Professional Documents

Culture Documents

Supply Chain Flexibility SEM Approach

Uploaded by

Robert K OtienoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supply Chain Flexibility SEM Approach

Uploaded by

Robert K OtienoCopyright:

Available Formats

Supply Chain Flexibility: Structural Equation Modeling Approach

C o p y r i g h t 2 0 1 1 S c i R e s .

J S S M

Supply Chain Flexibility: Structural Equation

Modeling Approach

Otieno Robert Kennedy; Ksenia K A Novikova

Transportation Management College, Dalian Maritime University, Dalian, P R China

robertko78@gmail.com, shenia3253@163.com

ABSTRACT

Increase in uncertainty and constant change in global business environment requires supply chains to be

flexible in order to be responsive to customer needs. Given that supply chain is so crucial for business suc-

cess and survival, research in this area is important in responding to the need to keep abreast with changes

in competitive environment. This study develops valid and reliable instruments to measure supply chain

flexibility and to test relationship among variables using structural equation modeling. The results show

strong, positive and direct relationship between the factors studied and the components of supply chain

flexibility. Implications of the findings of this research can help managers identify important elements in

achieving of supply chain flexibility. The research did not include effects of cost factors and therefore fur-

ther research is recommended to shed more light in this area.

Keywords: Supply chain flexibility, Logistics, Supply chain, Structural equation modeling

1. Introduction

Mike Peters, First Vice President, ProLogis Solutions

Group argues [1] that presently, there are few compa-

nies that are not touched by global issues. Business

environment is today more dynamic and the level of

uncertainty has increased [2]. Moreover, global operation

brings, on one hand chance and opportunity; on the

other hand is risk and uncertaintycomplexities, such as

substantial geographical distances, added forecasting

difficulties and inaccuracy, exchange rates, terrorism,

wars, political upheaval occurrence, government regula-

tions, local infrastructure competence, and so on [3,

pp.41].

Recent trends compel firms to look for flexible ways

of meeting customer demand [4]. Jack Gross, Vice Pres-

ident & General Manager International, Schneider Lo-

gistics, suggests that flexibility is critical to the success

of cross-border supply chains [1]. Flexibility to meet

customer requirements in international market is re-

garded as a vital performance metric. It has been

shown that partners in international supply chains should

be both agile and flexible so as to thrive in this conti-

nuously changing, uncertain business environment [5].

This research seeks to examine the dimensions and

characteristics of supply chain flexibility and goes fur-

ther to build a structural equation model of the same.

Since the practical importance and evidence of characte-

ristics of flexible supply chains that contribute to busi-

ness success is difficult to estimate, panel interview of

experts was chosen as a feasible technique for mining

data. Because of the qualitative nature of judgment of

flexibility and the need to acquire expert opinion on the

subject matter; it is difficult to gather experimental evi-

dence of supply chain flexibility [6]. Judgment of supply

chain flexibility being subjective, Linstone and Turoff

[6, pp.4] note that subjective judgment does not lend

itself to precise analytical techniques but can benefit

from subjective judgments on collective basis.

The paper will be comprised of five main sections.

Following the introductory section, which outlines the

nature of the study, the paper will present reviews on

related literature on supply chain flexibility. The section

will be devoted to defining it and outlining its theoretical

precepts. Next section will present and defend the se-

lected research methodology followed by presentation of

results of the research as well as their analyses and re-

lated discussions. The paper will further present implica-

tions of research findings and discussions of limitations

of the current study as well as recommendations for fur-

ther research. Finally, this paper will be concluded with

the presentation of summary and conclusions.

2. Literature Review

Supply Chain Flexibility: Structural Equation Modeling Approach

C o p y r i g h t 2 0 1 1 S c i R e s .

J S S M

Flexibility is defined as a hedge against diversity of the

business environment. Supply chain flexibility is also

understood as ability of the supply chain to possess a

ready capability to adapt to new different or changing

requirements which should be achieved without exces-

sive cost, time, organizational disruption, or perfor-

mance losses [7]. Flexible supply chain is supported by

a market-inclined strategy where all parties work to-

gether to come up with an efficient, fast (referring to

time), and reliable supply chain [8]. In cross-border

context, supply chain flexibility is regarded as the ability

of activities within the supply chain to respond effec-

tively to changing circumstances across borders. These

definitions highlight the aspects of cost-effectiveness

and efficiency of activities within supply chain, the issue

of change, the need for quick and efficient response to

customer needs, uncertainty and global business dy-

namism.

Duclos, et al., [9] note that definition of supply

chain flexibility should include all dimensions required

by all supply chain partners. They argue that for a ful-

ly flexible supply chain, all the six components of its

flexibility should be present. The components are opera-

tions flexibility, market flexibility, logistics flexibility,

supply flexibility, organizational flexibility and infor-

mation systems flexibility. Lummus, et al., [10] devel-

oped a conceptual model of supply chain flexibility and

reduced the components to five by dropping market

flexibility and relating them to customer satisfaction,

which is as a result of flexible supply chain. Zhang, et

al., [11] used competence and capability theory to study

components of logistics flexibility and regard supply

flexibility as a component of logistics flexibility. Their

study, which used LISREL software to build structural

equation model of logistics flexibility, therefore further

compact the components of supply chain flexibility to

four.

Operations flexibility is defined as ability to react to

customer trends by configuring assets and operations at

each node of the supply chain [10]. It encompasses both

service and manufacturing, including mix and volume

flexibilities [12]. Volverda [13] argues that operations

flexibility depends on ability of supply chain partner

organization to have flexible strategic attitude, manufac-

turing system, organizational design and human resource

practices. Manufacturing systems flexibility refers to the

ability of the system to respond to instability resulting

from the environment [14]. Koste and Malhotra [15]

include operations flexibility within organizational flex-

ibility and give five levels of the same. The levels are:

functional level having manufacturing flexibility; plant

level entailing volume, mix, expansion, modification and

new product flexibilities; shop floor level which includes

both routing and operation flexibilities and individual

resource level encompassing labor, machine and material

handling flexibilities. It is therefore seen that operations

flexibility is a component of organizational flexibility.

Therefore, supply chain flexibility components can

be broadly categorized as logistics flexibility, informa-

tion systems flexibility and organizational flexibility.

