Professional Documents

Culture Documents

BHP F&F Furnace Efficiency Improvements

Uploaded by

rsingle81Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BHP F&F Furnace Efficiency Improvements

Uploaded by

rsingle81Copyright:

Available Formats

FURNACE and FLARE

FURNACE EFFICIENCY IMPROVEMENTS NOx REDUCTION FLARE GAS RECOVERY EFFICIENCY SEMINARS CEMS

A DIVISION OF BHP ENGINEERING AND CONSTRUCTION, L.P. 715 Oak Park Ave Corpus Christi, TX 78408, USA Voice: (361) 693-6200 Fax: (361) 884-3522

FURNACE EFFICIENCY IMPROVEMENTS FLARE GAS RECOVERY EFFICIENCY SEMINARS NOx REDUCTION CONTINUOUS EMISSION MONITORING SYSTEM FEA STRESS ANALYSIS

CORPUS CHRISTI

715 OAK PARK AVENUE CORPUS CHRISTI TEXAS 78408 361-693-6200

VICTORIA

11202 US HWY. 59 NORTH, SUITE B VICTORIA TEXAS 77905 361-572-8039

BAYPORT

11837 FAIRMONT PARKWAY LA PORTE TEXAS 77571 979-429-6807

LAGOS

Plot 28 Block 93 Awkuzu Street Lekki 1 Lagos Nigeria 234-1-270-1581

www.bhpeng.com

FURNACE and FLARE

FURNACE EFFICIENCY IMPROVEMENTS NOx REDUCTION FLARE GAS RECOVERY EFFICIENCY SEMINARS CEMS

A DIVISION OF BHP ENGINEERING AND CONSTRUCTION, L.P. 715 Oak Park Ave Corpus Christi, TX 78408, USA Voice: (361) 693-6200 Fax: (361) 884-3522

REDUCE ENERGY COST UP TO 5 PERCENT ............................................................................3 ENERGY SERVICES ......................................................................................................................4 BENEFITS........................................................................................................................................4 FURNACE and FLARE ...................................................................................................................5 A. FURNACE EFFICIENCY IMPROVEMENTS ...................................................................... 5

B. NOx REDUCTION .................................................................................................................. 6

C. FLARE GAS RECOVERY...................................................................................................... 7

D. ENERGY LOSS SURVEY...................................................................................................... 8

E. PERSONNEL TRAINING....................................................................................................... 8

F. DATA COLLECTION AND REPORTS................................................................................. 9

CEMS..............................................................................................................................................10 FEA STRESS ANALYSIS .............................................................................................................12 PROJECT PROFILE - FURNACES ..............................................................................................13

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

REDUCE ENERGY COST UP TO 5 PERCENT Let our combustion experts give you timely, cost effective support and solutions for your combustion equipment problems. Furnace and Flare Engineers are experienced in design, startup, operation, troubleshooting, and analysis of combustion equipment. The charts below illustrate the savings possible from small efficiency improvements to a medium size heater (100MM BTU/Hr) using fuel valued at $5 to $10 per MM BTU.

$ 600,000 $ 500,000 $ 400,000 A nnual Savings, $ /Yr $ 300,000 @5% Impro vement $ 200,000 $1 00,000 $0 5 6 7 8 9 1 0 Fuel Co st, $ per M M B TU

5 % E xc e s s A ir

1 0 % E xc e s s A ir

Furnace Efficiency

S ta c k T e m p e ra tu re

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

ENERGY SERVICES Furnace and Flare offers the services of experienced engineers to improve the efficiency of your combustion equipment. A. FURNACE EFFICIENCY IMPROVEMENTS B. NOx REDUCTION C. FLARE GAS RECOVERY D. ENERGY LOSS SURVEYS E. PERSONNEL TRAINING FOR BETTER OPERATION F. DATA COLLECTION, CALCULATIONS AND REPORTS

BENEFITS Most improvements may be implemented with little capital investment, and results can be realized with minimum cost. Improvements to your combustion equipment can yield the following benefits. REDUCED ENERGY COST LOWERED EMISSIONS MAXIMIZED EFFICIENCIES EXTENDED EQUIPMENT SERVICE LIFE

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

FURNACE and FLARE offers the following technical services to improve the efficiency of your combustion equipment. These services cover the complete range of client needs from heater efficiency surveys and operator/ supervisor training to the recovery of products and fuel from flare gas. A. FURNACE EFFICIENCY IMPROVEMENTS The following investigation steps will be taken to develop a plan that will outline corrective action and issue a report of equipment and operating changes needed with an estimate of potential savings. STACK GAS ANALYSIS HEATER DRAFT PROFILE HEATER TEMPERATURE PROFILE OBSERVATION OF FLAME PATTERN MECHANICAL CONDITION OF EQUIPMENT PROCESS FLOW AND TEMPERATURE PROFILE TUNING THE FURNACE FOR OPTIMUM EFFICIENCY

