Professional Documents

Culture Documents

Trex 04520

Uploaded by

OSDocs2012Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trex 04520

Uploaded by

OSDocs2012Copyright:

Available Formats

From: Alberty, Mark W 2 S e n t :M o nJ u l 1 3 1 6 : 1 1 : 5 3 0 0 9 To: Morel, Brian P Cc: Hafle, Mark E Subject RE: Stresscage Macondo lmportance: Normal

Brian, I ran the worst ansescenarioand hereis what I found: 2.9 PPg Worst casepor pressure= ppg Overburden: 13.38 ratio of 0.33) with a Poisson's Worstcasesandfracturegradient= 8.14ppg ( calculated = 9.30E5 psi Young'smodulus Depletioncorrected Hole size= 20" Deviation:0 deg MaximumECD=lL.2ppg In this casetlre fracture width will be2471 microns. up We can only StressCage to roughly 800 microns. We really cannotplan to put 2500 micron size particles through the bit and LWD without ptugging both. So if this worst casewere to occur,we could not expectto prevent losses while drilling. using StressCage The real problJm here is the low Young's modulus.I calculatedYoung's modulusfrom both offset logs (MC 296 #l) and frorrour global correlations.I cannot make a caseto substantiallyraise Young's modulusto get us out of this problem fracture width. formulation and hopethat we do not seethe worst case So I would proposethat we go with a mar StressCage scenario.If we drill without losses,then great.However,we will needa contingenry plan if we do seea casethat is greaterthan 800 microns. Our contingencyprobably needsto be to driil with fibers through the zoneand then make We i *or" p".rrrur,"nt repair withEz Squiezeoncethe full depletedzonehasbeenexposed. can also plan to drill to You might want to sectionTD with f,bers should we faii to achiwe our desiredtarget strengthwith EZ Squeeze. considera water basemud in this interval due to the perceivedhigh risk of significant losses. formulation: Loadedto bear StressCage 12 ppb BaraCa-6600 500 S ppb SafeCarb (Yes,the M productl) 6 ppb BaraCarb150 5 ppb SafeCart 50 (aszumingthere is no barite) 4 ppb SteelSeal outcome.I am around Houstonfor the next few weeksand can come discuss t know this is probablyan unexpected if you like. Regards, 'Mark Alberty Modeling Results:

StressCageFormulation Report Well lfacondo (MC 252 #1) Date: 711312009 Preparedby: Mark Albert"v

Confidential

00068163 BP-HZN-MBl

TVD Depth Target Strenglh Fracture Hole ProductConcentration Comment PPB Feet psi PPG Mcrors Size saadat 10789(12.2 ECD) Depleted 6838 12.2 2471 20.00 10?89 sandat 10789(12.3ECD) DePleted 20.00 10789 6894 12.3 sandat 10789(12.4ECD) DePleted 20.00 10789 6950 r2.4

From:

Morel, Brian P

Sent: Monday,June08,2009 1:51PM To: Cc: Albrty,MarkW Hafle, Mark E StresscageMacondo

Subject

Mark, formulation for the Macondowell. Attachedis the wellbore schematicand Can you pleaseput togethera stresscage v'ith is the 16" hole section,there is potential that the pressured ppFG diagram. The main interval we are concerned we would needto stressgethem in order to reach interval sandsshownare depleted(production) and therefore TD. Let me know what elseyou need,and I will try to get my handson it' help strengtheningsands Our only other goal woutd be to push casingpoints as diep as possible,thereforeany would be useful in achiwing this goal. Thank You, Brian Morel 5-042309.xIs (Compressed) << File: MC252-Macondo-REV03-t3 >> (Compressed) 051609-Rev5-DEFINE.xls

Confidential

00068164 BP-HZN-MBl

You might also like

- Glassblowing for Laboratory Technicians: Including Vacuum Line Accessories and Their ApplicationsFrom EverandGlassblowing for Laboratory Technicians: Including Vacuum Line Accessories and Their ApplicationsRating: 5 out of 5 stars5/5 (1)

