Professional Documents

Culture Documents

Facility Visit

Uploaded by

Indo-MIMOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Facility Visit

Uploaded by

Indo-MIMCopyright:

Available Formats

132

Facility Visit - Indo-US MIM Tec Pvt Ltd

Modern Machine Tools - supplement March 2012

New Heights

Aiming

of Excellence

An organisation is defined by the people behind it and at Indo-US MIM Tec Pvt Ltd, its employees are always at the forefront vouching for the organisations credibility and quality. The common chord that runs through all verticals right from the top management to the operators at the shop floor is the hunger to learn something new and remain a step ahead in the race. And this is probably the reason why the organisation, which is one of the youngest aerospace companies, is still able to offer the most unique services in India today.

Debarati Basu

growth, the company is treading the path to be the pioneer in the industry to offer high precision aerospace machining. Stepping out of the herd always comes with the challenge of being accepted by the masses. But Indo-MIM (as it is commonly known), has broken the ice by making their work speak. In this short span, the company is already AS9100 Rev B certified for its machining shop and plating facility and has got approvals from leading aerospace companies in the US, UK and India. This young facility has already bagged production orders from leading aerospace companies in the world. Aerospace has come in waves to India. Around a decade ago, there were hints of aerospace in India. If you are too early to the game, you have to wait a long time for the results. And if you are late, you will find yourself amidst heavy competition. It was a question of timing and luck for us. We were at the right place and the right time to enter the market. After gaining competence in Metal Injection Molding (MIM) technology, our Chairman, Krishna Chivukula, and

xactly 15 months ago, the vast expanse of 28,000 sq ft at Doddaballapur, Bengaluru was an empty land with just a plan on the course of action to enter the most thriving sector of Indian machining industry and to build a facility which would offer state-of-art services for the aerospace industry. Today, the expanse is dotted with buildings that house a skilled-team that delivers advanced precision machined components for marquee aerospace customers. With its quick and rapid

Modern Machine Tools - supplement March 2012

Facility Visit - Indo-US MIM Tec Pvt Ltd

133

the Board of Directors decided to enter the aerospace industry, said Sridhara Ramachandran, Vice President and General Manager, Aerospace Products Group, Indo-US MIM Tec Pvt Ltd.

Shop Floor Excellence

Sridhara Ramachandran, Vice President and General Manager, Aerospace Products Group, Indo-US MIM Tec Pvt Ltd. We have an excellent team and a can-do culture. 5 years from now, if anyone thinks of Aerospace in India, they should think of IndoMIM first.

The key factor behind the success of any organisation is the people behind the job and the employees of Indo-MIM define the organisation. This became evident while visiting the shop floor where every employee behind each high precision equipment stood as the proud owner of the knowledge gained through the process. Building the right team is the most important factor. We had a plan in place, but we needed the right people to execute it so we scouted the planet to find the best talents and got them together. Aerospace being an emerging industry in India, finding shop-floor personnel with prior aerospace experience is difficult. But this is an industry where there is a lot to learn, said Ramachandran. Explaining the approach of the company for choosing the right people for the job, Ramachandran adds, We see if the candidate has the right attitude, is curious and has the hunger to learn. We provide intensive training and expose the shop floor personnel to various jobs ranging from simple to complex. We have trainees who spend a year rotating through various departments so that they have exposure to all aspects of a job.

Strategy for Success

Aerospace today is one of the most dynamic sectors in the Indian manufacturing industry. This sector is expected to grow significantly over the next decade. The key driver behind this growth is the $30 billion plus offset obligations for aerospace majors from the West. To play in the aerospace sector requires not just the deep pockets for investment but also a patient investment mindset. At some point you have to break the chicken and egg dilemma. You can delay the decision to invest until the probability of winning an order is significantly

high or invest and prove to the customers that you are committed and serious on executing to a plan. Our company decided to take the risk and make a reasonable investment, Ramachandran. To garner a profound knowledge about the need of the industry, the organisation polled leading aerospace companies to understand what they are looking for and to analyse the areas other Indian companies have usually failed in this industry. We then formulated a strategy to penetrate this industry. We placed an emphasis on people, hired a solid team and then supported them with the right capital equipment. People focus and the strategy to keep the supply chain simple has worked well for us, explains Ramachandran. While building the team was the most crucial decision, buying equipments was no haphazard process. To make optimal investments on equipments and technology, the company did an extensive survey of the major OEMs and their specification of machining requirements. The equipments, thus assembled, are an

impressive set of investments done with a long term and holistic vision to effectively cater to major section of the OEM demands. Such extensive planning helps the company to be ready for every production order instead of starting from the scratch for every new client. This also helps to lower the cost of production, making the business more competitive. Taking feedback from OEMs is also an effective measure adopted by the company to be ready on time.

