Professional Documents

Culture Documents

Flexovit Abrasives - Carbide Burs

Uploaded by

Flexovit AbrasivesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexovit Abrasives - Carbide Burs

Uploaded by

Flexovit AbrasivesCopyright:

Available Formats

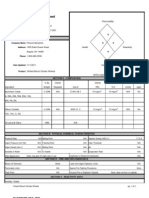

FLEXOVIT USA, INC.

MATERIAL SAFETY DATA SHEET

Flammability Rating

Used to comply with OSHA's Hazard Communication Standard, 29 CFR 1910.1200 Health Rating SECTION I - NAME AND PRODUCT

Company Name: Flexovit Abrasives Address: 1305 Eden-Evans Road

0 0 0

Reactivity Rating

Angola, NY 14006

Phone: 1-800-689-3539 Date Updated: 11/1/2011

Hazard Rating

Product: Carbide Burs

NFPA HAZARD RATING CODE SECTION II - COMPOSITION % By Ingredient Head:

Tungsten Carbide (limits for Tungsten dust) Cobalt Tantalum Carbide (limits for Tantalum dust) Titanium Carbide (limits for Titanium dust) Niobium Carbide (limits for Niobium dust) Molybdenum Carbide (limits f/ Molybdenum dust) Hafnium Carbide (limits for Hafnium dust) Chromium Carbide (limits f/ Chromium (+3) dust) Vanadium Carbide (limits for Vanadium dust) 41.0-97.0 3.0-30.0 0.0-52.0 0.0-20.0 0.0-20.0 0.0-10.0 0.0-10.0 0.0-5.1 0.0-2.0 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 5 mg/m 5 mg/m 5 mg/m

3 3

OSHA Regulate Cas #

OSHA PEL

ACGIH TLV

5 mg/m3 0.02 mg/m3 5 mg/m3 none established 5 mg/m3 10 mg/m3 0.5 mg/m3 0.5 mg/m3 none established 0.1 mg/m3 0.2 mg/m3 1.0 mg/m3 5 mg/m3 10 mg/m3 0.1 mg/m3 5 mg/m3 N/A 3.5 mg/m3 5 mg/m3 1.0 mg/m3 0.1 mg/m3 5 mg/m3 5 mg/m3 1.0 mg/m3 0.5 mg/m3 10 mg/m3 1.0 mg/m3 0.2 mg/m3 N/A 0.5 mg/m3 0.5 mg/m3 10 mg/m3 5 mg/m3 5 mg/m3 N/A 100 mg/m3

3 3

Other Limits

N/A N/A N/A N/A N/A N/A N/A N/A N/A

Carcinogen

No Yes No No No No No Yes No

Weight

0.1 mg/m

3 3

5 mg/m3 15 mg/m3 0.5 mg/m 0.5 mg/m

none established

3

Braze:

Silver Copper Zinc Nickel (limits for Copper fumes) (limits for Copper dust) (limits for Zinc Oxide fumes) (limits for Zinc Oxide dust) N/A N/A 7440-02-0 N/A N/A 7440-66-6 N/A N/A N/A N/A 7440-22-4 7440-50-8 0.01 mg/m 0.1 mg/m 5 mg/m3 10 mg/m

3

N/A N/A N/A N/A N/A N/A

No No No Yes

1.0 mg/m3

0.1 mg/m3 10 mg/m3 55 mg/m3 3.5 mg/m3 5 mg/m3 N/A 0.1 mg/m3 N/A N/A 1.0 mg/m3 1.0 mg/m3 15 mg/m

3

Shank:

Iron Carbon Manganese Phosphorus Sulfur Silicon Nickel Chromium Molybdenum Copper Tin Vanadium Aluminum Titanium Columbium Petroleum Naptha (Coating/Rust Preventative) Flexovit Carbide Burs

Contaminant:

Iron Oxide Fumes Carbon Oxide Carbon Black Manganese Dust Manganese Fumes Phosphorus (Yellow) Sulfur Respirable Dust Nickel Chromium Insoluble Compounds Dust Fumes Tin Oxide Dust Fumes as Vanadium Pentoxide Dust Fumes Titanium Dioxide Columbium Naptha <0.25 <0.25 N/A N/A N/A N/A 13463-67-7 7440-25-7 6032-32-4 0.01/0.20 N/A 7429-90-5 <0.25 <0.35 N/A N/A 7440-31-5 1314-62-1 <0.25 <0.25 0.20/0.35 0.40/0.70 0.40/0.60 0.20/0.30 <0.35 N/A N/A N/A N/A N/A N/A N/A 7723-14-0 7704-34-9 7740-21-3 7740-02-0 7740-47-3 7439-98-7 7440-50-8 0.75/1.00 N/A 7439-96-5 95.00 0.38/0.43 N/A N/A 1309-37-1 7440-44-0 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A No No No No No No No No No Yes Yes No No Yes No No

1.0 mg/m3 0.1 mg/m

3

10 mg/m3 0.5 mg/m3 0.1 mg/m3 N/A N/A 15 mg/m3 N/A 500 mg/m3

pg. 1 of 4

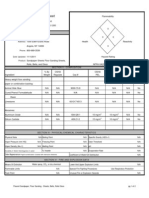

FLEXOVIT USA, INC.

SECTION III - PHYSICAL/CHEMICAL CHARACTERISTICS Head:

Boiling Point Vapor Pressure Vapor Density Solubility in Water (mm Hg.) (AIR=1) N/A N/A N/A Insoluble Specific Gravity Evaporation Rate Appearance/Odor How Best Monitored (H20=1) 11.0-15.5 0 N/A Dark Gray Metal/No odor Air Sample Percentage Volatile by Volume

Braze:

Melting Point Boiling Point Vapor Pressure Vapor Density Solubility in Water (mm Hg.) (AIR=1) N/A N/A N/A N/A No 27500 C (50000 F) High (mm Hg.) (AIR=1) N/A N/A Insoluble N/A 4000 F (mm Hg.) (AIR=1) Negligible <0.1% solubility <10mm Hg 5.0 Specific Gravity Evaporation Rate Appearance/Odor (H20=1) 7.5-8.5 None N/A Solid, odorless metal Percentage Volatile by Volume Specific Gravity Evaporation Rate Appearance/Odor (H20=1) 3711-2 N/A N/A White metal, no odor Percentage Volatile by Volume

Shank:

Melting Point Boiling Point Vapor Pressure Vapor Density Solubility in Water

Coating/Rust Preventative:

Melting Point Boiling Point Vapor Pressure Vapor Density Solubility in Water Specific Gravity Evaporation Rate Appearance/Odor (H20=1) 0-1 70 0.1 Amber colored liquid, hydrocarbon odor

Percentage Volatile by Volume

SECTION IV - FIRE AND EXPLOSION DATA Flash Point Extinguishing Media

1050 F (TCC) (Coating/Rust Preventative)

For powder fires, smother with dry sand, dry dolomite ABC type fire extinguisher, or flood with water. Also, dry chemical, foam, CO2

Special Fire Fighting Procedures

self-contained breathing apparatus.

For a powder fire confined to a small area

use a respirator approved for toxic dusts & fumes. For a large fire, fire fighters should use

Unusual Fire or Explosion Hazards SECTION V - REACTIVITY DATA

N/A

Stability Stable Hazardous Polymerization Conditions to Avoid Incompatibility Contact of dust with strong oxidizers may cause explosions. Also incompatable with acids.

can be formed which can be detonated. Fine powder & hydrogen peroxide solutions may explode. Incompatible with oxalic & tartaric acid.

Will not occur

Contact with incompatible materials

Silver-Acetylene and ethylenimine form explosive compounds with silver. If silver is treated with nitric acid in the presence of ethyl alcohol, silver fulminate Bromoazide explodes on contact with silver foil. Copper-Ammonium nitrate, bromates, iodates, chlorates, ethylene oxide, hydrazoic acid, potassium oxide, dimethyl sulfoxide & trichloroacetic acid, hydrogen peroxide, sodium peroxide, sodium azide, sulfuric acid, hydrogen sulfide & air, lead azide & actylenic compaounds. Copper ignites on contact with chlorine, fluorine, chlorine trifluoride, and hydrazinium nitrate. Nickel-May react with fluorine, ammonium nitrate, hydrogen and dioxane, performic acid, selenium, sulfur ammonia, hydrazine, phosphorous, titanium & potassium chlorate & antioxidants.