- Solving Partial Differential Equation Applications with PDE2DFrom EverandSolving Partial Differential Equation Applications with PDE2DNo ratings yet

- Problems and Solutions in Fracture MechanicsDocument24 pagesProblems and Solutions in Fracture MechanicsKumar Saheb86% (109)

- Solution Manual For Materials Engineering Science Processing and Design Ashby Shercliff Cebon 3rd Edition Full DownloadDocument9 pagesSolution Manual For Materials Engineering Science Processing and Design Ashby Shercliff Cebon 3rd Edition Full Downloadkimberlyromeroxfmtcqakeb100% (40)

- Structures and Materials Section 7 Stress ConcentrationDocument21 pagesStructures and Materials Section 7 Stress ConcentrationAdi Adams AndaroffsaNo ratings yet

- Problems in Fracture Mechanics: Problem: 1Document38 pagesProblems in Fracture Mechanics: Problem: 1andiNo ratings yet

- Casing Design Graphical MethodDocument25 pagesCasing Design Graphical MethodSarbast TaqanaNo ratings yet

- S1Document11 pagesS198675No ratings yet

- Bracket and Corbel DesignDocument11 pagesBracket and Corbel DesignJm CampitanNo ratings yet

- Tension Crack: Figure 1 Geometry and Material PropertiesDocument5 pagesTension Crack: Figure 1 Geometry and Material Propertiesully amaliaNo ratings yet

- Elementary Fracture Mechanics Solved ProblemsDocument14 pagesElementary Fracture Mechanics Solved ProblemsAlwin VinothNo ratings yet

- Amp 2021-07Document9 pagesAmp 2021-07Renata OsunaNo ratings yet

- 8-Casing Setting Depth DesignDocument27 pages8-Casing Setting Depth Designthiban1309910% (1)

- TMM4160 Fracture Mechanics Abaqus Project Report: Joakim Johnsen - Joakij@stud - Ntnu.no 3 October 2010Document12 pagesTMM4160 Fracture Mechanics Abaqus Project Report: Joakim Johnsen - Joakij@stud - Ntnu.no 3 October 2010mailnewaz9677No ratings yet

- Fracture Mechanics Stress Intensity Factor</TITLEDocument5 pagesFracture Mechanics Stress Intensity Factor</TITLEGopinath ChakrabortyNo ratings yet

- K a ≤ a ≡ π Qσ: IC crit ∞Document5 pagesK a ≤ a ≡ π Qσ: IC crit ∞lrodriguez_892566No ratings yet

- Casing Setting Depth DesignDocument26 pagesCasing Setting Depth Designehsan100% (1)

- Session - 4 Failure Analysis and Failure Prevention of Plastic PartsDocument48 pagesSession - 4 Failure Analysis and Failure Prevention of Plastic PartsTwin-Screw ExtruderNo ratings yet

- Solution SetDocument4 pagesSolution SetPrimawati RahmaniyahNo ratings yet

- Mechanical Properties of Materials HomeworkDocument3 pagesMechanical Properties of Materials HomeworkDenbe SantosNo ratings yet

- Chapter 4 EpfmDocument23 pagesChapter 4 Epfmwandee2393No ratings yet

- MEC-E8007 Fracture Mechanics SolutionsDocument4 pagesMEC-E8007 Fracture Mechanics SolutionsnguywdrtffdNo ratings yet

- Simulation of Crack Propagation in Rock in Plasma Blasting TechnologyDocument16 pagesSimulation of Crack Propagation in Rock in Plasma Blasting Technologybenicillo0% (1)

- Crack growth mechanisms in metalsDocument5 pagesCrack growth mechanisms in metalsjonthemes100% (1)

- Three Hours: Structural IntegrityDocument21 pagesThree Hours: Structural IntegrityLi'sNo ratings yet

- Ex. U78 MATERIALS RESOLT - NOU CAMP NOUDocument10 pagesEx. U78 MATERIALS RESOLT - NOU CAMP NOUVicent J. Sala CamarenaNo ratings yet

