Professional Documents

Culture Documents

ZF5hp24 Valve Body TSB

Uploaded by

rickybobbyjoeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZF5hp24 Valve Body TSB

Uploaded by

rickybobbyjoeCopyright:

Available Formats

V8 Sedan & XK8

SERVICE

DATE

9/97

307-03

TECHNICAL BULLETIN

MODEL

1997 MY-ON XK8 Range 1998 MY-ON V8 Sedan NA

Replacing Valve Body ZF 5HP 24 E Replacement Procedure Not In Workshop Manual

VIN

001001-ON 812256-ON

Issue: This bulletin outlines points to consider when removing and installing a valve body on the ZF 5 HP 24 E transmission. Action: Observe the following points when replacing a valve body: Cleanliness is of paramount importance in all aspects of the installation procedure. Temperature: WARNING: Do not attempt to remove the oil pan and valve body if the transmission temperature is above 50 degrees Celsius. There is a danger of sustaining severe burns from hot oil and components. Oil condition: Installation of a replacement valve body should not be attempted if the oil pan contains debris (friction material or excess metal deposits). NOTE: The oil in this transmission is not red in color but has an appearance similar to an engine oil which will darken in service. This is normal and should not be mistaken for burnt oil. Do not install a replacement valve body on a transmission with burnt or contaminated oil. The transmission should be replaced as excessive damage has occurred. Removal of valve body: Drain oil and remove oil pan. Remove the clip securing the electrical connector to the transmission housing prior to removing the valve body screws, note its position for reinstallation. Remove the output speed sensor and oil filter prior to removing the valve body screws. CAUTION: The screws that secure the valve body to the transmission have larger heads than the other valve body screws. Remove the larger headed screws only (17 of M6 X 60 and 5 of M6 X 30). Removing the other screws will cause the valve body to separate. 3. The valve body is located by a dowel on the main housing and will not always drop immediately as the last screw is removed. Do not use any type of lever to remove the valve body from the main housing once the screws are removed, since damage to transmission sealing/pressure surfaces is likely.

Bulletin Number 307-03 Page 1 of 3

1. 2. 2.

Date of issue 9/97

1.

Installing replacement valve body: Assistance may be required to support the valve body while the electrical connector is positioned in the transmission housing. Ensure the correct location of the valve body in the housing. As the valve body is positioned in the transmission housing, ensure the selector valve is located in the selector pin and that the dowel is located correctly. The valve body is secured by 22 screws (17 of M6 X 60 and 5 of M6 X 30, refer to illustration on next page). Do not tighten the screws before the valve body is flush with the main casing. Tighten only the large headed screws at first until only very slight resistance is felt then in sequence (working from the inside to the outside) gradually to 8 Nm 1 Nm. NOTE: Ensure also that none of the smaller headed screws are accidentally torqued to the higher torque of the large headed screws, as this will lead to transmission malfunction (correct torque for small headed screws, 6 Nm). Reinstall the oil filter and tighten to 5-6 Nm and the output sensor and retainer (8 Nm). Do not over-tighten the valve body screws, since this will cause the valves to stick leading to shifting problems and/or a loss of drive.

2.

1.

2.

Ensure that both speed sensors are securely located by their retaining clips. Failure to check this can result in transmission default or substitute function after start up. (Code P0715 Input speed sensor, code P0721 Output speed sensor) Reinstalling oil pan: Hold the replacement gasket in position with Vaseline as the oil pan is positioned on the main case. DO NOT USE ANY TYPE OF GASKET SEALANT (this will lead to contamination inside the transmission resulting in malfunction). Do not tighten any of the 22 screws (M6 x 20) until all are at least started on the threads (this will help to ensure the gasket is correctly aligned) Tighten the screws until they can be felt to grip the oil pan then tighten gradually to 10 Nm 1 Nm. CAUTION: Do not overtighten the oil pan screws. Overtightening the screws will distort the oil pan and damage the gasket, resulting in oil leakage.