Hazardous Decomposition Products

Metal fumes-Iron oxide, chromium,

Materials to Avoid

Strong acids, strong oxidizers

nickel, molybdenum, vanadium pentoxide, zinc oxides and other noxious gases may be produced during welding or burning operations. Oxides of carbon. Metal fumes/oxides produced from overheating while melting or brazing can be toxic.

Flexovit Carbide Burs

pg. 2 of 4

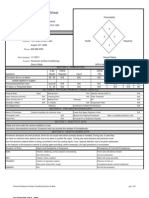

FLEXOVIT USA, INC.

SECTION VI - HEALTH HAZARD DATA Routes of Exposure:

Grinding cemented carbide product or handling of grinding sludges will produce dust of potentially hazardous ingredients which can be inhaled, swallowed or come in contact with the skin or eyes. Steel products in their natural state do not present an inhalation, ingestion, or contact hazard. However, operations such as burning, welding, brazing, sawing, or grinding may result in the effects listed below if exposure exceeds the permissible levels (PEL'S) listed in section I. Exposure to the listed elements occurs primarily through the inhalation of dust or fumes; however, certain constituents of this product may possibly cause effects directly on contact with the skin or eyes. Medical conditions which may be aggravated by exposure to this product include: conjunctivitis of the eye, dermatitis of the skin, asthma and Medical conditions which may be aggravated by exposure to this product include: conjunctivitis of the eye, dermatitis of the skin, asthma, and respiratory diseases. These elements may also be harmful if swallowed. During subsequent welding or brazing operations the welding rods, brazing materials, flux, etc. should also be considered as potential sources of contaminant exposure. Please consult the MSDS from your suppliers of such products for additional information and safety instructions.

Effects of Overexposure: Acute:

Iron (Iron Oxide) - Irritation of the eyes, nose, throat, metallic taste in the mouth, metal fume fever. Manganese - Irritation of the eyes, nose, throat, metallic taste in the mouth, metal fume fever. Chromium - Irritation of the eyes, nose, and lungs; dermatitis Nickel - Irritation of the eyes, nose, and lungs; dermatitis; "Nickel Itch"; Inflammatory reactions around nickel-containing medical implants & prostheses may also occur. Molybdenum - Slight irritation of the eyes, nose, and throat. Vanadium Pentoxide - Irritation to conjunctive and respiratory tract (greenish-black discoloration of the tongue and shortness of breath). Tin - Generally considered to exhibit a low order of toxicity, may cause irritation of the eyes, nose, throat, and skin. Titanium Dioxide - Considered a nuisance particulate. High concentrations can cause irritation of the eyes, nose, and throat. Copper - Fume or dust can cause irritation of the eyes, nose, and throat and a flu-like illness called "Metal Fume Fever". Symptoms include: fever, muscle aches, nausea, chills, cough, weakness, frontal headache, possible blurred vision, shallow respiration, throat dryness/irritation, a sweet or metallic taste, and chest tightness occuring over several hours. This condition may arise 4-12 hours after exposure & symptoms usually sunside within 24 hours.

SECTION VI - HEALTH HAZARD DATA. Con't. Chronic:

Iron (Iron Oxide) - Pulmonary effects, siderosis. Manganese -Bronchitis, pneumonitis, inflammation and/or ulceration of the upper respiratory tract, and possible cancer of the nasal passages & lungs. Chromium - Ferrochrome alloys have been associated with lung changes in workers expose to these alloys. Molybdenum - Pain in joints, hands, knees, and feet. Vanadium Pentoxide - Repeated exposure may cause more severe irritation to the upper respiratory tract such as chronic bronchitis or possible allergic skin rash. Nickel - Nickel and it's compounds have been reported to cancer of the lungs and throat. Silver -Can result in argyria, a cosmetic condition characterized by a gray discoloration of the eyes and skin. Inhalation Dust from grinding can cause irritation of the nose & throat. It also has the potential for causing transient or permanent respiratory disease, including occupational asthma & interstitial fibrosis in a small percentage of exposed individuals. It is reported that cobalt dust is the most probable cause of such respiratory diseases. Symptoms include coughing, wheezing, shortness of breath, chest-tightness & weight loss. Interstitial fibrosis (lung scarring) can lead to permanent disability or death. Certain pulmonary conditions may be aggravated by exposure. Skin Contact Skin Absorption Eye Contact Ingestion Can cause irritation or an allergic skin rash due to cobalt sensitization. Certain skin conditions (I.e. dry skin) may be aggravated by exposure. Fume may be absorbed through the skin and block the sweat glands causing a rash to occur. Can cause irritation. Reports outside the industry suggest that ingestion of significant amounts of cobalt has the potential for causing blood, heart & other organ problems.