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

B. NOx REDUCTION Troubleshooting and installation of modern burners is important for optimum fuel efficiency and LoNOx performance. FURNACE and FLARE has the experience to solve your burner problems. BURNER REGISTER OPERATION BURNER FLAME PATTERN DIAGNOSTICS TURNAROUND MAINTENANCE SUPERVISION BURNER TIP ALIGNMENT AND TOLERANCE ADJUSTMENTS AIR PREHEAT AND DUCT SYSTEM DIAGNOSTICS FUEL FILTRATION SYSTEMS DESIGN

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

C. FLARE GAS RECOVERY FURNACE and FLARE can assist you with any flare system problems from relief valve sizing to tip replacement to product recovery from flare gas. PSV SIZING WITH INLET AND OUTLET PIPE SIZING PER API 520 RELIEF SYSTEM DESIGN AND HYDRAULIC CALCULATIONS KNOCKOUT DRUM AND SEAL DRUM DESIGN FLARE TIP DIAMETER AND ELEVATION ESTIMATION PER API 521 FLARE GAS RECOVERY SYSTEM DESIGN AND INSTALLATION

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

D. ENERGY LOSS SURVEY The energy transmission and exchanger train will be investigated to develop a plan of action to reduce steam and heat transfer losses. STEAM SYSTEM SURVEYS BOILER EFFICIENCY INVESTIGATION HEAT EXCHANGER EFFICIENCY INVESTIGATION

E. PERSONNEL TRAINING FURNACE and FLARE can provide tools and understanding your operators and supervisors need to continuously monitor and adjust your combustion equipment for optimum efficiency. BURNER AND HEATER SEMINARS BOILER OPERATION AND TROUBLESHOOTING NOx FORMATION CHEMISTRY HAND'S ON PROBLEM SOLVING

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

F. DATA COLLECTION AND REPORTS All aspects of furnace and boiler operation can be captured for resolution of efficiency problems or stack gas compliance investigation. Reports will be issued in a timely manner. TIMELY REPORT OF FINDINGS SUGGESTIONS FOR ENERGY SAVINGS COST ESTIMATES FOR ANY EQUIPMENT CHANGES RESULTS OF EQUIPMENT MECHANICAL CONDITION PHOTOGRAPHS OF EXISTING EQUIPMENT CALCULATIONS INCLUDED WITH RAW OPERATING DATA

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

CEMS

(Continuous Emission Monitoring System)

BHP provided all phases of engineering including front end engineering, budget estimates, detailed engineering, installation, inspection and start up. The analyzer projects included: Sample System Analyzer Specifications & Purchase Analyzer / Control System Interface Design The following is a list of recent CEMS projects with cost range up to $500,000. BHP Heater Analyzer Projects Year Client Project Description Analyzed 2005 CITGO 2003 CITGO 2000 CITGO 1998 CITGO 2005 FHR 2004 FHR 2004 FHR 2003 FHR 2002 FHR 2001 FHR 2003 Valero #4 Platformer Heater CEMS SRU Claus Air Demand Analyzers SRU Tail Gas Incinerator CEMS #2 FCCU CEMS MIO Crude Boiler CEMS #2 Parex Heater CEMS Toluene Heater CEMS Thermal Oxider CEMS MSTDP Heater CEMS BTX Heaters CEMS (4 Stack System) Three Rivers Fuel Gas H2S Analyzer NOx, O2 H2S, SO2 SO2, O2 NOx, CO, O2 NOx, CO, O2 NOx, CO, O2 NOx, CO, O2 H2S NOx, CO, O2 NOx, CO, O2 H2S

Plus numerous other on-line process analyzer projects.

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

10

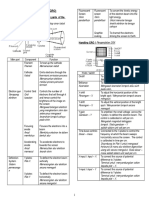

Continuous Emission Monitoring System

FHR BTX Heaters CEMS (4 Stack System) NOx, CO, O2

Dual Stream Monitoring

Single Stream Monitoring

Firing Efficiency Analyzer O2 & Combustibles

Manual Operation

Automatic Operation

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

11

FEA STRESS ANALYSIS Before Revision Over Stress

After Revision Over Stress Removed

Stress contour views of heater stack for a heater upgrades project Structural design capabilities utilizing FEA improves structural design economy & saves T/A time.

