Professional Documents

Culture Documents

Blister Packing

Uploaded by

Govinder KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blister Packing

Uploaded by

Govinder KumarCopyright:

Available Formats

Specification

Blister packing machine (For R & D purpose) Purpose :- Blister packing machine shall be used for packing in R & D section. General Requirements:Blister packing machine shall produce high quality blisters both in PVC- ALU, and ALU-ALU.

Compact Model with SS 304 fabricated body. Fully Stainless steel cladding confirming GMP Standards Packing materials like PVC-ALU and ALU-ALU. Ideal for Small Batch Applications. Flat Forming, Flat Sealing & Punching. Tool less change over. No Skilled operator required.

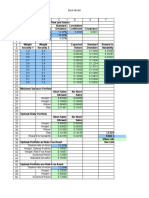

Desired / Suggested Capacity/output: 1 blister 90X150mm per stroke in ALU - ALU and 2 blisters 70 x 100 mm per stroke in PVC - ALU Dimensions: Max. Forming depth : 10 mm Max Blister size for PVC / ALU : 70 x 100 mm Max Blister per cycle :2 Max Blister size for ALU / ALU : 90 x 150 mm Max Blister per cycle :1 Temperature : 0 - 200 C Standard Voltage : 440 V, III Phase, 50 Hz Power Consumption : 4.5 KW Compressed Air : 6 - 8 bar Machine dimension : 500 x 640 x 1400 mm Cleaning /Cleaning of external product non-contact parts shall be done Manually Sanitization/ Sterilization: The Equipment shall be easily accessible for cleaning the non-product and contact part. Equipment contact parts shall be easily dismountable and cleanable. Safety Requirements: Following facilities must be provided to Protect Personnel, Article and Equipment Emergency Stop function . Alarm Notification.

Appropriate closure of all the rotating parts. Supporting rails surrounding RMG Platform. Proper earthing of the Equipment. GMP Requirements: All Validation Documents (DQ,IQ,OQ) along with Process and Instrumentation Diagram (PID) Vendor shall support client in execution of all the Qualification Phases. Installation of the Equipment and Training to Operator shall be provided by the Party Party should give Training to our Employees for Operation and Maintenance of the System, after the System is fully installed. Material of Construction: All following metallic critical contact surfaces should be constructed of 316L Grade Stainless Steel or better with internal mirror surface finish of 0.5m Ra and external surface finish matte finish of 1.2m Ra. All non-product contact metallic surfaces should be constructed of 304 Grade Stainless Steel or better (316 Steel for Sterile Area Equipment), external surface finish as matte finish< 1.2m Ra. Gaskets, seals and O-rings coming in direct / indirect contact surfaces should be constructed of approved Polymeric Materials Food Grade only. Use of Lubricants: Any Lubricant, used in the Equipment must be of Food Grade and Nontoxic Others :Party should clarify / mention any deviation from our Technical Specifications, otherwise it will be assumed that Party will abide by our Specifications Party should submit all the Documents related to Maintenance & Operations of Equipments to Authority The Entire System should be Guaranteed for a minimum period of ONE YEAR and all Accessories shall be Guaranteed as per the Manufacturers claim Party should produce all Calibration Certificates Party should provide a List of all the Consumables & Spare Parts used in the Equipments Party should submit Performance Certificates / Customer Feedbacks from at least Five (05) Clients for having supplied similar Equipment and satisfactory working of the same, for the last Three (03) years Party should depute at least one service person during the Guarantee / Warranty period within 24 Hrs. of registering the complaint, irrespective of Holidays / Festival, for rectifying the problem concerned.

You might also like

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- IQ-PQ-EQ Documents For FDC - IRN75Document12 pagesIQ-PQ-EQ Documents For FDC - IRN75Doan Chi ThienNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Supplement 7 TS Qualification Storage Areas ECSPP ECBSDocument32 pagesSupplement 7 TS Qualification Storage Areas ECSPP ECBSMilagros BorhorquezNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- URS Lab Scale Counter Pressure Autoclave (Rev 1b)Document12 pagesURS Lab Scale Counter Pressure Autoclave (Rev 1b)puneetogupta100% (2)

- Practical Approaches to Method Validation and Essential Instrument QualificationFrom EverandPractical Approaches to Method Validation and Essential Instrument QualificationNo ratings yet

