Professional Documents

Culture Documents

A High Strength Corrosion Resistant Alloy INCO 686 Solves Fastener Problems in The Marine Industry

Uploaded by

fkhortonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A High Strength Corrosion Resistant Alloy INCO 686 Solves Fastener Problems in The Marine Industry

Uploaded by

fkhortonCopyright:

Available Formats

A High Strength, Corrosion-Resistant Alloy Solves Fastener Problems in the Marine Industry

by Edward L. Hibner & Lewis E. Shoemaker Huntington Alloys / Special Metals Corporation Huntington, WV 25705, USA Introduction Vessels and equipment built for service in seawater and other marine environments must employ fasteners that are resistant to corrosion by the aggressive service conditions to which they are exposed. Contractors and fabricators who build ships for the U.S. Navy must recognize this requirement, as a structure is no stronger or more reliable than its weakest member. Failure of a nut or bolt can have catastrophic results. Because the fastener is generally much smaller than the components it is used to support, the fasteners generally must be more corrosion resistant to offset any effects of galvanic corrosion. Should the fastener be anodic to the remainder of the structure, the relative size effect could cause severe corrosion and degradation of the fastener in a short period of time. Thus, corrosion-resistant nickelbase fasteners have been extensively used in marine service. For example, MONEL alloy K-500 (UNS N05500) fasteners are used with alloy steel in a seawater environment. However, the resulting galvanic coupling can induce hydrogen charging and subsequent embrittlement of the fasteners, and failures of the alloy K-500 have occurred. Consequently, more noble high strength bolting materials are needed. INCONEL alloy 686 (UNS N06686) is a high performance nickel-base alloy that exhibits high tensile strength and fracture toughness. It offers excellent resistance to corrosion in marine environments, superior even to alloy K-500, which has set the standard for marine performance for many years. In addition, the strength of alloy 686 can be further enhanced by cold work. Thus, bolts with yield strength levels up to 150 ksi (equivalent or superior to alloy K-500) can be produced. An extensive program has been conducted qualify the alloy 686 fasteners for marine service on naval vessels and equipment. --------------------MONEL &INCONEL are registered trademarks of the Special Metals Corporation Group of companies.

INCONEL alloy 686 INCONEL alloy 686 is a nickel base alloy enhanced by its content of chromium, molybdenum, and tungsten. The typical chemical composition of the alloy is reported in Table 1. The content of chromium gives the alloy resistance to oxidizing corrodents while molybdenum and tungsten allow it to resist reducing media and seawater. All these elements have the effect of solid solution strengthening the alloy. Alloy 686 is covered by ASTM, SAE, and AWS specifications and is approved for ASME and VdTV construction. It is approved under NACE MR0175 for service in severe sour gas environments. Table 1 Chemical Composition (%) of INCONEL alloy 686 Ni 58 Cr 21 Mo 16 W 4 Fe 1 C 0.006

Comparative Corrosion Resistance By virtue of its high content of alloying elements, alloy 686 offers excellent resistance to corrosion by a variety of aggressive media. To demonstrate its resistance to various marine environments many types of corrosion tests were conducted. A standard test for comparing the corrosion resistance of alloys is the ASTM G48 method. A temperature to induce pitting and crevice corrosion in acidified ferric chloride is determined. The critical pitting temperature (CPT) is determined by raising the temperature incrementally until the onset of corrosion. Alloys are then ranked by their relative values. The minimum accepted CPT for North Sea offshore applications is 40oC (104oF), while in pulp and paper bleaching environments, this temperature is typically 50oC (122oF). A ranking of alloys is shown in Table 2. Corrosion Resistance in Seawater Since most intended applications will expose the fasteners to seawater, alloy 686 was extensively tested in marine media. Figure 1 displays the air and seawater high cycle fatigue curves for cold worked alloy 686 bar in ambient seawater and, for comparison, in air. It is seen that the curves are essentially identical, indicating that the seawater has no effect on the performance of the alloy. Crevice corrosion data for alloy 686 and similar alloys evaluated in quiescent seawater at 25C (77F) for 60 days are shown in Table 3. The alloy 686 plate and alloy 686 weldment samples were resistant to crevice corrosion, as was the alloy C-276 (UNS N10276) plate samples. While alloy 625 (UNS N06625) is widely used in marine construction, the samples corroded in this test demonstrating the superior performance of alloy 686. Crevice corrosion tests were also performed in flowing seawater. Tube sections with vinyl sleeve crevices were exposed in flowing seawater at 14.4C (58F) for 180 days. Alloys 686 and C-276 did not crevice corrode, while alloy 625 specimens crevice corroded to a maximum depth of 0.11 mm (0.0043 in.).