Supply chain flexibility can be achieved through ensur-

ing organizational commitment and proper information

system capability [8].

Few researchers have attempted to model supply

chain flexibility. A number of studies ([7], [8], [11])

developed models of supply chain flexibility or its com-

ponents. Lummus, et al., [8] proposed a conceptual mod-

el that defined supply chain flexibility based on the

cross-functional, cross business nature of the supply

chain. Zhang et al., [11] used competence and capability

theory to study logistics flexibility as a component of

supply chain by testing the relationship between struc-

tural equation model constructs (competences and capa-

bilities) of flexible logistics. Their work did not focus on

information systems and did not treat organizational

flexibility effects in good depth. More work is needed

especially in this area to fill this area to shed light to

areas that require greater attention by the government of

any regional economic union, country, business practi-

tioners and the academia in order to further businesses

and knowledge in supply chain management.

2.1. Logistics Flexibility

Logistics flexibility is defined as the ability to

cost-effectively receive and deliver products as sources

of supply and customers change [8]. According to lite-

rature logistics flexibility has four components grouped

into two namely competences (internal logistics

strengths) and capabilities (customer-desired visible

logistics strengths) [11]. Physical supply flexibility and

purchasing flexibility are classified as competences

while physical distribution flexibility and demand man-

agement flexibility are grouped as capabilities [16].

Demand management is regarded as an informa-

tion-intensive and market-sensing activity that must meet

demands quickly by creating and managing close cus-

tomer relationships ( [11], [16 ]).

2.2. Organizational Flexibility

Organizational flexibility is the ability of a firm to antic-

ipate, react and adapt to environmental changes [17]. It is

classified into five levels, including workforce and oper-

ations flexibilities. With reference to human resource,

organizational flexibility is defined as the ability to align

labor force skills to flexibility requirements [18]. A re-

sponse to environmental change through flexible

supply chain may require various changes in alignment

Supply Chain Flexibility: Structural Equation Modeling Approach

C o p y r i g h t 2 0 1 1 S c i R e s .

J S S M

of labor force. The organization management should

develop the capability of workforce to respond to mod-

ern requirements for flexibility. These capabilities in-

clude ability of workers to perform cross-functional ac-

tivities [18]. The workforce should also be linked to

supply chain to efficiently contribute to firm organiza-

tional flexibility and overall supply chain flexibility

([19], [20]).

2.3. Supply chain Information Systems Flex-

ibility

Keith Goldsmith, Senior Vice President, Business De-

velopment and Technology, TNT Logistics [1] notes:

The movement of goods is not really the challenge,

information is. Information system is key to performing

adaptations that result in supply chain flexibility. Infor-

mation systems flexibility is defined as the ability to

align information system architectures and systems with

the changing information needs of the organization as it

responds to changing business conditions, variations in

customer demand and prevailing uncertainties [8]. Ac-

cording to Kotler, [21, pp. 87] Supply chain information

system flexibility is defined as flexibility of an inte-

racting structure of people, equipment, and procedures

that together make relevant information available to the

supply chain manager for the purposes of planning, im-

plementation and control.

3. Research Methodology

The researchers followed these procedural rules in this

research by identifying the research tools and strategies

that will be employed, and relating their application to

specified research objectives [22] as in the subsequent

sections of this paper.

3.1. Research Hypotheses

The hypotheses for the study, for each item identified in

the study related to each of the four attributes of supply

chain flexibility described above, were, Null Hypothe-

sis H

0

: The supply chain flexibility characteristic iden-

tified has no significant contribution to supply chain

flexibility, otherwise; Hypothesis H

1

: The supply chain

flexibility characteristic identified has significant contri-

bution to supply chain flexibility.

3.2. Research Design

The study began by assuming that each of the listed cha-

racteristics has no significant contribution to supply

chain flexibility, until there was statistical proof to justi-

fy rejection of this null hypothesis. The acceptable con-

fidence interval for this study was 95% confidence lim-

it. Research questions were,

Q1: Which characteristics have significant con-

tribution to flexible supply chain?

Q2: What is the appropriate model of supply

chain flexibility?

The objectives of this study were to get expert panel's

consensus on the factors or characteristics that should be

varied or put in place to achieve supply chain flexibility;

to identify which of the factors are critical to realization

of flexible supply chain especially across national boun-

daries and to develop a model of supply chain flexibility.

In order to get clear background about the topic

of survey, the researchers reviewed an extensive amount

of literature concerning the subject matter, flexibility in

international supply chains, some available work on

modeling supply chain flexibility and research methods.

3.3. Selection of respondents

A set of priorities were considered in selecting a sample

of expert respondents for the panel interview. Purposive

criterion-based selection bases the selection of the study

settings and participants upon features and characteristics

that enable the researchers to gather deeper information

in the areas of research interest [23]. Therefore, the kind

of sampling used in this research was purposeful and

strategic [24], taking into consideration convenience and

ease of access to study situations and participants were

given only secondary importance.

There has never been a consensus on the optim-

al number of respondents in panel interviews. It is indi-

cated that the approximate size of expert interview is

generally under 50, but a bigger number of respondents

have been employed [25]. Between 10 and 15 respon-

dents could be sufficient if the background of the subject

matter is homogeneous [25]. To sum up, the size of

respondents is variable [26].

Theoretically, sample size, N, is calculated us-

ing Equation (1).

N =

pq

__

s

zo

2

_

_

2

_

(1)

where, N sample size or number of respondents; p

confidence limit, 0.95; q= Probability of rejecting the

null hypothesis, 0.05; Z

u2

cumulative distribu-

tion function, CDF, score of normal distribution at sig-

nificance level of 0.05 (Z

u2

=1.96); e sampling error,

e =0.085, the value was selected slightly above the

value used in entrepreneurship research, which is e

=0.075 [27].

Supply Chain Flexibility: Structural Equation Modeling Approach

C o p y r i g h t 2 0 1 1 S c i R e s .

J S S M

Substituting these values in the above equation gives

N=25.256, leading to theoretical minimum sample size

of N= 25 expert respondents for the above stated condi-

tions.

