakulanya / Söli LentDocument4 pagesBalakulanya / Söli Lentapi-19803089No ratings yet

- Arch 2018 Thesis FormatDocument15 pagesArch 2018 Thesis FormatAlphaGrace Elizaga ApallaNo ratings yet

- Optimized for Document on ooooooooo TopicsDocument9 pagesOptimized for Document on ooooooooo TopicsnunosmarquesNo ratings yet

- JKJKJKDocument2 pagesJKJKJKFatihul AhmadNo ratings yet

- 01 - RM - Sec PreDocument14 pages01 - RM - Sec PreJONNYNo ratings yet

- Double Click To Convert 02.zoomDocument34 pagesDouble Click To Convert 02.zoomedrian cadaydayonNo ratings yet

- KKKKDocument82 pagesKKKKsaijalajNo ratings yet

- Arch 2018 Thesis FormatDocument15 pagesArch 2018 Thesis FormatJohn Michael JanorasNo ratings yet

- XXXXXXXXXXXXXX XXXXXX X XXXXXXXXXX XXXXXXDocument21 pagesXXXXXXXXXXXXXX XXXXXX X XXXXXXXXXX XXXXXXRicardopalelaNo ratings yet

- Template BuletinDocument2 pagesTemplate BuletinRony Ramdhan LaatahzanNo ratings yet

- الحان اسبوع الآلام PDFDocument18 pagesالحان اسبوع الآلام PDFFady SolimanNo ratings yet

- 003 RelaxDocument3 pages003 RelaxVittoria LambertiNo ratings yet

- XXXXXXXXXXXXXX XXXXXX X XXXXXXXXXX XXXXXXDocument17 pagesXXXXXXXXXXXXXX XXXXXX X XXXXXXXXXX XXXXXXRicardopalelaNo ratings yet

- Protective+Coatings Boja+ Cjenovna+GrupaDocument7 pagesProtective+Coatings Boja+ Cjenovna+Grupapagoo7091No ratings yet

- A1 Vertical TemplateDocument1 pageA1 Vertical TemplateTheeva RajNo ratings yet

- 4 Rus Surrealism and Self RepresentationDocument12 pages4 Rus Surrealism and Self Representationveralynn35No ratings yet

- 54 Modele CV PerspicaceDocument1 page54 Modele CV PerspicaceyoussefriifiNo ratings yet

- MPPH 4 Questions RedactedDocument1 pageMPPH 4 Questions RedactedBen DencklaNo ratings yet

- 48x96 Horizontal Templatev12Document1 page48x96 Horizontal Templatev12nissrine hammamNo ratings yet

- 2Document27 pages2api-3700286No ratings yet

- 222Document2 pages222Nguyen Anh Tu QP0115No ratings yet

- Binary Table Conversion GuideDocument9 pagesBinary Table Conversion GuideGabriela YugchaNo ratings yet

- TemplateDocument2 pagesTemplateleonardus_widyatmoko_drNo ratings yet

- 269835【การทำงานล่วงเวลามีผลกับการซื้อเกมบอลหรือไม่】วิธีการชนะรางวัลใหญ่ในลอตเตอรี่ลาว กฎการชนะลอตเตอรี่ขนาดใหญ่-คราวน์สำรองDocument13 pages269835【การทำงานล่วงเวลามีผลกับการซื้อเกมบอลหรือไม่】วิธีการชนะรางวัลใหญ่ในลอตเตอรี่ลาว กฎการชนะลอตเตอรี่ขนาดใหญ่-คราวน์สำรองoroughmhfpNo ratings yet

- Artick Monkeys - D Is For Dangerous - DrumsDocument2 pagesArtick Monkeys - D Is For Dangerous - Drumsandreaeli6No ratings yet

- X XXXXXXXXXXXXXXXXXXXXXDocument12 pagesX XXXXXXXXXXXXXXXXXXXXXkumki yaanaiNo ratings yet

- HJJHJJJJJJJJJHHH HHHHHHHHHH HHHHHHHHHH HHHHHHHHHH HHHHHHHHHH HHHHHHHHHHDocument86 pagesHJJHJJJJJJJJJHHH HHHHHHHHHH HHHHHHHHHH HHHHHHHHHH HHHHHHHHHH HHHHHHHHHHsaijalajNo ratings yet

- Recordando A Amy Winehouse: Gaceta UnidDocument6 pagesRecordando A Amy Winehouse: Gaceta UnidClaudia Giovanna Garrido MendezNo ratings yet

- Poster 2023 2024 MasterialsDocument1 pagePoster 2023 2024 Masterialsbabaarbi14No ratings yet

- Terima Kasih TuhanDocument2 pagesTerima Kasih Tuhansihombingpaskah17No ratings yet

- 5 MemosDocument30 pages5 MemosNodiNo ratings yet

- ARISAN TGL. . NO NamaDocument12 pagesARISAN TGL. . NO NamaGedeYudiAstawaNo ratings yet