Since the fastener material is often dissimilar to the components being joined (which also may be dissimilar), a galvanic coupling often exists. This can induce galvanic corrosion. To evaluate the galvanic compatibility of alloy 686 with other corrosion resistant alloys, tests were performed in ambient temperature seawater for 180 days. Alloys 686 was determined to be galvanically compatible with alloys 625, 400, and K-500. It is noted that significant size differences can affect this compatibility. Seawater is used on board vessels for various reasons. The water is chlorinated to avoid fouling. The addition of chlorine to the seawater increases its corrosivity. Crevice corrosion tests of a number of alloys were conducted in chlorinated seawater at 60C (140F) for 60 days and 200C (392F) for 90 days. Of the alloys tested at 60C (140F), only alloy 686 showed no evidence of crevice attack under these conditions. At 200C (392F), only alloys 686 and grade 2 titanium were free of attack Hydrogen Embrittlement As stated earlier, hydrogen embrittlement has been a problem with marine fasteners, especially when dissimilar material are coupled. Alloy 686 was shown to be resistant to hydrogen embrittlement in the NACE International TM0177 sulfide stress cracking test. To further quantify the alloys resistance to hydrogen embrittlement, notched specimens were exposed under stress in seawater for 5,000 hours and charged with hydrogen. The ratio of the strength of such specimens determined under slow strain conditions to that of unexposed specimens is an indication of the alloys resistance to hydrogen. The ratios of the alloy 686 specimens were 0.96, indicating excellent resistance. Mechanical Properties Alloy 686 is a solid solution strengthened, single phase, austenitic alloy. While its strength at room temperature is high, it can be enhanced by cold work (Figure 2). Alloy 686 exhibits an excellent combination of strength, ductility, and toughness when either annealed or cold worked. The tensile properties of the alloy at room temperature are seen in Table 4. The yield strength and impact strength of cold worked alloy 686 bar are reported in Table 5. Alloy 686 bar cold worked to a yield strength of 148.0 ksi (1020 MPa) exhibited 54.1 % tensile elongation and an impact strength of 98 ft-lb (133 N-m) at 32F (0C). Materials worked to a yield strength of 114.8 ksi (792 MPa) exhibited 56.8 % tensile elongation and an impact strength of 177 ft-lb (240 N-m). Fracture toughness was evaluated for alloy 686 plate cold rolled to yield strengths of 108 to 120 ksi (745 to 827 MPa) exhibited excellent fracture toughness values of 319 to 362 ksi(in.), 351 to 398 MPa(m), at 75F (24C) as determined by ASTM Standard Test Method E992, the equivalent energy methodology (KEE). Fastener Properties Threaded fastener tensile and 10 wedge tensile values (ASTM F606) were determined for in. x 13 (manufactured from 114.8 ksi yield strength / 144.0 ksi tensile strength stock), 7/16 in. x 14 (manufactured from 148.0 ksi yield strength / 161.7 ksi tensile strength stock), and 5/16 in. x 16 (manufactured from 95.3 ksi yield strength / 130.3 ksi tensile strength stock) hex head bolts made to ANSI B18.2.1 with Class 2A threads formed by chasing. Tensile data for the bolts tested are presented in Tables 6 and 7. As is seen, the properties of the bolts essentially match those of the starting stock.