CORPUS CHRISTI VICTORIA BAYPORT LAGOS

12

FURNACE and FLARE

FURNACE EFFICIENCY IMPROVEMENTS NOx REDUCTION FLARE GAS RECOVERY EFFICIENCY SEMINARS

A DIVISION OF BHP ENGINEERING AND CONSTRUCTION, L.P. 715 Oak Park Ave Corpus Christi, TX 78408, USA (361) 693-6200

PROJECT PROFILE - FURNACES

Furnace and Flare Engineers have completed many projects to upgrade Heaters and Boilers for LoNOx requirements and improve energy conservation. Notable Burner and Heater Projects: Refinery LoNOx Burners - Burner Installed Cost $1.3 million CITGO Refining Company - Corpus Christi, TX Provided engineering with PFD's, P&ID's, Electrical One-lines, Instrument Loop drawings, Tie-ins, and mechanical specifications to retrofit the # 5 Platformer furnace with LoNOx burners.

Refinery LoNOx Burners - Burner Installed Cost $1.5 million CITGO Refining Company - Corpus Christi, TX Provided engineering with PFD's, P&ID's, Electrical One-lines, Instrument Loop drawings, Tie-ins, and mechanical specifications to retrofit the # 4 Platformer furnace with LoNOx burners.

Refinery LoNOx Burners - Burner Cost $1.0 million Flint Hills Resources - Corpus Christi, TX Provided engineering with PFD's, Tie-ins, P&ID's, Electrical One-lines, Instrument Loop drawings, and mechanical specifications to retrofit the West Crude furnace with LoNOx burners. This project included new fuel gas coalescing filters, air preheater, burner controls and air ducts. Co-Gen Auxiliary Burners Valero Refining - Corpus Christi, TX A Duct Burner system was added to the existing Cogeneration/Steam Generation Unit in the East Plant to provide supplemental firing to increase steam generation. Provided initial process evaluation, scope definition, complete engineering, equipment specification and selection, construction management and start-up assistance for this project.

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

13

6-Oil System Reactivation Equistar Chemicals, LP - Corpus Christi, TX Complete detail design for the reactivation of the 6-Oil facilities for the A Boilers at the Equistar Corpus Christi Plant, including mechanical /piping, instrument/electrical and Triconex programming update. This project converted 4 boilers from natural gas to heavy waste oil fuel firing.

Waste Liquid Boiler and Turbo-Gen. Set - Total Project Cost $5.0 Million Celanese Chemical Provided project management and complete project design for full discipline Waste Liquid Boiler and 600# Steam Turbo-Generator Set.

SRU Waste Heat Boilers and Superheater - Total Project Cost $1.6 Million Valero Refining - Corpus Christi, TX Provided complete detail process and project engineering including mechanical, I&E, structural, and piping design. This project was performed on a crash basis. Partial issues of drawings were required to expedite construction. Assisted in construction inspection. Gas Oil HDS Unit Revamp - Total Project Cost $8.0 Million Valero Refining - Corpus Christi, TX Provided a 25% increased flow rate to the Gas Oil Treater Stabilizer Heat with heat integration, improved preheat capabilities and energy conservation. This increased product recovery was achieved while meeting desired product specifications. Major new equipment included a reactor, heater, trayed vessel, drums, air-cooled exchangers, shell & tube exchangers, numerous pumps and instrumentation. Provided initial process simulations and evaluations, scope definition, definitive project estimate, complete engineering, equipment specification and selection, construction management and start-up assistance for this project. The pre-outage construction portion of this project was accomplished in six weeks, while the unit outage portion o the effort was accomplished in twenty days. Peak workforce for this project was 300 men.

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

14

Refinery LoNOx Burners - Burner Installed Cost $450,000 Valero Refining Three Rivers, TX Provided engineering with PFD's, P&ID's, Electrical One-lines, Instrument Loop drawings, Tie-ins, Piping isometrics and mechanical specifications to retrofit the Vacuum Unit furnace with LoNOx burners.

Refinery LoNOx Burners - Burner Installed Cost $550,000 Valero Refining Three Rivers, TX Provided engineering with PFD's, P&ID's, Electrical One-lines, Instrument Loop drawings, Tie-ins, Piping isometrics and mechanical specifications to retrofit the two (2) furnaces in the #1 Reformer Unit with LoNOx burners.

Refinery LoNOx Burners - Burner Installed Cost $250,000 Valero Refining Three Rivers, TX Provided engineering with PFD's, P&ID's, Electrical One-lines, Instrument Loop drawings, Tie-ins, Piping isometrics and mechanical specifications to retrofit the HF Alky Unit furnace with LoNOx burners.

Furnace Efficiency Improvements- Installed Cost $750,000 Valero Refining Three Rivers, TX Provided engineering with PFD's, P&ID's, Electrical One-lines, Instrument Loop drawings, Tie-ins, Piping isometrics, FEA analysis of existing and modified structure, structural steel drawings and mechanical specifications to retrofit the #1 Reformer Unit furnace with added convection section with steam coils and addition stack high to provide required draft to recover waste heat.