- Mapping of land plots and vegetation in Vedea River valleyDocument1 pageMapping of land plots and vegetation in Vedea River valleyGanea IonelNo ratings yet

- 36x48 Trifold Templatev12Document1 page36x48 Trifold Templatev12vaniaNo ratings yet

- Bingo Da TabuadaDocument6 pagesBingo Da TabuadaandreiarpcssousaNo ratings yet

- Student Assessment ReportDocument5 pagesStudent Assessment Reportnanda arsyiaNo ratings yet

- Your Download Has StartedDocument3 pagesYour Download Has StartedGimurtu MusatNo ratings yet

- Matrix data representationDocument1 pageMatrix data representationROMUALDONo ratings yet

- Model 111Document121 pagesModel 111Rotaru RaduNo ratings yet

- Latihan 021Document2 pagesLatihan 021Dwik BungaNo ratings yet

- Bảng Thống Kê Chấm Công (Ký Hiệu)Document4 pagesBảng Thống Kê Chấm Công (Ký Hiệu)Quann NguyễnNo ratings yet

- RicisDocument12 pagesRicisMay MedikaNo ratings yet

- Materi ThailandDocument1 pageMateri ThailandPrima Sarana MedikaNo ratings yet

- Skimming ExamplesDocument2 pagesSkimming ExamplesHai Duy Nguyen-LeNo ratings yet

- PDF Makalah Konsep Berpikir Kritis Dalam Keperawatan CompressDocument10 pagesPDF Makalah Konsep Berpikir Kritis Dalam Keperawatan CompressRaysha AlfitrhaNo ratings yet

- Student assessment scores and timesDocument5 pagesStudent assessment scores and timesnanda arsyiaNo ratings yet

- Format Full ReportDocument5 pagesFormat Full ReportAnonymous EGGIDhNo ratings yet

- FloorDocument12 pagesFloorVivian LissethNo ratings yet

- Poster TemplateDocument1 pagePoster Templatekhucviet9a123No ratings yet

- 1/16 Fin World Latin Championship 16 April 2011: Cha Sa J PD RDocument16 pages1/16 Fin World Latin Championship 16 April 2011: Cha Sa J PD RcomicreaderNo ratings yet

- Response of Free VibrationDocument7 pagesResponse of Free VibrationAnonymous pD2ymRUguNo ratings yet

- 03 OutDocument2 pages03 OutVardan VardanyanNo ratings yet

- Silvius Leopold Weiss - Lute Suite n.13 (WL33)Document20 pagesSilvius Leopold Weiss - Lute Suite n.13 (WL33)Riccardo Percacci100% (3)

- Repeating text documentDocument175 pagesRepeating text documentantilexikonNo ratings yet

- Chain Reaction v3 Skirmish Wargame RulesDocument42 pagesChain Reaction v3 Skirmish Wargame RulesJoshua RaincloudNo ratings yet

- HH NovelsDocument1 pageHH NovelsJoshua RaincloudNo ratings yet

- Ravenfeast Points Calculator v1Document15 pagesRavenfeast Points Calculator v1Joshua RaincloudNo ratings yet

- RulesDocument5 pagesRulesJoshua RaincloudNo ratings yet

- Heresy ArmiesDocument2 pagesHeresy ArmiesJoshua RaincloudNo ratings yet

- GangDocument1 pageGangJoshua RaincloudNo ratings yet

- Ravenfeast Points Calculator v1Document15 pagesRavenfeast Points Calculator v1Joshua RaincloudNo ratings yet

- Oathsworn Journal 3Document25 pagesOathsworn Journal 3Joshua Raincloud50% (2)

- Ranged Weapons: ROF Damage PBDocument6 pagesRanged Weapons: ROF Damage PBJoshua RaincloudNo ratings yet

- Bundock & Bayonet 1Document6 pagesBundock & Bayonet 1Joshua ReyesNo ratings yet

- KnightsDocument1 pageKnightsJoshua RaincloudNo ratings yet

- Cavalry Actions TableDocument2 pagesCavalry Actions TableJoshua RaincloudNo ratings yet

- Why Must We Fight Tribe Against Tribe?: PlusDocument21 pagesWhy Must We Fight Tribe Against Tribe?: PlusStefan BeemanNo ratings yet

- Joshua Todd: Contact DetailsDocument2 pagesJoshua Todd: Contact DetailsJoshua RaincloudNo ratings yet

- SBG CardsDocument6 pagesSBG Cardsthon_aasenNo ratings yet

- Why Must We Fight Tribe Against Tribe?: PlusDocument21 pagesWhy Must We Fight Tribe Against Tribe?: PlusStefan BeemanNo ratings yet

- To SeeDocument1 pageTo SeeJoshua RaincloudNo ratings yet

- Bundock & Bayonet 1Document6 pagesBundock & Bayonet 1Joshua ReyesNo ratings yet