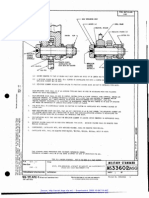

The untested nut and bolt and a tested bolt are shown in Figure 3. It is seen that the fracture is ductile. Fastener Specifications Requirements for INCONEL alloy 686 fasteners are contained in the common specifications including ASTM F467, F467M, F468, and F468M and SAE J2271, J2280, J2295, and J2485.The ASTM fastener grade designations are: Ni 686 Grade 1 Ni 686 Grade 2 Ni 686 Grade 3 F467BN F467BN F467BN 85-ksi min. yield strength 125-ksi min. yield strength 150-ksi min. yield strength

In addition, three strength grades of the alloy will be added to the next edition of MIL-DTL-1222. Summary INCONEL alloy 686 has been tested and qualified for manufacture of fasteners for service in aggressive marine environments. By cold working, fasteners with yield strength levels up to 150 ksi can be made. The resulting products exhibit excellent resistance to corrosion by seawater and hydrogen embrittlement. Alloy 686 fasteners are galvanically compatible with the common materials of marine construction. The high strength fasteners exhibit good ductility and fracture toughness. Thus, alloy 686 fasteners are expected to solve many of the problems encountered with existing grades of corrosion-resistant marine fasteners. Several companies have demonstrated their ability to manufacture alloy 686 fasteners and hardware, which means that the products should be readily available. For more information on INCONEL alloy 686 the readers are invited to visit the Special Metals website, www.specialmetals.com or contact Lewis Shoemaker by telephone at (304) 526-5664 or by e-mail at Lshoemaker@specialmetals.com.

TABLE 2 CRITICAL CREVICE AND CRITICAL PITTING TEMPERATURES IN AN ACIDIFIED 6% FERRIC CHLORIDE SOLUTION (ASTM G48 C & D) Alloy 686 C-276 725 625 925 825 304SS Critical Crevice Temperature C F >85 >185 45 113 35 95 30 35 86 95 5 41 5 41 <0 <32 Critical Pitting Temperature C F >85 >185 >85 >185 >85 >185 >85 >185 30 86 30 86 15 59

TABLE 3 CREVICE CORROSION OF WROUGHT AND WELD SAMPLES OF ALLOYS 686, 625 & C-276 IN QUIESCENT SEAWATER AT 25C (77F) FOR 60 DAYS Wrought Materials alloy 686 alloy 625 alloy C-276 (SMC) alloy C-276 (non-SMC) Weldments alloy 686 alloy 625 Number of Sites Attacked/ Number of Sites Available 0/6 2/6 0/6 1/2 Maximum Depth of Attack, mm (in.) 0.00 (0.000) 0.11 (0.004) 0.00 (0.000) 0.02 (0.001)

0/6 1 /2

0.00 (0.000) 0.49 (0.019)

TABLE 4 ROOM TEMPERATURE TENSILE PROPERTIES OF COLD WORKED ALLOY 686

Cold Work (%) 0 5 10 15 Test Location Typical Mid- Radius Total Thickness Mid- Radius Total Thickness Mid- Radius Total Thickness 0.2% Yield Strength (ksi) 52 67.8 72.8 99.5 90.6 103.8 98.5 Tensile Strength (ksi) 105 117.3 116.0 131.7 123.7 134.3 126.0 Elongation (%) 52 56 56.5 41.5 48.8 38.5 44.3

TABLE 5 CHARPY-V-NOTCH IMPACT STRENGTH OF COLD WORKED ALLOY 686 BAR AT 0F (-18C) Yield Strength (ksi) 148.0 114.8 95.3 Impact Energy, ft-lb (N-m) 98 (133) 177 (240) 178 (241) Lateral Expansion in. (mm) 0.046 (1.17) 0.068 (1.73) 0.058 (1.47)