Oil: Use only Esso LT71141 - This transmission is designed to operate with this oil only DO NOT USE ANY ALTERNATIVE OIL. (The use of oil other than Esso LT71141 will lead to transmission clutch failure within a short period of time) Oil filling: A dedicated pump is required to add oil through the level plug, located towards the rear of the transmission. Do not use any container or pump previously used for any other liquid since this will contaminate the oil. 1. Add transmission fluid via the filler plug until it begins to spill out. 2. Set up the PDU to monitor the transmission oil temperature by making the following menu selections: DIAGNOSTICS, TOOLBOX, POWERTRAIN, DATALOGGER, TRANSMISSION, TOT (transmission oil temperature). Start the engine. 3. Move the selector lever through all positions (in car) and return to P.

Page 2 of 3

Bulletin Number 307-03

Date of issue 9/97

4. Continue to add oil until a continual dribble is seen to run out of the level orifice. The temperature must be between 30 - 50 degrees Celsius. (30 degrees is the optimum temperature and equates to maximum oil level; 50 degrees Celsius equates to minimum oil level). Once the correct level is achieved, reinstall and tighten the oil level plug before the engine is switched off.

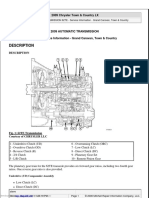

ZF 5HP 24 E VALVE BODY

PRESSURE REGULATORS SOLENOID VALVES

ELECTRICAL CONNECTOR CLIP

Date of issue 9/97

Bulletin Number 307-03 Page 3 of 3

You might also like

- Ac Tech Form - Re5r05aDocument4 pagesAc Tech Form - Re5r05aossoskiNo ratings yet

- 345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224Document9 pages345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224valangelofNo ratings yet

- Corolla MMT Transmission DTC P0810 RepairDocument8 pagesCorolla MMT Transmission DTC P0810 RepairMauricio Guerrero100% (3)

- 94 A 541 eDocument15 pages94 A 541 eEli Mires100% (1)

- New Product Announcement: Zf6Hp19A / Audi 09LDocument1 pageNew Product Announcement: Zf6Hp19A / Audi 09LFSR1407No ratings yet

- Transmission NoteDocument6 pagesTransmission Notesyariza ismailNo ratings yet

- A24a S24aDocument79 pagesA24a S24aluisridik3No ratings yet

- 16R-10-11 GM 5l40e No MovementDocument2 pages16R-10-11 GM 5l40e No MovementAyhan ÜmitNo ratings yet

- Transfer Case MP 3023Document103 pagesTransfer Case MP 3023jackson vivasNo ratings yet

- Isolate No Reverse On A Jatco JF506E: Basic Test ProceduresDocument6 pagesIsolate No Reverse On A Jatco JF506E: Basic Test ProceduresGemblonk Ask100% (1)

- Automatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElDocument212 pagesAutomatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElVIDAL ALEJANDRO GARCIAVARGASNo ratings yet

- Ax4s Axod eDocument62 pagesAx4s Axod etransmisionesmg1No ratings yet

- Aa80e EngDocument772 pagesAa80e EngMarco MeloncelliNo ratings yet

- Atb209 Isuzu 4l80-E ...... High or Low PressureDocument3 pagesAtb209 Isuzu 4l80-E ...... High or Low PressureAleNo ratings yet

- Reassembly: (A) Check Bearing PositionDocument21 pagesReassembly: (A) Check Bearing PositionRonfermNo ratings yet

- LubeGuard Transmission Fluid AdditivesDocument2 pagesLubeGuard Transmission Fluid AdditivesDon BoyerNo ratings yet

- Atb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesDocument4 pagesAtb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesAleNo ratings yet

- 01JDocument1 page01JPedroMecanicoNo ratings yet

- Transmission Installation Guide Quick ReferenceDocument2 pagesTransmission Installation Guide Quick Referenceiriana2009No ratings yet

- Technical Information NoticeDocument7 pagesTechnical Information NoticejesusNo ratings yet

- Index: T H M 4 4 0 - T 4Document104 pagesIndex: T H M 4 4 0 - T 4Anonymous eExWojLxNo ratings yet

- 6T40 Gen III - Start StopDocument3 pages6T40 Gen III - Start Stopchoco84No ratings yet