- The Defense of RorkeDocument9 pagesThe Defense of RorkeJoshua RaincloudNo ratings yet

- Combat Zone Chronicles Game MechanicsDocument2 pagesCombat Zone Chronicles Game MechanicsJoshua RaincloudNo ratings yet

- Front Rank... Fire! - 1377757165382Document7 pagesFront Rank... Fire! - 1377757165382donpeppe1No ratings yet

- Product Models Comparison: Fortigate 1100E Fortigate 1800FDocument1 pageProduct Models Comparison: Fortigate 1100E Fortigate 1800FAbdullah AmerNo ratings yet

- SWOT Analysis of Fruit Juice BusinessDocument16 pagesSWOT Analysis of Fruit Juice BusinessMultiple UzersNo ratings yet

- Screenshot 2021-10-02 at 12.22.29 PMDocument1 pageScreenshot 2021-10-02 at 12.22.29 PMSimran SainiNo ratings yet

- TSM V5.3 Technical GuideDocument456 pagesTSM V5.3 Technical GuideparifsNo ratings yet

- Whitmore EZ-Switch LubricantDocument1 pageWhitmore EZ-Switch LubricantDon HowardNo ratings yet

- 110 TOP Single Phase Induction Motors - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsDocument42 pages110 TOP Single Phase Induction Motors - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive Examsvijay_marathe01No ratings yet

- Application For Freshman Admission - PDF UA & PDocument4 pagesApplication For Freshman Admission - PDF UA & PVanezza June DuranNo ratings yet

- Computer Application in Business NOTES PDFDocument78 pagesComputer Application in Business NOTES PDFGhulam Sarwar SoomroNo ratings yet

- BUS 301 Final AssesmentDocument15 pagesBUS 301 Final AssesmentTanzim ShahriarNo ratings yet

- Portfolio Corporate Communication AuditDocument8 pagesPortfolio Corporate Communication Auditapi-580088958No ratings yet

- Applied Econometrics ModuleDocument142 pagesApplied Econometrics ModuleNeway Alem100% (1)

- M88A2 Recovery VehicleDocument2 pagesM88A2 Recovery VehicleJuan CNo ratings yet

- What Is PID - TutorialDocument5 pagesWhat Is PID - Tutorialsocrates19582405No ratings yet

- Approvals Management Responsibilities and Setups in AME.BDocument20 pagesApprovals Management Responsibilities and Setups in AME.BAli LoganNo ratings yet

- Carbon Trust Certification OverviewDocument2 pagesCarbon Trust Certification OverviewMatt MaceNo ratings yet

- Makerere University: Office of The Academic RegistrarDocument2 pagesMakerere University: Office of The Academic RegistrarOPETO ISAACNo ratings yet

- Design of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI UnitDocument41 pagesDesign of A Double Corbel Using CAST Per ACI 318-02 Appendix A, SI Unityoga arkanNo ratings yet

- Moi University: School of Business and EconomicsDocument5 pagesMoi University: School of Business and EconomicsMARION KERUBONo ratings yet

- Fayol's Principles in McDonald's ManagementDocument21 pagesFayol's Principles in McDonald's Managementpoo lolNo ratings yet

- Crypto Is New CurrencyDocument1 pageCrypto Is New CurrencyCM-A-12-Aditya BhopalbadeNo ratings yet

- Infor Mashup SDK Developers Guide Mashup SDKDocument51 pagesInfor Mashup SDK Developers Guide Mashup SDKGiovanni LeonardiNo ratings yet

- DMT80600L104 21WTR Datasheet DATASHEETDocument3 pagesDMT80600L104 21WTR Datasheet DATASHEETtnenNo ratings yet

- Socomec EN61439 PDFDocument8 pagesSocomec EN61439 PDFdesportista_luisNo ratings yet

- Csit 101 Assignment1Document3 pagesCsit 101 Assignment1api-266677293No ratings yet

- A Study On Capital BudgetingDocument2 pagesA Study On Capital BudgetingANKIT SINGHNo ratings yet

- Nº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRDocument33 pagesNº SSR-1 NS-R-3 Draf R1 Site Evaluation For Nuclear Installations FRdaniel addeNo ratings yet

- NFPA 99 Risk AssessmentDocument5 pagesNFPA 99 Risk Assessmenttom ohnemusNo ratings yet

- Integrated Project Management in SAP With Noveco EPMDocument34 pagesIntegrated Project Management in SAP With Noveco EPMrajesh_das3913No ratings yet

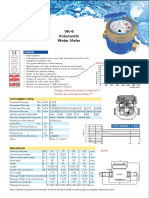

- Baylan: VK-6 Volumetric Water MeterDocument1 pageBaylan: VK-6 Volumetric Water MeterSanjeewa ChathurangaNo ratings yet

- Ge Dir ReportsDocument1 pageGe Dir Reportsselvam chidambaramNo ratings yet