TABLE 6 ROOM TEMPERATURE THREADED FASTENER TENSILE TEST DATA FOR COLD WORKED ALLOY 686 BOLTS Ultimate Tensile Load, lb 19,660 19,471 19,749 16,761 16,669 16,871 9,895 9,870 9,920 Ultimate Tensile Strength, ksi (MPa) 138 (952) 137 (945) 139 (958) 158 (1089) 157 (1083) 159 (1096) 128 (883) 127 (876) 128 (883) 0.2% Yield Load, lb 16,741 16,569 16,877 15,776 15,683 15,890 0.2% Yield Strength, ksi (MPa) 118 (814) 117 (807) 119 (821) 148 (1020) 148 (1020) 149 (1027) 98 (676) 97 (669) 98 (676)

1/2 in. x 13 Bolt 7/16 in. x 14 Bolt 5/16 in. x 16 Bolt

Average Minimum Maximum Average Minimum Maximum Average Minimum Maximum

TABLE 7 ROOM TEMPERATURE 10 WEDGE TENSILE TEST DATA FOR THREADED BOLTS OF COLD WORKED ALLOY 686 BAR Ultimate Tensile Load, lb 19,568 19,030 19,820 16,814 16,560 16,910 9,840 9,840 9,840 Ultimate Tensile Strength, ksi (MPa) 138 (952) 134(924) 140 (965) 158 (1098) 156 (1076) 159 (1096) 127 (876) 127 (876) 127 (876)

1/2 in. x 13 Bolt 7/16 in. x 14 Bolt 5/16 in. x 16 Bolt

Average Minimum Maximum Average Minimum Maximum Average Minimum Maximum

1000 900 800 700 600 500 400 300 200 100 0 1.00E+04

Air Seawater

Stress, MPa

1.00E+05

1.00E+06 Log Cycles

1.00E+07

1.00E+08

FIGURE 1 High Cycle Fatigue Data for Alloy 686 0.75 in. (19 mm) Bar Cold Worked to 145 ksi Yield Strength

250

Yield Strength, ksi

200 150 100 50 0 0 10 20 30 40 50 M id - R a d iu s T o ta l T h ic k n e s s

% C o ld W o r k F IG U R E 2 E f f e c t o f C o ld W o r k o n Y ie ld S t r e n g t h o f A llo y 6 8 6 ( U N S N 0 6 6 8 6 )

FIGURE 3 INCONEL alloy 686 5/16 in. X 16 Bolts and Nut. The fracture surface of the bolt broken during tensile testing exhibits ductile fracture .

You might also like

- Mil-S-1222 Rev HDocument44 pagesMil-S-1222 Rev HfkhortonNo ratings yet

- Mil-S-1222 Rev HDocument44 pagesMil-S-1222 Rev HfkhortonNo ratings yet

- Mil-S-1222 Rev HDocument44 pagesMil-S-1222 Rev HfkhortonNo ratings yet

- MS33602Document1 pageMS33602fkhortonNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ® Sand Content Kit Instruction CardDocument2 pages® Sand Content Kit Instruction CardTg TarroNo ratings yet

- The Utilization of Plastic Wrappers in The Production of Non Load Bearing Hollow BlocksDocument130 pagesThe Utilization of Plastic Wrappers in The Production of Non Load Bearing Hollow Blocksvanessa JeanNo ratings yet

- Eman AliDocument99 pagesEman AlijahangiriNo ratings yet

- Characterization and Study of Turkish Perlite: October 2007Document9 pagesCharacterization and Study of Turkish Perlite: October 2007Raul Alvarado VlncNo ratings yet

- Answer ATSDocument17 pagesAnswer ATSkembara08No ratings yet

- Power Design: Exxtraaa Smoothh.Document2 pagesPower Design: Exxtraaa Smoothh.John GonzalezNo ratings yet

- Molybdenum ToxicityDocument19 pagesMolybdenum ToxicityAdarshBijapurNo ratings yet

- Pga Manual Hasxmde-Im-Ex X-Stream x2fd 201210Document148 pagesPga Manual Hasxmde-Im-Ex X-Stream x2fd 201210Umar SaeedNo ratings yet