Vision 2015

Vivek Chivukula, Manager - Business Development, Indo-US MIM Tec Pvt Ltd. We did not want to make the same mistakes that others had made in this sector. We work in a way so that when leading companies walk into our shop floor, they wont feel out of place.

The supply chain in India for the aerospace industry is still in a formative stage. The present supply chain is complex and riddled with uncertainties due to a weak infrastructure in India. Understanding the weak links in the supply chain and working towards eliminating them has been a constant effort of the group. Quality and hundred percent ontime delivery performance is key in the aerospace industry. With just a handful of machine shops involved in aerospace machining, parts hop from one special process facility to another and it goes all over the country before it comes back as the final product. We want to simplify the supply chain process and for that we aim to co-locate everything in one campus and make it a one stop state-of-the-art shop. This would not just save on time but also ensure better quality inspection of products, said Vivek Chivukula, Manager- Business Development, IndoUS MIM Tec Pvt Ltd. The Doddaballapur facility already has precision machining and special process shops. The special process facility offers services including non-destructive testing, heat treatment, a comprehensive list of chemical processing, painting, surface cleaning and part marking under the same roof. Indo-MIM has proved that effective planning, long term vision and a good team to hold on to the reins is all it takes to reach the skies.

debarati.basu@infomedia18.in

You might also like

- Indo-MIM Chairman Dr. Krishna Chivukula Interview - Bangalore MirrorDocument1 pageIndo-MIM Chairman Dr. Krishna Chivukula Interview - Bangalore MirrorIndo-MIMNo ratings yet

- Indo-MIM ET - March 2015 PDFDocument1 pageIndo-MIM ET - March 2015 PDFIndo-MIMNo ratings yet

- Engine Technology - Sept 2014Document1 pageEngine Technology - Sept 2014Indo-MIMNo ratings yet

- IBM-Tool Room Article - AprilDocument1 pageIBM-Tool Room Article - AprilIndo-MIMNo ratings yet

- KC Interview - Deccan Herald 15 Oct 2014Document1 pageKC Interview - Deccan Herald 15 Oct 2014Indo-MIMNo ratings yet

- Medical Device Network-MIMDocument3 pagesMedical Device Network-MIMIndo-MIMNo ratings yet

- Industrial Business Mart - May Indo MIMDocument1 pageIndustrial Business Mart - May Indo MIMIndo-MIMNo ratings yet

- INDO - US MIM CSR Coverage - Deccan Herald 1st NovDocument1 pageINDO - US MIM CSR Coverage - Deccan Herald 1st NovIndo-MIMNo ratings yet

- Indo-MIM's In-House ISP - October 2014Document2 pagesIndo-MIM's In-House ISP - October 2014Indo-MIMNo ratings yet

- Gasgoo - KJ InterviewDocument5 pagesGasgoo - KJ InterviewIndo-MIMNo ratings yet

- Mpif 2014Document3 pagesMpif 2014Indo-MIMNo ratings yet

- INNOVATION Is The Key: Manoj Kabre, Indo-MIMDocument1 pageINNOVATION Is The Key: Manoj Kabre, Indo-MIMIndo-MIMNo ratings yet

- Indomim - AeromagDocument1 pageIndomim - AeromagIndo-MIMNo ratings yet

- Engine Technology - May Issue 2014Document1 pageEngine Technology - May Issue 2014Indo-MIMNo ratings yet

- Indo-MIM CMM ArticleDocument3 pagesIndo-MIM CMM ArticleIndo-MIMNo ratings yet

- Indo-MIM Industrial Mart ArticleDocument1 pageIndo-MIM Industrial Mart ArticleIndo-MIMNo ratings yet

- Mart Dec 2013 IndomimDocument1 pageMart Dec 2013 IndomimIndo-MIMNo ratings yet

- Indo-MIM Engine Technology Feb 14Document1 pageIndo-MIM Engine Technology Feb 14Indo-MIMNo ratings yet

- Indo-MIM - Engine Technology - Nov Issue 2013Document1 pageIndo-MIM - Engine Technology - Nov Issue 2013Indo-MIMNo ratings yet

- INDO-MIM Adds A Feather in The Cap With Three Awards From MPIF - CMM Magazine PDFDocument2 pagesINDO-MIM Adds A Feather in The Cap With Three Awards From MPIF - CMM Magazine PDFIndo-MIMNo ratings yet

- Safety Crowns Indo-MIMDocument1 pageSafety Crowns Indo-MIMIndo-MIMNo ratings yet

- MMT - INDO-MIM Wins MPIF Awards PDFDocument1 pageMMT - INDO-MIM Wins MPIF Awards PDFIndo-MIMNo ratings yet