Within the current study, members of the panel

were selected and a set of 60 experts, in the field of lo-

gistics and supply chain management in P. R. China,

USA, India, Myanmar and Kenya, to form a group of

potential panelists representing broad professional de-

mographic. Of the selected 60 expert respondents 27

participated throughout all the three rounds of the survey

which is an acceptable number since it is above the

theoretical, N =25. Table 1 shows sample of expert res-

pondents.

The interview was done in three phases or rounds. Ques-

tionnaire for the first iteration or Round 1 was open

ended, unstructured, easy to comprehend and with brief

questions or statements within acceptable, practical peak

limits of 20 to 25 words per statement to increase

chances of accuracy of responses [28]. The questionnaire

for Round 2 contained 45 factors, identified in the first

stage and from literature, that were viewed to contribute

to supply chain flexibility. It was ensured that question-

naire was free from ambiguous statements or compound

events as much as possible [29].

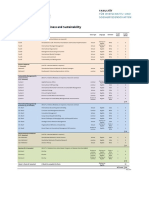

Table 1. Sample of Expert Respondents

Firm /institution

size (no. of em-

ployees)

Employees/people

Represented by experts

% of employees

represented

Respondents

expected (

c

)

Respondents

who partici-

pated (

o

)

100-249 1,505 43 32 12

250-499 770 22 11 5

500-999 525 15 7 4

1,000+ 700 20 10 6

_

2

test (_

2

=7.683, df =3, p= 0.053)

Job title

CEO/president 805 23 11 6

Vice president 525 15 8 5

Manager 1,890 54 37 13

Director 280 8 4 3

_

2

test (_

2

=10.183, df =3, p=0.0171)

Total 3,500 100 60 27

_

2

is obtained using the formula:

(]c-]c)

2

]c

The question in the questionnaires for the subsequent

iterations (i.e. Rounds 2 and 3) was,

Which of the following do you think have

significant contribution to supply chain flexibility?

The respondents were required to respond to the question

by giving weighted responses for each of the 45 charac-

teristics and also for any added factor. The weights were

as per the importance of the factor to realizing supply

chain flexibility (1=strongly disagree, 2=moderately

disagree, 3=agree, 4=strongly agree, 5= very strongly

agree; and 0= dont know).

Dissemination of survey questionnaires to the res-

pondents was carried out using email because of con-

venience and time economy. After deadline of the first

round of survey (after a duration of 3 weeks), responses

were analyzed and aggregated.

3.4. Methods of Data Analysis

Responses were analyzed by calculating the median and

inter-quartile range of data for each of the 45 characteris-

tics in Rounds 2 and 3 of the interview process. The

median can also be used to arrange the 45 characteristics

in order of the average weight or importance. In-

ter-quartile range shows how experts responses varied,

and was regarded as a measure of consensus.

4. Results and Analysis

4.1. Round 1

Introductory emails were sent to about 60 potential par-

ticipants with a closing date three weeks later. The sur-

vey included a welcome and introduction, a short expla-

Supply Chain Flexibility: Structural Equation Modeling Approach

C o p y r i g h t 2 0 1 1 S c i R e s .

J S S M

nation of the interview technique (Delphi process) and an

open ended questionnaire on supply chain flexibility.

The specific question posed was,

Which firms characteristics or capabilities do you

think have SIGNIFICANT contribution to supply

chain flexibility?

By the end of the third week, 27 participants had re-

sponded. Also, it was felt that a significant number of

ideas was already generated and that the respondents

possessed sufficient heterogeneity to raise the quality of

the survey output and to avoid bandwagon effect [ 6].

4.2. Round 2

The median and the inter-quartile range of responses are

shown in Table 2. The top-rated 16 characteristics had

median scores of 5 which is maximum in the Likert scale

used. Three of them were logistics flexibility (LOF)

characteristics, another three were information systems

flexibility (ISF) factors, while ten were for organization-

al flexibility (ORG). Total consensus in rating (in-

ter-quartile range of 0.00) was seen for the item ability to

ensure data accuracy and timeliness. The highest in-

ter-quartile range of 2.00 was in the rating of LOF3,

LOF6 and LOF8 showing low consensus for the items.

4.3. Round 3

The results (see Table 2) show that 17 characteristics had

a median of 5.00, two items had median of 4.50 and 17

items had a median of 4.00 showing that the experts

either strongly agreed or very strongly agreed to

their significance to supply chain flexibility. Generally,

there was low inter-quartile range in this round; eight

items had lower inter-quartile range in Round 3 than in

the second one. In this round, the item Have compliant

planning system (ORG13) had inter-quartile range of

0.00 indicating total consensus, while Ensure data ac-

curacy and timeliness which had inter-quartile range of

0.00 in Round 2 showed drop to the value of 1.00.

A test using z-statistics showed that 31 (68.89%) of

45 characteristics fell within 95% confidence limit. Of

the 31, ten items had median of 3.00 showing that though

respondents agreed to their significance, they possibly

have greater significance to supply chain flexibility than

the respondents thought.

4.4. Model

Model of supply chain flexibility can be built from each

group of characteristics from the results and previous

analysis. A total of 31 items with statistical significance

based on p0.05 in Round 3 were used in building the

model. A number of characteristics were dropped during

modeling because of their low factor of loading (less

than 0.7), or because of lack of fit tested by model fit

indices or both. In cases where characteristics were

dropped, the remaining ones covered their aspects re-

sulting into no loss of objectivity and retaining the con-

tent validity domain.

4.4.1. Test for Model Fit

Based on clarifications given in literature [30], the test-

ing needed for development of a model of supply chain

flexibility was done using Bentler-Bonett Normed Fit

Index (NFI), Bollens Incremental Fit index (IFI), Tuck-

ler-Lewis Index (TLI), Standardized Root Mean Resi-

dual (SRMR) and Root-Mean-Square Error Approxima-

tion (RMSEA). The IFI was selected because it is rela-

tively unaffected by sample size our sample size N= 27,

was small) [31]. If NFI, IFI and TLI >0.9, the model is

accepted, if it is closer to 1 the model is good. SRMR

and RMSEA=0 indicates perfect fit [32] and IFI and TLI

>0.95 are attractive. TLI was used to check on the sim-

plicity of the model that is to adjust for parsimony [33].