- URS-oct BlenderDocument4 pagesURS-oct BlenderQANo ratings yet

- How To Validate An AutoclaveDocument3 pagesHow To Validate An AutoclaveqhpuongNo ratings yet

- Regulatory Aspects of Pharmaceutical Quality System: Brief IntroductionFrom EverandRegulatory Aspects of Pharmaceutical Quality System: Brief IntroductionNo ratings yet

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210No ratings yet

- User Requirement Specification For Moisture Analyser: Company NameDocument6 pagesUser Requirement Specification For Moisture Analyser: Company Namevamshi krishnaNo ratings yet

- MicroDocument3 pagesMicroPrince MoniNo ratings yet

- Studies On Cleaning Validation For A Cream and Ointment Manufacturing LineDocument7 pagesStudies On Cleaning Validation For A Cream and Ointment Manufacturing LinesppNo ratings yet

- Schedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumDocument77 pagesSchedule M: Jijo Thomas M.Pharm Pharmaceutics College of Pharmaceutical Sciences TrivandrumVivek PanchabhaiNo ratings yet

- URs For V-BlenderDocument11 pagesURs For V-BlenderTanChantrea100% (1)

- SOP For Operation of Carton Coding MachineDocument3 pagesSOP For Operation of Carton Coding MachineJayant Kumar JhaNo ratings yet

- Capsule FillingDocument23 pagesCapsule FillingErum ManzoorNo ratings yet

- DESIGN QUALIFICATION AUTOMATIC CAPSULE FILLING MACHINE - Pharmaceutical Guidance PDFDocument14 pagesDESIGN QUALIFICATION AUTOMATIC CAPSULE FILLING MACHINE - Pharmaceutical Guidance PDFShoaib BiradarNo ratings yet

- Sterilization Validation QsiteDocument52 pagesSterilization Validation Qsiteskype2121No ratings yet

- Steam SterilizerDocument24 pagesSteam Sterilizerj.k.kumar83% (6)

- Validation of Sterilization ProcessesDocument3 pagesValidation of Sterilization ProcessesNovitra DewiNo ratings yet

- IQ and OQ Protocol MET ONE 3413 CountersDocument112 pagesIQ and OQ Protocol MET ONE 3413 Counterslau50% (2)

- IQ For Strip Packing Machine SE - 140Document15 pagesIQ For Strip Packing Machine SE - 140Fernanda GarantiaNo ratings yet

- F Ex of e Nadine Hydrochloride Master Batch RecordDocument18 pagesF Ex of e Nadine Hydrochloride Master Batch RecordKrisnanti Angela SariNo ratings yet

- Media Fill FDA 483 Observations 3Document9 pagesMedia Fill FDA 483 Observations 3vijayns_250355172No ratings yet

- 30 ML Moulded Vial Filling OQDocument15 pages30 ML Moulded Vial Filling OQSubhash NaiduNo ratings yet

- AHU Block-V Rev 00 - 2023Document36 pagesAHU Block-V Rev 00 - 2023Chirag S. PatelNo ratings yet

- Subject:: 1) Installation QualificationDocument2 pagesSubject:: 1) Installation QualificationDonig FermanianNo ratings yet

- Validation of Sterilization: GMP and Qa Class: BDocument50 pagesValidation of Sterilization: GMP and Qa Class: BHikmah Purnama AzaniNo ratings yet

- Tablet Tooling in Compression MachineDocument32 pagesTablet Tooling in Compression Machinesubirme0% (1)

- Prot OQ HVACDocument12 pagesProt OQ HVACamrinNo ratings yet

- Procedure For Media-Fill Simulation of Aseptic TechniqueDocument5 pagesProcedure For Media-Fill Simulation of Aseptic Techniquelimiyanto100% (1)

- GSOP6.2.001 C 4/26/2011 76336 Quality Controlled Environments For ManufacturingDocument18 pagesGSOP6.2.001 C 4/26/2011 76336 Quality Controlled Environments For ManufacturingRickz2k8100% (1)

- Procedurefor Cleaning ValidationDocument21 pagesProcedurefor Cleaning ValidationQ CNo ratings yet

- What Are The Key Benefits of Validation?Document6 pagesWhat Are The Key Benefits of Validation?siva sankarNo ratings yet