- Wire Gf4aelDocument2 pagesWire Gf4aelLogam LopezNo ratings yet

- WS ATF Level Adjustment For U660E/F Transmissions: Drivetrain Autom I TR Nsmi !TR Le USADocument11 pagesWS ATF Level Adjustment For U660E/F Transmissions: Drivetrain Autom I TR Nsmi !TR Le USAAlex Maceira GraterolNo ratings yet

- Lube Gard AtfDocument249 pagesLube Gard Atfjuan garcia guerraNo ratings yet

- NAG 1/W5A580 Auto Transmission Diagnosis and RepairDocument42 pagesNAG 1/W5A580 Auto Transmission Diagnosis and RepairKamerom CunninghamNo ratings yet

- LuK TecBr WDC 210x297 LowRes ENDocument28 pagesLuK TecBr WDC 210x297 LowRes ENTop AutoNo ratings yet

- A760E F H VBL InteractiveDocument1 pageA760E F H VBL InteractivehaddadiNo ratings yet

- Torqshift 6Document8 pagesTorqshift 6acmemail583100% (1)

- 55 50SNDocument1 page55 50SNPedroMecanicoNo ratings yet

- U6600E Shift ProblemsDocument4 pagesU6600E Shift ProblemsAlex Maceira Graterol100% (1)

- AX7 Service Manual Automated Manual TransmissionDocument148 pagesAX7 Service Manual Automated Manual TransmissionAlexis FuentesNo ratings yet

- 722 3Document12 pages722 3Daniel AlvaradoNo ratings yet

- Converter Lining CatalogDocument76 pagesConverter Lining CatalogMarianoNo ratings yet

- ZF 4HP16 OptraDocument5 pagesZF 4HP16 OptraGERARDO CESSANo ratings yet

- ZF6HP34Document1 pageZF6HP34PedroMecanicoNo ratings yet

- AL4 Pressure Regulation FaultDocument3 pagesAL4 Pressure Regulation Faultsirajmy100% (1)

- Technical Service Information: Automatic Transmission Service GroupDocument9 pagesTechnical Service Information: Automatic Transmission Service GroupMario MastronardiNo ratings yet

- Atb 003Document2 pagesAtb 003Tejon Aguilar100% (1)

- Technical Service Information: Automatic Transmission Service GroupDocument6 pagesTechnical Service Information: Automatic Transmission Service GroupPlanta Damiana2No ratings yet

- G4a El FallasDocument8 pagesG4a El FallasLogam Lopez100% (1)

- Re5f22a PDFDocument297 pagesRe5f22a PDFnetralka.byyandex.ruNo ratings yet

- Dodge JourneyDocument387 pagesDodge Journeycesar alejandro scavoNo ratings yet

- VW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFDocument68 pagesVW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFlucafelicianioanNo ratings yet

- Suspension Trasera 97-98Document6 pagesSuspension Trasera 97-98kilofome05No ratings yet

- SWAG Fluessigkeiten 2012 2013Document33 pagesSWAG Fluessigkeiten 2012 2013Hatem NasrNo ratings yet

- Jatco/Nissan JF016E, JF017E: (RE0F10D) (RE0F10E)Document1 pageJatco/Nissan JF016E, JF017E: (RE0F10D) (RE0F10E)ak_adamNo ratings yet

- 521Document270 pages521ccbulgariaNo ratings yet

- 09D-TG AtsgDocument75 pages09D-TG AtsgValdir Gomiero100% (1)

- 2012-197 Re5r05aDocument9 pages2012-197 Re5r05aAleNo ratings yet

- 01m Manual Valve AdjustmentDocument1 page01m Manual Valve AdjustmentfulltransmissionNo ratings yet

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- 2005 KJ Transmission DSLDocument244 pages2005 KJ Transmission DSLmock_er100% (2)

- 4L80-E VacTestLocations PDFDocument4 pages4L80-E VacTestLocations PDFDexter213No ratings yet

- Timing Belt (Timing Belt) - ALLDATA Repair StratusDocument10 pagesTiming Belt (Timing Belt) - ALLDATA Repair StratusFran SanchezNo ratings yet