4.4.2. Correlations of Attributes of Supply

Chain Flexibility

The three attributes of supply chain flexibility

represented by models in previous sections can be

tested using correlation coefficients. The test is to

show that a change in one attribute can be related

to a change in the other attribute. Pearsons corre-

lation coefficient, p

,]

, between two attributes of

supply chain flexibility, i and j is given by Equa-

tion (2).

p

,]

=

cuu(X

|

,X

j

)

o

|

o

j

(2)

where, co:(X

, X

]

) is the covariance of the

attributes X

i

in the first sub-model and X

j

in

the second sub-model; o

the standard

deviation of the sample of characteristics

within the first sub-model; and o

]

the

standard deviation of the of characteristics

within the second sub-model. Correlation

coefficient is in the range of -1p

,]

+1 [34].

As p

,]

tends to 1, there is strong correla-

tion.

Table 2. Rounds 2 and 3 Median and Inter-quartile Range

Supply chain Flexibility Characteristic

Ability to:

Label

Round 2 Round 3

Me- In- Me- In- One

Supply Chain Flexibility: Structural Equation Modeling Approach

C o p y r i g h t 2 0 1 1 S c i R e s .

J S S M

dian ter-quarti

le Range

dian ter-quart

ile

Range

Sample

z-stat

Have variety of transportation choices LOF1 5.00 1.00 5.00 1.00 4.290

Use demand to synchronize delivery LOF2 5.00 1.00 5.00 1.00 2.881

Effectively implement quick response LOF3 5.00 2.00 5.00 1.00 1.964

Effect quick and effective delivery LOF4 4.50 1.00 5.00 1.00 2.038

Vary transport vehicles LOF5 4.00 1.00 4.00 1.00 -2.100

Reduce intermediaries in the supply chain LOF6 4.00 2.00 4.00 1.75 -1.256

Have collaborative forecasting of customer

requirements with partners

LOF7 4.00 1.00 4.00 1.00 -1.480

Reduce lead time LOF8 4.00 2.00 4.00 2.00 -0.357

Achieve demand visibility LOF9 4.00 1.00 4.00 1.00 0.520

Ensure Inventory visibility LOF10 4.00 1.00 4.00 1.00 1.476

Adjust storage capacity LOF11 3.00 1.00 3.00 1.00 -6.689

Initiate product postponement LOF12 3.00 1.00 3.00 0.75 -6.074

Aggregate shipment from many places LOF13 3.00 1.00 3.00 1.00 -5.822

Effectively us third-party logistics LOF14 3.00 1.00 3.00 1.00 -4.945

Ensure availability of inventory regionally

and use data inventory

LOF15 3.00 1.00 3.50 1.00 -3.459

Avail inventory in centralized locations LOF16 3.00 1.00 3.00 1.00 -3.678

Align and control information systems with

partners

ISF1 5.00 1.00 4.50 1.00 1.594

Better the quality of information ISF2 5.00 1.00 5.00 1.00 4.382

Ensure data accuracy and timeliness ISF3 5.00 0.00 5.00 1.00 3.972

Share information with partners ISF4 4.00 1.00 4.00 1.00 -2.826

Improve human resource capabilities ORG1 5.00 1.75 5.00 1.00 1.222

Create workforce liaison in the supply chain ORG2 5.00 1.00 5.00 1.75

0.839

Have clear supply chain strategy ORG3 5.00 1.00 4.00 1.00 2.290

Have flexibility initiatives supported by top

management

ORG4 5.00 1.00 5.00 0.75 5.165

Improve internal communications ORG5 5.00 1.00 5.00 0.75 3.607

Be equipped with excellent communication

skills and tools and counteract language and

cultural barriers

ORG6 5.00 1.00 5.00 1.00 4.701

Focus on organizational transformation ORG7 5.00 1.00 5.00 1.00 1.480

Ensure employees are conversant with

company strategies

ORG8 5.00 1.00 5.00 1.00 3.501

Have positive cooperation among em-

ployees

ORG9 5.00 1.00 5.00 1.00 5.247

Boost strategic relationship with key cus-

tomers

ORG10 5.00 0.75 5.00 0.75 2.912

Comply with global requirements and bor-

der-crossing procedures

ORG11 4.50 1.00 4.00 1.00 1.717

Respond quickly to customers' emergency ORG12 4.50 1.00 5.00 1.00 3.037

Supply Chain Flexibility: Structural Equation Modeling Approach

C o p y r i g h t 2 0 1 1 S c i R e s .

J S S M

needs and micro-economic uncertainties

Have compliant planning system ORG13 4.00 1.00 4.00 0.00 -0.472

Apply comprehensive performance meas-

ures

ORG14 4.00 1.00 4.00 1.00 -2.267

Have competitive knowledge ORG15 4.00 1.00 4.00 1.75 0.463

Have support of related government minis-

try

ORG16 4.00 1.00 4.00 1.00 1.496

Effectively implement company's supply

chain strategy

ORG17 4.00 1.00 4.50 1.00 3.450

Effect win-win logistics strategies with

supply chain partners

ORG18 4.00 2.00 4.00 1.00 0.245

Effectively motivate employees ORG19 4.00 1.00 5.00 1.00 5.639

Adjust workforce related practices ORG20 3.00 1.75 3.00 2.00 -2.481

Change organizational culture ORG21 3.00 1.00 3.00 1.00 -6.044

Provide proper workforce training ORG22 3.00 1.00 4.00 1.00 -2.375

Encourage organizational learning ORG23 3.00 1.00 3.00 1.00 -4.397

Endow workforce with empowerment ORG24 3.00 1.75 3.00 1.00 -5.509

Start cost-saving initiatives with supply

chain partners

ORG25 3.00 1.75 3.00 1.00 -4.821

4.4.2.1. Logistics Flexibility and Information

Systems Flexibility

Logistics flexibility and information systems flex-

ibility are correlated as shown in Figure 1. Variance

o

2

for logistics flexibility is 0.17 and that for in-

formation systems flexibility, o

]

2

is 0.36. Cova-

riance is 0.23 (see AMOS

graphic diagram in Fig-

ure 1). Pearsons correlation coefficient, p

,]

, is

0.9297 , showing that logistics flexibility and infor-

mation systems flexibility have very strong positive

correlation.