- Assignment 5 SolutionsDocument4 pagesAssignment 5 SolutionsNickshan NahenthiramNo ratings yet

- Shear Strength of Soil Solved ProblemsDocument13 pagesShear Strength of Soil Solved ProblemsGino BulataoNo ratings yet

- Stress Intensity Factor and Fracture Toughness TestingDocument31 pagesStress Intensity Factor and Fracture Toughness TestingShahrul Azmin0% (1)

- MECH 532 Homework on Materials Issues and Fracture TestingDocument2 pagesMECH 532 Homework on Materials Issues and Fracture Testingwinter_snow714No ratings yet

- Design of Two Way Spanning Floor-SlabDocument26 pagesDesign of Two Way Spanning Floor-SlabSana UllahNo ratings yet

- Fatigue life of hip implantDocument20 pagesFatigue life of hip implantLeia Seungho100% (1)

- Serviceability Limit State. Deflections. Rectangular Plate With Simple Supports and Uniform LoadingDocument5 pagesServiceability Limit State. Deflections. Rectangular Plate With Simple Supports and Uniform Loadingsmartman35No ratings yet

- Lifting Lug CalculationDocument8 pagesLifting Lug CalculationLathesh JanarthananNo ratings yet

- Prestressed - Structures - Basic Rules For DimensioningDocument17 pagesPrestressed - Structures - Basic Rules For DimensioningTamaduianu IoanNo ratings yet

- Computer Simulation of Cumulative Fatigue Damage: Facta UniversitatisDocument9 pagesComputer Simulation of Cumulative Fatigue Damage: Facta UniversitatisBilly ChrisNo ratings yet

- John Starkenberg and Toni M. Dorsey - A Computational Study of Detonation Failure in Composition B and Cast TNT ChargesDocument50 pagesJohn Starkenberg and Toni M. Dorsey - A Computational Study of Detonation Failure in Composition B and Cast TNT ChargesSteemWheel100% (1)

- 2018-Min-8 & 10Document13 pages2018-Min-8 & 10Muhammad Zaka EmadNo ratings yet

- Mae (256F) - HW2 PDFDocument6 pagesMae (256F) - HW2 PDFClaireNo ratings yet

- Exercises On Fracture MechanicsDocument33 pagesExercises On Fracture Mechanicsyaswanth199260% (5)

- Notes On Dresden Sp2020+1 Emdrive PaperDocument5 pagesNotes On Dresden Sp2020+1 Emdrive PaperAaron LuoNo ratings yet

- Barker Microfarads (Radial Thru-Hole) 678D SeriesDocument7 pagesBarker Microfarads (Radial Thru-Hole) 678D Seriesester853No ratings yet

- Exp 4 Unconfined TestDocument6 pagesExp 4 Unconfined TestumarNo ratings yet

- Design Aid 15.4.4 Required Development Lengths, In., For Reinforcing Bars (Grade 60)Document1 pageDesign Aid 15.4.4 Required Development Lengths, In., For Reinforcing Bars (Grade 60)troyscribdNo ratings yet

- unit 2 fluctuating loadDocument30 pagesunit 2 fluctuating loadaditya.1540011No ratings yet

- Fatigue crack propagationDocument20 pagesFatigue crack propagationKianoosh EmamzadehNo ratings yet

- Examples: Stress and Strain in Flexible PavementsDocument51 pagesExamples: Stress and Strain in Flexible PavementsmahletNo ratings yet

- Assignment 01Document3 pagesAssignment 01sahilbarbade.ee101No ratings yet

- Elastic-Plastic Fracture Mechanics: Professor S. SureshDocument28 pagesElastic-Plastic Fracture Mechanics: Professor S. Sureshshilan_m26No ratings yet

- Tutorial Sheet No.3: Leak Off Test and MAASPDocument14 pagesTutorial Sheet No.3: Leak Off Test and MAASPali jabbarNo ratings yet

- Lifting Lug Design ThuwalDocument80 pagesLifting Lug Design Thuwalnarutothunderjet216No ratings yet