Furnace Efficiency Improvements - Installed Cost $ 2,500,000 Valero Refining Three Rivers, TX Provided engineering with PFD's, P&ID's, Electrical One-lines, Instrument Loop drawings, Tie-ins, Piping isometrics, FEA analysis of existing and modified structure, structural steel drawings and mechanical specifications to retrofit three (3) #1 Crude Unit furnace with added convection sections with steam coils and addition stack high to provide required draft to recover waste heat.

CORPUS CHRISTI

VICTORIA

BAYPORT

LAGOS

15

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Effects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesDocument9 pagesEffects of Cryogenic Cooling on Grinding Forces, Temperature and Residual StressesChirag JainNo ratings yet

- Cathode Ray Oscilloscope (Cro)Document2 pagesCathode Ray Oscilloscope (Cro)jesunathan44@yahoo.comNo ratings yet

- Commissioning Report Generator - SAMPLEDocument5 pagesCommissioning Report Generator - SAMPLEMax JohnNo ratings yet

- Description Wincc Project Scanner enDocument9 pagesDescription Wincc Project Scanner enDugPigeonNo ratings yet

- Kinematics equations motion problemsDocument3 pagesKinematics equations motion problemsAhmed HossainNo ratings yet

- Absolute-Pressure Sensors: Micromechanics, Hybrid DesignDocument3 pagesAbsolute-Pressure Sensors: Micromechanics, Hybrid Designc20get100% (2)

- Hallite Metric Fluid Power CatalogDocument342 pagesHallite Metric Fluid Power CatalogOscar Acevedo Miranda100% (1)

- DTH Drilling MachineDocument8 pagesDTH Drilling MachineREL PromoNo ratings yet

- Industrial Transmission CatalogueDocument22 pagesIndustrial Transmission CatalogueAzhar MandhraNo ratings yet

- Slump and Compacting Factor Test Values and Uses in Concrete WorkabilityDocument2 pagesSlump and Compacting Factor Test Values and Uses in Concrete WorkabilityNick GeneseNo ratings yet

- Selden Keel Boat v1 LmarineriggingDocument72 pagesSelden Keel Boat v1 LmarinerigginglmarinegroupNo ratings yet

- 4E Roadmap for Energy Efficient Electric Motors and Motor SystemsDocument30 pages4E Roadmap for Energy Efficient Electric Motors and Motor SystemsCarlos LopezNo ratings yet

- Super Seal II Float Shoe Nose Options: CementingDocument4 pagesSuper Seal II Float Shoe Nose Options: CementingJuan Miguel RobledoNo ratings yet

- Install bladder tanks under homesDocument4 pagesInstall bladder tanks under homessauro100% (1)

- 90ma012 - CarrierDocument32 pages90ma012 - Carrierrafaelpaiva871531No ratings yet

- DrillingMotors MKT 001 01Document10 pagesDrillingMotors MKT 001 01Aman Aayra SrivastavaNo ratings yet

- Squashing Commits with RebaseDocument4 pagesSquashing Commits with RebaseDavid BeaulieuNo ratings yet

- Heat StrokeDocument8 pagesHeat StrokePrateek Barapatre0% (1)

- Monarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListDocument1 pageMonarch Industrial Products (I) Pvt. Ltd. Decorative Floor Toppings Supply Order Price ListgangadevimgmNo ratings yet

- HarvestersDocument132 pagesHarvestersLeTraitimbenletkNo ratings yet

- IONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11Document3 pagesIONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11dhiaa mohammedNo ratings yet

- Accenture Robotic Process Auto POV FinalDocument12 pagesAccenture Robotic Process Auto POV FinalJake RuksNo ratings yet

- Galaxy Electrical: Zener DiodesDocument3 pagesGalaxy Electrical: Zener Diodesdragon-red0816No ratings yet

- Diamond DA 42 Systems - V12 - 5clases 19 de JunioDocument402 pagesDiamond DA 42 Systems - V12 - 5clases 19 de JunioLiu Antonio Tang100% (1)

- TBR Wipro LeanDocument8 pagesTBR Wipro LeanAnonymous fVnV07HNo ratings yet

- LN Tutorial Services - Machine Design, Materials & Shop PracticesDocument4 pagesLN Tutorial Services - Machine Design, Materials & Shop PracticesEngr Amethyst RiegoNo ratings yet

- 10.4 Modes of TransportDocument12 pages10.4 Modes of TransportAya Magdy AhmedNo ratings yet

- Caterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)Document28 pagesCaterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)kfsmmeNo ratings yet

- Alcatel Support Document For Cable System in CubaDocument11 pagesAlcatel Support Document For Cable System in CubaDEGNISSODENo ratings yet

- Sika PDS - E - Sika FastFix - 138 TPDocument2 pagesSika PDS - E - Sika FastFix - 138 TPlwin_oo2435No ratings yet