Model fit: NFI=0.898; IFI= 0.989; TLI= 1.000;

RMSEA= 0.000, SRMR= 0.0627 and

2

{N=32,

df=13, p= 0.04} = 23.14.

Figure 1. Logistics Flexibility and Information

Systems Flexibility

4.4.2.2. Logistics Flexibility and Organiza-

tional Flexibility

Variance o

2

for logistics flexibility is 0.17 and

that for organizational flexibility, o

]

2

is 0.12.

Covariance is 0.11 (see Figure 2). Pearsons corre-

lation coefficient, p

|,j

, is 0.77015 , showing that

logistics flexibility and organizational flexibility

have strong positive correlation. Model fit: NFI=0.

855; IFI= 0.878; TLI= 0.908; RMSEA= 0.084,

SRMR= 0.0742 and _

2

{N=32, df=64, p=

0.000561}= 107.362.

Figure 2. Logistics Flexibility and Organiza-

tional Flexibility

.23

.17

Logistics

Flexibility

LOF1

.07

e1

1.35

1

LOF2

.50

e2

.86

LOF3

.36

e3

1.62 1

LOF4

.43

e4

.36

Information

Systems

Flexibility

ISF1

.42

e5

1

ISF2

.24

e6

.45

1

ISF3

.33

e7

1

1.00

.67

1.00

1

1

.17

Logistics

Flexibility

LOF1

.10

e1

1

LOF2

.48

e2

1

LOF3

.33

e3

1

LOF4

.43

e4

1 1.00

1.68

.93

1.29

.12

Organizational

Flexibility

ORG3

.27

e5

ORG4

.27

e6

1

ORG5

.39

e7

1

ORG8

.15

e8

1

ORG9

.18

e9

1

ORG10

.42

e10

1

ORG11

.40

e11

1

ORG12

.18

e12

1

ORG17

.28

e13

1

1

.91

2.30

1.08

1.00

1.25

1.54

1.55

1.10

1.31

.11

J. Service Science & Management, 201

doi:****/jssm.2011.***** Published Online

Copyright 2011 SciRes.

4.4.2.3. Organizational Flexibility and Inform

Systems Flexibility

Variance o

2

for organizational flexibility is 0.11 and

that for information systems flexibility,

Covariance is 0.21 (See AMOS

graphic diagram in Fi

ure 3). Pearsons correlation coefficient,

showing that organizational flexibility and information

systems flexibility have very strong positive

Model fit: NFI=0. 834; IFI= 0.906; TLI= 0.918;

RMSEA= 0.078, SRMR= 0.0727 and

df=53, p= 0.000001} = 117.704.

Figure

model generally covered those which were dropped. Model fit:

NFI=0.901; IFI= 0.911; TLI= 0.905; RMSEA= 0.068, SRMR=

0.0517 and _

2

{N=32, df=252, p= 0.000}= 509.277.

4.5. Reliability of Model Estimates

Reliability is estimated by determining Cronbachs [35] , as in

Equation (3).

o =

K

K-1

(1 -

c

K

i=1 Y

i

2

c

X

2

)

where, K is number of items in the model;

SUPPLY

CHAIN

FLEXIBILITY

.11

Organizational

Flexibility

ORG3

ORG4

ORG5

ORG8

ORG9

2.44

ORG10

ORG11

ORG12

ORG17

1.15

.88

1.55

1.08

1.29

1.00

1.27

1.57

.44

Information

Systems

Flexibility

ISF1

1.00

ISF2

.39

ISF3

.56

.21

11, *, **

Published Online ** 2011 (http://www.scirp.org/journal/jssm)

Organizational Flexibility and Information

for organizational flexibility is 0.11 and

that for information systems flexibility, o

]

2

is 0.44.

graphic diagram in Fig-

ficient,p

|,j

, is 0.954545

tional flexibility and information

strong positive correlation.

.906; TLI= 0.918;

SRMR= 0.0727 and _

2

{N=32,

Figure 3. Organizational Flexibility and I

Systems Flexibility

4.4.2.4. Overall Model of Supply Chain

Figure 4 shows the model of supply chain

ing AMOS

graphic. Model fit indices NFI, IFI, TLI,

RMSEA, SRMR and

2

indicate good model for

chain flexibility. The model shows an overall variance

of supply chain flexibility characteristics as 0.01. R

gression weights are 1.00 for lo

for organizational flexibility and

systems flexibility; in order of their increasing impo

tance to the contribution to supply chain

of the characteristics given by respondents were not i

cluded in building this final model in Figure

their low regression weights and low loading factors (of

less than 0.7). However, there was no loss of objectivity

since the items in the

igure 4. Model of Supply Chain Flexibility

model generally covered those which were dropped. Model fit:

NFI=0.901; IFI= 0.911; TLI= 0.905; RMSEA= 0.068, SRMR=

= 0.000}= 509.277.

Reliability is estimated by determining Cronbachs [35] , as in

(3)

is number of items in the model; o

i

2

va-

riance component i for the current sample of charact

ristics; and o

X

2

variance of ob

scores.

Reliability occurs when Cronbachs alpha is above 0.7 [36]

. A value of 0.70.8 is good, and a value above 0.8 is very good

( [15], [36]). Cronbachs alpha for, l

mation systems flexibility and organizati

0.7407, 0.708 and 0.8592 respectively. Since all the Cronbachs

alpha are greater than 0.7, the reliability of all model constructs

is confirmed.