- 12 Performance Qualification of EO Process Method CDocument4 pages12 Performance Qualification of EO Process Method CRakeshNo ratings yet

- Performance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .Document14 pagesPerformance Qualification FOR Blister Packing Machine ( .BLOCK) EQUIPMENT ID: .mehrdarou.qaNo ratings yet

- VMPDocument29 pagesVMPj.k.kumar100% (2)

- URS Air SamplerDocument6 pagesURS Air SamplerHưng Lữ Nguyễn Phúc100% (2)

- Disinfectant ValidationDocument8 pagesDisinfectant ValidationSiva SubrahmanyamNo ratings yet

- Pantoprazole 40mg InjectionDocument36 pagesPantoprazole 40mg Injectiondaizhussain004No ratings yet

- CommMill IQOQPQDocument16 pagesCommMill IQOQPQAtul Sharma100% (2)

- CIQA PQ Template Protocol Lyophilization Process Sample VersionDocument3 pagesCIQA PQ Template Protocol Lyophilization Process Sample VersionAbdul KalimNo ratings yet

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemDocument20 pagesStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (3)

- Syringe Filling AccuracyDocument5 pagesSyringe Filling AccuracyJan WyrwasNo ratings yet

- Validation Protocall For AutoclaveDocument7 pagesValidation Protocall For AutoclaveBalakrishnan S NadarNo ratings yet

- Sterilization Validation ReportDocument10 pagesSterilization Validation ReportCompliance DepartmentNo ratings yet

- Media Fill Indicador de ColorDocument6 pagesMedia Fill Indicador de Colorsteven correaNo ratings yet

- Temperature Mapping Study and QualificationDocument19 pagesTemperature Mapping Study and QualificationJewel Hernandez100% (2)

- IQ Protocol Air ShowerDocument9 pagesIQ Protocol Air Showerziauddin bukhariNo ratings yet

- Protocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeDocument6 pagesProtocol Design Qualification (DQ) : Romaco Kilian S 710 PrimeTim100% (1)

- URS - Ampoule Labelling MachineDocument15 pagesURS - Ampoule Labelling Machinedhanu_lagwankarNo ratings yet

- Form URS FPP Vial Washing Machine 050307.odtDocument10 pagesForm URS FPP Vial Washing Machine 050307.odtNur ChamidahNo ratings yet

- en Centrifuge 12 DG SpinDocument50 pagesen Centrifuge 12 DG SpinDodik E. PrasetyoNo ratings yet

- Validation ProtocolDocument9 pagesValidation ProtocolVikram ChhabraNo ratings yet

- PQ-Sample fIVEDocument13 pagesPQ-Sample fIVEcpkakopeNo ratings yet

- Headspace Oxygen Measurement in Vials and AmpoulesDocument4 pagesHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNo ratings yet

- Complaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYDocument38 pagesComplaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYscl1116953No ratings yet

- Form - Pelaporan B3Document16 pagesForm - Pelaporan B3sukma nugraNo ratings yet

- Hospital - Data Collection & Literature StudyDocument42 pagesHospital - Data Collection & Literature StudyNagateja MallelaNo ratings yet

- Intoduction To WeldingDocument334 pagesIntoduction To WeldingAsad Bin Ala QatariNo ratings yet

- Maya Mendez ResumeDocument2 pagesMaya Mendez Resumeapi-520985654No ratings yet

- Sol. Mock Test CBSE BiologyDocument3 pagesSol. Mock Test CBSE BiologysbarathiNo ratings yet

- Hmo Details November 2022 1Document6 pagesHmo Details November 2022 1Saad BelloNo ratings yet

- Constantino V MendezDocument3 pagesConstantino V MendezNīc CādīgālNo ratings yet

- Hodgkin LymphomaDocument44 pagesHodgkin LymphomaisnineNo ratings yet

- BHP Billiton Petroleum Contract Letter For ABDUL SATTARDocument5 pagesBHP Billiton Petroleum Contract Letter For ABDUL SATTARAbdul SattarNo ratings yet

- Rigging: GuideDocument244 pagesRigging: Guideyusry72100% (11)

- Tcu Module Pe1 Lesson 1Document7 pagesTcu Module Pe1 Lesson 1Remerata, ArcelynNo ratings yet

- SSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemDocument56 pagesSSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemJose Ramón Orenes ClementeNo ratings yet

- Jurnal SOL MeningiomaDocument6 pagesJurnal SOL MeningiomaConnie SianiparNo ratings yet

- Chapter 03Document35 pagesChapter 03david jenil nabuaNo ratings yet

- AA-036322-001 - Anchor Bolt DetailsDocument1 pageAA-036322-001 - Anchor Bolt DetailsGaurav BedseNo ratings yet

- CFPB Discount Points Guidence PDFDocument3 pagesCFPB Discount Points Guidence PDFdzabranNo ratings yet

- Doingwell Coaching ServicesDocument4 pagesDoingwell Coaching ServicesPaweł PawełNo ratings yet

- L Addison Diehl-IT Training ModelDocument1 pageL Addison Diehl-IT Training ModelL_Addison_DiehlNo ratings yet

- Aluminium - Hull Structure in Naval ApplicationsDocument6 pagesAluminium - Hull Structure in Naval ApplicationsStefano CostaNo ratings yet

- Key ScientificDocument4 pagesKey ScientificGarrettNo ratings yet

- Carolyn Green Release FinalDocument3 pagesCarolyn Green Release FinalAlex MilesNo ratings yet

- Pressure Vessels SHO ProgrammeDocument42 pagesPressure Vessels SHO Programmehew ka yeeNo ratings yet

- Floret Fall Mini Course Dahlia Sources Updated 211012Document3 pagesFloret Fall Mini Course Dahlia Sources Updated 211012Luthfian DaryonoNo ratings yet

- Checklist For Surge Arrester Rev00Document3 pagesChecklist For Surge Arrester Rev00Santhosh Kumar VinayagamNo ratings yet

- Mdp36 The EndDocument42 pagesMdp36 The Endnanog36No ratings yet

- Classification of Nanostructured Materials: June 2019Document44 pagesClassification of Nanostructured Materials: June 2019krishnaNo ratings yet

- PPC Production PlantDocument106 pagesPPC Production PlantAljay Neeson Imperial100% (1)

- BKM 10e Ch07 Two Security ModelDocument2 pagesBKM 10e Ch07 Two Security ModelJoe IammarinoNo ratings yet

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeFrom EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeRating: 5 out of 5 stars5/5 (2)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiFrom EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiRating: 4.5 out of 5 stars4.5/5 (5)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.From EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Rating: 4 out of 5 stars4/5 (17)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterFrom EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterRating: 4 out of 5 stars4/5 (467)

- It's All Too Much: An Easy Plan for Living a Richer Life with Less StuffFrom EverandIt's All Too Much: An Easy Plan for Living a Richer Life with Less StuffRating: 4 out of 5 stars4/5 (232)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyFrom EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyRating: 4 out of 5 stars4/5 (40)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (847)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingFrom EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingRating: 4 out of 5 stars4/5 (2997)

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeFrom EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeRating: 4.5 out of 5 stars4.5/5 (164)

- Let It Go: Downsizing Your Way to a Richer, Happier LifeFrom EverandLet It Go: Downsizing Your Way to a Richer, Happier LifeRating: 4.5 out of 5 stars4.5/5 (67)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffFrom EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffRating: 4.5 out of 5 stars4.5/5 (578)

- Summary of KC Davis's How to Keep House While DrowningFrom EverandSummary of KC Davis's How to Keep House While DrowningRating: 5 out of 5 stars5/5 (1)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (79)

- Kitchen Cabinets Center: Your One Stop Guide for Everything Kitchen Cabinets Related. Guide to Building, Assembling, Refacing, PaintingFrom EverandKitchen Cabinets Center: Your One Stop Guide for Everything Kitchen Cabinets Related. Guide to Building, Assembling, Refacing, PaintingRating: 2 out of 5 stars2/5 (4)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsFrom EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsRating: 5 out of 5 stars5/5 (339)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesFrom EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesRating: 4 out of 5 stars4/5 (11)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritFrom EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritRating: 4.5 out of 5 stars4.5/5 (3)

- Organizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlFrom EverandOrganizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlRating: 4.5 out of 5 stars4.5/5 (204)