Emergency & First Aid Procedures:

Inhalation

Remove to fresh air. If breathing is difficult, give oxygen. If not breathing, give artificial respiration. If symptoms of pulmonary involvement develop (coughing, wheezing, shortness of breath, etc.) remove from exposure & seek medical attention.

Skin Contact Skin Absorption Eye Contact Ingestion

If irritation or rash occurs, thoroughly wash affected area with soap & water and isolate from exposure. If condition persists seek medical attention. Remove from exposure. Wash thoroughly with water. If condition persists, seek medical attention. If irritation occurs, flush with copious amounts of water. If irritation persists, seek medical attention. For dust or mists: If substantial quantities are swallowed, dilute with a large amount of water, induce vomiting & seek medical attention. Otherwise: May be toxic; If swallowed, DO NOT induce vomiting unless directed by a physician. Give a glass of water only if the person is conscious. Call a physician.

Carcinogenic Assessment (NTP Annual Report, IARC Monographs, others):

The International Agency for Research on Cancer (IARC) found there was inadequate evidence that metallic cobalt is carcinogenic to humans but that there is sufficient evidence that it is carcinogenic in animals. IARC concluded that metallic cobalt is possibly carcinogenic to humans (Substance Group 2B). Cobalt has not been classified as a known or suspected carcinogen by OSHA or the National Toxicology Program (NTP). Chromium is listed by IARC and NTP as a human carcinogen.

Flexovit Carbide Burs

pg. 3 of 4

FLEXOVIT USA, INC.

SECTION VII- STORAGE HANDLING AND USE PROCEDURES Handling & Storage: Other Precautions:

Maintain good housekeeping procedures to prevent dust accumulation during grinding. Avoid dust inhalation & direct skin contact with dust. Clean up using methods which avoid dust generation such as vacuum (with appropriate filter to prevent airborne dust levels exceeding

the PEL & TLV) or wet clean-up. If airborne dust is generated, use an appropriate NIOSH approved respirator. Wash hands

thoroughly after handling, before eating or smoking. Wash exposed skin at the end of the work shift. Do not shake clothing, rags or other items to remove dust. Dust should be removed by washing or vacuuming (with the appropriate filters) the clothing, rags or other items. **Periodic medical examinations are recommended for individuals regularly exposed to dust or mist.

Steps To Be Taken in Case Material is Released or Spilled:

Ventilate area of spill. Clean up using methods which avoid dust generation such as vacuum (with the appropriate filters) or wet clean up. If airborne dust is generated, use an appropriate NIOSH approved respirator.

Waste Disposal Method:

Dispose of in accordance with the applicable government regulations. May be sold as scrap for reclamation.

SECTION VIII- CONTROL MEASURES Protection Respiratory Requirements and Referrals

Use an appropriate NIOSH approved respirator if airborne dust concentrations exceed the applicable PEL or TLV. All requirements set forth in 29 CFR 1910.134 should be met.

Ventilation

Use adequate local exhaust ventilation to limit personal exposure to airborne dust to levels below the PEL or TLV. If such equipment is not available, use respirators as specified above. Refer to "Industrial Ventilation" by ACGIH for manual of recommended practices.

Protective Gloves Eye Protection Personal Hygiene Other

Protective gloves or barrier cream are recommended when contact with dust or mist is likely. Prior to applying the barrier cream or use of protective gloves, wash thoroughly. Leather gloves are recommended for welding or brazing. Safety Glasses with side shields or goggles are recommended. Eyewash equipment should be available & accessible at the workplace. Face shield is recommended. Welding shield is required for welding operations. Always wash hands and face before eating, drinking, or smoking. Provide safety shower in work area. Protective clothing should be worn if repeated or prolonged skin contact or contamination is likely.