4.6. Validity of Model Estimates

.18

Organizational

Flexibility

ORG3

.30

e8

ORG4

.30

e9

ORG5

.42

e10

ORG8

.14

e11

ORG9

.28

e12

ORG10

.39

e13

ORG11

.34

e14

ORG12 e15

1

1

1

1

1

1

1

1

1.76

ORG17

.32

e16

1

1.00

.91

1.23

.81

1.00

1.07

1.00

Logistics

Flexibility

LOF1

.15

.47

.41

e3

.50

e1

1

LOF2 e2

1

LOF3

1

LOF4 e4

1

1.92

1.20

1.47

1.00

.37

ISF1 e5

ISF2

.22

e6

ISF3

.34

e7

1

1

1 .61

.48

1.00

Information

Systems

Flexibility

.01

SUPPLY

CHAIN

FLEXIBILITY

1.00

1.93

1.21

1.19

.29

e1

1

.28

e2

1

.40

e3

1

.16

e4

1

.13

e5

1

.41

e6

1

.40

e7

1

.19

e8

.28

e9

1

1

.34

e10

1

.25

e11

1

.36

e12

1

JSSM

Organizational Flexibility and Information

lexibility

Supply Chain Flexibility

supply chain flexibility us-

graphic. Model fit indices NFI, IFI, TLI,

indicate good model for supply

flexibility. The model shows an overall variance

flexibility characteristics as 0.01. Re-

gression weights are 1.00 for logistics flexibility; 1.21

for organizational flexibility and 1.93 for information

systems flexibility; in order of their increasing impor-

supply chain flexibility. Most

of the characteristics given by respondents were not in-

s final model in Figure 4 because

sion weights and low loading factors (of

less than 0.7). However, there was no loss of objectivity

for the current sample of characte-

variance of observed total test

Reliability occurs when Cronbachs alpha is above 0.7 [36]

0.8 is good, and a value above 0.8 is very good

( [15], [36]). Cronbachs alpha for, logistics flexibility, infor-

mation systems flexibility and organizational flexibility are

0.7407, 0.708 and 0.8592 respectively. Since all the Cronbachs

alpha are greater than 0.7, the reliability of all model constructs

Validity of Model Estimates

Supply Chain Flexibility: Structural Equation Modeling Approach

Copyright 2011 SciRes. JSSM

Convergent validity is measured by Average Variance Ex-

tracted, AVE [37]. The Average Variance Extracted (AVE) for

X [38] with indicators or characteristics x

1

, x

2

, ..., x

n

is given by

Equation (4).

AIE =

|x

i

2

]vu(X)

|x

i

2

]vu(X)+|vu(s

i

)]

(4)

where,

i

the loading of x

i

on X, obtained from principal

component and factor analysis using SPSS soft-

ware; |Ior(e

)] sum of error variances; Ior(X)

variance of rating weights for each characteristic; x

i

characteristic within each attribute of supply chain flex-

ibility, as observed or measured variable; X attribute

of supply chain flexibility e.g. logistics flexibility, as a

latent variable.

The values of AVE for logistics flexibility, information sys-

tems flexibility and organizational flexibility are 0.51217,

0.5091 and 0.5139 respectively, which are acceptable values,

above 0.5, according to literature [15]. Factors of loading were

higher than 0.7 except for ORG17 and LOF2 whose factors of

loading were 0.697 and 0.646, respectively. This could be be-

cause of their relatively low fit to data, and thus comparatively

less contribution to model fit.

5. Implications of Research Findings

The findings of this research have various implications to

business practitioners, theory and further research. Improving

supply chain flexibility can help firms to respond to ever in-

creasing uncertainty and dynamism in global business envi-

ronment through addressing the vital characteristics identified

in this research (see Table 2) and making necessary adapta-

tions. Supply chain should be organized in a responsive and

competitive fashion.

The results of the survey provided a set of characteristics

(see Tables 2), important to theory and to practitioners, aimed

at improving supply chain flexibility. It is noted with respect to

information characteristics, as affirmed by both this research

and literature, that accuracy and timeliness of data is crucial to

supply chain flexibility [5]. Literature also supports the charac-

teristics identified as, ability to: achieve demand visibility

[5], align and control information systems with partners [38]

and share information with partners [39]. The participants

identified the importance of improving information flow as a

significant factor that can bolster supply chain flexibility.

Model results shed light into the correlation between vari-

ous attributes of, logistics flexibility, information system flex-

ibility and organizational flexibility. All pairs of attributes

showed strong positive correlation indicating that an improve-

ment in the core factors like information systems and organiza-

tional aspects goes along with improvement in supply chain

flexibility.

6. Limitations and Further Research

Precautions were taken to avoid obvious limitations, but it is

impossible to avoid all concerns [11, pp. 88]. In this study, the

assumption is that senior managers and academic experts in the

field of supply chain management and logistics have know-

ledge of variables studied in this research. A repeat of the same

study with marketing executives could be a point of interest. In

the process of measurement model analysis, some characteris-

tics were dropped, which could impact content validity of the

research. Further research should evaluate supply chain flex-

ibility measures developed in this research and also test struc-

tural model results to provide further evidence on validity and

reliability of the instruments used in this research. Data collec-

tion in this study was based on 27 expert respondents which,

though supported by literature on Delphi technique, could re-

sult into less reliable results. Another limitation is that the re-

search did not consider implications of costs on supply chain

flexibility. Future research, perhaps with larger sample sizes

and in more specific region or country, can shed more light in

this area and provide further confirmation of results in this

research.

7. Summary and Conclusions

The paper describes supply chain flexibility and its attributes

namely: logistics flexibility, information systems flexibility and

organizational flexibility. Research model that relates the

attributes to each other and to various characteristics examined

is developed. The study constructs a network of supply chain

flexibility constructs and conducts analysis across a large

number of firms. The study is one of the initial investigations

into supply flexibility using structural equation modeling.

Sub-dimensions of supply chain flexibility were measured

using carefully designed, valid and reliable instruments shown

in Table 2. Great care was taken during item generation and

evaluation to capture the content domain of the constructs;

moreover, factor structure is simple and has good loading

above 0.7 except for the two ORG17 and LOF2 whose factors

of loading were 0.697 and 0.646, respectively but with high

regression weights of 1.19 and 1.20 in the final model in Figure

4. The research instruments proposed in this study mark a good

progress towards establishing standard supply chain flexibility

measures and can be applied in evaluating the flexibility of

supply chain or in comparing flexibility across a number of

supply chains, or between firms, countries or regions.

8. References

[1.] World Trade, (2006), The difference between managing a

global vs. domestic supply chain is a matter of degree:,

available at

http://goliath.ecnext.com/coms2/gi_0198-337619/The-differen

ce-between-managing-a.html

[2.] Wind, Jerry and Vijay Mahajan (1997) Issues and Opportuni-

ties in New Product Development: An Introduction to the Spe-

cial Issue, J MARKETING RES, No.34, 1 12.