- Edexcel Intl A Levels Biology Unit 3 Wbi13 v1Document6 pagesEdexcel Intl A Levels Biology Unit 3 Wbi13 v1seif nimer100% (1)

- Procure APIs Simply and Cost-Effectively with TiefenbacherDocument16 pagesProcure APIs Simply and Cost-Effectively with Tiefenbacherমোঃ এমদাদুল হকNo ratings yet

- Variable Speed Chillers With PicvDocument1 pageVariable Speed Chillers With PicvPradeep SukumaranNo ratings yet

- H2S RefersherDocument35 pagesH2S RefersherAhmed AbdallahNo ratings yet

- Gujarat Technical University: Year Group No.: 13 Subject TopicDocument11 pagesGujarat Technical University: Year Group No.: 13 Subject TopicParth AnajwalaNo ratings yet

- Granted patents for novel extraction process of oxyresveratrolDocument18 pagesGranted patents for novel extraction process of oxyresveratrolCharowar HussainNo ratings yet

- A Review On Tungsten Oxide (WO3) and Their Derivatives For Sensor ApplicationsDocument7 pagesA Review On Tungsten Oxide (WO3) and Their Derivatives For Sensor ApplicationsQuang Triểu VõNo ratings yet

- TransducerDocument12 pagesTransducerYashiro IsanaNo ratings yet

- Lipids: Fats, Oils, Steroids and Their ImportanceDocument3 pagesLipids: Fats, Oils, Steroids and Their ImportanceEvangeline Galac AbrilNo ratings yet

- Methoxyphenol (Although 3-Allyl-4-Methoxyphenol Can't Be Excluded Either) - Thus, The ProtonDocument5 pagesMethoxyphenol (Although 3-Allyl-4-Methoxyphenol Can't Be Excluded Either) - Thus, The ProtonAnonymous f8P42082UNo ratings yet

- P7 - Proper Staining of Blood SmearDocument3 pagesP7 - Proper Staining of Blood SmearAlthea Jam Grezshyl GaloNo ratings yet

- RA 9165: Comprehensive Dangerous Drugs ActDocument52 pagesRA 9165: Comprehensive Dangerous Drugs ActCabagan IsabelaNo ratings yet

- Washing Machine DAEWOO DWD F1011 SERVICE MANUAL PDFDocument16 pagesWashing Machine DAEWOO DWD F1011 SERVICE MANUAL PDFFdelS100% (1)

- Understanding Selectivity of Hard and Soft Metal Cations Within Biological Systems Using The Subvalence ConceptDocument16 pagesUnderstanding Selectivity of Hard and Soft Metal Cations Within Biological Systems Using The Subvalence ConceptAnother Gaming MailNo ratings yet

- Recent Researches in Metallurgical Engineering - From Extraction To FormingDocument198 pagesRecent Researches in Metallurgical Engineering - From Extraction To FormingJosé Ramírez100% (2)

- Cynamic Product Catalog 2018Document24 pagesCynamic Product Catalog 2018api-445881982No ratings yet

- E-Lab Report 2Document8 pagesE-Lab Report 2AIMAN HAZIQ PAKHURUDDINNo ratings yet

- Contractor Quality Control Plan For Welding WorkDocument3 pagesContractor Quality Control Plan For Welding WorkCak Nhass50% (2)

- Relationship Between Compressive Split Tensile of Self Compacting ConcreteDocument12 pagesRelationship Between Compressive Split Tensile of Self Compacting Concretesanthu256100% (1)

- Thermoplastic Elastomers TPE, TPR PDFDocument6 pagesThermoplastic Elastomers TPE, TPR PDFMohammad Amir AliNo ratings yet

- The Essentials of Continuous EvaporationDocument5 pagesThe Essentials of Continuous EvaporationRajendraNo ratings yet

- Desuperheater Catalog of DAEJU CONTROL CO., LTD.Document28 pagesDesuperheater Catalog of DAEJU CONTROL CO., LTD.Ki Ho ChungNo ratings yet