COMPANY USE

The information and recommendations set forth herein are taken from sources and references believed to be accurate and complete as of the date hereof. However, Flexovit U.S.A., Inc. makes no expressed or implied warranty with respect to the accuracy of the information or the suitability of the recommendations, and assumes no liability to any user therof.

Flexovit Carbide Burs

pg. 4 of 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Flexovit Abrasives - Label Specification ChartDocument1 pageFlexovit Abrasives - Label Specification ChartFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Cartridge Rolls Spiral Bands PadsDocument2 pagesFlexovit Abrasives - Cartridge Rolls Spiral Bands PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Bench Grinder WheelsDocument2 pagesFlexovit Abrasives - Bench Grinder WheelsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Cupstone Hand Rubs Floor StonesDocument2 pagesFlexovit Abrasives - Cupstone Hand Rubs Floor StonesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Vitrified Mounted PointsDocument2 pagesFlexovit Abrasives - Vitrified Mounted PointsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Resinoid Bonded Plugs and ConesDocument2 pagesFlexovit Abrasives - Resinoid Bonded Plugs and ConesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Grinding Cutoff Wheels Reinforced ResinoidDocument2 pagesFlexovit Abrasives - Grinding Cutoff Wheels Reinforced ResinoidFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Flap DiscsDocument2 pagesFlexovit Abrasives - Flap DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - PSA Sanding DiscsDocument2 pagesFlexovit Abrasives - PSA Sanding DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Nylon Pads and Mesh ScreensDocument2 pagesFlexovit Abrasives - Nylon Pads and Mesh ScreensFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Mounted Flap WheelsDocument2 pagesFlexovit Abrasives - Mounted Flap WheelsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Floor Sanding Sheets Rolls Belts DiscsDocument3 pagesFlexovit Abrasives - Floor Sanding Sheets Rolls Belts DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Resin Fiber Sanding DiscsDocument2 pagesFlexovit Abrasives - Resin Fiber Sanding DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Quick Change Sanding DiscsDocument1 pageFlexovit Abrasives - Quick Change Sanding DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Shop and Plumber RollsDocument1 pageFlexovit Abrasives - Shop and Plumber RollsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Trim Kut Sanding DiscsDocument1 pageFlexovit Abrasives - Trim Kut Sanding DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Sandpaper and Floor Sanding Sheets Rolls Belts DiscsDocument2 pagesFlexovit Abrasives - Sandpaper and Floor Sanding Sheets Rolls Belts DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Resin Fiber Discs Ceramic GrainDocument2 pagesFlexovit Abrasives - Resin Fiber Discs Ceramic GrainFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Sanding BeltsDocument1 pageFlexovit Abrasives - Sanding BeltsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Steel Wool PadsDocument1 pageFlexovit Abrasives - Steel Wool PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Hand-PadsDocument1 pageFlexovit Abrasives - Hand-PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Unmounted Flap WheelsDocument1 pageFlexovit Abrasives - Unmounted Flap WheelsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Clean Strip DiscsDocument2 pagesFlexovit Abrasives - Clean Strip DiscsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Surface Conditioning Discs BeltsDocument2 pagesFlexovit Abrasives - Surface Conditioning Discs BeltsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives Overview (English)Document6 pagesFlexovit Abrasives Overview (English)Flexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Nylon Floor PadsDocument2 pagesFlexovit Abrasives - Nylon Floor PadsFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Diamond BladesDocument3 pagesFlexovit Abrasives - Diamond BladesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives - Troubleshooting Diamond AbrasivesDocument4 pagesFlexovit Abrasives - Troubleshooting Diamond AbrasivesFlexovit AbrasivesNo ratings yet

- Flexovit Abrasives CatalogDocument92 pagesFlexovit Abrasives CatalogFlexovit AbrasivesNo ratings yet

- The Prediction of Travel Behaviour Using The Theory of Planned BehaviourDocument16 pagesThe Prediction of Travel Behaviour Using The Theory of Planned Behaviourhaneena kadeejaNo ratings yet