[3.] Song, Zhihui, (2005), Risks and Uncertainty Analysis on In-

Supply Chain Flexibility: Structural Equation Modeling Approach

Copyright 2011 SciRes. JSSM

ternational Logistics, Chinese Business Review, Vol. 4, No. 4,

41 44.

[4.] Chase, R. B., Jacobs, F. R. and Aquilano, N. J. (2004), Opera-

tions Management for Competitive Advantage, Irwin/ Mc

Graw-Hill: Boston, MA.

[5.] Lummus, R. R., Vokurka, R. J. and Duclos, L. K. (2005)

Delphi Study on Supply Chain Flexibility, INT J PROD RES,

Vol. 43, No. 13, 2687 2708.

[6.] Linstone, H. A. and Turoff, M. (1975) The Delphi Method:

Techniques and Applications, (Addison-Wesley): Reading MA

[7.] Van Hoek, R., Commandeur, H. and Vos, B. (1998) Reconfi-

guring Logistics Systems through Postponement Strategies,

Journal of Business Logistics, Vol. 19, No. 1, 33 54.

[8.] Upton, D.M. (1995) What really makes factories flexible?

HARVARD BUS REV, Vol. 73, No. 4, 74 84.

[9.] Duclos, L., Vokurka, R. and Lummus, R. (2003). A conceptual

model of supply chain flexibility IND MANAGE DATA

SYST, Vol. 103, No. 6, 446 456.

[10.] Lummus,Rhonda R., Duclos,Leslie K., and Vokurka,Robert J.

(2003). Supply Chain Flexibility: Building a New Mod-

el GLOBAL J FLEX SYST MANAG, Vol. 4, No. 4, 1 13.

[11.] Zhang, Q., Vonderembse, M. A. and Lim, J. S. (2005) Logis-

tics flexibility and its impact on customer satisfaction, INT J

LOGIST MANAG, Vol. 16, No. 1, 7195

[12.] Juan, J. P-I. and Josefa, R-M. Measuring Operational Flexiblity

Manufacturing Information Systems,

[13.] Volberda H. W. (1998) Building the Flexible Firm: How to

Remain Competitive. Ed. Oxford University Press, New York.

[14.] Gupta Y P and Goyal S (1989) Flexibility of Manufacturing

Systems: Concepts and Measurements, EUR J OPER RES,

Vol. 43, 119 135.

[15.] Koste L. J. and Malhorta M. K. (1999) A Theoretical

Framework for Analysing the Dimensions of Manufacturing

Flexibility, J OPER MANAG, Vol. 18, 75 93.

[16.] Day, G. S. (1994), The Capabilities of Market-driven Organi-

zations, J MARKETING, Vol. 58, 37 52.

[17.] Bueno E (1996) Business Organiza-

tion: Structure, Processes and Models, Ed Pyramid, Madrid

[18.] Cordery, J., Sevastos, P., Mueller, W. and Parker, S. (1993)

Correlates of Employee Attitudes toward Functional Flexibili-

ty, HUM RELAT, Vol. 46, 705 723.

[19.] Jomehri, N., Javanshir, H. and Nezhad, S. E. (2010) An empir-

ical study to determine the critical success factors on customer

retention: A case study of Iranian banking sector, Management

Science Letters, available at

http://growingscience.com/msl/msl_2010_12.pdf

[20.] Moller, K. and Wilson, D. (1995) Business Marketing: An

Interaction and Network Perspective,: Norwell, MA Kluwer

[21.] Kotler, P. (1986) Principles of Marketing, Prentice-Hall, N. J.

[22.] Sekaran, U. (2003) Research Methods for Business A

SkillBuilding Approach, John Wiley & Sons, Inc., New York

[23.] Miles, M.B. and Huberman, M. (1994) Qualitative Data

Analysis: A Source Book of New Methods, Sage Publications.

London

[24.] Crabtree, B. and Miller, W. (1999) Doing Qualitative Re-

search, Sage Publications, London.

[25.] Witkin, B. R., and Altschuld, J. W. (1995) Planning and

Conducting Needs Assessment: A Practical Guide, Sage Pub-

lications, Inc., Thousand Oaks, CA

[26.] Delbecq, A. L., Van de Ven, A. H., and Gustafson, D. H.

(1975) Group Techniques for Program Planning, Scott, Fores-

man, and Co., Glenview, IL

[27.] Pinilla, C. (2004), International Entrepreneurship in Local

SMEs Supplier Networks, J ECON ISSUES, available at

e-archivo.uc3m.es/bitstream/10016/7321/2/international_IJEI_

2004.pdf

[28.] Salancik, J. R., Wenger, W. and Helfer, E. (1971) The Con-

struction of Delphi Event Statements, TECHNOL FORECAS

SOC, Vol. 3, No. 1, 65 73.

[29.] Martino, J. P. (1983) Technological Forecasting for Deci-

sion-making, Elsevier, New York

[30.] Newsom, (2005) Some Clarifications and Recommendations

on Fit Indices, USP 655 SEM Winter,

[31.] Hu, L. and Bentler, P. M. (1999) Cutoff criteria for Fit Indexes

in Covariance Structure Analysis: Conventional Criteria ver-

sus New Alternatives, Structural Equation Modeling, Vol. 6, 1

55.

[32.] Hunter, L., McGregor, A., MacInnes, J. and Sproull, A. (1993)

The Flexible Firm: Strategy and Segmentation, BRIT J IND

RELAT, Vol. 39, 383 407.

[33.] Mulaik, S. A., James, L. R., Van Alstine, J., Bennett, N.,

Lind, S. and Stilwell, C. D. (1989) Evaluation of Goodness-

of-Fit Indices for Structural Equation Models, PSYCHOL

BULL, Vol. 105, No. 3, 430 445

[34.] Huber, Peter. J. (2004) Robust Statistics, Wiley, N. Y.

[35.] Zinbarg, R., Revelle, W., Yovel, I. and Li, W. (2005) Cron-

bachs , Revelles , and McDonalds : Their relations with

each other and two alternative conceptualizations of relia-

bility, PSYCHOMETRICA, Vol. 70, 123 133.