- MIM TechnologyDocument2 pagesMIM TechnologyIndo-MIMNo ratings yet

- Taysad MART UpdateDocument1 pageTaysad MART UpdateIndo-MIMNo ratings yet

- Automotive Engg ShowDocument1 pageAutomotive Engg ShowIndo-MIMNo ratings yet

- Best PracticesDocument4 pagesBest PracticesIndo-MIMNo ratings yet

- Break The MouldDocument3 pagesBreak The MouldIndo-MIMNo ratings yet

- MART April 2013 Sridhara Article PDFDocument3 pagesMART April 2013 Sridhara Article PDFIndo-MIMNo ratings yet

- On FaceDocument8 pagesOn FaceIndo-MIMNo ratings yet

- Emerging TechnologyDocument3 pagesEmerging TechnologyIndo-MIMNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ADII11 Metode Deteksi OutlierDocument50 pagesADII11 Metode Deteksi Outlier21-A-2-19 Nazli Amaliya RamadhaniNo ratings yet

- Th255, Th255c Axle Cat ServiceDocument280 pagesTh255, Th255c Axle Cat ServiceKevine KhaledNo ratings yet

- Wiley Wesleyan UniversityDocument36 pagesWiley Wesleyan UniversityBirunda SilvaNo ratings yet

- Popular Mechanics 2010-06Document171 pagesPopular Mechanics 2010-06BookshebooksNo ratings yet

- 2VAA001695 en S Control NTCS04 Controller Station Termination UnitDocument43 pages2VAA001695 en S Control NTCS04 Controller Station Termination UnitanbarasanNo ratings yet

- Plenaristas León 2022xDocument6 pagesPlenaristas León 2022xGloria MontielNo ratings yet

- A Hirshfeld Surface Analysis and Crystal StructureDocument8 pagesA Hirshfeld Surface Analysis and Crystal StructureLidiane MicheliniNo ratings yet

- Senior Design Projects 201-2020 - For Website - MEDocument5 pagesSenior Design Projects 201-2020 - For Website - MEYujbvhujgNo ratings yet

- Movement Joints (NHBC)Document5 pagesMovement Joints (NHBC)hemendraengNo ratings yet

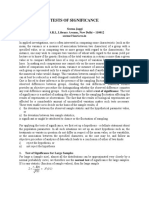

- 5 Tests of Significance SeemaDocument8 pages5 Tests of Significance SeemaFinance dmsrdeNo ratings yet

- Republic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityDocument3 pagesRepublic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityErika Joy EscobarNo ratings yet

- Mock DataDocument56 pagesMock DataAnonymous O2bvbOuNo ratings yet

- Materials Technical Specification.: Stainless SteelDocument6 pagesMaterials Technical Specification.: Stainless SteelMario TirabassiNo ratings yet

- 9.tools and Equipment 1Document13 pages9.tools and Equipment 1NKH Mega GasNo ratings yet

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- Information HandoutsDocument6 pagesInformation HandoutsPooja Marwadkar TupcheNo ratings yet

- MAPEH 6- WEEK 1 ActivitiesDocument4 pagesMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- WORK ORDER TITLEDocument2 pagesWORK ORDER TITLEDesign V-Tork ControlsNo ratings yet

- AWS D1.5 PQR TitleDocument1 pageAWS D1.5 PQR TitleNavanitheeshwaran SivasubramaniyamNo ratings yet

- Workflowy - 2. Using Tags For NavigationDocument10 pagesWorkflowy - 2. Using Tags For NavigationSteveLangNo ratings yet

- An Introduction To Community DevelopmentDocument21 pagesAn Introduction To Community DevelopmentThuyAnh NgnNo ratings yet

- Use DCP to Predict Soil Bearing CapacityDocument11 pagesUse DCP to Predict Soil Bearing CapacitysarvaiyahimmatNo ratings yet

- Empowerment Technology - Week 2Document3 pagesEmpowerment Technology - Week 2yahgieNo ratings yet

- Exhaust Brake PDFDocument2 pagesExhaust Brake PDFFeliciaNo ratings yet

- Syllabus Agri 2015Document248 pagesSyllabus Agri 2015parvathivignesh279No ratings yet

- wt-and-fds-practical-slipsDocument32 pageswt-and-fds-practical-slipsRohidas SapkalNo ratings yet

- Transportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDocument11 pagesTransportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDaniel Juan De Dios OchoaNo ratings yet

- RB450G Trouble ShootingDocument9 pagesRB450G Trouble Shootingjocimar1000No ratings yet

- Lec08 (Topic 4 Define Classes)Document33 pagesLec08 (Topic 4 Define Classes)huaiencheengNo ratings yet

- Designers' Guide To Eurocode 7 Geothechnical DesignDocument213 pagesDesigners' Guide To Eurocode 7 Geothechnical DesignJoão Gamboias100% (9)