- How To Get Into Top IIMs - Ahmedabad, Bangalore, Calcutta and Lucknow - CareerAnnaDocument97 pagesHow To Get Into Top IIMs - Ahmedabad, Bangalore, Calcutta and Lucknow - CareerAnnaMoinak94No ratings yet

- Ingo Plag Et AlDocument7 pagesIngo Plag Et AlDinha GorgisNo ratings yet

- The Theory of Paulo FreireDocument8 pagesThe Theory of Paulo FreireLola Amelia100% (3)

- Thesis ClarinetDocument8 pagesThesis Clarinetmeganjoneshuntsville100% (2)

- Pod HD500X SMDocument103 pagesPod HD500X SMerendutekNo ratings yet

- Week 5 Class 2Document33 pagesWeek 5 Class 2ppNo ratings yet

- Build The Tango: by Hank BravoDocument57 pagesBuild The Tango: by Hank BravoMarceloRossel100% (1)

- Silo - Tips - Datex Ohmeda S 5 Collect Users Reference ManualDocument103 pagesSilo - Tips - Datex Ohmeda S 5 Collect Users Reference Manualxiu buNo ratings yet

- Fogarty HardwickDocument35 pagesFogarty HardwickBen KellerNo ratings yet

- Precontraint 502S2 & 702S2Document1 pagePrecontraint 502S2 & 702S2Muhammad Najam AbbasNo ratings yet

- Menken & Sanchez (2020) - Translanguaging in English-Only SchoolsDocument27 pagesMenken & Sanchez (2020) - Translanguaging in English-Only SchoolsSumirah XiaomiNo ratings yet

- The List of Official United States National SymbolsDocument3 pagesThe List of Official United States National SymbolsВікторія АтаманюкNo ratings yet

- Unity School of ChristianityDocument3 pagesUnity School of ChristianityServant Of TruthNo ratings yet

- Security Information and Event Management (SIEM) - 2021Document4 pagesSecurity Information and Event Management (SIEM) - 2021HarumNo ratings yet

- Hp Ux系统启动的日志rcDocument19 pagesHp Ux系统启动的日志rcMq SfsNo ratings yet

- 1 Mile.: # Speed Last Race # Prime Power # Class Rating # Best Speed at DistDocument5 pages1 Mile.: # Speed Last Race # Prime Power # Class Rating # Best Speed at DistNick RamboNo ratings yet

- Sperber Ed Metarepresentations A Multidisciplinary PerspectiveDocument460 pagesSperber Ed Metarepresentations A Multidisciplinary PerspectiveHernán Franco100% (3)

- Cable GlandDocument25 pagesCable Glandfernando.magalhaesmowNo ratings yet

- Becg Unit-1Document8 pagesBecg Unit-1Bhaskaran Balamurali0% (1)

- Computer Education in Schools Plays Important Role in Students Career Development. ItDocument5 pagesComputer Education in Schools Plays Important Role in Students Career Development. ItEldho GeorgeNo ratings yet

- Prepare Active Directory and Domains For Exchange 2013 PDFDocument18 pagesPrepare Active Directory and Domains For Exchange 2013 PDFAdam DanielNo ratings yet

- Palma vs. Fortich PDFDocument3 pagesPalma vs. Fortich PDFKristine VillanuevaNo ratings yet

- Eris User ManualDocument8 pagesEris User ManualcasaleiroNo ratings yet

- Choose The Correct Answer by Crossing A, B, or C (Pilihlah Jawaban Yang Benar Dengan MemberDocument3 pagesChoose The Correct Answer by Crossing A, B, or C (Pilihlah Jawaban Yang Benar Dengan MemberJufriNo ratings yet

- Chapter 4 TeethDocument17 pagesChapter 4 TeethAbegail RuizNo ratings yet

- First Floor Plan SCALE:1:50: Master BedroomDocument1 pageFirst Floor Plan SCALE:1:50: Master BedroomRiya MehtaNo ratings yet

- Listen The Song and Order The LyricsDocument6 pagesListen The Song and Order The LyricsE-Eliseo Surum-iNo ratings yet

- Gucci MurderDocument13 pagesGucci MurderPatsy StoneNo ratings yet

- Extinction Summary Handout PDFDocument1 pageExtinction Summary Handout PDFJohn DNo ratings yet