[36.] Ping, R.A. (2005) What is the Average Variance Extracted

for a Latent Variable Interaction (or quadratic)? available at

http://home.att.net/ ~rpingjr/ave1.doc

[37.] Nunnally, J.C. (1978). Psychometric Theory, McGraw-Hill,

New York

[38.] Gabauer, J. and Schober, F. (2005) Information System Flex-

ibility and the Performance of Business Processes, Journal of

the Association for Information Systems (JAIS) URL:

http://www.business.uiuc.edu/Working_Papers/papers/05011

2.pdf

[39.] Magretta, J. (1998) The Power of Virtual Integration: An In-

terview with Dell Computers Michael Dell, HARVARD BUS

REV, Vol. 76, 72 85.

You might also like

- Lessons 11 and 12 Engineering Mathematics I Production OptionDocument33 pagesLessons 11 and 12 Engineering Mathematics I Production OptionRobert K OtienoNo ratings yet

- Lesson 9 Engineering Mathematics I Production OptionDocument15 pagesLesson 9 Engineering Mathematics I Production OptionRobert K OtienoNo ratings yet

- The County Government Act 2012 PDFDocument124 pagesThe County Government Act 2012 PDFRobert K OtienoNo ratings yet

- Compression Test Lab ReportDocument11 pagesCompression Test Lab ReportRobert K OtienoNo ratings yet

- Zonal InshaDocument4 pagesZonal InshaRobert K OtienoNo ratings yet

- NELBDocument13 pagesNELBRobert K OtienoNo ratings yet

- Effects of Availability of Organic Food: Products On Consumer Choice For FastDocument13 pagesEffects of Availability of Organic Food: Products On Consumer Choice For FastRobert K OtienoNo ratings yet

- Prayers of DavidDocument1 pagePrayers of DavidRobert K OtienoNo ratings yet

- Review of Literature ConsultedDocument3 pagesReview of Literature ConsultedRobert K OtienoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Unit 1 .Introduction To Strategic ManagementDocument10 pagesUnit 1 .Introduction To Strategic Managementsoucollegemba625004100% (1)

- Mastering Strategic Management Vol1 1 1st Edition Ketchen Test BankDocument35 pagesMastering Strategic Management Vol1 1 1st Edition Ketchen Test Banksugarstearoneymw4l9100% (26)

- Diversification StrategyDocument9 pagesDiversification StrategyYashovardhan Shah ♠No ratings yet

- Resume by Alexia Wallick For WebsiteDocument3 pagesResume by Alexia Wallick For Websiteapi-301881945No ratings yet

- Marketing Manager Job DescriptionDocument3 pagesMarketing Manager Job DescriptiondhaiwatsNo ratings yet

- National Electronics Policy 2012Document4 pagesNational Electronics Policy 2012imahere_suryaNo ratings yet

- Strategic Management: Unit IDocument59 pagesStrategic Management: Unit INeha SrivastavaNo ratings yet

- MBA 510 SyllabusDocument5 pagesMBA 510 SyllabusShashank GuptaNo ratings yet

- Chapter 1 - Defining Marketing For The 21 CenturyDocument10 pagesChapter 1 - Defining Marketing For The 21 CenturymulanjamellaNo ratings yet

- W14 MGMT - 4260 S01 International Business J.ismail OutlineDocument9 pagesW14 MGMT - 4260 S01 International Business J.ismail OutlineSayed Shahid JilaniNo ratings yet

- Mibas Curriculum Wise 1617Document1 pageMibas Curriculum Wise 1617Asif NawazNo ratings yet

- Sustainability Report 2014 - SME BankDocument91 pagesSustainability Report 2014 - SME Bankabu100% (1)

- Waves Audit ReportDocument18 pagesWaves Audit ReportWaqas AhmadNo ratings yet

- Assessment Description and Marking Criteria Marketing Planning (2019 MOD004454 TRI1 F01CAM) 3000 WordsDocument8 pagesAssessment Description and Marking Criteria Marketing Planning (2019 MOD004454 TRI1 F01CAM) 3000 WordsPawitt Lertpanurot100% (1)

- HRM 638 (A) - Paris France Hotel Case Study - Su Mmer 2020Document4 pagesHRM 638 (A) - Paris France Hotel Case Study - Su Mmer 2020Iqbal JoyNo ratings yet

- Industry 4.0 and The Effects of Digitization On OrganisationsDocument2 pagesIndustry 4.0 and The Effects of Digitization On OrganisationsSouvik BiswasNo ratings yet

- Manual Part I Business SimDocument30 pagesManual Part I Business SimJonasNo ratings yet

- Project Report On Amazon CompressDocument19 pagesProject Report On Amazon CompressSaumya BharadwajNo ratings yet

- 1 SMDocument10 pages1 SMNika DinisaNo ratings yet

- MGT 201Document10 pagesMGT 201Saim Lovely SulmanNo ratings yet

- Summer Internship Report ON Analysis of Strategic and Digital Marketing AT Peacock SolarDocument46 pagesSummer Internship Report ON Analysis of Strategic and Digital Marketing AT Peacock SolarRupeshNo ratings yet

- Research Paper of Khadim JanDocument13 pagesResearch Paper of Khadim JanKhadim Jan100% (2)

- Sas Marketing Optimization FactsheetDocument4 pagesSas Marketing Optimization FactsheetcamariusNo ratings yet

- Civil Engineering Level 6 OSDocument161 pagesCivil Engineering Level 6 OSmatundura100% (1)

- BISD Course Manual Ebc4106 - 2020Document30 pagesBISD Course Manual Ebc4106 - 2020Marcel LasselsbergerNo ratings yet

- KSDL ProfileDocument30 pagesKSDL ProfileManju Cool0% (1)

- 08Document284 pages08Amira SeddiqNo ratings yet

- Fournier ArquitecturaDocument54 pagesFournier ArquitecturaJaime Fournier FerraNo ratings yet

- A Study On Brand Awareness of Nirapara Sortex RiceDocument79 pagesA Study On Brand Awareness of Nirapara Sortex RiceAdarsh Jayaraj20% (5)

- Organizational Development Is The Process of Helping Organizations Improve Through ChangeDocument2 pagesOrganizational Development Is The Process of Helping Organizations Improve Through ChangeSayed HashimiNo ratings yet