- MMAE - SolidsDocument23 pagesMMAE - SolidsEduardo VillanuevaNo ratings yet

- Stress Analysis Repor15Document196 pagesStress Analysis Repor15Jose QuiroaNo ratings yet

- Lecture Note 4Document4 pagesLecture Note 4Trường ĐàoNo ratings yet

- New Casing DesignDocument37 pagesNew Casing DesignemiljuchiacNo ratings yet

- Component DesignDocument32 pagesComponent Designdaniel hambissaNo ratings yet

- Test ReportDocument18 pagesTest ReportBilel MahjoubNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Fatigue Design: International Series on the Strength and Fracture of Materials and StructuresFrom EverandFatigue Design: International Series on the Strength and Fracture of Materials and StructuresNo ratings yet

- DOJ Pre-Trial Statement On QuantificationDocument14 pagesDOJ Pre-Trial Statement On QuantificationwhitremerNo ratings yet

- 2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411Document41 pages2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411OSDocs2012No ratings yet

- BP's Proposed Findings - Combined FileDocument1,303 pagesBP's Proposed Findings - Combined FileOSDocs2012No ratings yet

- HESI's Proposed FOF and COLDocument335 pagesHESI's Proposed FOF and COLOSDocs2012No ratings yet

- 2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlDocument13 pages2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlOSDocs2012No ratings yet

- State of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)Document23 pagesState of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)OSDocs2012No ratings yet

- To's Post-Trial BriefDocument57 pagesTo's Post-Trial BriefOSDocs2012No ratings yet

- 2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349Document13 pages2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349OSDocs2012No ratings yet

- BP Pre-Trial Statement On QuantificationDocument13 pagesBP Pre-Trial Statement On Quantificationwhitremer100% (1)

- To's Proposed FOF and COLDocument326 pagesTo's Proposed FOF and COLOSDocs2012No ratings yet

- HESI's Post-Trial BriefDocument52 pagesHESI's Post-Trial BriefOSDocs2012No ratings yet

- BP's Post-Trial BriefDocument72 pagesBP's Post-Trial BriefOSDocs2012No ratings yet

- USAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)Document49 pagesUSAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)OSDocs2012No ratings yet

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Document121 pagesUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012No ratings yet

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Document199 pagesPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012No ratings yet

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Document72 pagesPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- Macondo Bod (Basis of Design)Document23 pagesMacondo Bod (Basis of Design)OSDocs2012No ratings yet

- State of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)Document22 pagesState of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)OSDocs2012No ratings yet

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsDocument1 pageFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012No ratings yet

- Exterior: Circa 2003Document1 pageExterior: Circa 2003OSDocs2012No ratings yet

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Document5 pagesArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012No ratings yet

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Document1 pageDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012No ratings yet

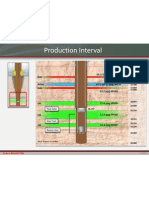

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasDocument1 pageProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012No ratings yet

- Circa 2003Document1 pageCirca 2003OSDocs2012No ratings yet

- DR Gene: CloggedDocument1 pageDR Gene: CloggedOSDocs2012No ratings yet

- Webster:: Trial Transcript at 3975:2-4Document1 pageWebster:: Trial Transcript at 3975:2-4OSDocs2012No ratings yet

- Circa 2003Document1 pageCirca 2003OSDocs2012No ratings yet

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyDocument22 pagesApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012No ratings yet

- Laboratory Results Cement Program Material Transfer TicketDocument13 pagesLaboratory Results Cement Program Material Transfer TicketOSDocs2012No ratings yet

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateDocument1 pageEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012No ratings yet

- Machining Processes SyllabusDocument2 pagesMachining Processes SyllabusshailkhanNo ratings yet

- Lm331 AppnoteDocument8 pagesLm331 AppnoteEward KenNo ratings yet

- Preparation, Structure and Morphology of Polymer Supports: David C. SherringtonDocument12 pagesPreparation, Structure and Morphology of Polymer Supports: David C. Sherringtonkishorkumarn8212No ratings yet