- 00 01 PDFDocument2 pages00 01 PDFКонстантин МалетинNo ratings yet

- Front Suspension Cylinder Purge and ChargeDocument14 pagesFront Suspension Cylinder Purge and ChargezhenyupanNo ratings yet

- Ohlins DTC Einbauanleitung FPK 107 EnglischDocument6 pagesOhlins DTC Einbauanleitung FPK 107 EnglischIvan TlNo ratings yet

- Torque Converter Catalog - 2012 LoResDocument342 pagesTorque Converter Catalog - 2012 LoResRoberto Perez100% (1)

- Transtar - 2007 Transfer Case ChainsDocument20 pagesTranstar - 2007 Transfer Case Chainsrobertoperez525No ratings yet

- Manual Trans and Transfer Case Parts CatalogueDocument339 pagesManual Trans and Transfer Case Parts CatalogueBrad Franc67% (3)

- 2007 HD Difftrans 2006Document334 pages2007 HD Difftrans 2006David RosadoNo ratings yet

- 2011 PDF Catalog AllisonDocument56 pages2011 PDF Catalog Allisonthierrylindo86% (7)

- Axle InfoDocument120 pagesAxle InfoposttonNo ratings yet

- Acura WarrantyDocument1 pageAcura WarrantyDavid RosadoNo ratings yet

- 4f50n TSB Neutral ConditionDocument3 pages4f50n TSB Neutral ConditionDavid RosadoNo ratings yet

- 4 L 60 EgroundDocument2 pages4 L 60 EgroundDavid RosadoNo ratings yet

- ZF SolenoidsDocument4 pagesZF SolenoidsDavid Rosado100% (3)

- ZF SolenoidsDocument4 pagesZF SolenoidsDavid Rosado100% (3)

- ZF S6-650 Manual Transmission Service GuideDocument48 pagesZF S6-650 Manual Transmission Service GuideLuisYFer1100% (2)

- TC002 06Document3 pagesTC002 06David Rosado100% (1)

- Illustrated Parts List: TA-Y00-400003 (FS-6306) August 2012Document15 pagesIllustrated Parts List: TA-Y00-400003 (FS-6306) August 2012David Rosado100% (1)

- P0710Document5 pagesP0710David RosadoNo ratings yet

- ZF 6HP19 Automatic Transmission - Available Spare Parts: 6 HP 19 - Gearbox Housing 6 HP 19 A HousingDocument14 pagesZF 6HP19 Automatic Transmission - Available Spare Parts: 6 HP 19 - Gearbox Housing 6 HP 19 A HousingDavid RosadoNo ratings yet

- 6S 750 CatalogDocument13 pages6S 750 CatalogDavid Rosado100% (1)

- 4 L 60 EgroundDocument2 pages4 L 60 EgroundDavid RosadoNo ratings yet

- Flywheel Kingo 400 PGDocument453 pagesFlywheel Kingo 400 PGDavid RosadoNo ratings yet

- Roto HydramaticDocument43 pagesRoto HydramaticDavid RosadoNo ratings yet

- 6HP32Document15 pages6HP32dejanflojdNo ratings yet

- 2010 H S - U.S. O: Oliday Chedule PerationsDocument1 page2010 H S - U.S. O: Oliday Chedule PerationsDavid RosadoNo ratings yet

- P2716Document4 pagesP2716David RosadoNo ratings yet

- DTC p1374Document3 pagesDTC p1374David RosadoNo ratings yet

- 57917e 19KDocument1 page57917e 19KDavid RosadoNo ratings yet

- ZF6HP26 Park InfoDocument4 pagesZF6HP26 Park InfoDavid Rosado100% (1)

- Extended Rav4 Warranty PDFDocument6 pagesExtended Rav4 Warranty PDFDavid RosadoNo ratings yet

- Speedo calibration chart seconds per mileDocument1 pageSpeedo calibration chart seconds per mileDavid RosadoNo ratings yet

- S547M SparePartsDocument9 pagesS547M SparePartsDavid RosadoNo ratings yet