- Partition Coefficient Determination MethodsDocument24 pagesPartition Coefficient Determination MethodsdeshmukhgeolNo ratings yet

- Physics: Pearson EdexcelDocument16 pagesPhysics: Pearson EdexcelEffendi Jabid KamalNo ratings yet

- 2.PV Semisolid Fda PDFDocument37 pages2.PV Semisolid Fda PDFYuli SukmawatiNo ratings yet

- Recent Advancements in Aircraft Engine Health Management (EHM) Technologies and Recommendations For The Next StepDocument13 pagesRecent Advancements in Aircraft Engine Health Management (EHM) Technologies and Recommendations For The Next StepDanu MamlukatNo ratings yet

- Standing WaveDocument31 pagesStanding WaveJeff GicharuNo ratings yet

- 3bit Flash ADC 180nmDocument6 pages3bit Flash ADC 180nmMurali ShettyNo ratings yet

- Understanding FRP BoomsDocument4 pagesUnderstanding FRP BoomsFernandoNo ratings yet

- Imp 4Document38 pagesImp 4nikhilNo ratings yet

- Chapter 3 - Vectors and Coordinate Systems - SolutionsDocument7 pagesChapter 3 - Vectors and Coordinate Systems - SolutionsJeff BEzosNo ratings yet

- Ref. - No.: 261 - Ruston Gas Turbine Power Generation PackagesDocument8 pagesRef. - No.: 261 - Ruston Gas Turbine Power Generation Packagesscribdkhatn0% (1)

- 111年下A卷題庫Document10 pages111年下A卷題庫陳奕安No ratings yet

- HBS86 Hybrid Servo Drive DatasheetDocument7 pagesHBS86 Hybrid Servo Drive DatasheetDipu RudaniNo ratings yet

- Kepler's Three Laws of Planetary MotionDocument12 pagesKepler's Three Laws of Planetary MotionAlyssa Rose RamosNo ratings yet

- 316 316l Data SheetDocument2 pages316 316l Data SheetDiman Aditya KardiNo ratings yet

- More Practice QuestionsDocument13 pagesMore Practice QuestionsGarv AnandNo ratings yet

- Performance Evaluation of Elevated Storage Reservoir With Hybrid StagingDocument11 pagesPerformance Evaluation of Elevated Storage Reservoir With Hybrid StagingVelumani sNo ratings yet

- Acp2011 Final LR NewDocument72 pagesAcp2011 Final LR NewExodus Kwaku OforiNo ratings yet

- Pump Centrifugal Pre Commissioning ITPDocument10 pagesPump Centrifugal Pre Commissioning ITPMohamad IbrahimNo ratings yet

- Weather CardDocument2 pagesWeather Cardmekstone100% (1)

- High Frequency Circuit Design CourseDocument5 pagesHigh Frequency Circuit Design CourseadauNo ratings yet

- Free Fall: Objective: The Purpose of This Experiment Is To Prove ThatDocument5 pagesFree Fall: Objective: The Purpose of This Experiment Is To Prove ThatSunday Glo M. Cabuyao100% (1)

- Boiler Performance Guarantee R0Document3 pagesBoiler Performance Guarantee R0Prafitri KurniawanNo ratings yet

- Lecture Notes On Mathematical Methods PH2130 - 2012/2013: Glen D. Cowan Physics DepartmentDocument8 pagesLecture Notes On Mathematical Methods PH2130 - 2012/2013: Glen D. Cowan Physics DepartmentbbteenagerNo ratings yet

- Analysis of Benzoic Acid Kinetics Using Temperature vs Time GraphsDocument3 pagesAnalysis of Benzoic Acid Kinetics Using Temperature vs Time GraphssnowinceptionNo ratings yet

- Factors Affecting The Velocity of Sound in A GasDocument2 pagesFactors Affecting The Velocity of Sound in A GasShuvam ShahNo ratings yet

- Physics QuestionsDocument25 pagesPhysics QuestionsCarlos KasambiraNo ratings yet

- Boundary Wall DesignDocument26 pagesBoundary Wall DesignAtanu Bhattacharya50% (2)